Method for making near infrared band three-dimensional photon crystal

A photonic crystal, near-infrared technology, applied in the directions of light guide, optics, optical components, etc., can solve the problems of three-dimensional photonic crystal difficulty, and achieve the effect of high precision and insensitive card installation stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

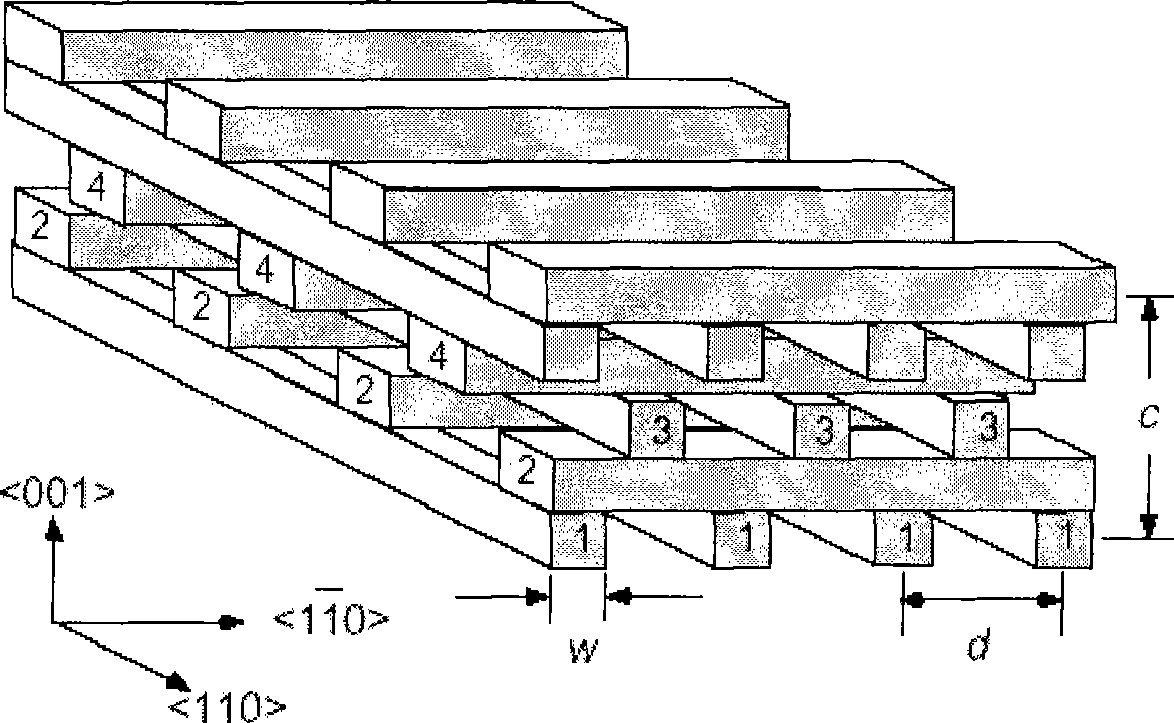

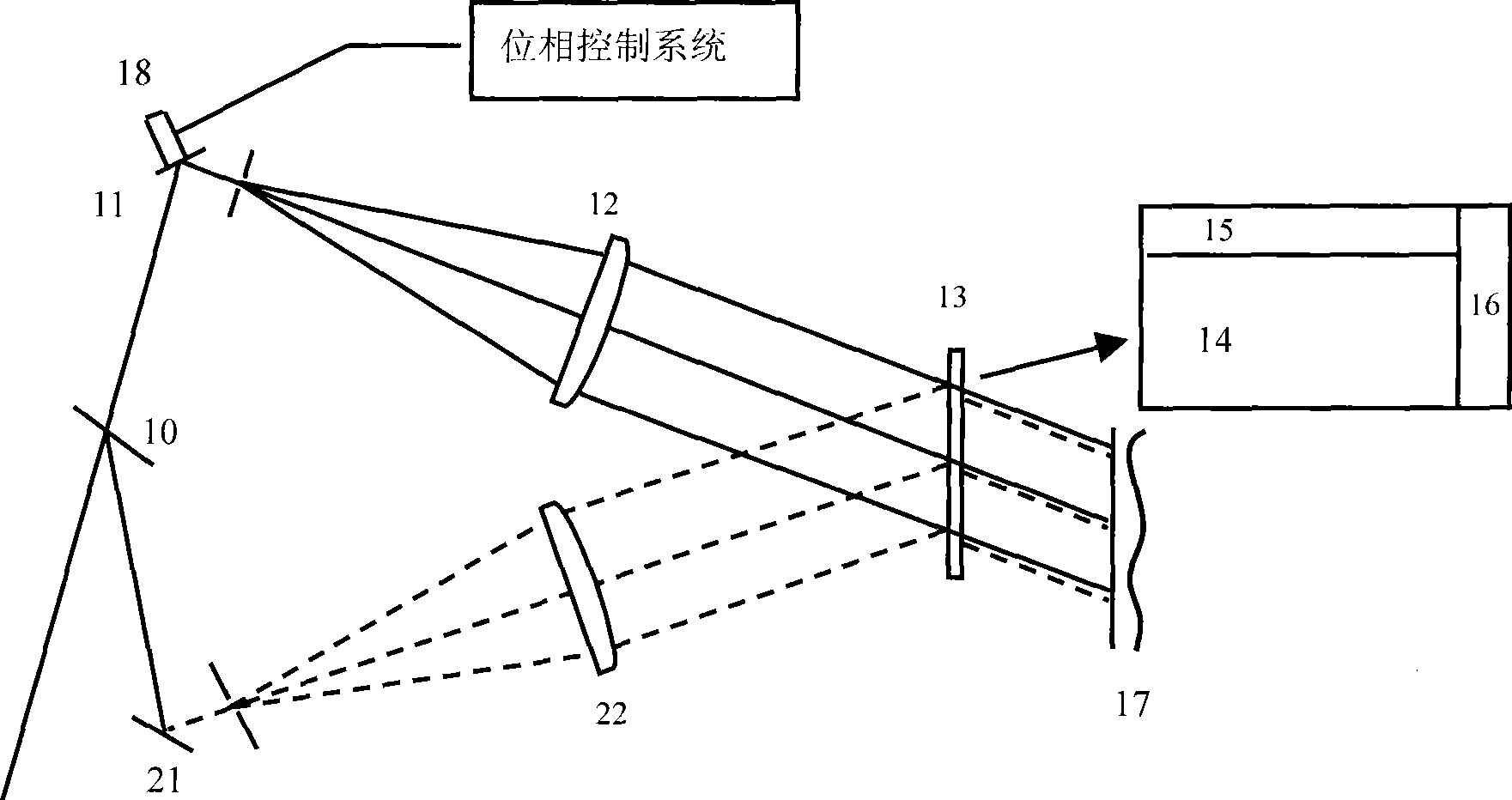

[0055] Embodiment 1: A method for making a three-dimensional photonic crystal in the near-infrared band, which is implemented by layer-by-layer superposition method, comprising the following steps:

[0056] (1) Deposit a silicon dioxide layer on a silicon substrate by ECR-CVD method, and control the thickness to be 0.2 microns;

