Patents

Literature

34results about How to "Improve green ball quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of high-chromium high-vanadium type vanadium-titanium ore pellets

The invention relates to a preparation method of high-chromium high-vanadium type vanadium-titanium ore pellets. The invention relates to a preparation method of vanadium-titanium ore pellets. With existing high-chromium high-vanadium type vanadium-titanium ore pellet preparation technologies, pellet superfusion is possible to occur, and pellet caking or nodulation are possible to occur, such that the quality of finished pellet product is influenced. The invention aims at solving the problem. The preparation method of the high-chromium-high vanadium type vanadium-titanium ore pellets comprises the steps of material blending, mixed drying, palletizing, green pellet screening, and shaft furnace roasting. Vanadium content of vanadium-titanium powder in the vanadium-titanium pellets is higherthan 4.5%, such that a requirement by blast furnace vanadium-titanium smelting is satisfied. The high-chromium-high vanadium type vanadium-titanium ore pellet preparation method provided by the invention is used for preparing vanadium-titanium ore pellets.

Owner:HEILONGJIANG JIANLONG IRON & STEEL

Method for preparing oxidated pellets from pure hematite concentrate

A method for preparing oxidated pellets from pure hematite concentrate includes the following steps: after the hematite concentrate is preprocessed until the specific surface area is larger than or equal to 1300cm2.g-1, compound additive which accounts for 0.5 to 1.6 percent by weight of the total amount of hematite concentrate is added, damp milling is then carried out, pelletizing, drying, preheating and roasting are sequentially carried out after damp milling, and thereby the finished oxidated pellet product is obtained. The compound additive is the mixture of humic acid, calcium peroxide and paigeite, the mixture is ground to the grain size of negative 0.074mm after mixing, and the percentage by weight is not lower than 95 percent. The method solves the problems in the preparation of oxidated pellets from the hard-to-pelletize, hard-to-roast hematite concentrate, such as poor pellet quality, high preheating and roasting temperatures, long time, low finished pellet product strength. The method is simple, the quality of the prepared hematite concentrate pellets is high, the preheating and roasting temperatures are low, the time is short, and the method is suitable for the preparation of the oxidated pellets from the hematite concentrate, particularly the preparation of the oxidated pellets from hard-to-pelletize, hard-to-roast spiegeleisen concentrate. The method can realizeindustrialized production.

Owner:CENT SOUTH UNIV

Composite additive for preparing hematite concentrate pellet and application thereof

A composite additive for preparing hematite concentrate pellets comprises the following components: humic acid, calcium peroxide, and paigeite. During application, the composite additive is added which has a mass percent of 0.5%-1.6% of the total mass of the hematite concentrates, and the finished product pellets are obtained by pelletization, preheating, and roasting. Compared with pellets prepared by traditional technology, the hematite pellets prepared by the composite additive of the invention have improved falling strength of the green pellets, and compression strength of the finished product pellets; the preheating temperature and roasting temperature suitable for the pellets are reduced; both the preheating time and roasting time are shortened; the TFe grade is increased by 0.8%-1.2%. The composite additive of the invention has reasonable component ratios, is easy to process and manufacture, has a low using amount and a low residual amount, can significantly improve the pelletability of hematite concentrates which are difficult to be palletized, can improve the green pellet quality, has good heat stability, and can effectively reduce the preheating and roasting temperatures and shorten the preheating and roasting time of hematite concentrates. The composite additive of the invention is applicable to the production of oxidized pellets by hematites, and is especially applicable to the production of oxidized pellets by specularites. The composite additive of the invention is applicable to large-scale industrial production.

Owner:CENT SOUTH UNIV

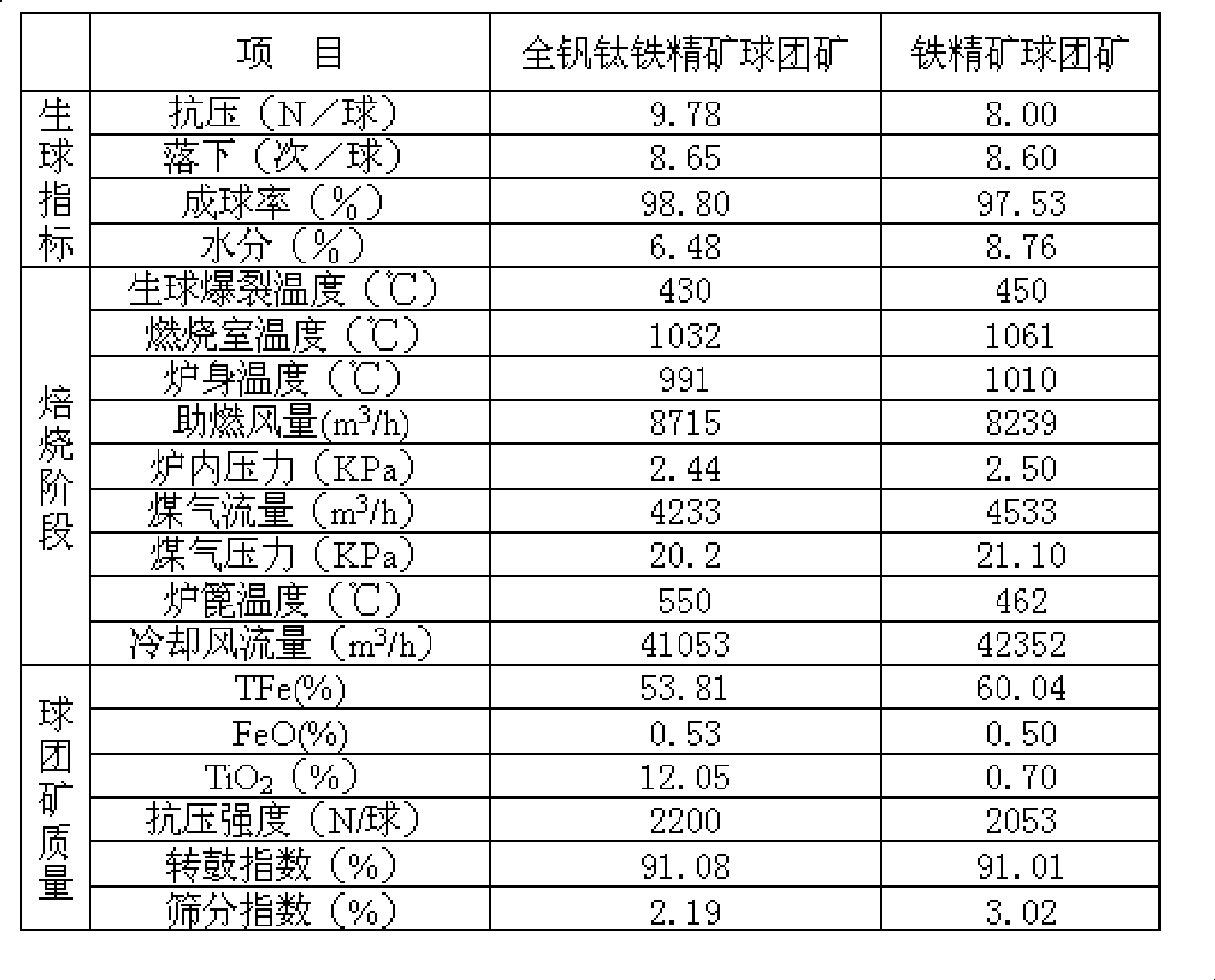

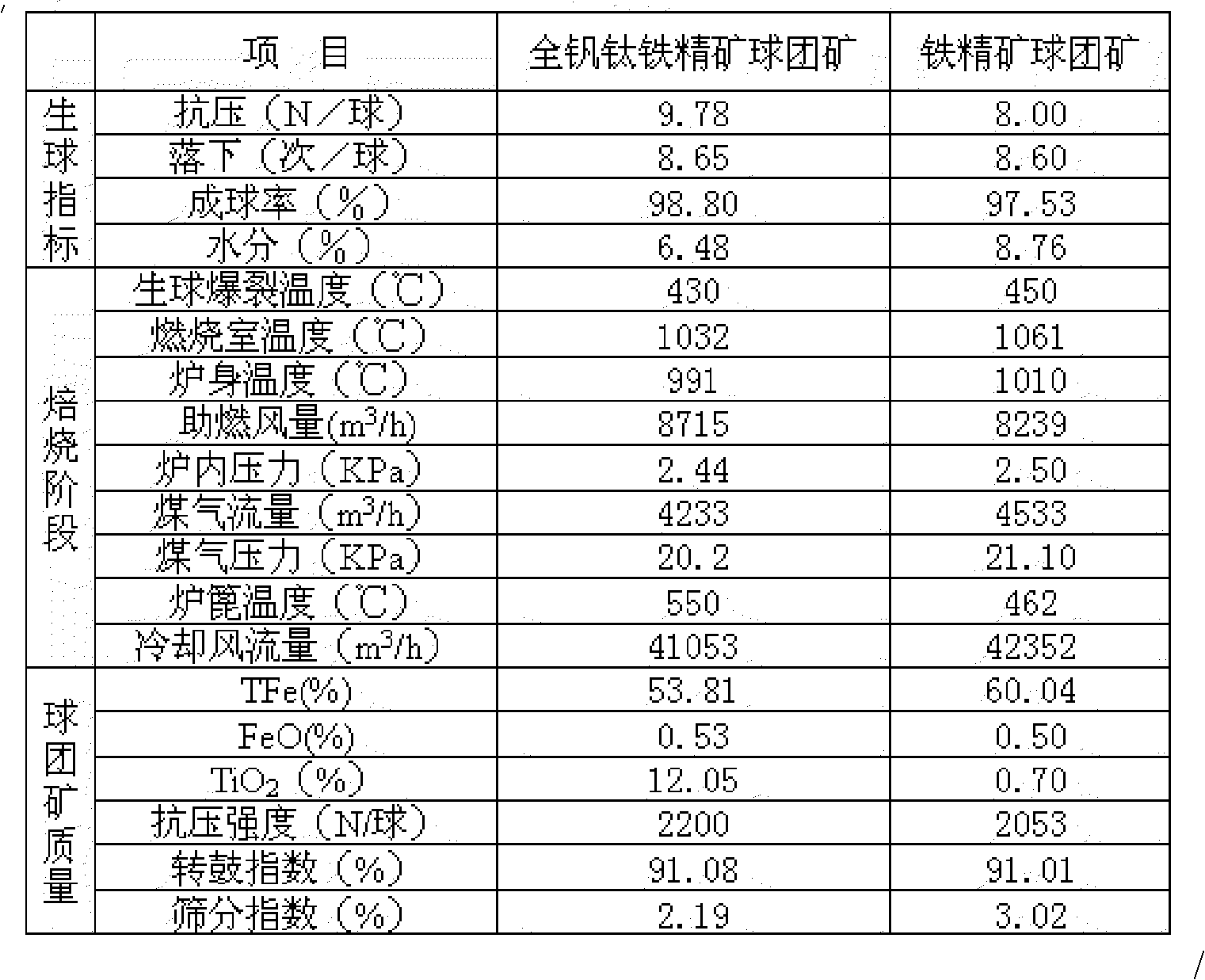

Application of shaft furnace in baking full-vanadium ferrotitanium ore concentrate pellet ore

InactiveCN101418371AHigh compressive strengthMeet strength requirementsShaft furnaceSodium BentoniteBlast furnace smelting

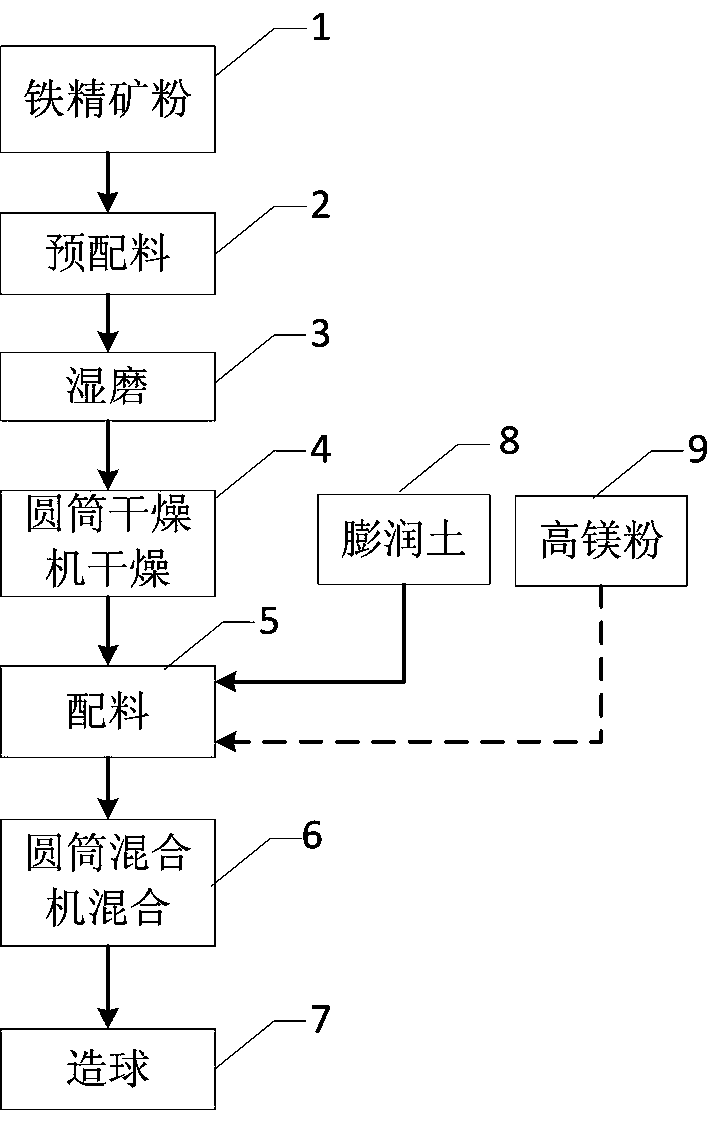

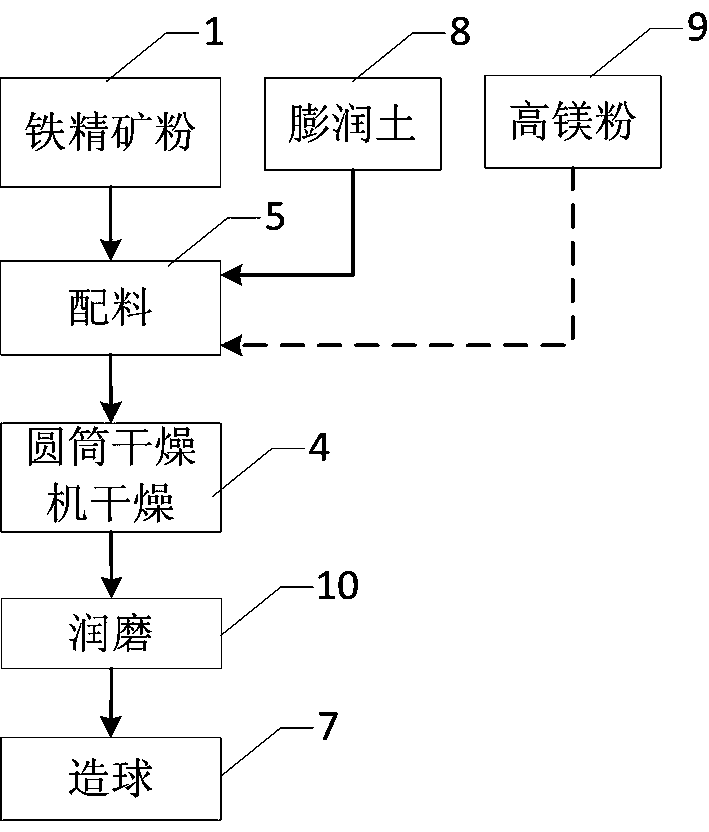

The invention relates to application of a shaft furnace to the roasting of full vanadium titanium iron ore concentrate pellet, which belongs to the technical field of the preparation method for the pellet. According to the method, the full vanadium titanium iron ore concentrate and 1.0 to 1.4 percent of bentonite are taken as raw materials which are used to prepare the full vanadium titanium iron ore concentrate pellet through even mixing, damp milling, pelletizing, drying and roasting, wherein the roasting temperature is 1,000 to 1,050 DEG C, and the roasting time is 30 to 60 minutes. The compressive strength of the full vanadium titanium iron ore concentrate pellet obtained by the method reaches 2,200N / piece. The pellet can be directly used for blast furnace smelting and also be used as a furnace protecting product during the blast furnace smelting of common ore.

