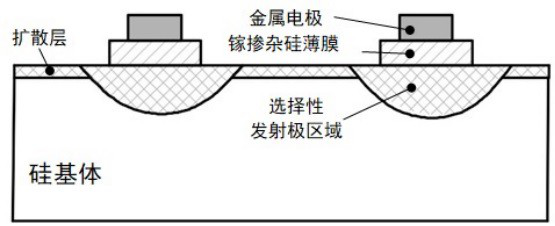

Method for preparing selective emitter by using gallium-doped silicon nano slurry

A nano-slurry, doped silicon technology, applied in photovoltaic power generation, climate sustainability, final product manufacturing, etc., can solve the problems of high cost, high temperature thermal damage of boron diffusion in production equipment, and improvement of solar cell performance, etc. High, improve the minority carrier lifetime, improve the effect of battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

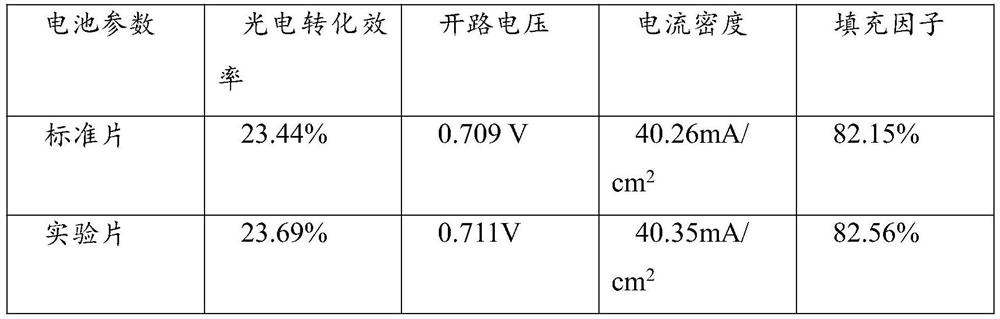

Embodiment 1

[0032] This embodiment provides a method for preparing a selective emitter by using gallium-doped silicon nano-slurry. The gallium-doped silicon nano-slurry used is prepared by mixing gallium-doped nano-silicon particles and an organic carrier. The gallium-doped silicon nano-slurry is used as raw material, the pattern is printed by a screen printing machine, and the selective emitter is prepared by laser-assisted diffusion. Specific steps are as follows:

[0033] Step 1: Select a phosphorus-doped N-type single crystal silicon wafer with a resistivity of 0.5-2Ω·cm, place it in a texturing tank, and place it in a sodium hydroxide solution with a specific gravity of 5-15%. Under the condition of 75 ~ 80 ℃, the surface texture is formed to form a suede structure;

[0034] Step 2: Clean the surface of the silicon wafer with a chemical solution, the solution is a mixed solution of hydrofluoric acid and hydrochloric acid, the cleaning time is 2Min, and the temperature is 20-25°C;

...

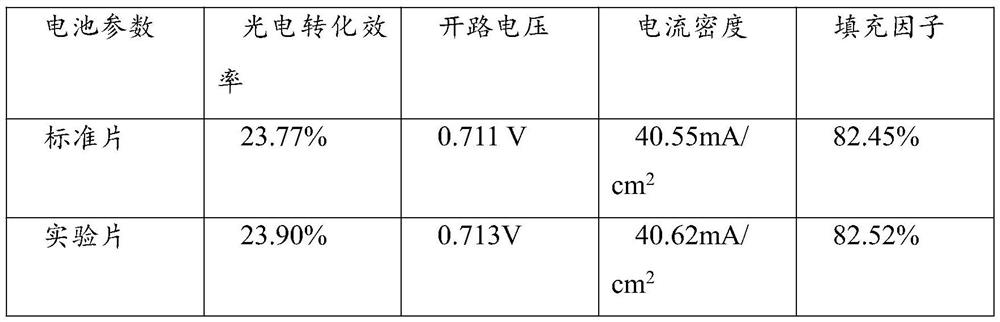

Embodiment 2

[0048] This embodiment provides a method for preparing a selective emitter by using gallium-doped silicon nano-slurry. The gallium-doped silicon nano-slurry used is prepared by mixing gallium-doped nano-silicon particles and an organic carrier. The gallium-doped silicon nano-slurry is used as raw material, the pattern is printed by a screen printing machine, and the selective emitter is prepared by laser-assisted diffusion. Specific steps are as follows:

[0049] Step 1: Select a phosphorus-doped N-type single crystal silicon wafer with a resistivity of 0.5-2Ω·cm, place it in a texturing tank, and place it in a sodium hydroxide solution with a specific gravity of 5-15%. Under the condition of 75 ~ 80 ℃, the surface texture is formed to form a suede structure;

[0050] Step 2: Clean the surface of the silicon wafer with a chemical solution, the solution is a mixed solution of hydrofluoric acid and hydrochloric acid, the cleaning time is 2Min, and the temperature is 20-25°C;

...

Embodiment 3

[0064] This embodiment provides a method for preparing a selective emitter by using gallium-doped silicon nano-slurry. The gallium-doped silicon nano-slurry used is prepared by mixing gallium-doped nano-silicon particles and an organic carrier. The gallium-doped silicon nano-slurry is used as raw material, the pattern is printed by a screen printing machine, and the selective emitter is prepared by laser-assisted diffusion. Specific steps are as follows:

[0065] Step 1: Select a phosphorus-doped N-type single crystal silicon wafer with a resistivity of 0.5-2Ω·cm, place it in a texturing tank, and place it in a sodium hydroxide solution with a specific gravity of 5-15%. Under the condition of 75 ~ 80 ℃, the surface texture is formed to form a suede structure;

[0066] Step 2: Clean the surface of the silicon wafer with a chemical solution, the solution is a mixed solution of hydrofluoric acid and hydrochloric acid, the cleaning time is 2Min, and the temperature is 20-25°C;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com