Method for preparing lithium niobate micro-disk cavity with any polarization pattern in submicron period

A periodic polarization, lithium niobate technology, applied in instruments, nonlinear optics, optics, etc., can solve the problems of single pattern and large polarization period, and achieve the effect of simple operation and fixed-point operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical details of the present invention will be clearly and completely described below in conjunction with the accompanying drawings and embodiments. Examples provide detailed implementation and specific operation process, but the present invention is not limited to the following examples.

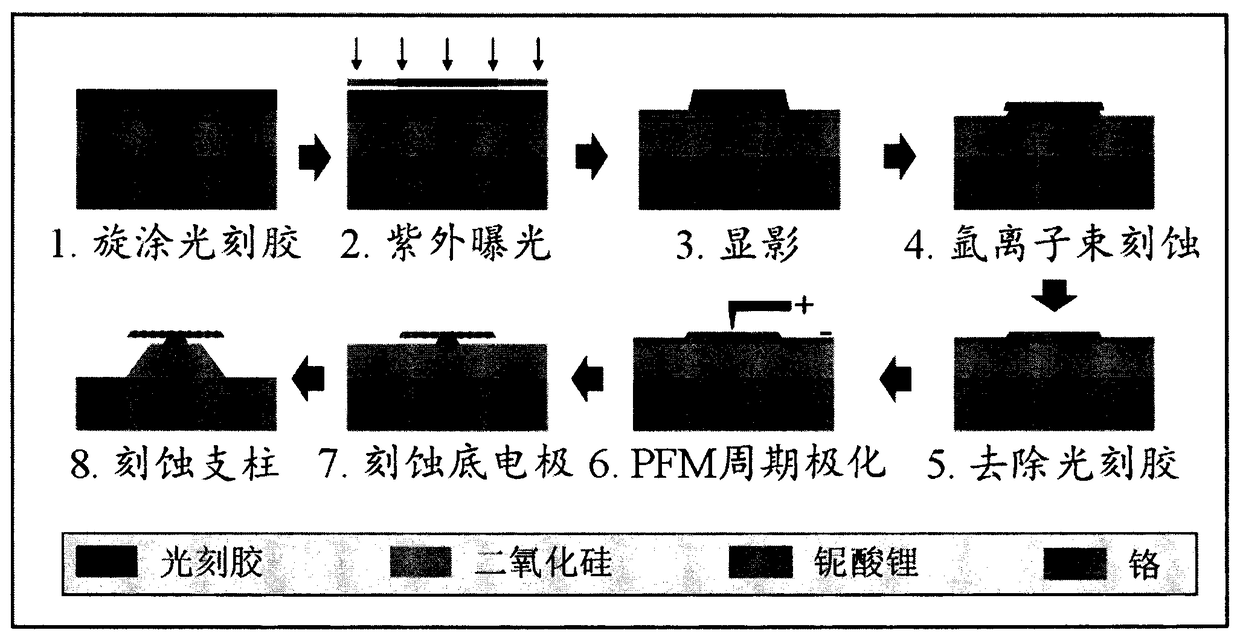

[0037] According to the first technical solution of the present invention, a method for preparing a lithium niobate microdisk cavity with a submicron periodic arbitrary polarization pattern is provided, which includes the following steps:

[0038] Step 1, generating a lithium niobate thin film with a lower electrode;

[0039] Step 2, preparing a microdisk cavity mask pattern on the lithium niobate film;

[0040] Step 3, performing reactive ion beam etching on the sample to form a lithium niobate microdisk;

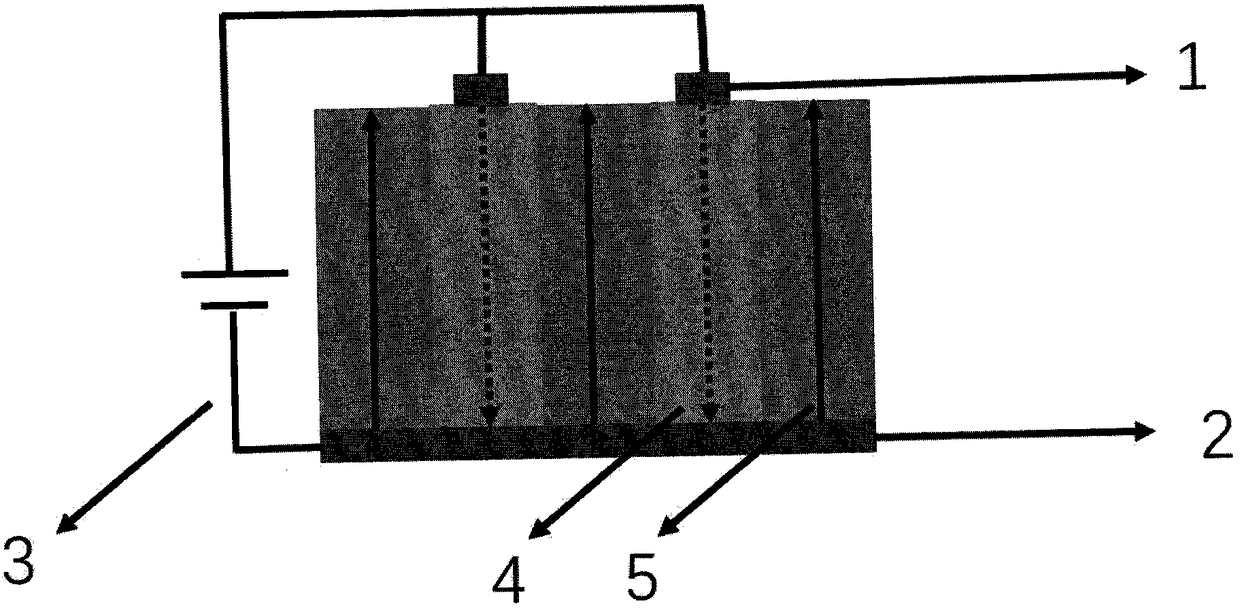

[0041] Step 4, constructing a polarization structure with any pattern on the lithium niobate microdisk;

[0042] Step five, etching the metal layer and the silicon dio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com