Owner:攀钢集团成都钢铁有限责任公司

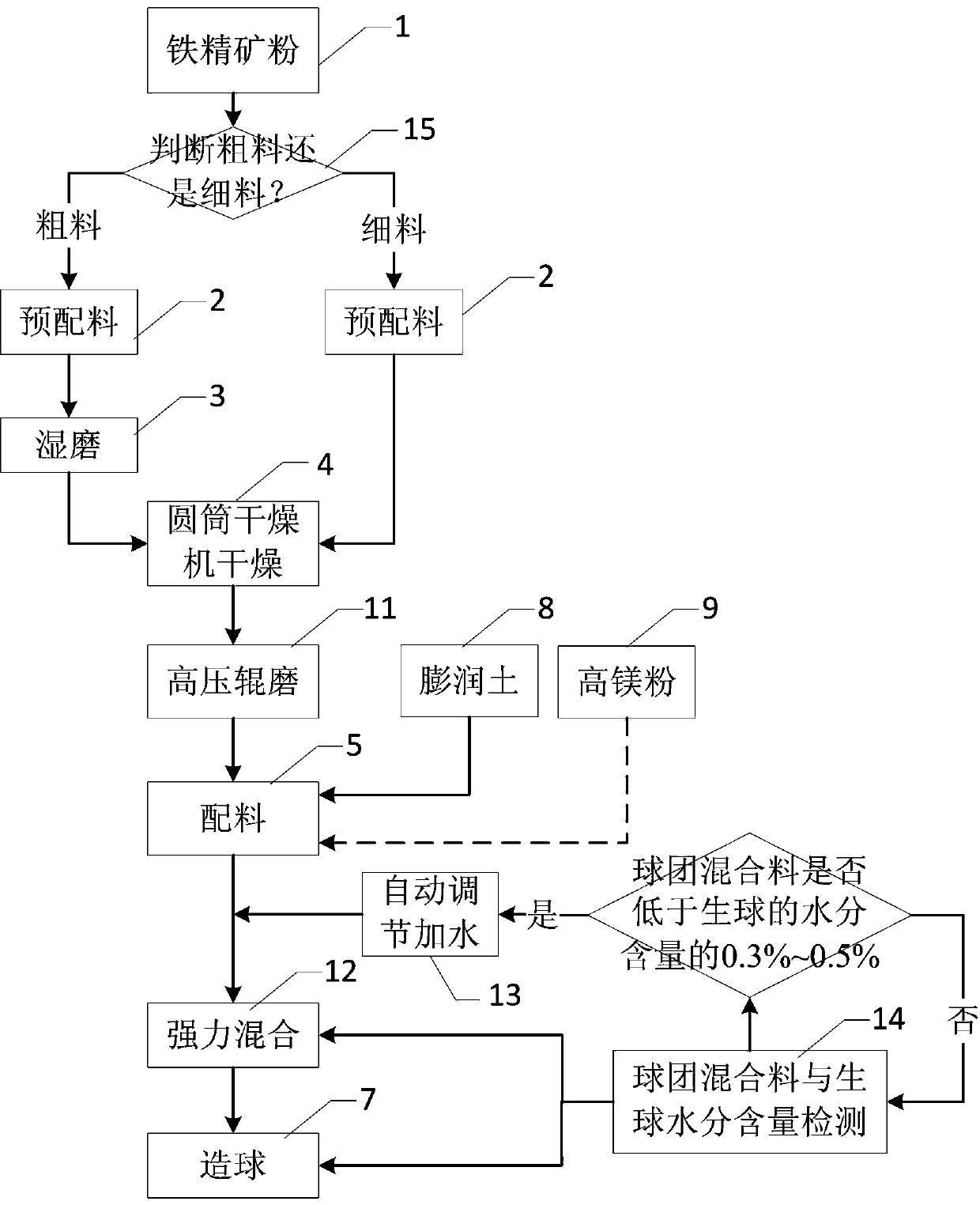

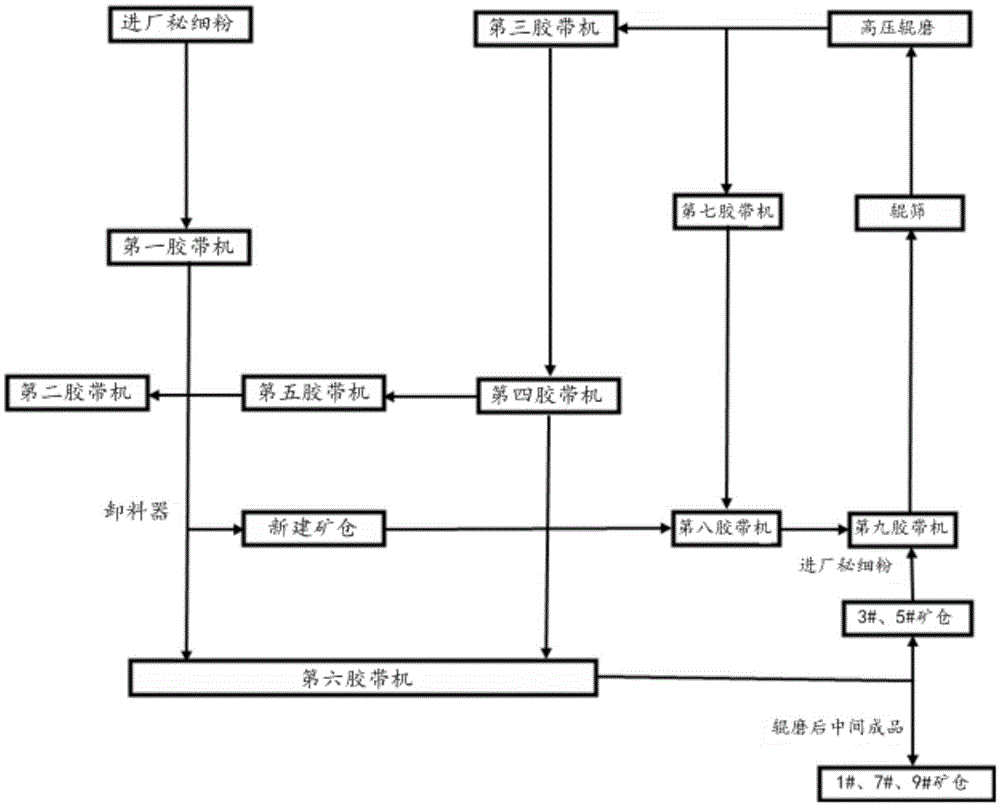

Iron mine pellet raw material preparation method facilitating efficient pelletizing

The invention relates to the field of research of pellet mine manufacturing techniques of the iron and steel metallurgy industry, in particular to an iron mine pellet raw material preparation method facilitating efficient pelletizing. The method includes the steps that whether iron concentrate fines are coarse materials or fines is judged, if the iron concentrate fines are the coarse materials, the iron concentrate fines are subjected to wet grinding after pre-dosing; the iron concentrate fines are dried and smashed by a high pressure rolling mill; the iron concentrate fines after smashing aremixed with bentonite and the like to obtain a pellet mixture through intensive mixing; the pellet mixture enters a pelletizer to be subjected to pelletizing to obtain pelletizing green-balls; and thewater content of the pelletizing mixture before entering the pelletizer and the water content of the pelletizing green-balls are separately detected, the pelletizing mixture before entering the pelletizer is automatically regulated and intensively mixed with water, and the pelletizing mixture water content range is controlled below 0.3%-0.5% of the green-ball suitable water content. According tothe iron mine pellet raw material preparation method facilitating efficient pelletizing, the technical problem that the water content of production raw materials is difficult to control in the preparation process is solved, and the strength and the production efficiency of pelletizing green-balls are improved.

Owner:ANYANG IRON & STEEL

Preparation technique of iron ore pellets

InactiveCN102936652AReduce dosageGive full play to the bonding effectCarboxymethyl celluloseSodium Bentonite

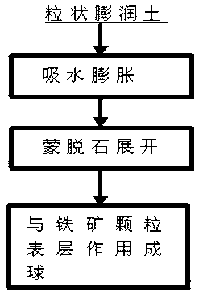

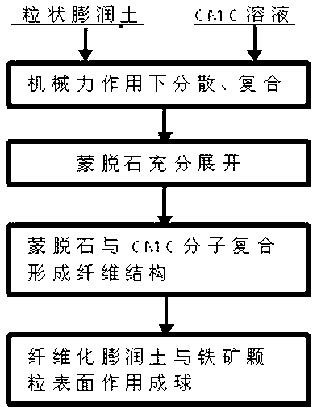

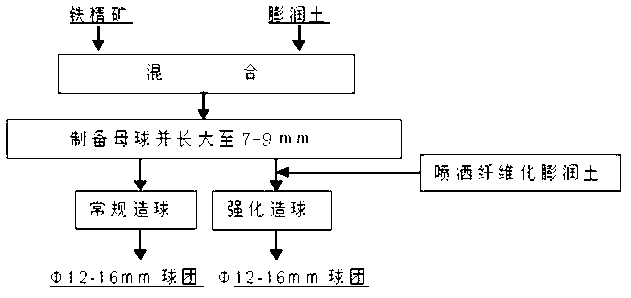

The invention discloses a preparation technique of iron ore pellets, which comprises the following steps: (1) adding 0.5-1% of bentonite to iron concentrate, evenly mixing to obtain a mixture of which the water content is 1-3% lower than the propery pelletizing water content, pelletizing with a disk pelletizer or drum pelletizer, and when seed pellets grow into pellets with the diameters of 8mm or so, spraying fiberized bentonite in the pellet growth region to continue pelletization until qualified green pellets with the diameters of 12-16mm are obtained; and (2) the fiberized bentonite is prepared by the following steps: bentonite and a CMC (carboxymethyl cellulose) solution are mixed, so that smectite molecules in the bentonite sufficiently absorb water and expand under the actions of water molecules and CMC molecules under the action of mechanical stirring force, and spread to be compounded with the CMC molecules, thereby preparing the fiberized bentonite. The fiberized bentonite is atomized and sprayed to the pellet growth region to efficiently act on the iron concentrate granule surface and fully display the binding action, thereby obviously enhancing the quality of the green pellets and the strength of the preheated pellets and roasted pellets.

Owner:CENT SOUTH UNIV

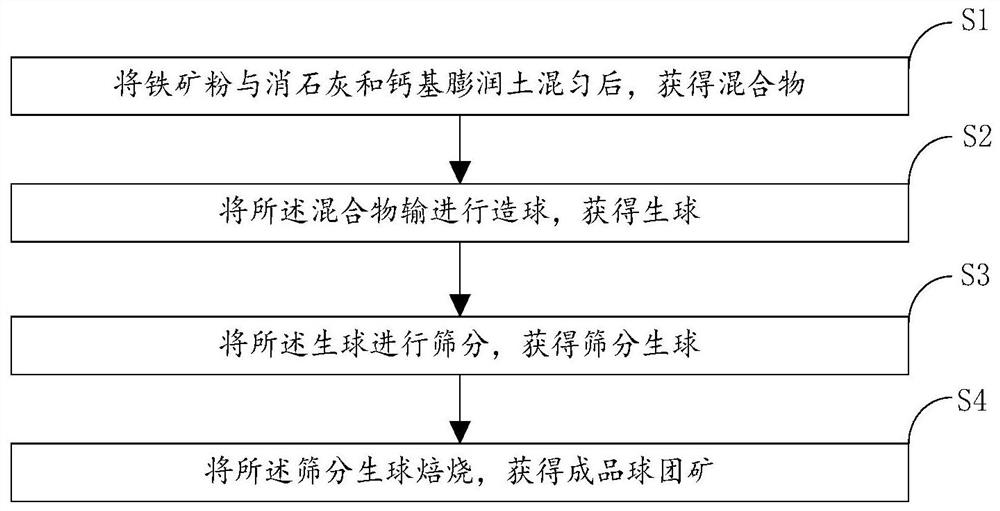

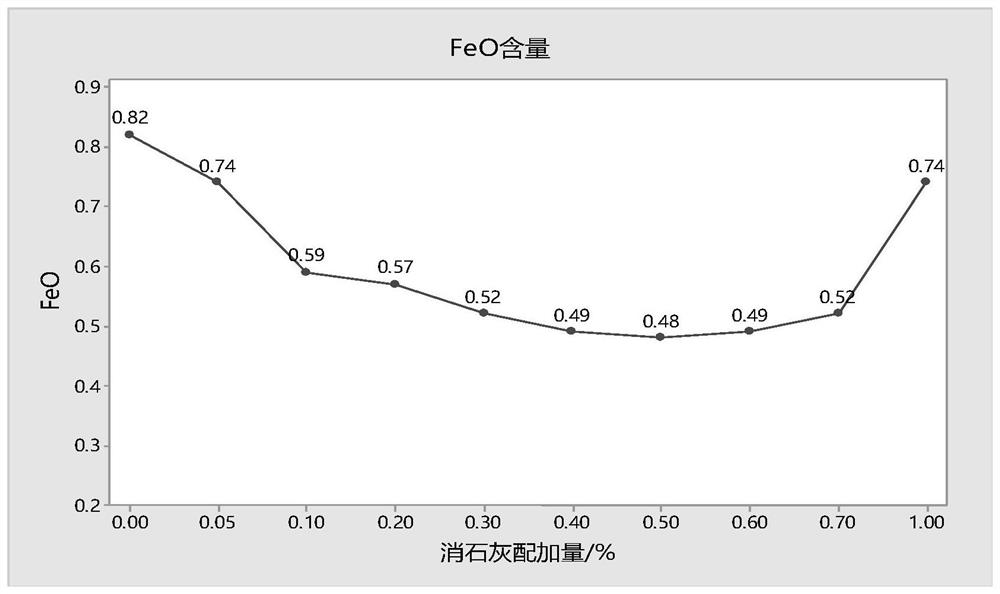

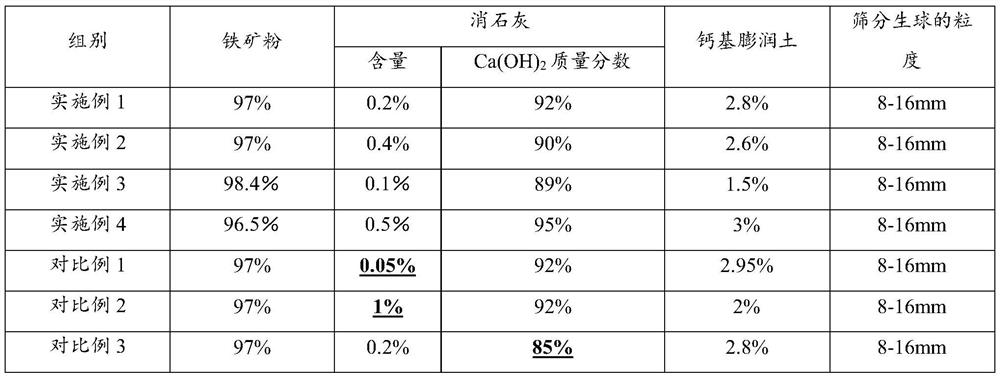

Finished pellet and preparation method thereof

The invention discloses a finished pellet. The finished pellet comprises, by mass: 96.5%-98.4% of iron ore powder, 0.1%-0.5% of slaked lime and 1.5%-3% of calcium bentonite, and the mass fraction of Ca(OH)2 in the slaked lime is more than 88%. The invention also discloses a preparation method of the finished pellet. The preparation method comprises the steps of uniformly mixing the proportioned iron ore powder with the slaked lime and the calcium bentonite to obtain a mixture; and carrying out pelletizing, screening and roasting on the mixture to obtain the finished pellet. According to the finished pellet and the preparation method thereof, through adding the small amount of slaked lime, the specific surface area of the mixture can be improved, the falling strength and granularity uniformity of green pellets are further improved, and the quality of the green pellets is improved; the improvement of the quality of the green pellets is beneficial to the improvement of the circulation ofthe hot gas flow in a material layer, and sufficient oxidizing atmosphere is provided for the pellets in the roasting process, so that the content of FeO in the finished pellets is reduced; and the small amount of slaked lime plays a role of sulfur fixation, and the influence of the combination of sulfur and oxygen on the oxidation of ferrous iron is reduced.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

