Gallium-doped bismuth ferrite hypertetragonal phase epitaxial thin film and its preparation method and application

A technology of epitaxial thin film and bismuth ferrite, applied in chemical instruments and methods, crystal growth, polycrystalline material growth, etc., can solve the problems of large polarization value, relaxation, and small leakage, and achieve large and stable polarization value High performance and low leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The gallium-doped bismuth ferrite supertetragonal phase epitaxial thin film of the present invention is prepared by the following method:

[0028] S1: set Bi 2 o 3 , Fe 2 o 3 and Ga 2 o 3 After mixing, they are sintered and pressed into BFGO blocks.

[0029] Weigh high-purity Bi according to the molar ratio of 1.1:0.6:0.4 2 o 3 , Fe 2 o 3 and Ga 2 o 3 The powder is 60g in total, mixed evenly and then ground, then pre-fired at 650°C for 12h. Grinding and ball milling are performed again after calcining, and the target is pressed after adding PVA binder. After pressing and sintering at 830 °C for 2 h, BFGO blocks were obtained.

[0030] S2: Deposit BFGO on the substrate to obtain BFGO film.

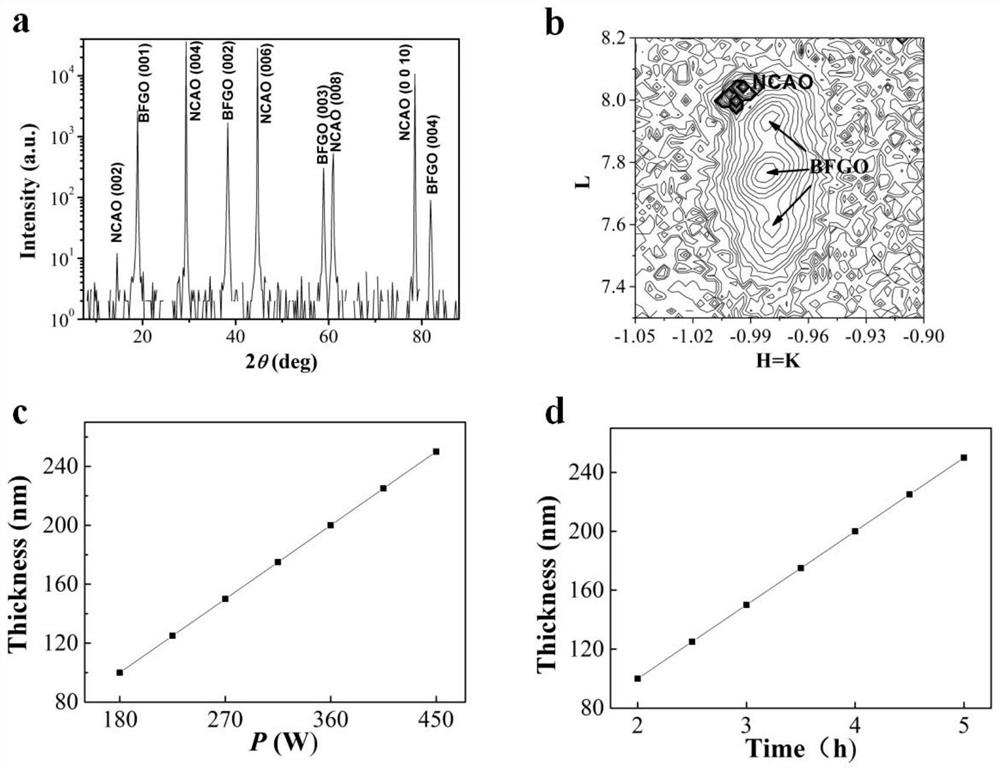

[0031] Take the BFGO block as the target material, put it into the target holder in the magnetron sputtering chamber, and then put (001) oriented NdCaAlO on the sample stage in the chamber 4 (abbreviated as NCAO) single crystal substrate, and the distance between the t...

Embodiment 2

[0037] The gallium-doped bismuth ferrite supertetragonal phase epitaxial thin film of the present invention is also prepared by the following method:

[0038] S1: set Bi 2 o 3 , Fe 2 o 3 and Ga 2 o 3 After mixing, they are sintered and pressed into BFGO blocks.

[0039] Weigh high-purity Bi according to the molar ratio of 1.1:0.6:0.4 2 o 3 , Fe 2 o 3 and Ga 2 o 3 The powder is 60g in total, mixed evenly and then ground, then pre-fired at 650°C for 12h. Grinding and ball milling are performed again after calcining, and the target is pressed after adding PVA binder. After pressing and sintering at 830 °C for 2 h, BFGO blocks were obtained.

[0040] S2: BFGO is deposited on the substrate to obtain gallium-doped bismuth ferrite supertetragonal phase epitaxial film.

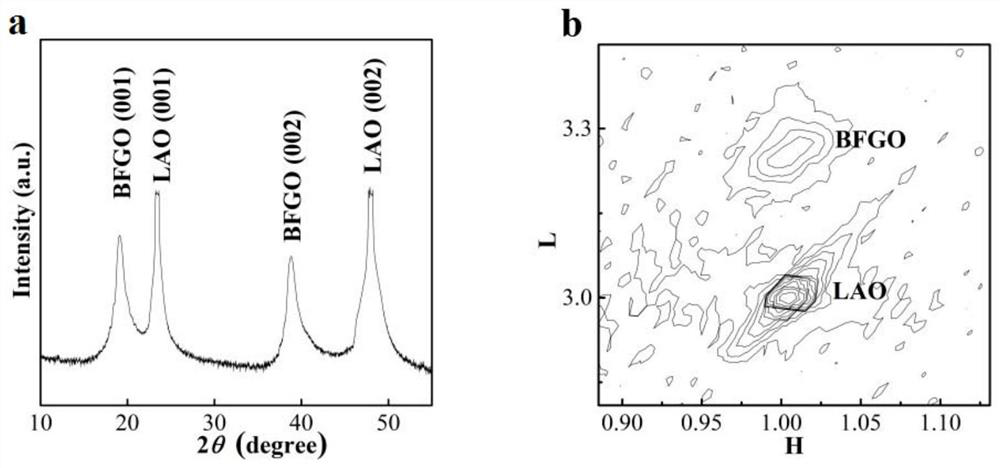

[0041] In a pulsed laser deposition system, LaAlO with (001) orientation 3 (abbreviated as LAO) as the substrate, the BFGO block as the target, and the target spacing is adjusted to 5cm, and the vacuum ...

Embodiment 3

[0044] The gallium-doped bismuth ferrite supertetragonal phase epitaxial thin film of the present invention is prepared by the following method:

[0045] S1: set Bi 2 o 3 , Fe 2 o 3 and Ga 2 o 3 After mixing, they are sintered and pressed into BFGO blocks.

[0046] Weigh high-purity Bi according to the molar ratio of 1.1:0.5:0.5 2 o 3 , Fe 2 o 3 and Ga 2 o 3 The powder is 60g in total, mixed evenly and then ground, then pre-fired at 650°C for 12h. Grinding and ball milling are performed again after calcining, and the target is pressed after adding PVA binder. After pressing and sintering at 830 °C for 2 h, BFGO blocks were obtained.

[0047] S2: Deposit BFGO on the substrate to obtain BFGO film.

[0048] Take the BFGO block as the target material, put it into the target holder in the magnetron sputtering chamber, and then put (001) oriented NdCaAlO on the sample stage in the chamber 4 (abbreviated as NCAO) single crystal substrate, and the distance between the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com