Dust removing system of chain grate machine tail part

A technology of dust removal system and chain grate machine, which is applied in the field of dust removal, can solve the problems of increased maintenance workload, harsh environment at the tail of the machine, and large dust pollution at the tail of the machine, so as to reduce the maintenance amount of workers and reduce the amount of cooked balls returned to ore , Improve the effect of tail environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

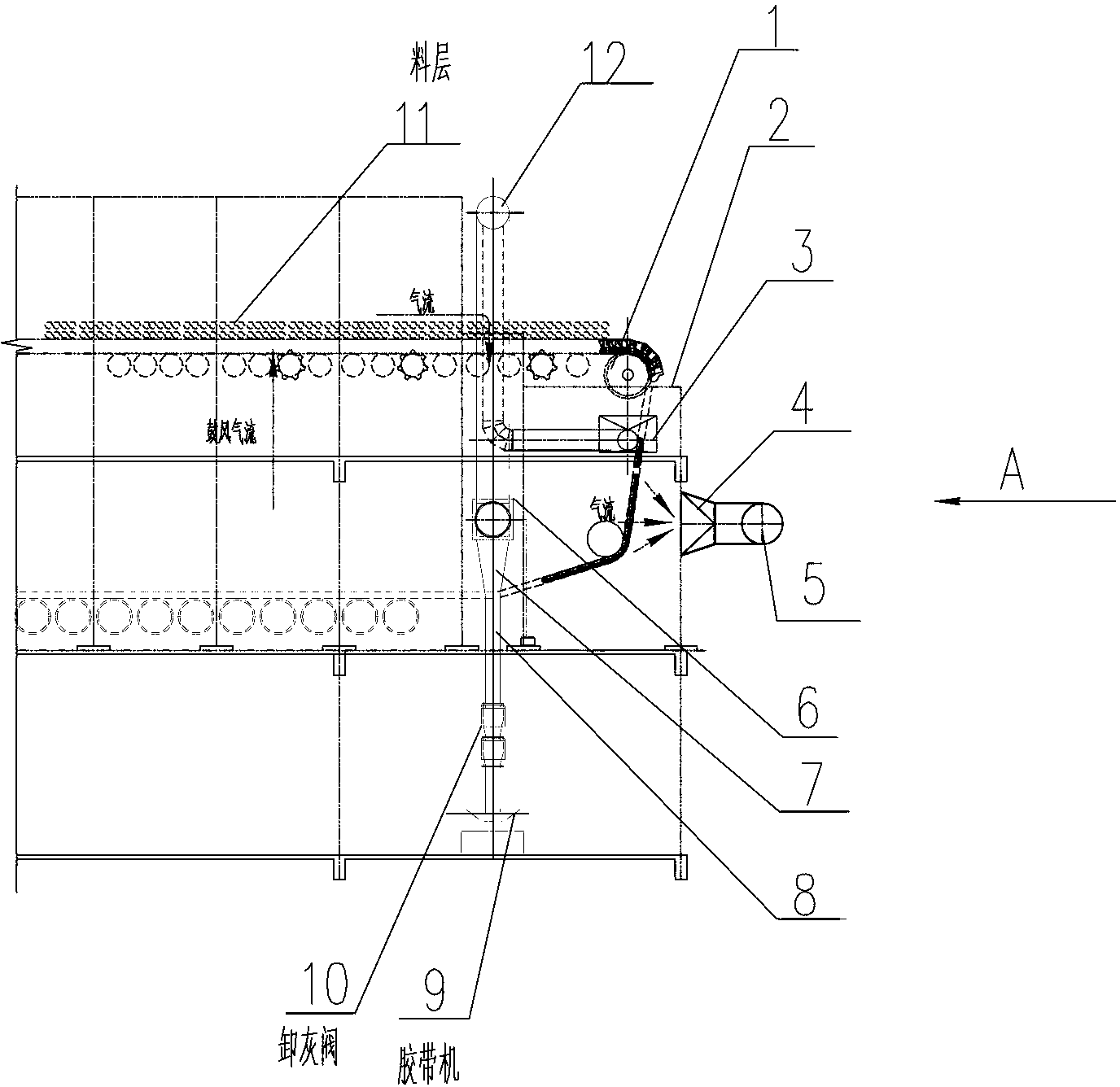

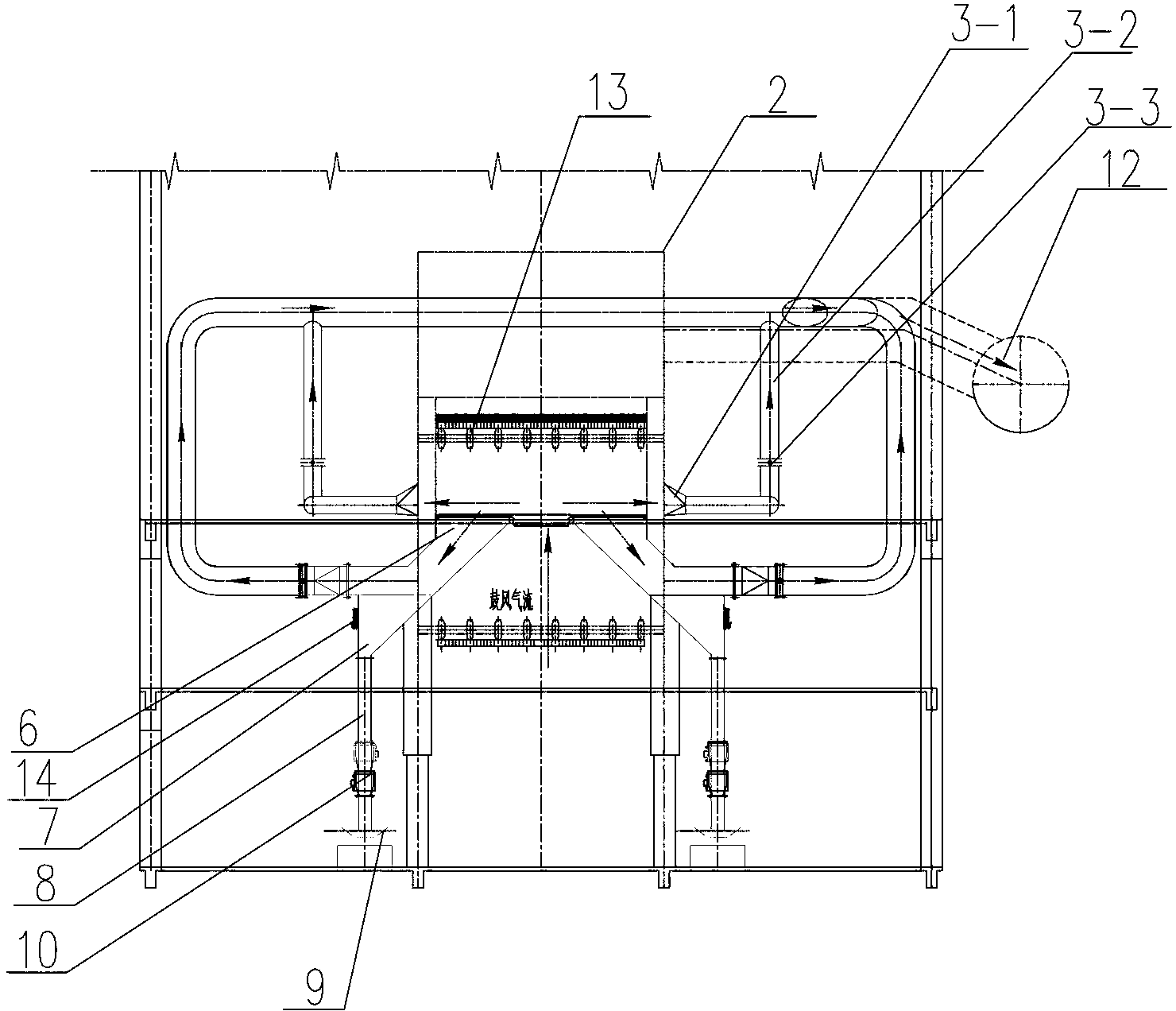

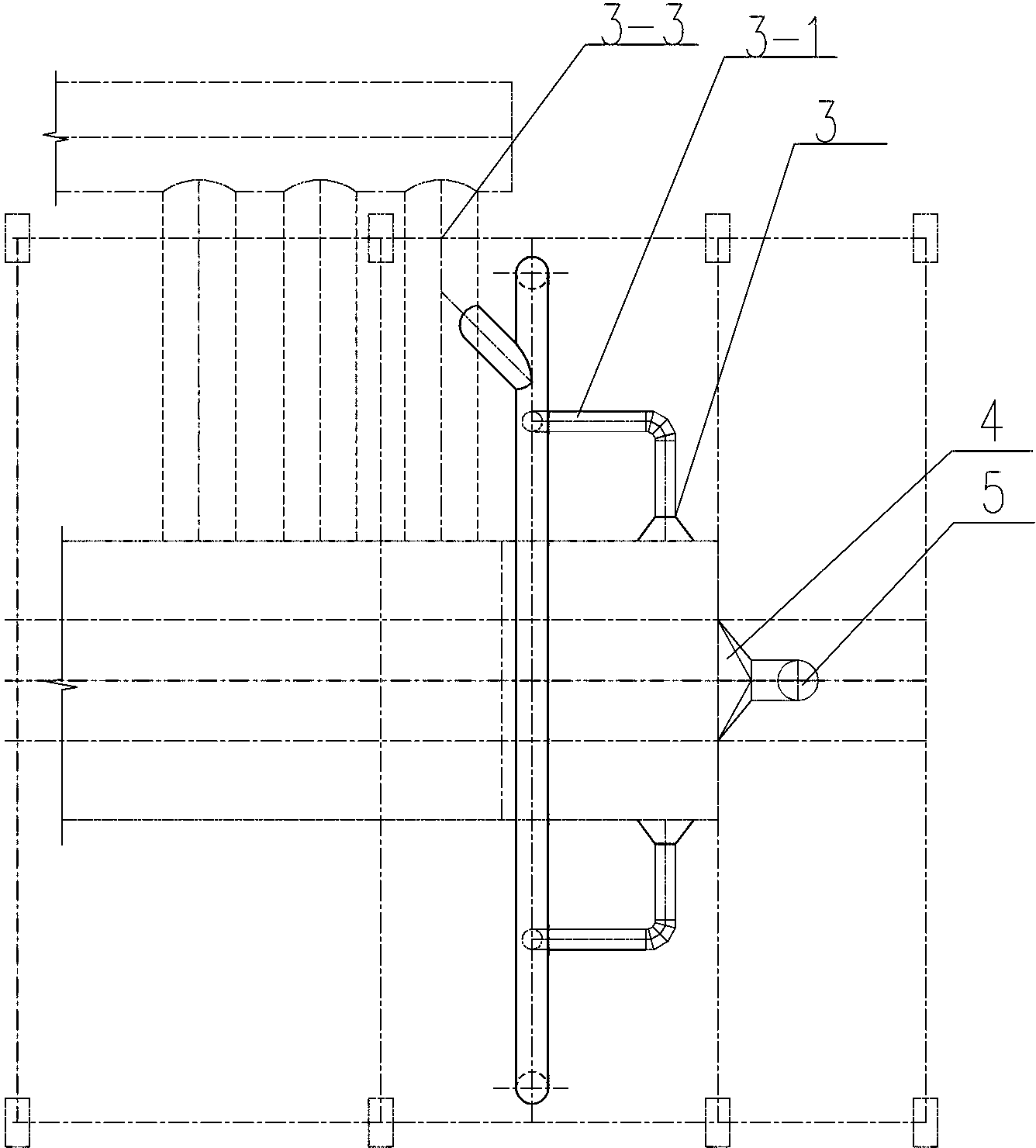

[0016] like figure 1 , 2 The dust removal system of the chain grate machine tail of the present invention shown in and 3 comprises the chain grate machine tail mechanism with the chain grate machine tail wheel 1 and the chain grate machine tail wheel backhaul device, it is characterized in that on the chain grate machine tail mechanism Organic tail sealing cover 2, chain grate machine tail wheel return segment dust removal device is set on the top of said machine tail sealing cover 2, chain grate machine tail integral dust removal device is set in the middle part of said machine tail sealing cover 2, in said machine tail sealing cover 2 The end of the lower return journey of the chain grate machine tail is equipped with a chain grate machine tail sealing bellows dust removal device,

[0017] Tail sealing cover 2 of the present invention is a sealing cover body made of ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com