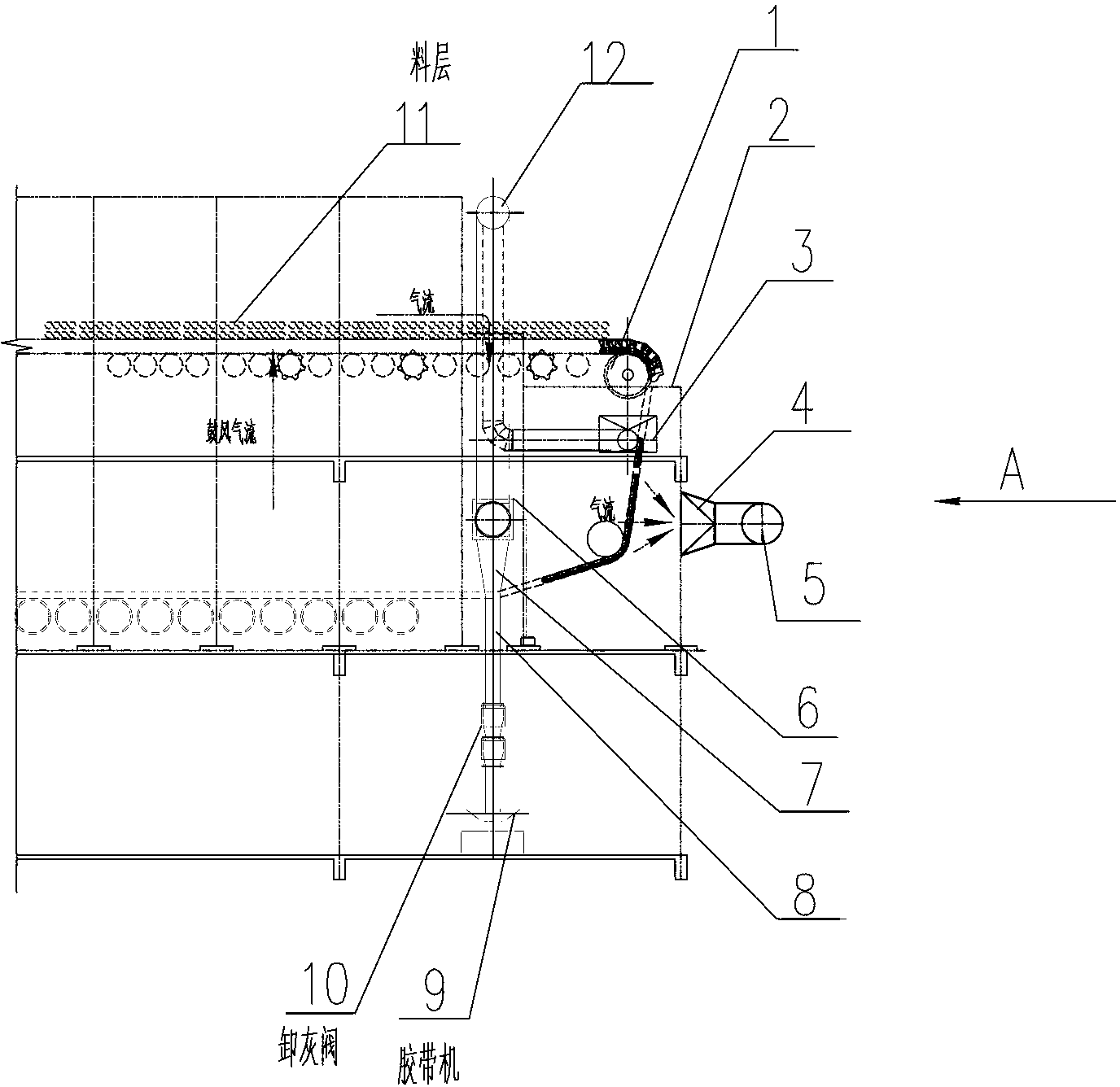

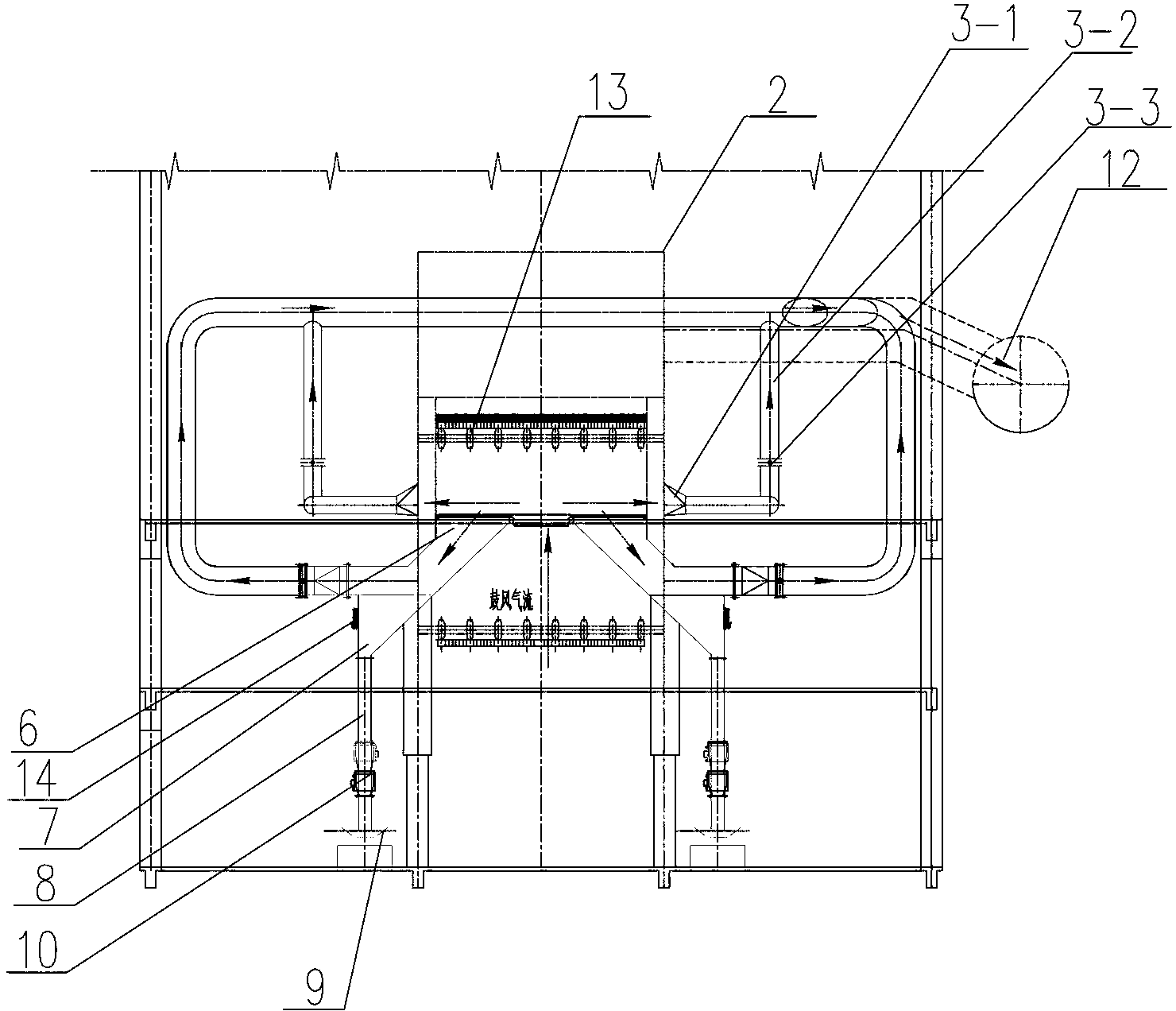

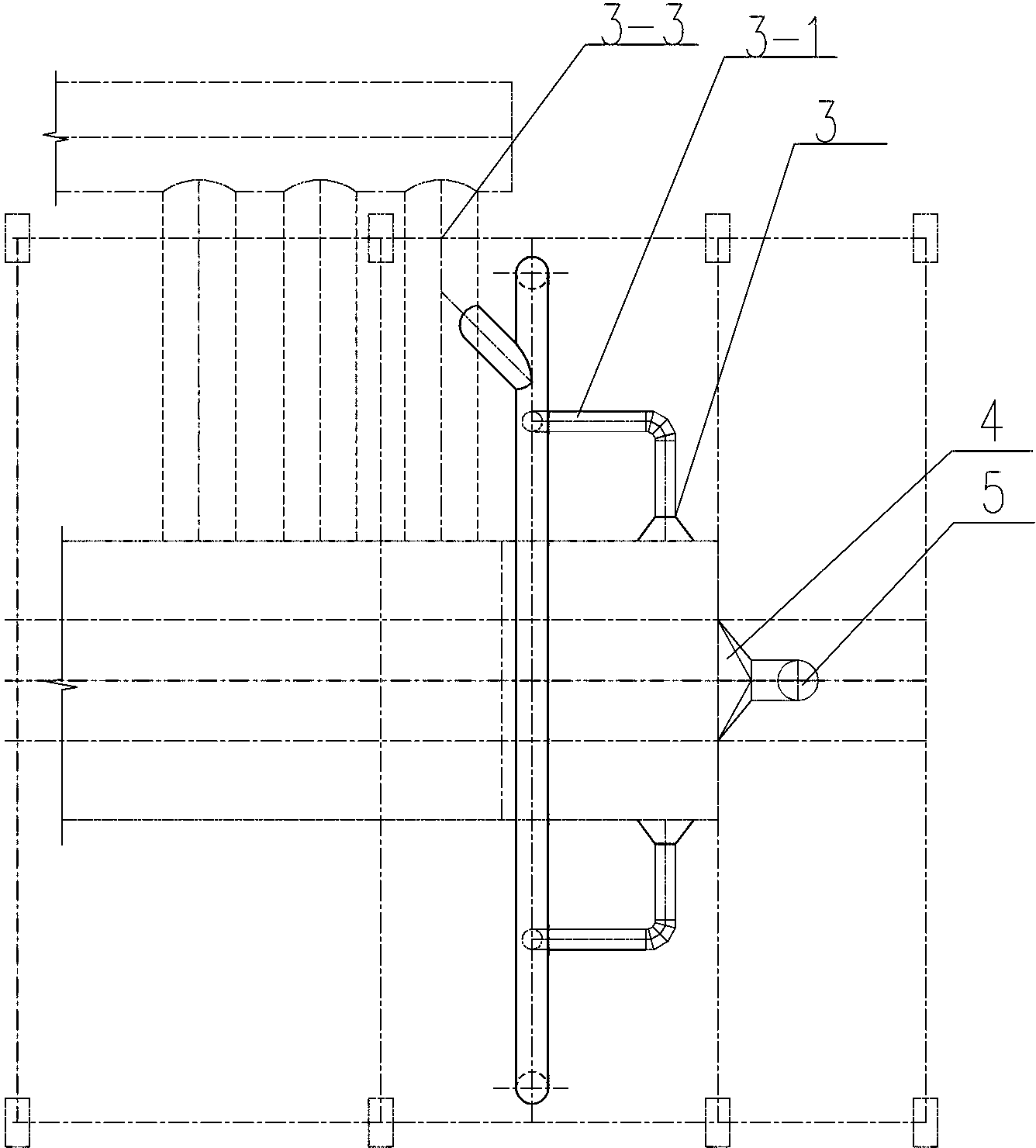

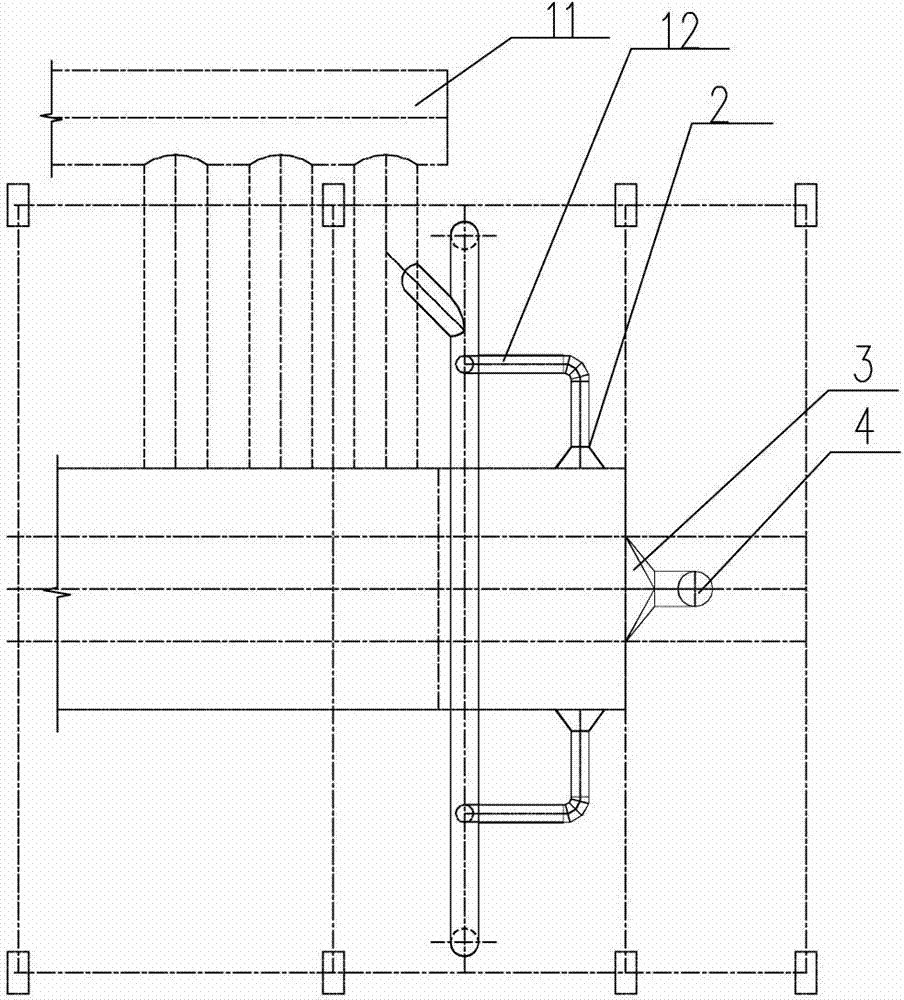

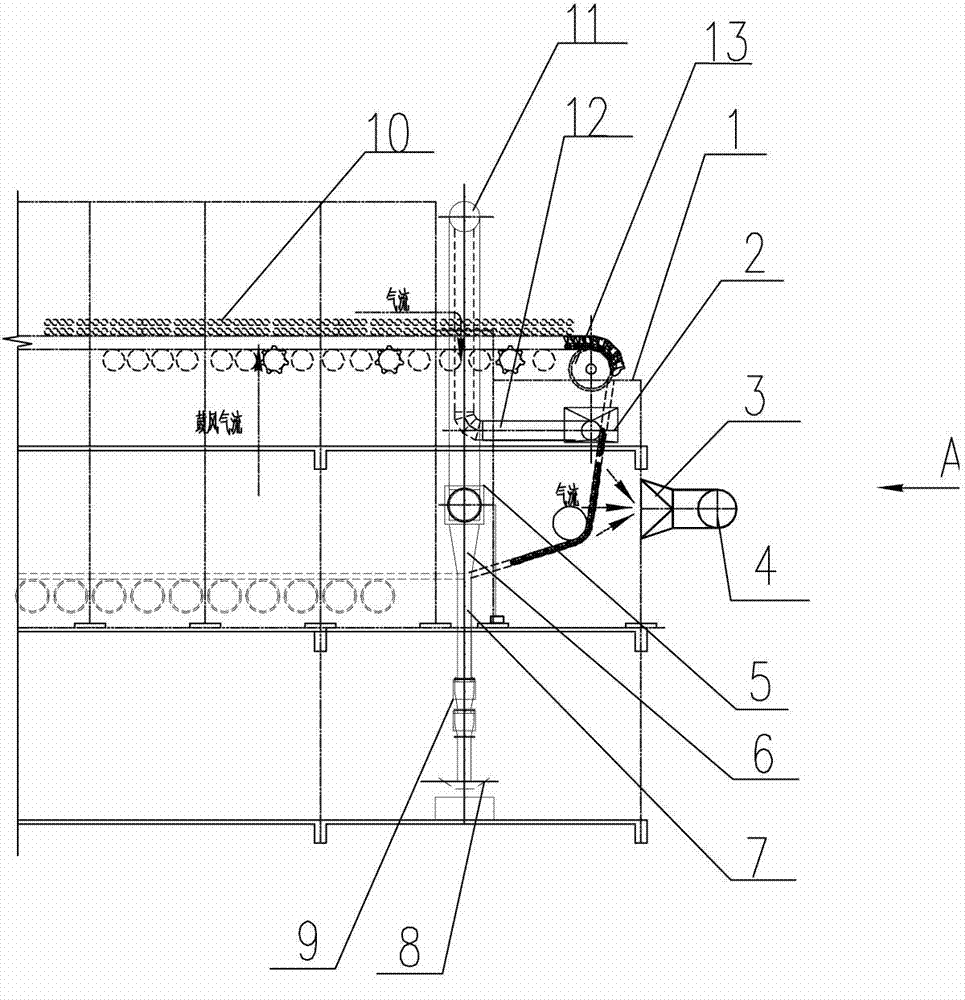

Dust removing system of chain grate machine tail part

InactiveCN103075892APrevent spillageReduce maintenanceWaste heat treatmentEngineeringTemperature gradient

