High-efficiency metal 3D printing equipment and method

A 3D printing and metal technology, applied in the field of 3D printing, can solve problems such as slow running speed, difficult control of process parameters, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

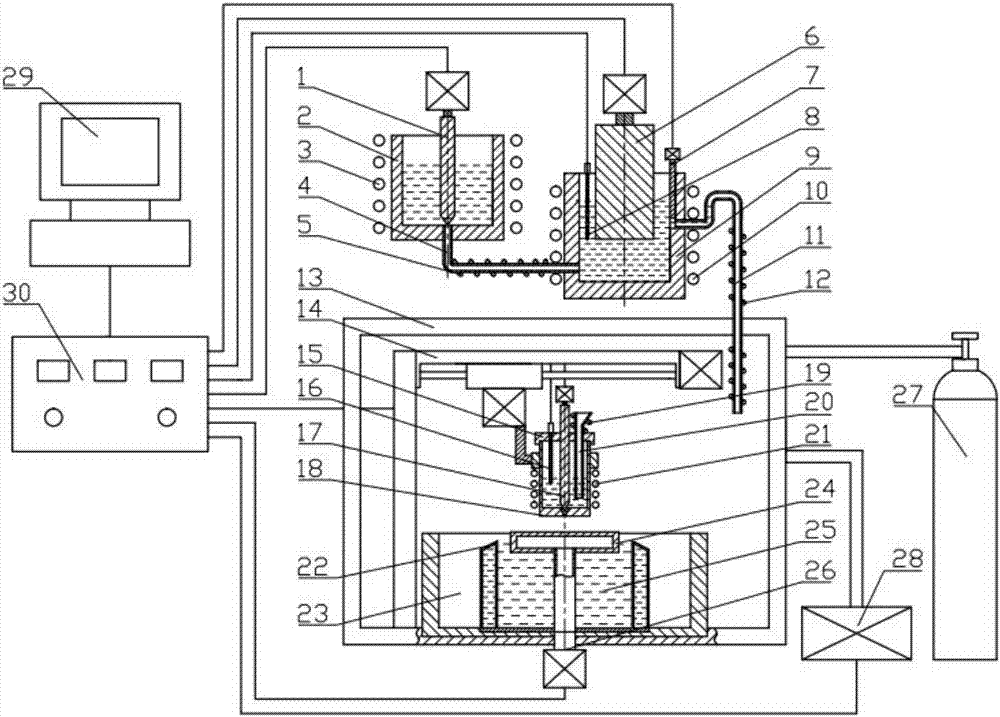

[0051] Efficient 3D printing of pure tin cans.

[0052] According to the size and precision requirements of pure tin cans, the diameter of the outlet of the nozzle 18 is selected to be 1.5mm; the nozzle top cover 15 is installed above the nozzle 18, the sealing door of the forming chamber 13 is closed, and the sealing baffle 7 is controlled by the controller 30 Block the liquid outlet of the holding furnace 9, open the vacuum system 28, and vacuumize the forming chamber 13; close the vacuum system 28, open the inflation system 27, and fill the forming chamber 13 with protective gas until the forming chamber 13 The air pressure reaches an atmospheric pressure; the liquid outlet at the bottom of the melting furnace 2 is blocked by controlling the melting furnace stopper rod 1 through the controller 30, and solid pure tin raw materials are loaded into the melting furnace 2; the melting furnace heater 3 is turned on, and the melting furnace 2 The pure tin raw material is heated to...

Embodiment 2

[0054] Efficient 3D printing of tin alloy parts.

[0055]According to the size and precision requirements of the tin alloy parts, the diameter of the nozzle 18 discharge opening is selected to be 1mm; the nozzle top cover 15 is installed on the nozzle 18, the sealing door of the forming chamber 13 is closed, and the sealing baffle 7 is controlled by the controller 30 The liquid outlet of the holding furnace 9 is blocked, open the vacuum system 28, and vacuumize the forming chamber 13; close the vacuum system 28, open the inflation system 27, and fill the forming chamber 13 with protective gas until the air pressure in the forming chamber Reach an atmospheric pressure; Control the melting furnace plug rod 1 by the controller 30 to block the liquid outlet at the bottom of the melting furnace 2, and load the solid tin alloy raw material into the melting furnace 2; Tin alloy raw material is heated to 350 DEG C; Turn on melt transmission pipeline heater 5, holding furnace heater 10...

Embodiment 3

[0057] Efficient 3D printing of copper alloy molds.

[0058] According to the size and precision requirements of the copper alloy mould, the diameter of the nozzle 18 discharge port is selected to be 2 mm; the nozzle top cover 15 is installed on the top of the nozzle 18, the sealing door of the forming chamber 13 is closed, and the sealing baffle 7 is controlled by the controller 30. The liquid outlet of the holding furnace 9 is blocked, open the vacuum system 28, and vacuumize the forming chamber 13; close the vacuum system 28, open the inflation system 27, and fill the forming chamber 13 with protective gas until the air pressure in the forming chamber Reach an atmospheric pressure; Control the melting furnace plug rod 1 by the controller 30 to block the liquid outlet at the bottom of the melting furnace 2, and load solid copper alloy raw materials into the melting furnace 2; Heat the copper alloy raw material to 1250°C; turn on the melt transfer pipe heater 5, the holding f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com