Silicon mask used for super-diffraction photoetching with line width of below 200 nanometers and manufacturing method thereof

A super-diffraction and mask technology, applied in the field of nano-processing, to achieve the effect of convenient mask and manufacturing method, good ultraviolet light blocking, and large depth of pattern layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The first embodiment of the present invention is to make a silicon mask with periodic lines with a period of 100nm and a line width of 50nm. The exposure wavelength is 365nm. The mask includes a transparent quartz substrate and a silicon film pattern on it.

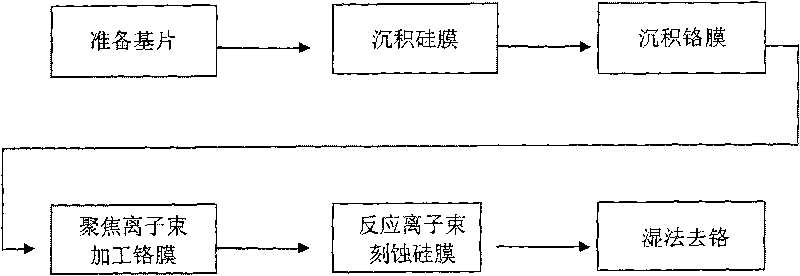

[0027] The mask fabrication steps are as follows figure 1 Shown:

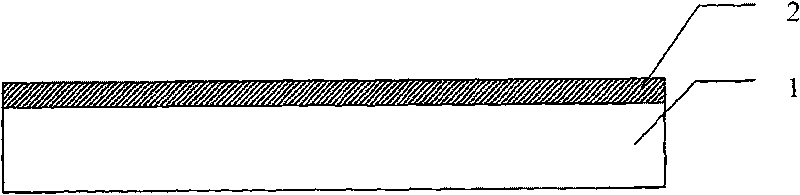

[0028] (1) select quartz material to make ultraviolet light transparent substrate;

[0029] (2) Utilize the magnetron sputtering coating machine to coat a layer of silicon film with a thickness of about 70nm on the transparent quartz substrate;

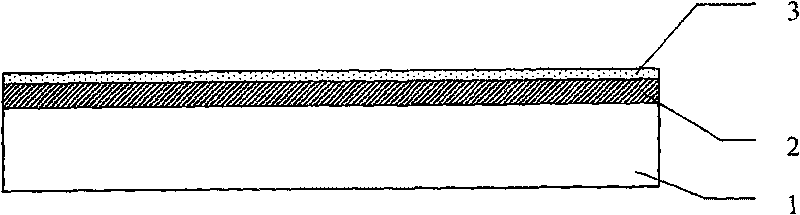

[0030] (3) Utilize the magnetron sputtering film coater to plate a layer of chromium film with a thickness of 20nm on the upper surface of the silicon film, as a pattern shielding layer in the later etching process;

[0031] (4) Utilize the focused ion beam to directly process the chromium film with a thickness of 20nm, so that periodic nano-line patterns with a period of 100nm and a line width of 50nm ar...

Embodiment 2

[0035] The second embodiment of the present invention is to make a silicon mask with periodic lines with a period of 200nm and a line width of 80nm. The exposure wavelength is 365nm. The mask includes a transparent quartz substrate and a silicon film pattern on it.

[0036] The mask fabrication steps are as follows figure 1 Shown:

[0037] (1) select quartz material to make ultraviolet light transparent substrate;

[0038] (2) utilize a magnetron sputtering coating machine to coat a layer of silicon film with a thickness of about 100 nm on the transparent quartz substrate;

[0039] (3) Utilize the magnetron sputtering film coater to plate a layer of chromium film with a thickness of 30nm on the upper surface of the silicon film, as a pattern shielding layer in the later etching process;

[0040] (4) Utilize the focused ion beam to directly process the chromium film with a thickness of 30nm, so that periodic nano-line patterns with a period of 200nm and a line width of 100nm ...

Embodiment 3

[0044] The second embodiment of the present invention is to make a silicon mask with periodic lines of 64nm and line width of 32nm, and the exposure wavelength is 365nm. The mask includes a transparent quartz substrate and a silicon film pattern on it.

[0045] The mask fabrication steps are as follows figure 1 Shown:

[0046] (1) Select calcium fluoride material to make ultraviolet light transparent substrate;

[0047] (2) Coating a layer of silicon film with a thickness of about 50 nm on the transparent calcium fluoride substrate by using a magnetron sputtering coating machine;

[0048] (3) Utilize the magnetron sputtering film coater to plate a layer of chromium film with a thickness of 10nm on the upper surface of the silicon film, as a pattern shielding layer in the later etching process;

[0049] (4) Utilize the focused ion beam to directly process the chromium film with a thickness of 10nm, so that periodic nano-line patterns with a period of 64nm and a line width of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com