The invention relates to a dust removing method in the production process of metallurgical pellets, in particular to a dust removing system of a chain grate machine tail part. The dust removing system comprises a chain grating machine tail part mechanism with a chain grate machine wheel and a chain grate machine tail wheel return device; the dust removing system is characterized in that a machine tail seal cover is arranged on the chain grate machine tail part mechanism; chain grate machine tail wheel return segment dust removing devices are arranged on the upper part of the machine tail seal cover; an overall chain grate machine tail dust removing device is arranged in the middle part of the machine tail seal cover; and a tail sealing wind box dust removing device of the chain grate machine is arranged at the end part of the lower return of the chain grate machine tail. According to the dust removing system provided by the invention, as the chain grate machine tail wheel return segment dust removing devices are arranged at the three main dust-raising spots of the chain grate machine tail mechanism, and are connected with external exhaust fans by pipelines, thereby forming a negative pressure environment; the three dust removing systems are compensated to one another and are linked with one another, so that the high temperature waste gas can be effectively prevented from overflowing, the tail machine environment of the chain grate machine workshop can be improved, the service life of the heat resistant parts of the equipment can be ensured; and moreover, the temperature gradients of the materials are smoothed, and the mine return quantity of the cured pellets can be reduced.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

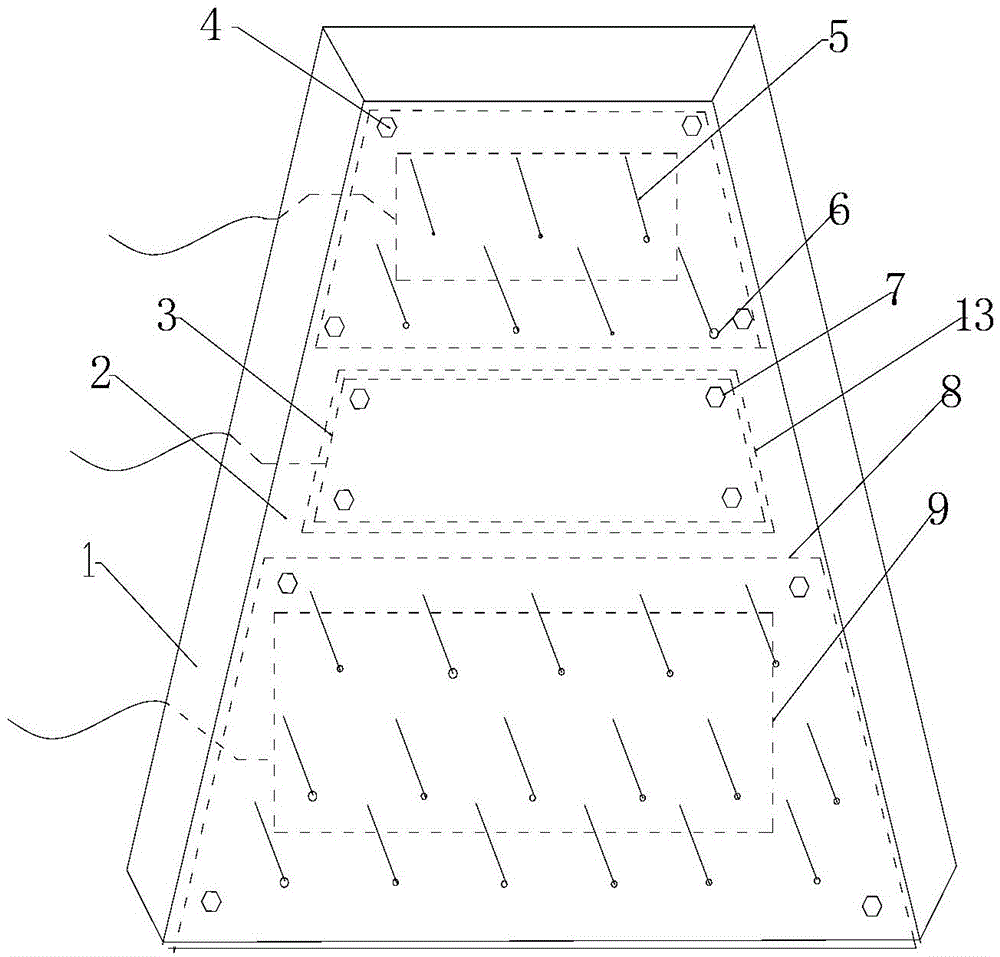

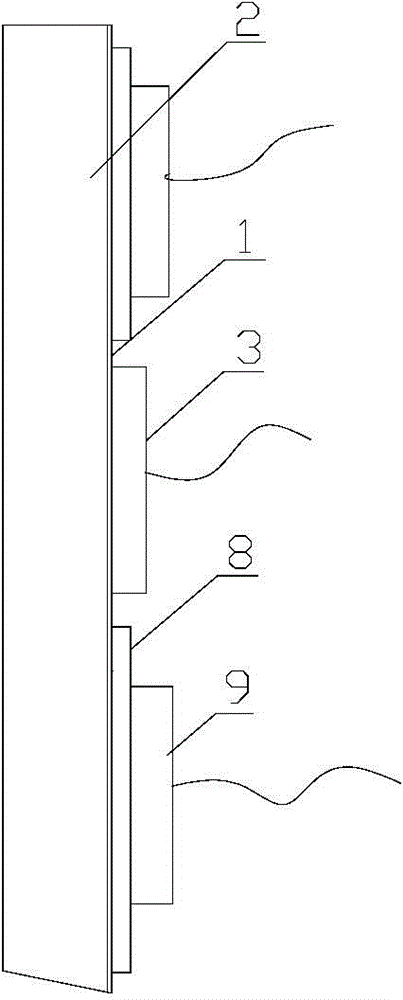

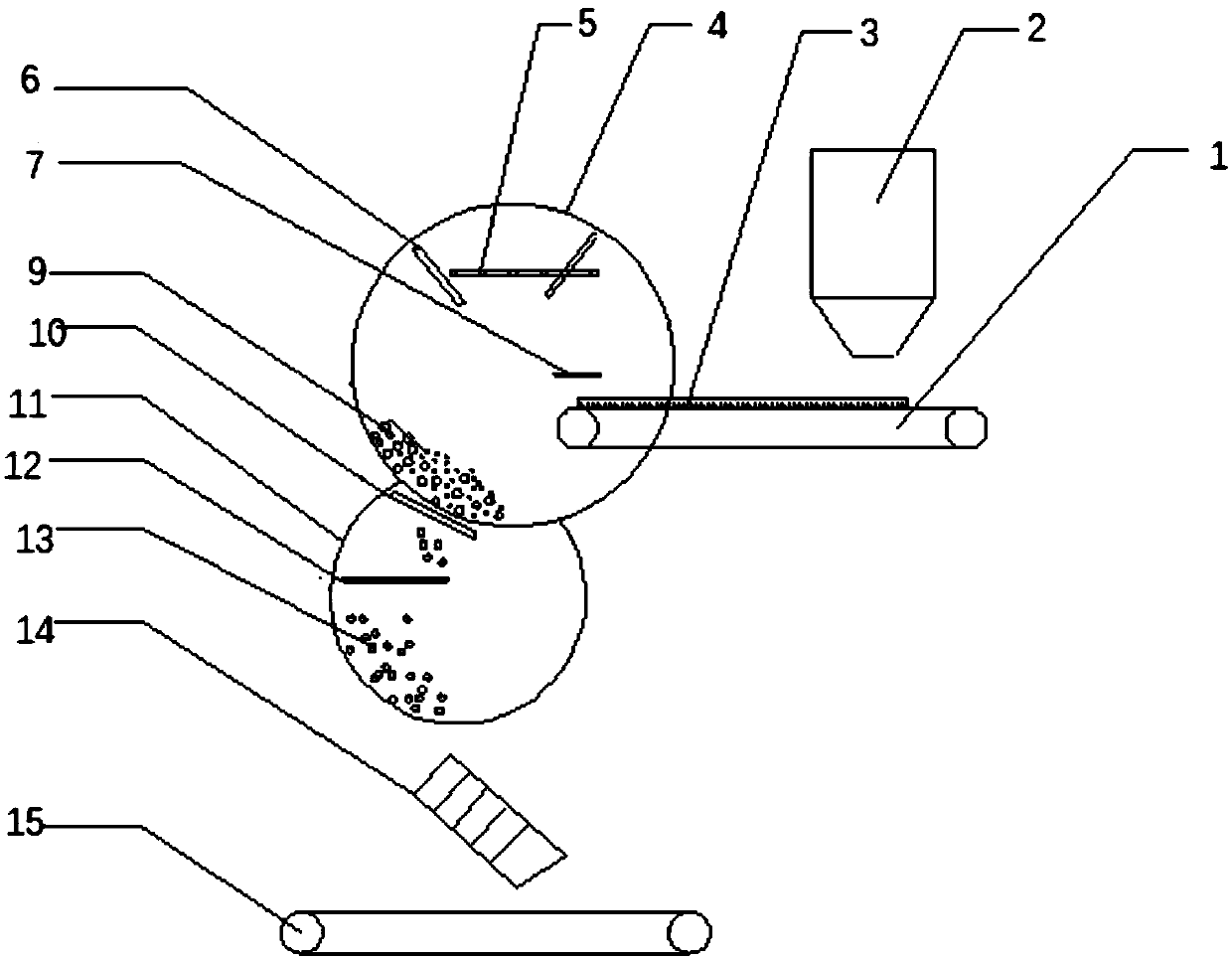

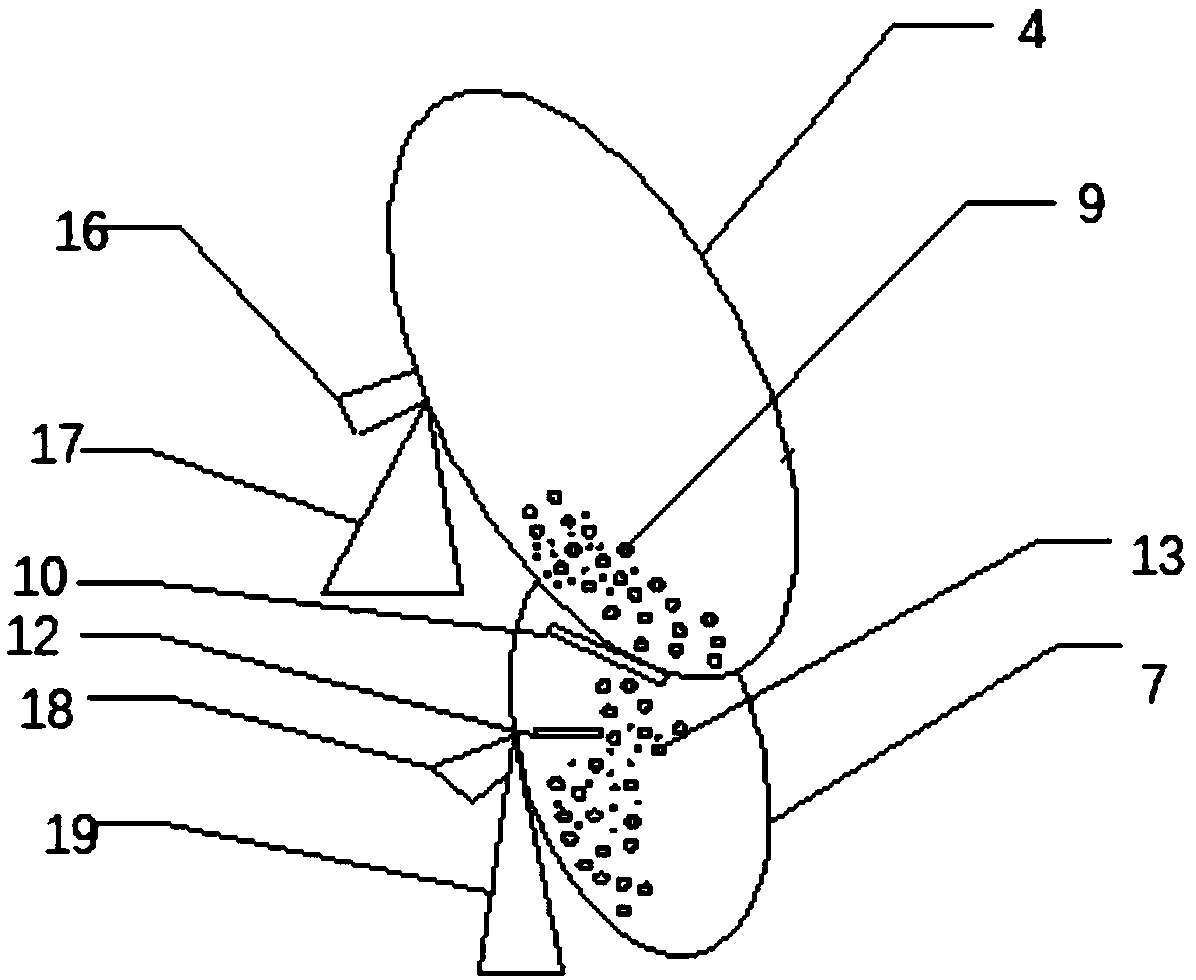

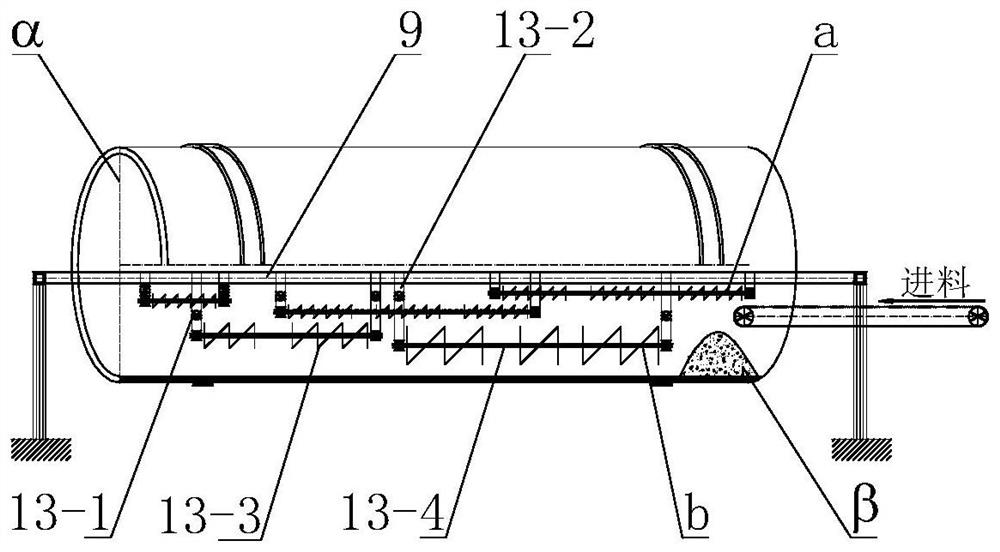

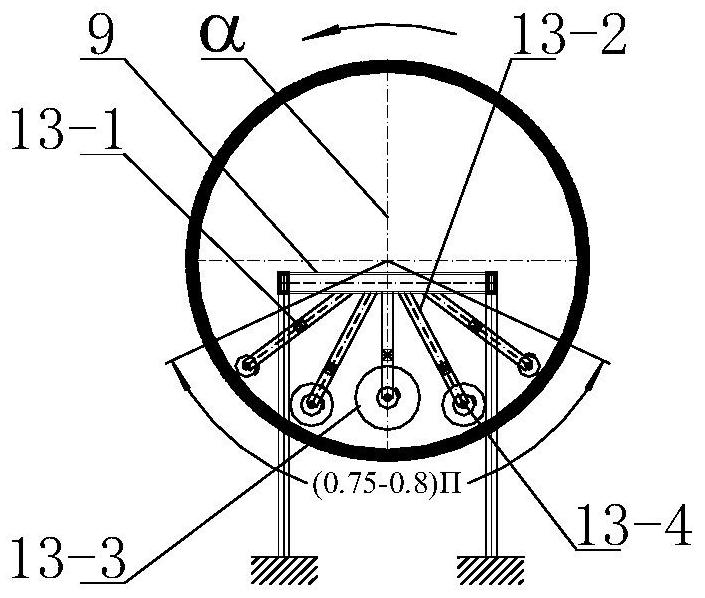

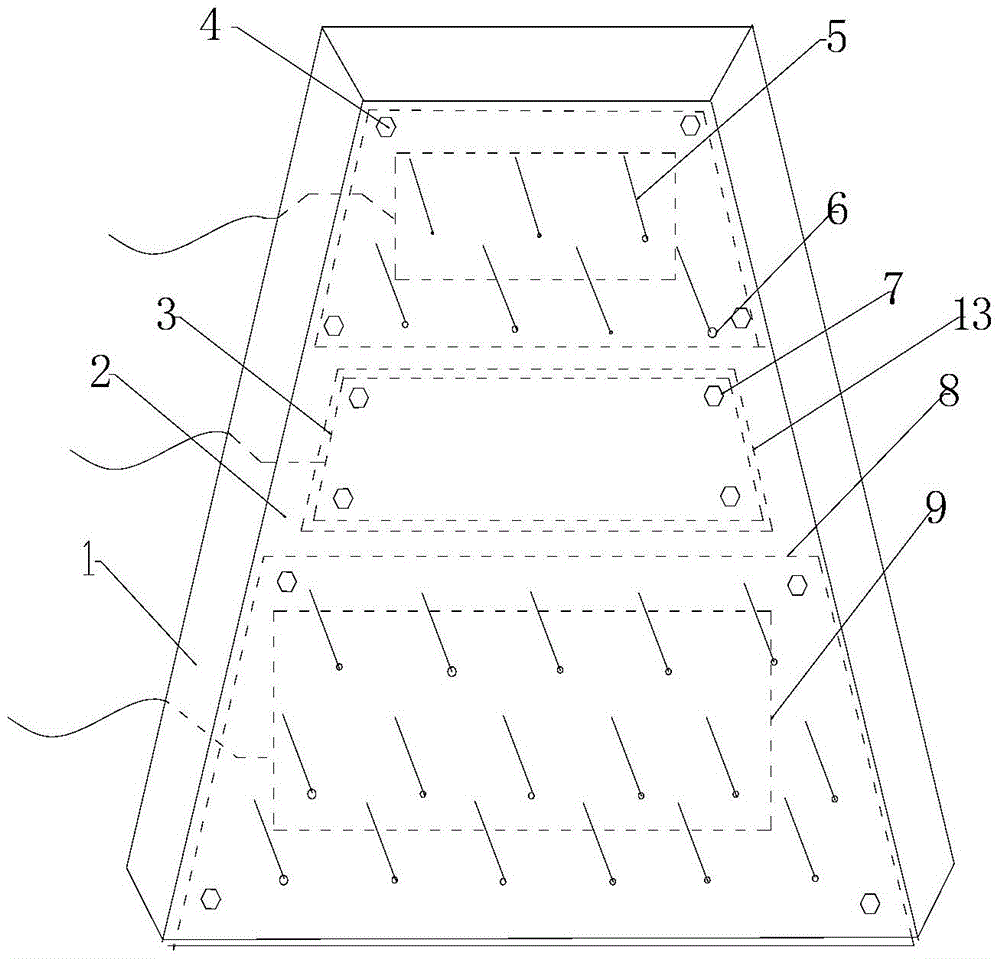

