Microwave heating preparation device for pre-oxidized fiber

A technology of microwave heating and pre-oxygenation, which is used in textiles and papermaking, fiber chemical characteristics, etc., can solve the problems of low dielectric constant, closed equipment, large energy consumption, etc., and achieves improved bulk density, stable wave absorption, and novel methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

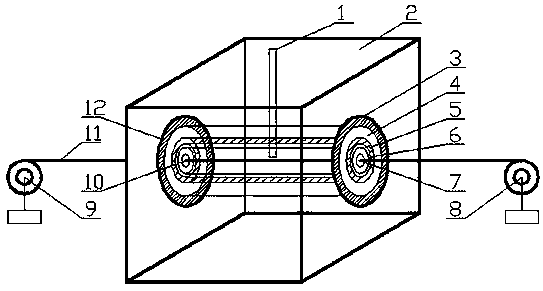

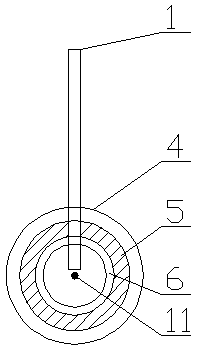

[0018] like Figures 1 to 2 As shown, the device for preparing pre-oxygen wire by microwave heating includes microwave oven 2, carrier tube 5 and wave-absorbing coating 6, the interior of microwave oven 2 is provided with horizontal carrier tube 5, and the inner surface of carrier tube 5 is sprayed with wave-absorbing coating 6 , the carrier tube 5 is made of mullite (3Al 2 O 3 • 2SiO 2 , diameter 100mm, thickness 20mm) no absorbing material, absorbing coating 6 is ferrite, thickness 1mm.

[0019] It also includes a first protective cover 3, asbestos 4, a wire outlet 7, a first rolling shaft 8, a second rolling shaft 9, a wire inlet 10 and a second protective cover 12, and the outer surface of the carrier tube 5 is provided with asbestos 4. A second protective cover 12 and a first protective cover 3 are respectively provided on the contact surface of the carrier tube 5 and the microwave oven 2, and the second protective cover 12 and the first protective cover 3 are respecti...

Embodiment 2

[0022] like Figures 1 to 2 As shown, the device for preparing pre-oxygen wire by microwave heating includes microwave oven 2, carrier tube 5 and wave-absorbing coating 6, the interior of microwave oven 2 is provided with horizontal carrier tube 5, and the inner surface of carrier tube 5 is sprayed with wave-absorbing coating 6 , the carrier tube 5 is made of mullite (3Al 2 O 3 • 2SiO 2 , diameter 100mm, thickness 20mm) without absorbing material, absorbing coating 6 is silicon carbide absorbing material, thickness 2mm.

[0023] It also includes a first protective cover 3, asbestos 4, a wire outlet 7, a first rolling shaft 8, a second rolling shaft 9, a wire inlet 10 and a second protective cover 12, and the outer surface of the carrier tube 5 is provided with asbestos 4. A second protective cover 12 and a first protective cover 3 are respectively provided on the contact surface of the carrier tube 5 and the microwave oven 2, and the second protective cover 12 and the first...

Embodiment 3

[0026] like Figures 1 to 2 As shown, the device for preparing pre-oxygen wire by microwave heating includes microwave oven 2, carrier tube 5 and wave-absorbing coating 6, the interior of microwave oven 2 is provided with horizontal carrier tube 5, and the inner surface of carrier tube 5 is sprayed with wave-absorbing coating 6 , the carrier tube 5 is made of corundum (Al 2 O 3 , diameter 100mm, thickness 20mm) without absorbing material, absorbing coating 6 is ferrite absorbing material, thickness 3mm.

[0027] It also includes a first protective cover 3, asbestos 4, a wire outlet 7, a first rolling shaft 8, a second rolling shaft 9, a wire inlet 10 and a second protective cover 12, and the outer surface of the carrier tube 5 is provided with asbestos 4. A second protective cover 12 and a first protective cover 3 are respectively provided on the contact surface of the carrier tube 5 and the microwave oven 2, and the second protective cover 12 and the first protective cover ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com