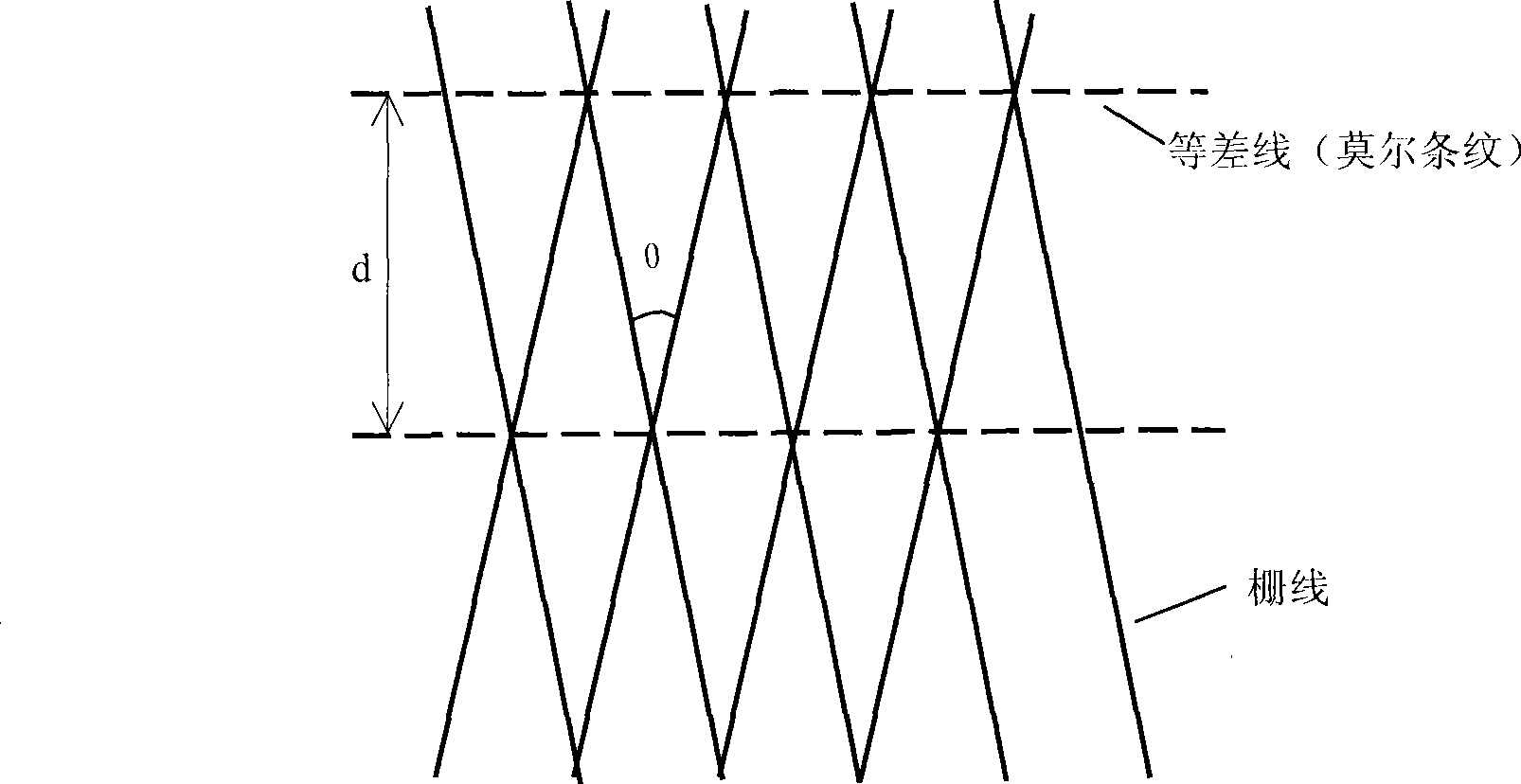

[0057] (2) Coating photoresist, using holographic photolithography to make a photoresist mask on the photoresist, the period (d) of the one-dimensional grating structure obtained is 0.7 microns; the duty ratio (w / d) is 0.4;

[0058] (3) Reactive ion beam etching is used to realize mask transfer, and grooves are formed on the silicon dioxide layer. In this embodiment, trifluoromethane reactive ion beam etching is used, with ion energy of 390ev, ion beam current of 90mA, and accelerating voltage 270v, working pressure 1.3×10 -2 Pa;

[0059] (4) ECR-CVD method is used to fill the etched trench with high refractive index material silicon;

[0060] (5)...

Embodiment 2

[0075] Embodiment 2: A method for making a three-dimensional photonic crystal in the near-infrared band, which is realized by layer-by-layer superposition method, comprising the following steps:

[0076] (1) Deposit a silicon dioxide layer on a silicon substrate by ECR-CVD method, and control the thickness to be 0.2 microns;

[0077] (2) Coating photoresist, using holographic photolithography to make a photoresist mask on the photoresist, the period (d) of the one-dimensional grating structure obtained is 0.7 microns; the duty ratio (w / d) is 0.35;

[0078] (3) Reactive ion beam etching is used to realize mask transfer, and grooves are formed on the silicon dioxide layer. In this embodiment, trifluoromethane reactive ion beam etching is used, with ion energy of 390ev, ion beam current of 90mA, and accelerating voltage 270v, working pressure 1.3×10 -2 Pa;

[0079] (4) One side edge of the silicon substrate is set as the first reference grating area, and the ECR-CVD method is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com