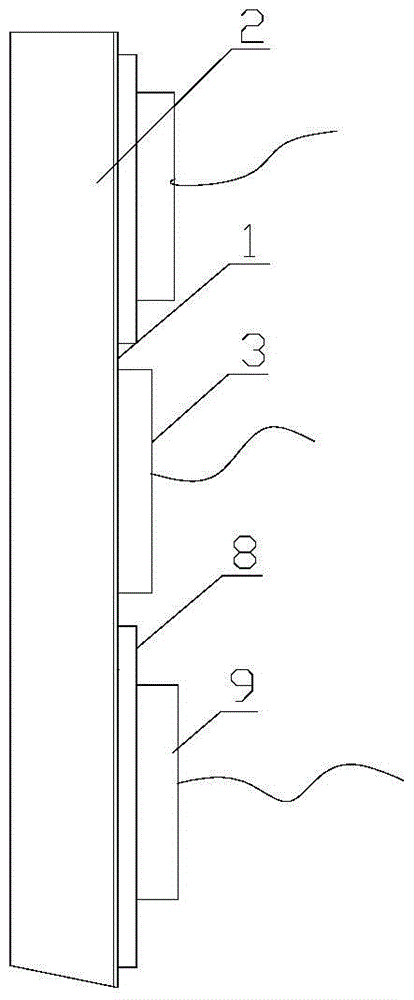

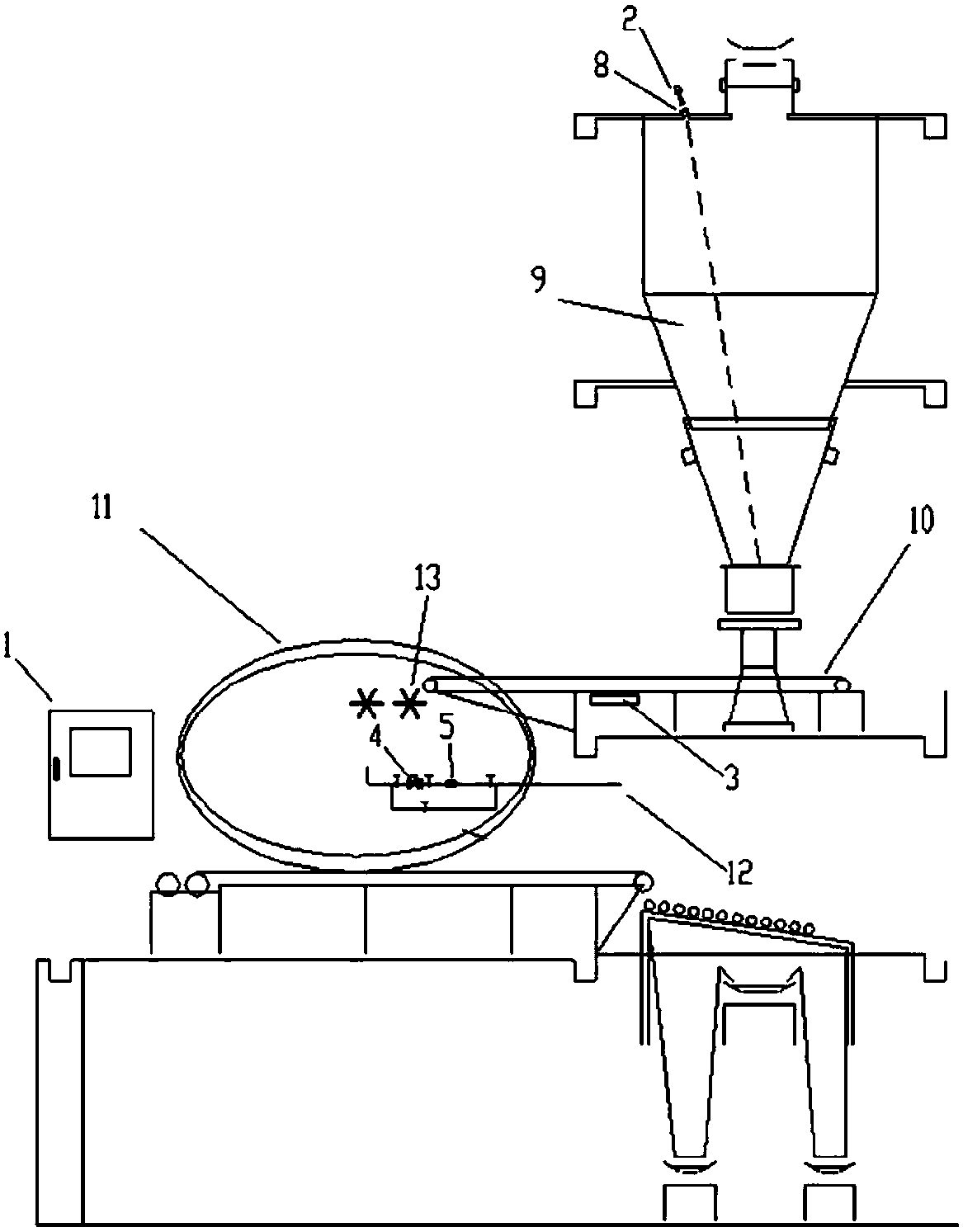

Pelletizing raw material loosening and blanking device and method

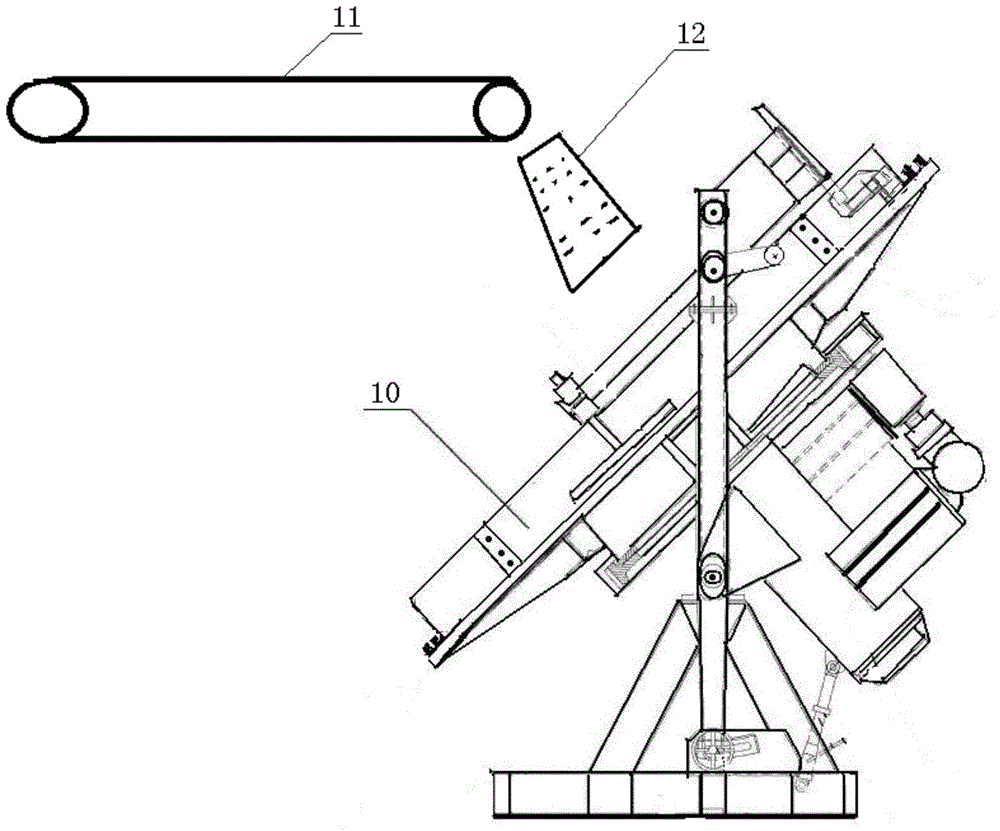

The invention discloses a pelletizing raw material loosening and blanking device and method. The pelletizing raw material loosening and blanking device comprises a base plate, enclosure plates, a material loosening plate, a vibrating plate and a driving device. The enclosure plates are welded to the four sides of the base plate. The vibrating plate is fixed to the middle of the lower surface of the base plate. Material loosening holes are evenly distributed in the upper portion and the lower portion of the base plate respectively. Material loosening bars penetrate through the material loosening holes. The lower ends of the material loosening bars are welded to the material loosening plate. The driving device is connected to the lower surface of the material loosening plate. The material loosening plate is movably connected to the base plate through shaft pins. The material loosening and blanking device is obliquely arranged between a feeding belt and a disc pelletizer. The material loosening bars vibrate at a certain frequency under the driving of the driving device, and thus pelletizing raw materials fallen onto the base plate are loosened into mineral powder with the uniform granularity; meanwhile, the base plate also vibrates continuously under the action of the vibrating plate, so that the mineral powder dispersed on the base plate is evenly distributed in a pelletizing disc. By the adoption of the pelletizing raw material loosening and blanking device and method, the dispersity of the pelletizing raw materials fallen into the pelletizing disc can be improved, the contact area between a green pellet and the mineral powder is increased, the pelletizing time is sufficient, and the quality of the green pellet is improved; the quality of returned materials is reduced, and the load of a screening system is reduced.

