Gallium doped zinc oxide target and preparation method of transparent conductive film thereof

A transparent conductive film, zinc oxide technology, applied in the field of optoelectronic functional materials, can solve the problems of toxicity, high price, unstable ITO, etc., and achieve the effect of reducing cost, low cost and saving precious metal indium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Preparation of gallium-doped zinc oxide target

[0022] Firstly, zinc and gallium oxide powders were prepared by solid state ball milling method. According to Ga 2 o 3 / (ZnO+Ga 2 o 3 ) mass ratio is 5% and takes by weighing zinc oxide (purity is 99.99%) powder and gallium oxide (purity is 99.99%) powder, takes by weighing the polyethylene glycol that accounts for powder gross mass 1%, takes by weighing three times Grinding balls with powder quality; put the weighed powder, polyethylene glycol and grinding balls into the ball milling jar, then add a certain amount of absolute ethanol, seal and fix the ball milling jar on the ball mill, and then / min speed ball milling for 5 hours. After ball milling, pour out the slurry, dry at 80°C for 5 hours, then pre-sinter the powder at 700°C and high-purity oxygen for 5 hours, and then sieve and granulate the powder to obtain Zinc and gallium oxide powders that can be used for target sintering have been obtained. ...

Embodiment 2

[0024] Embodiment 2: Preparation of gallium-doped zinc oxide transparent conductive film

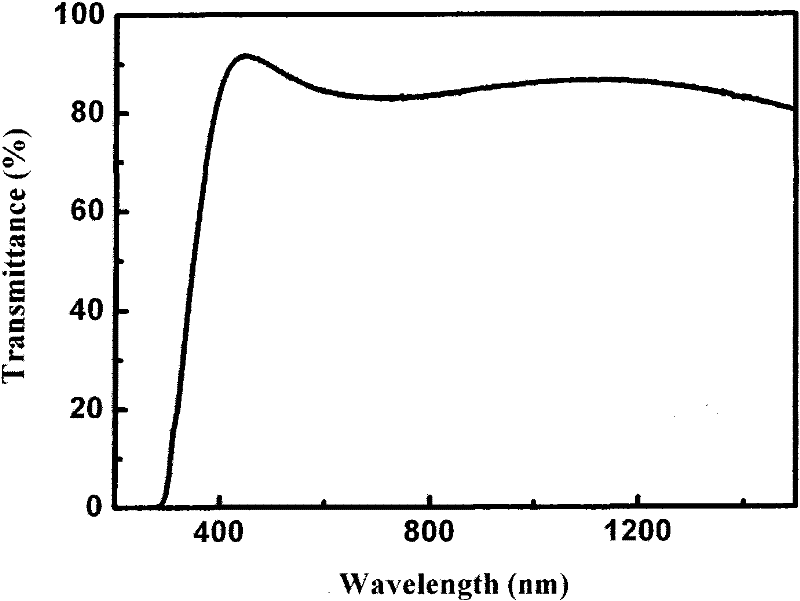

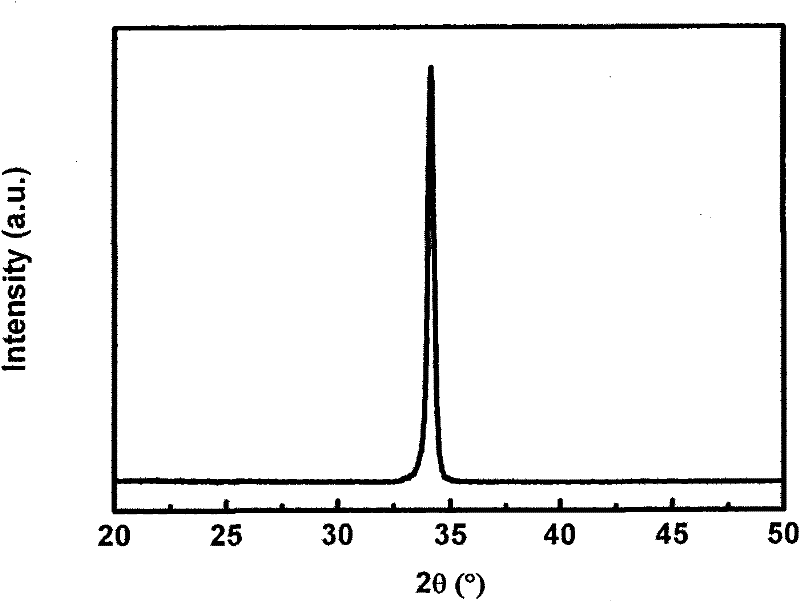

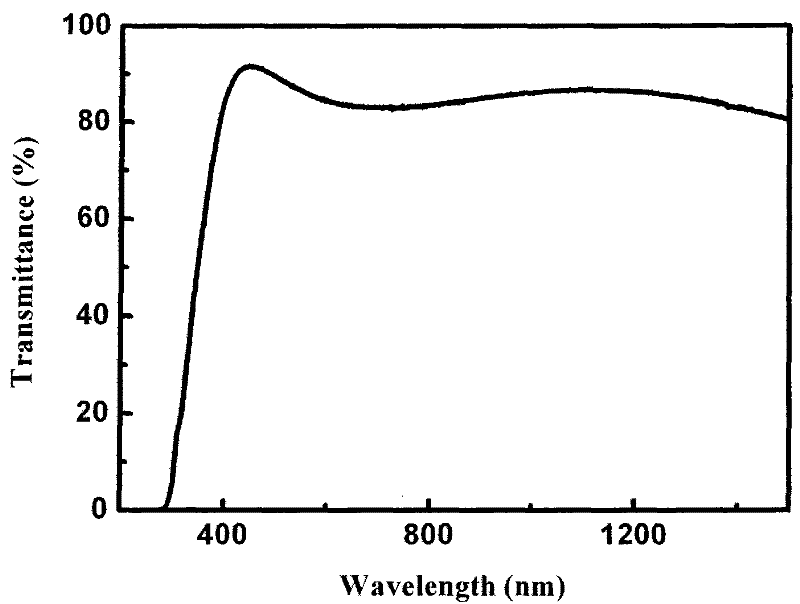

[0025] The gallium-doped zinc oxide target prepared in Example 1 was used to prepare a transparent conductive film by magnetron sputtering. Install the target on the corresponding position of the magnetron target gun, and evacuate until the background vacuum degree of the vacuum chamber is higher than 2.0×10 -4 Pa, with quartz glass as the substrate, the substrate temperature is kept at 400°C, 20sccm argon gas (sccm means standard milliliter per minute) is introduced into the vacuum chamber, the pressure of the vacuum chamber is adjusted to 0.15Pa, and the power of the radio frequency power supply is adjusted to 100W. The target was pre-sputtered for 10 min before the formal deposition of the film. A gallium-doped zinc oxide transparent conductive film with a thickness of about 320 nm was prepared according to the above process conditions. The test shows that the crystal structure of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com