Owner:ANGANG STEEL CO LTD

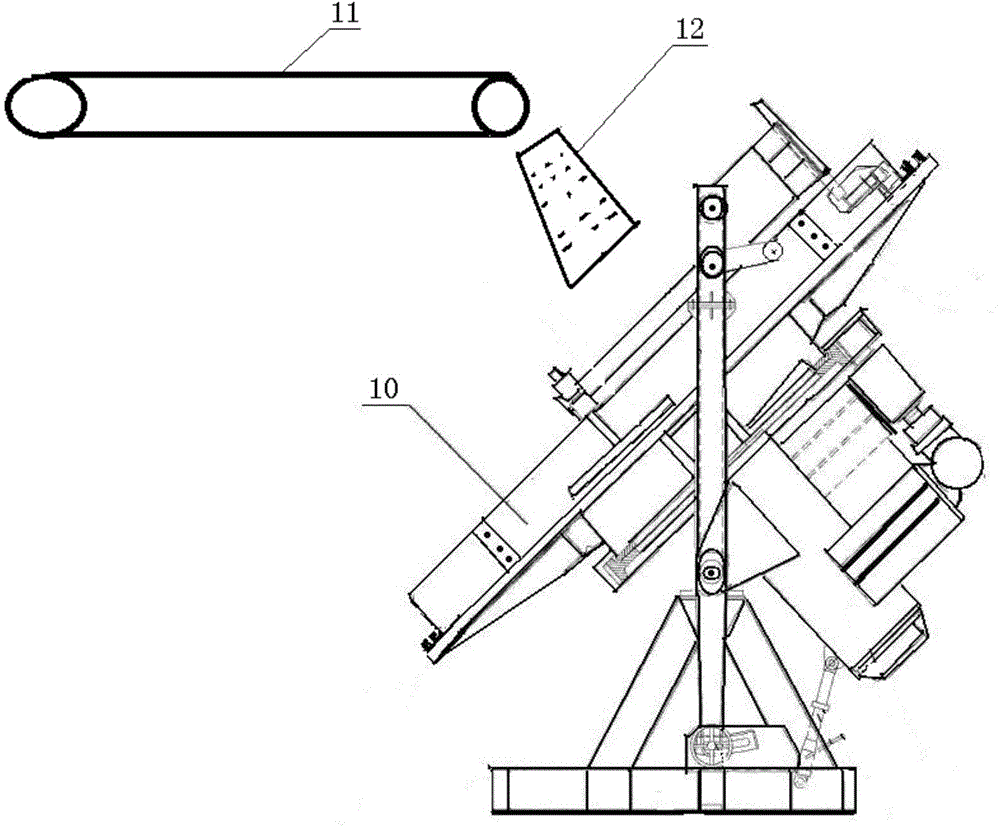

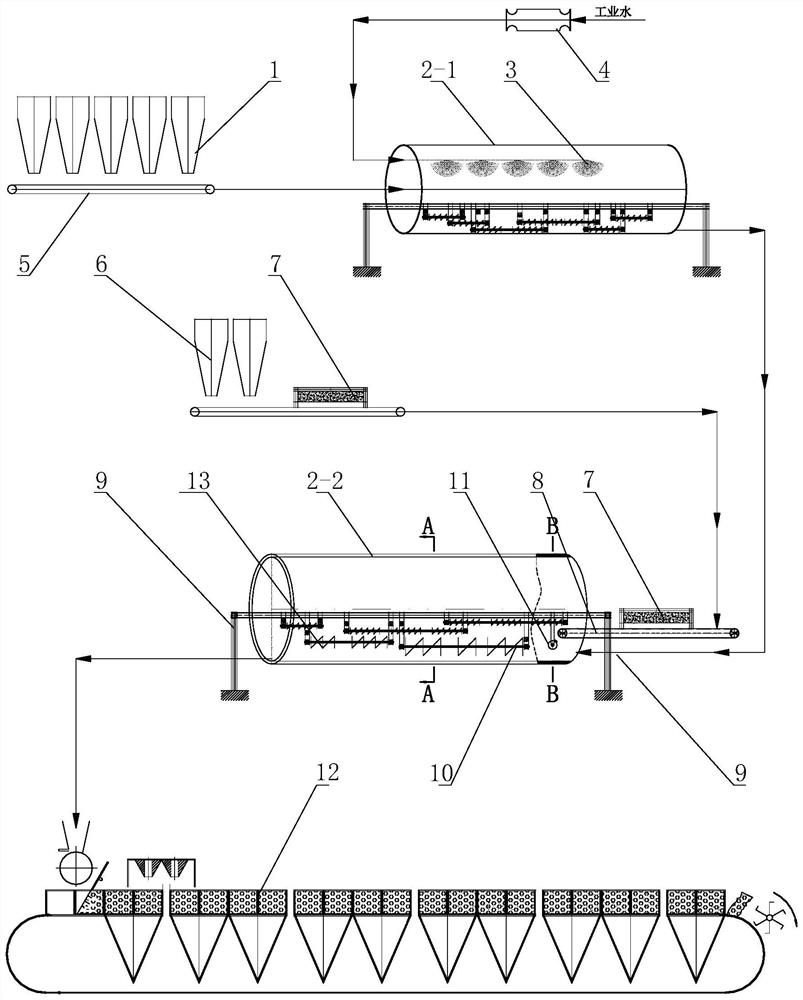

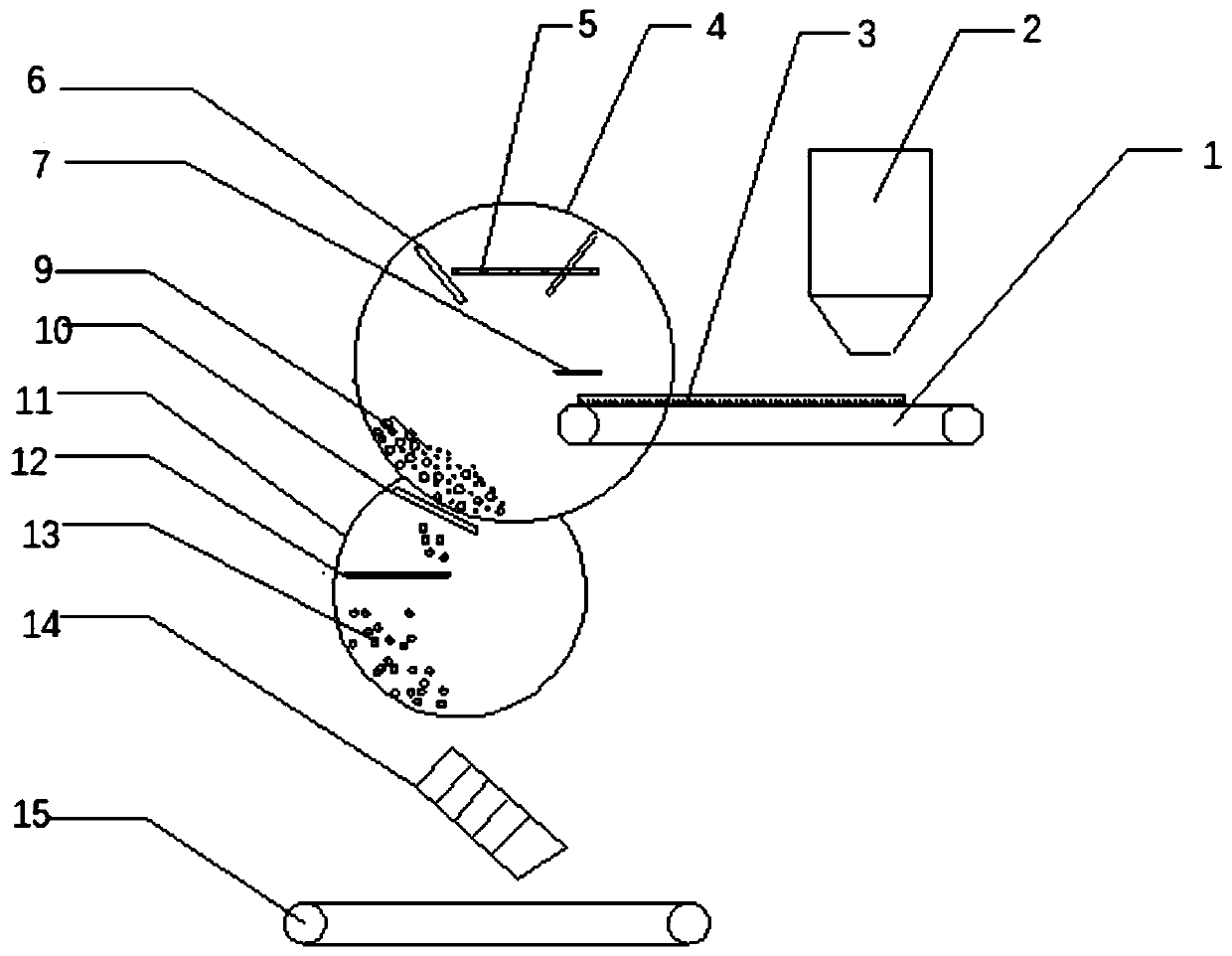

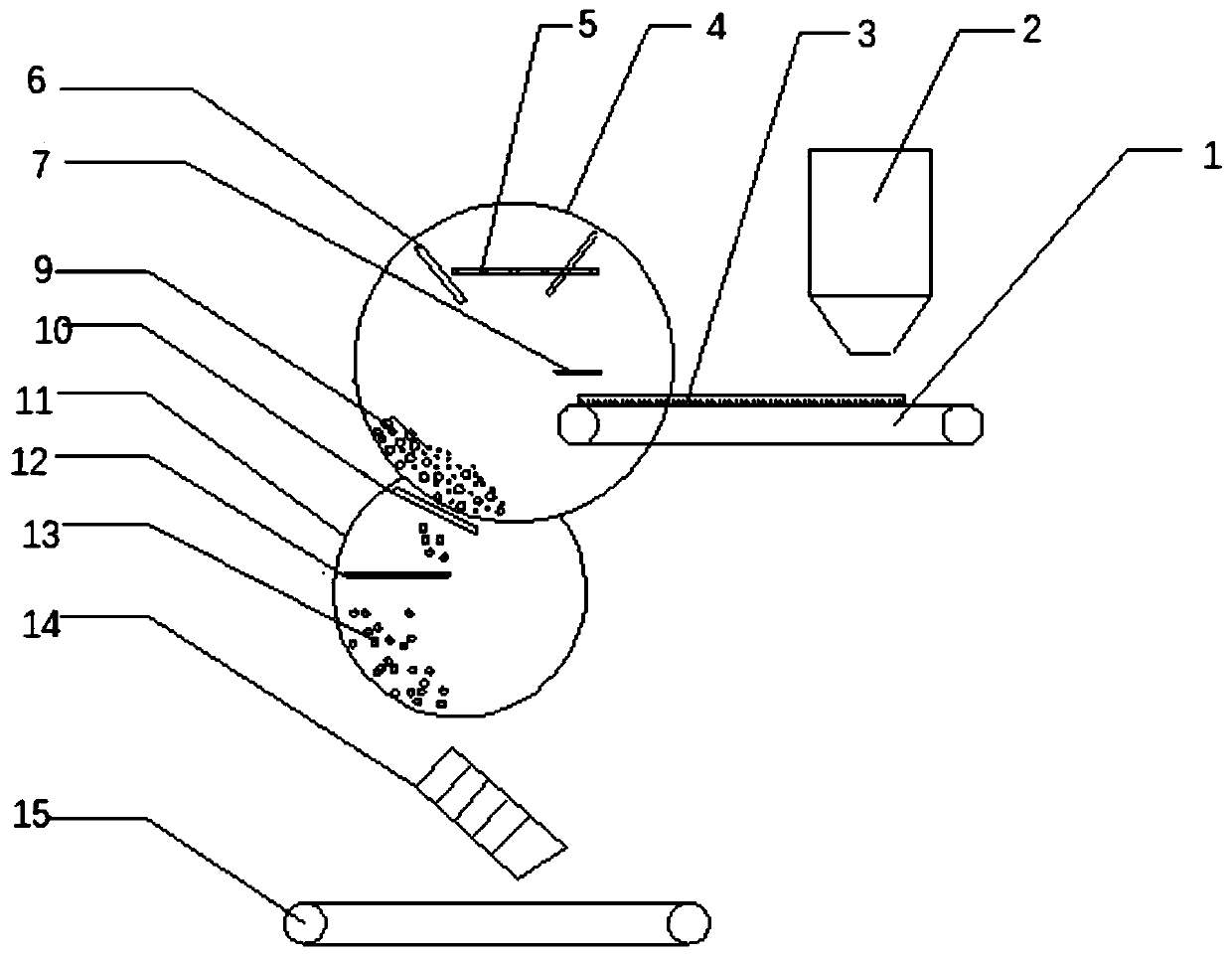

Iron ore pellet balling device

The invention discloses an iron ore pellet balling device. The device comprises an ore powder bin containing ore powder, an ore powder belt arranged below the ore powder bin, a first balling disc connected with the ore powder belt and a second balling disc arranged below the first balling disc. Ore powder falls onto the ore powder belt from the interior of the ore powder bin. Ore powder is conveyed into the first balling disc under the action of the ore powder belt, and green balls with the first weight are generated under the action of the first balling disc. Ore powder, not generating greenballs, in the first balling disc and the green balls with the first weight enter the second balling disc, and green balls with the second weight are generated under the action of the second balling disc. The technical effects that the ore return rate in the pellet balling process is greatly reduced, the yield is increased, the surface quality and strength of the green balls are improved, and energy consumption is reduced are achieved.

Owner:SHOUGANG CORPORATION

Method for preparing oxidated pellets from pure hematite concentrate

Owner:CENT SOUTH UNIV

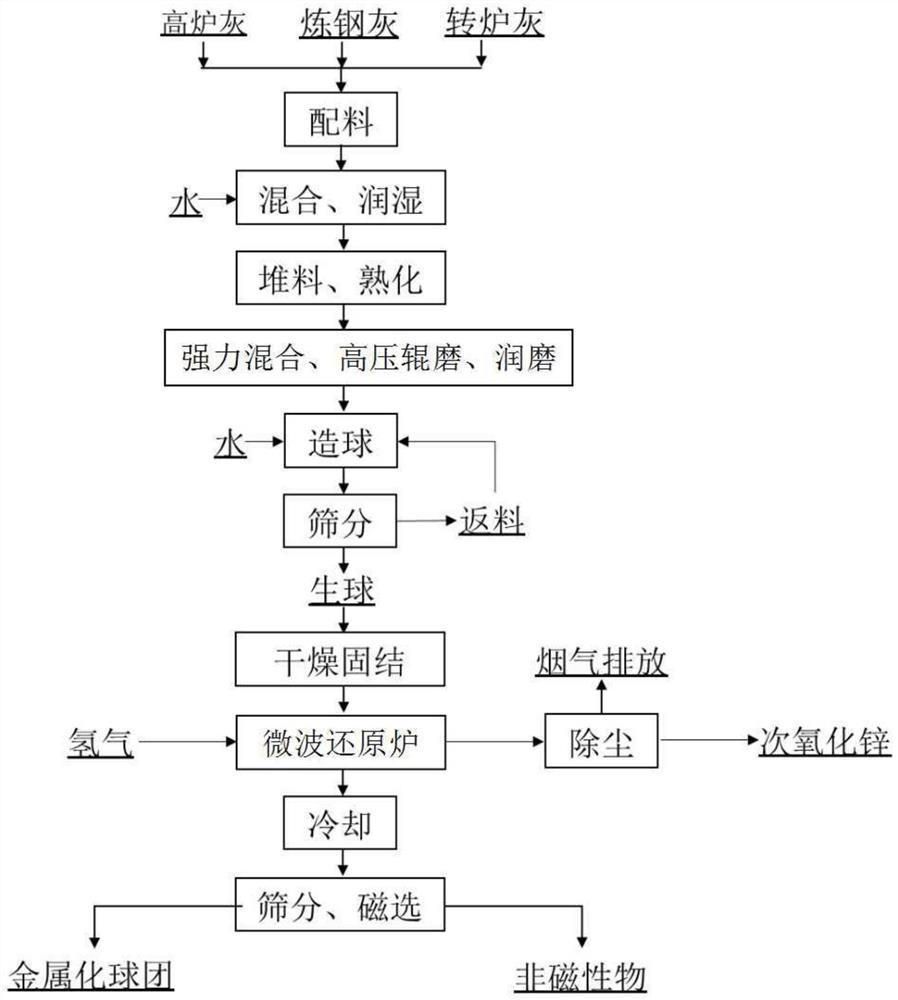

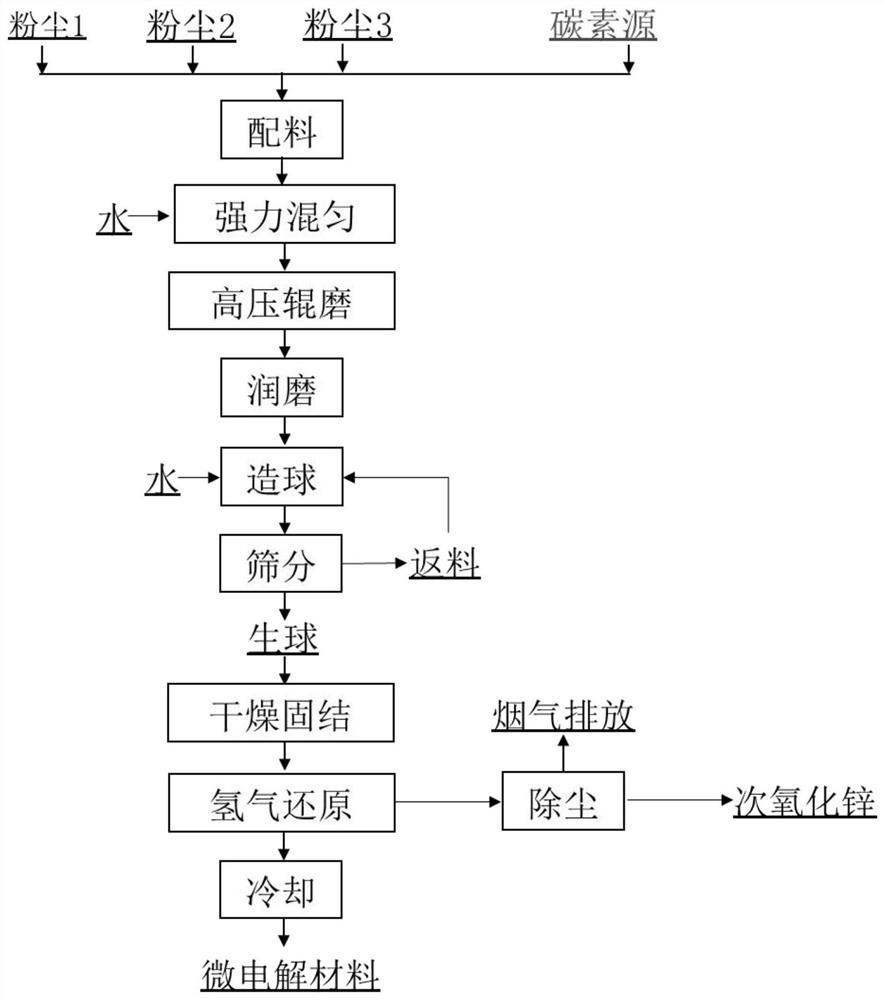

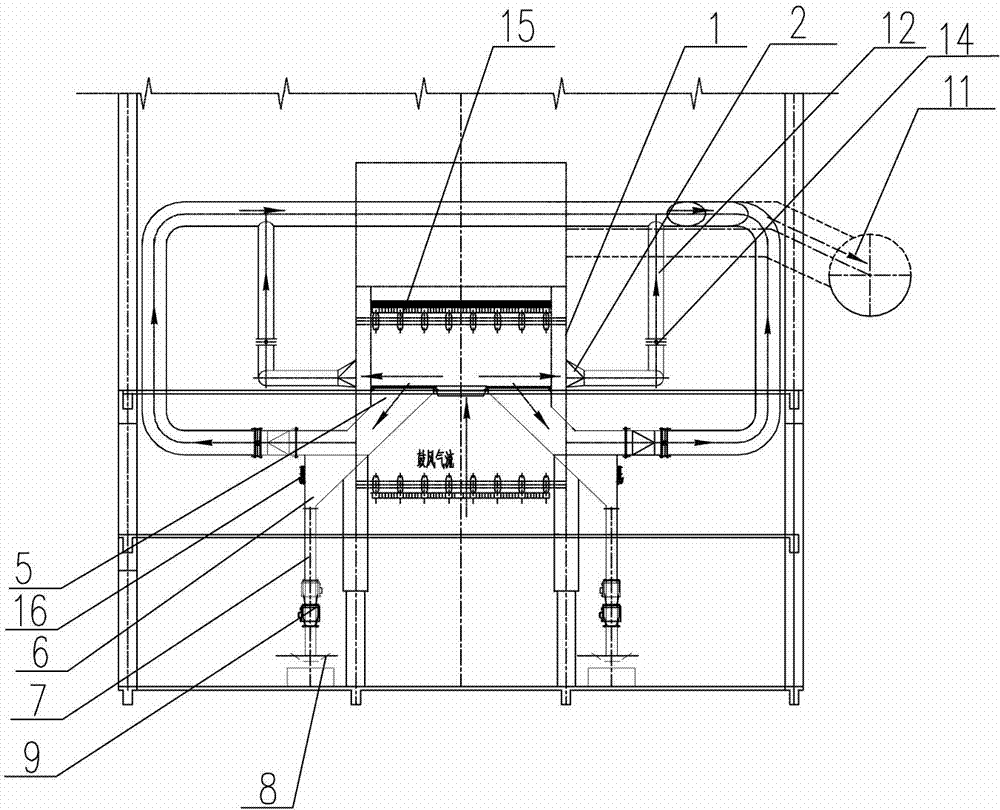

Method for dezincification of zinc-containing dust through microwave hydrogen reduction

PendingCN114525401AHigh carbon contentImprove absorbing performanceProcess efficiency improvementMixed materialsZinc

The invention discloses a method for dezincification of zinc-containing dust through microwave hydrogen reduction, which belongs to the technical field of ferrous metallurgy and comprises the following steps: S1, carrying out optimized ore blending on different types of zinc-containing dust in a steel plant to obtain an ore-blended zinc-containing dust material; s2, a binder is added into the zinc-containing dust material obtained after ore blending, powerful mixing treatment is conducted, then high-pressure roller milling and wet milling combined treatment is conducted, and a uniformly-mixed material is obtained; s3, pelletizing the uniformly mixed material to obtain green pellets, and drying to obtain dry pellets; and S4, the dry balls are put into a microwave reduction furnace to be subjected to hydrogen reduction treatment, cooling is conducted under the protective atmosphere after reduction, and reduced dezincified balls are obtained. Aiming at the characteristics of high carbon content and excellent wave-absorbing performance in the zinc-containing dust of the iron and steel plant and the characteristics of high heating speed, small heat loss, strong penetrating power, convenience in operation and the like of microwave heating, the defects of high energy consumption and serious pollution of traditional heating can be obviously improved when the zinc-containing dust is heated.

Owner:CENT SOUTH UNIV

Magnetized water granulation process for sintering mixture based on electrostatic dispersion of powder fuel

The invention discloses a sintered mixture magnetized water granulation process based on powder fuel electrostatic dispersion, and solves the problems of high water consumption, high energy consumption, unreasonable heat gradient distribution in the whole sintering process, adhesion to the inner wall of a cylinder mixer and poor operation stability in the water adding, uniform mixing and granulation process of the existing sintered mixture. The main technical scheme comprises the following steps: adding all sintering raw materials except the solid fuel into a primary mixing machine for mixing granulation, discharging from the primary mixing machine, feeding into a secondary mixing machine for further mixing granulation with the added solid fuel, and feeding into a sintering machine; wherein magnetized water is sprayed into the primary mixer to wet the sintering raw materials. The process is simple, energy-saving and consumption-reducing, easy to transform, low in operation cost, reasonable in gradient distribution of heat in the sintering process, high in burnout degree, long in service life of equipment and environment-friendly.

Owner:WUHAN WUTUO TECH +2

A kind of high vanadium high chromium type vanadium titanium magnetite pellets

ActiveCN107267748BGuaranteed outputQuality assuranceBlast furnace detailsMagnetiteBlast furnace smelting

A high-vanadium and high-chromium vanadium-titanium magnetite pellet belongs to the field of blast furnace smelting technology in the comprehensive utilization method of high-vanadium and high-chromium vanadium-titanium magnetite. The chemical composition and mass percentage of the high-vanadium and high-chromium vanadium-titanium magnetite pellets are: V2O5: 0.45-0.62%, TiO2: 2.29-3.20%, Cr2O3: 0.22-0.48%, TFe: 61.88-64.22 %, CaO: 0.11~0.63%, SiO2: 3.18~4.77%, MgO: 0.32~0.89%, Al2O3: 1.62~4.0%, the balance is unavoidable impurities; among them, in TFe, Fe2O3 accounts for pellet mass percentage: 87.51~91.41%, FeO accounts for 0.3~0.8% of the pellet mass. The ratio of raw materials used to prepare pellets, the bentonite ratio is reduced by more than 1%, and the pellet grade is improved; the quality of green pellets is effectively improved, and the output and quality of pellets are guaranteed.

Owner:NORTHEASTERN UNIV LIAONING

Preparation method of carbon-containing micro-electrolysis material

ActiveCN114574692AImprove adsorption capacityAchieve recyclingWater contaminantsDispersed particle separationElectrolysisMixed materials

The invention discloses a preparation method of a carbon-containing micro-electrolysis material, which comprises the following steps: S1, optimally proportioning a zinc-containing dust material, a carbon source and a binder to obtain a mixture; s2, intensively and uniformly mixing the mixture obtained in the step S1, and then carrying out high-pressure roller milling and wet milling combined treatment to obtain a uniformly mixed material; s3, pelletizing the uniformly mixed material obtained in the step S2 to obtain green pellets, and drying to obtain dry pellets; and S4, the dry balls obtained in the step S3 are loaded into a gas-based shaft furnace to be subjected to hydrogen reduction treatment, cooling is conducted under the protective atmosphere after reduction, and the carbon-containing micro-electrolysis material is obtained. According to the preparation method of the carbon-containing micro-electrolysis material, Fe and C contained in zinc-containing dust are fully utilized, dezincification of the zinc-containing dust and preparation of the micro-electrolysis material are achieved in one step through a reduction method, the traditional preparation process of the micro-electrolysis material is changed, and short-process and high-value comprehensive utilization of the zinc-containing dust is achieved.

Owner:CENT SOUTH UNIV

Dust removal system at the tail of the chain grate machine

ActiveCN103697711BGuaranteed service lifePrevent spillageWaste heat treatmentEngineeringTemperature gradient

The invention relates to a dust removing method in the production process of metallurgical pellets, in particular to a dust removing system of a chain grate machine tail part. The dust removing system comprises a chain grating machine tail part mechanism with a chain grate machine wheel and a chain grate machine tail wheel return device; the dust removing system is characterized in that a machine tail seal cover is arranged on the chain grate machine tail part mechanism; chain grate machine tail wheel return segment dust removing devices are arranged on the upper part of the machine tail seal cover; an overall chain grate machine tail dust removing device is arranged in the middle part of the machine tail seal cover; and a tail sealing wind box dust removing device of the chain grate machine is arranged at the end part of the lower return of the chain grate machine tail. According to the dust removing system provided by the invention, as the chain grate machine tail wheel return segment dust removing devices are arranged at the three main dust-raising spots of the chain grate machine tail mechanism, and are connected with external exhaust fans by pipelines, thereby forming a negative pressure environment; the three dust removing systems are compensated to one another and are linked with one another, so that the high temperature waste gas can be effectively prevented from overflowing, the tail machine environment of the chain grate machine workshop can be improved, the service life of the heat resistant parts of the equipment can be ensured; and moreover, the temperature gradients of the materials are smoothed, and the mine return quantity of the cured pellets can be reduced.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

High chromium-high vanadium type vanadium titanium ore pellet

The invention relates to a high chromium-high vanadium type vanadium titanium ore pellet, in particular to a vanadium titanium ore pellet. The invention mainly solves the problems that pelletizing granularity is coarse and pelletizing performance is poor in the high chromium-high vanadium type vanadium titanium ore pellet prepared by the prior art. The high chromium-high vanadium type vanadium titanium ore pellet is prepared by 45-50 parts by weight of vanadium titanium ore, 50-55 parts by weight of iron material and 1.8-2.1 parts by weight of bentonite, wherein the iron material comprises 11-28wt% of iron powdered ore and 72-89wt% of ultrafine iron powder. The preparation method of the pellet is realized by the following steps of: burdening, drying and mixing, pelletizing, green pellet screening and shaft furnace roasting. Vanadium content of vanadium titanium powder in the vanadium titanium ore pellet provided by the invention reaches up to more than 4.5%, and blast furnace vanadium titanium smelting requirement is met. The high chromium-high vanadium type vanadium titanium ore pellet provided by the invention is applicable to furnace charge for blast furnace vanadium titanium smelting.

Owner:HEILONGJIANG JIANLONG IRON & STEEL

A kind of preparation method of high-vanadium high-chromium type vanadium-titanium magnetite pellets

A method for preparing high-vanadium and high-chromium vanadium-titanium magnetite pellets, which belongs to the field of blast furnace smelting technology in the comprehensive utilization method of high-vanadium and high-chromium vanadium-titanium magnetite. The preparation method includes grinding imported high-vanadium and high-chromium vanadium-titanium magnetite, batching according to the proportion of pellet raw materials, drying and mixing the raw materials, adding base water to mix, simmering, pelletizing, and pelletizing. Green balls of 8 to 16 mm are obtained by screening, and then baked and pre-oxidized, roasted in a shaft furnace, and cooled to obtain high-vanadium and high-chromium vanadium-titanium magnetite pellets. This method solves the problem that pellets are prone to over-melting, resulting in agglomeration or nodulation, which affects the output and quality of finished pellets. It effectively improves the quality of green pellets and ensures the output and quality of pellets.

Owner:NORTHEASTERN UNIV LIAONING

A device and method for distributing loose materials for pelletizing raw materials

Owner:ANGANG STEEL CO LTD

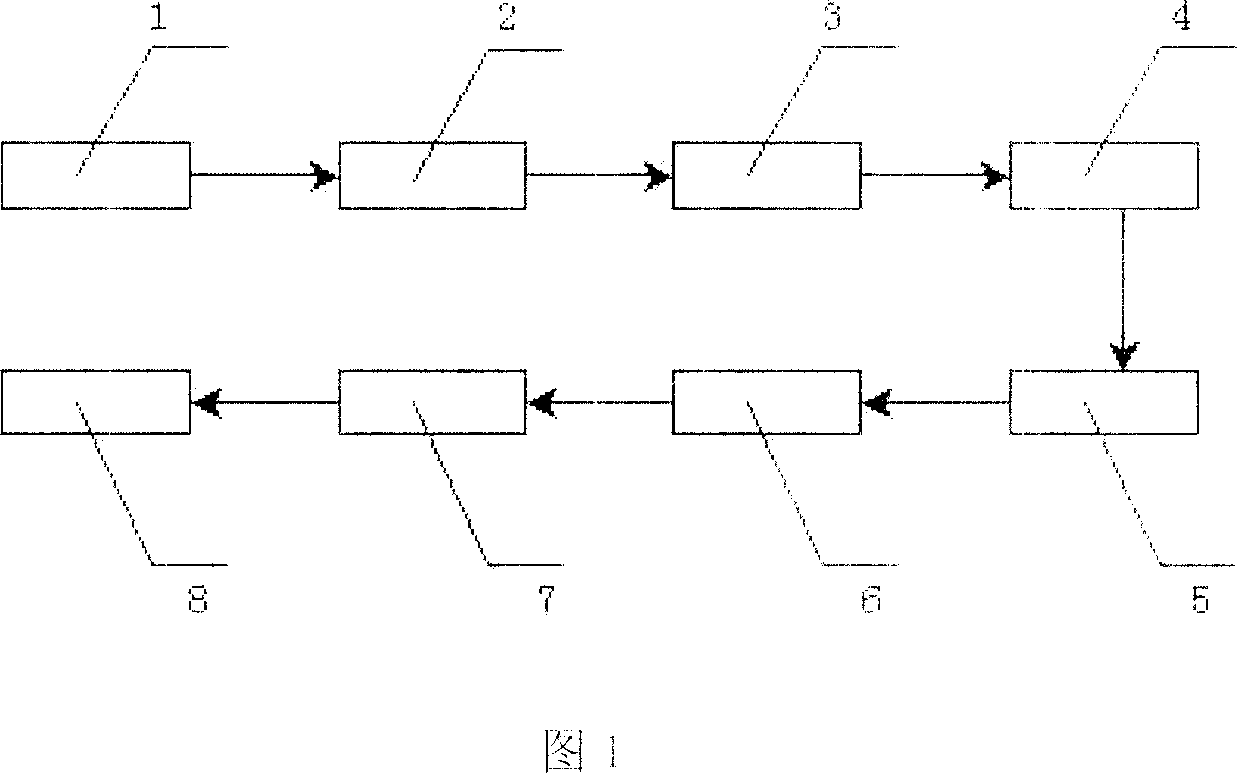

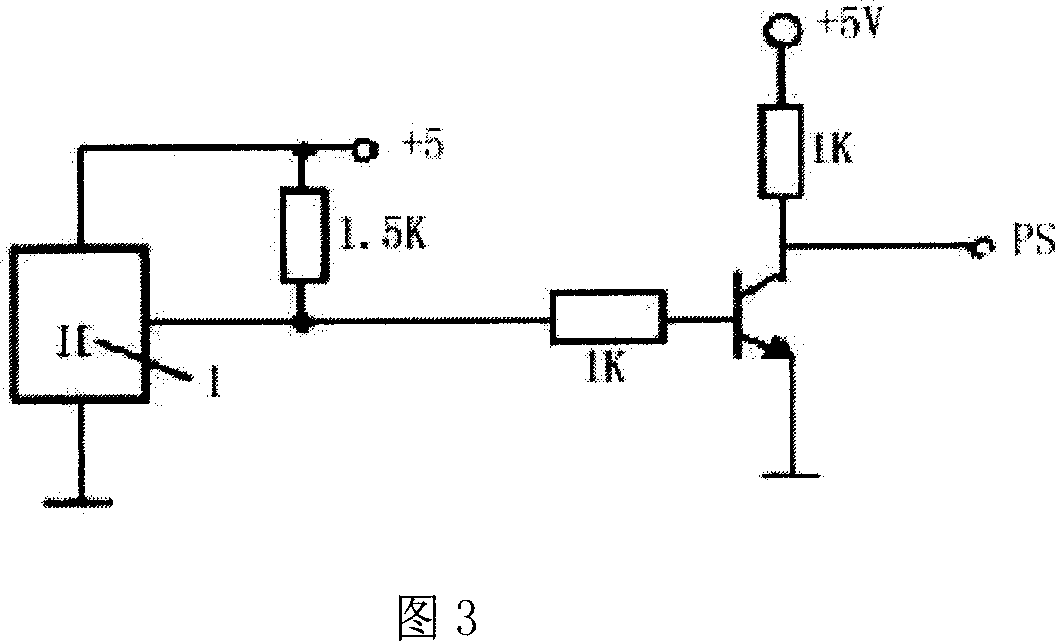

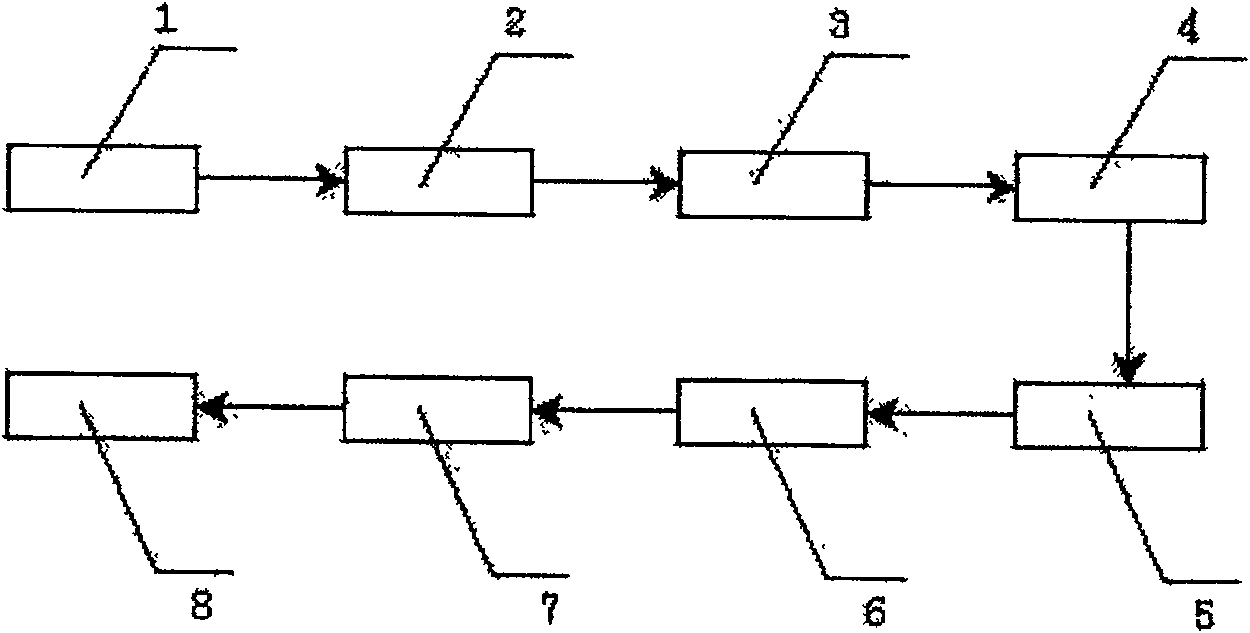

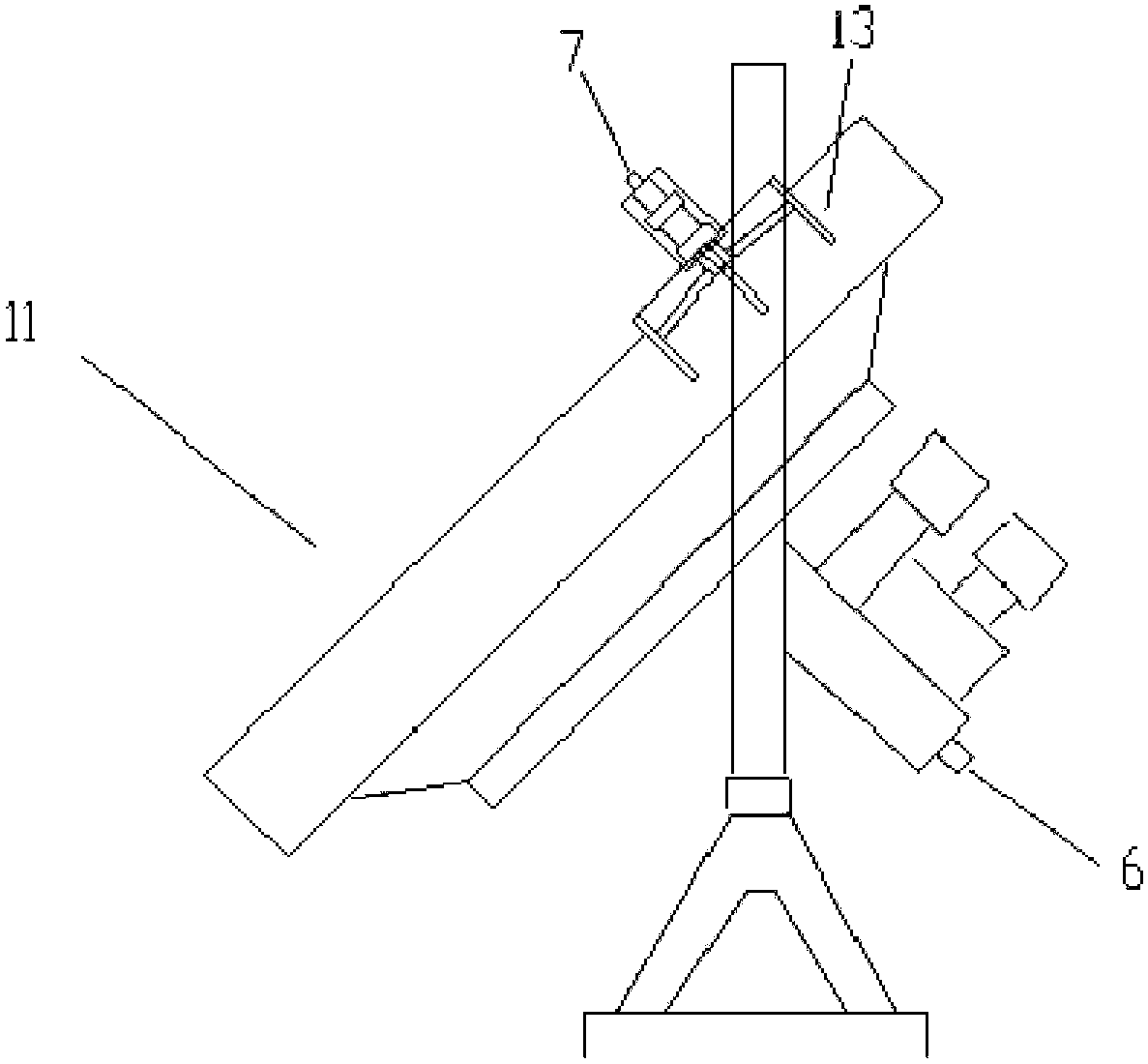

Movable scraper optimum control for cleaning balling pan bottom

InactiveCN1919440AImprove productivityBest configurationGranulation in rotating dishes/pansCircular discMathematical model

The invention discloses an active scraper optimization control to clean balling base bottom, which comprises the following steps: obtaining angular speed omega of disc balling machine, establishing track curved mathematic model, trace curved density mathematic model and mathematic model of covering index, taking covering index delta in the artificial program to optimize, affirming optimum parameter omegai for active scraper, inputting the optimum parameter omegai in the programmable controller PLC[5], connecting programmable controller PLC[5] and converter [6], connecting converter [6] and converting motor [7], driving the active scraper [8] by converting motor [7] through driving system.

Owner:WUHAN UNIV OF SCI & TECH

Production ingredients capable of improving quality of finished pellets and preparation process of production ingredients

InactiveCN113584303AImprove breathabilityGuarantee the quality of calcinationEconomic benefitsMagnetite

The invention discloses production ingredients capable of improving the quality of finished pellets. The production ingredients comprise the following components of 77%-80% of first magnetite, 2.5%-3.5% of second magnetite, 8%-12% of hematite, 6%-8% of fly ash and 1.5%-1.9% of bentonite. The invention further discloses a preparation process of the production ingredients capable of improving the quality of the finished pellets. The preparation method comprises the following steps of quantitative weighing, material mixing, pelletizing and matched burning. The preparation process has the beneficial effects that after the ingredients provided by the invention are adopted, the quality of green pellets is obviously improved, the air permeability in a furnace is good, the air pressure can be reduced by 1kpa, the coal gas is reduced by 3000m<3> / h, and the temperature of a calcining zone is increased by 20 DEG C (the calcining temperature is increased to 1150 plus or minus 20 DEG C from the original 1130 plus or minus 20 DEG C) because hematite and fly ash are added, so that the calcining quality of the pellets is ensured; by adopting an existing ingredient scheme, the problem of treatment of the fly ash is well solved, a virtuous cycle is established for utilization of the fly ash, and the method has high economic benefits and environmental protection effects.

Owner:舞钢中加钢铁有限公司

Application of shaft furnace in baking full-vanadium ferrotitanium ore concentrate pellet ore

InactiveCN101418371BHigh compressive strengthMeet strength requirementsShaft furnaceBlast furnace smeltingShaft furnace

The invention relates to application of a shaft furnace to the roasting of full vanadium titanium iron ore concentrate pellet, which belongs to the technical field of the preparation method for the pellet. According to the method, the full vanadium titanium iron ore concentrate and 1.0 to 1.4 percent of bentonite are taken as raw materials which are used to prepare the full vanadium titanium ironore concentrate pellet through even mixing, damp milling, pelletizing, drying and roasting, wherein the roasting temperature is 1,000 to 1,050 DEG C, and the roasting time is 30 to 60 minutes. The compressive strength of the full vanadium titanium iron ore concentrate pellet obtained by the method reaches 2,200N / piece. The pellet can be directly used for blast furnace smelting and also be used asa furnace protecting product during the blast furnace smelting of common ore.

Owner:攀钢集团成都钢铁有限责任公司

Movable scraper optimum control for cleaning balling pan bottom

InactiveCN100571858CImprove productivityBest configurationGranulation in rotating dishes/pansFrequency changerCircular disc

Owner:WUHAN UNIV OF SCI & TECH

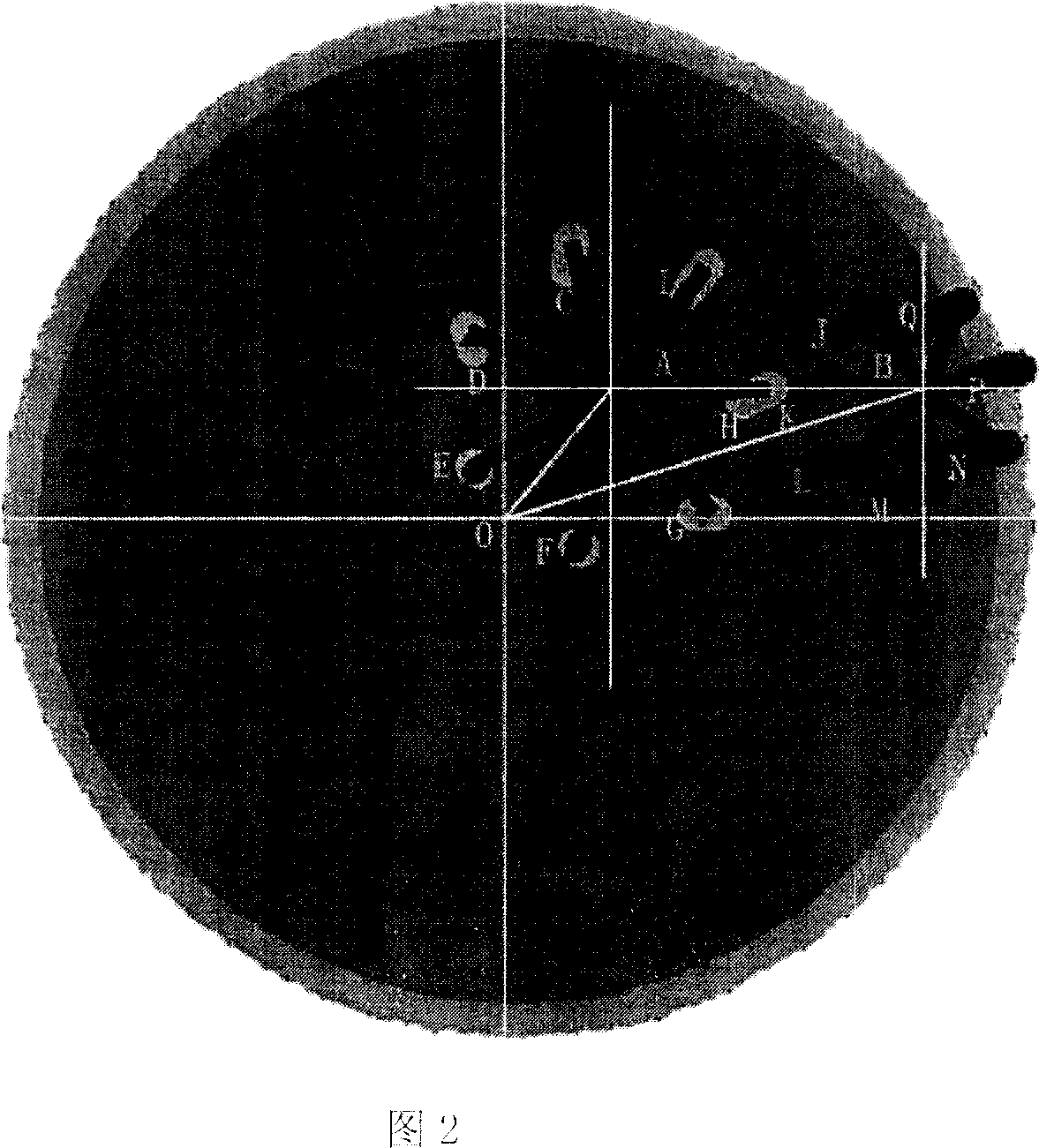

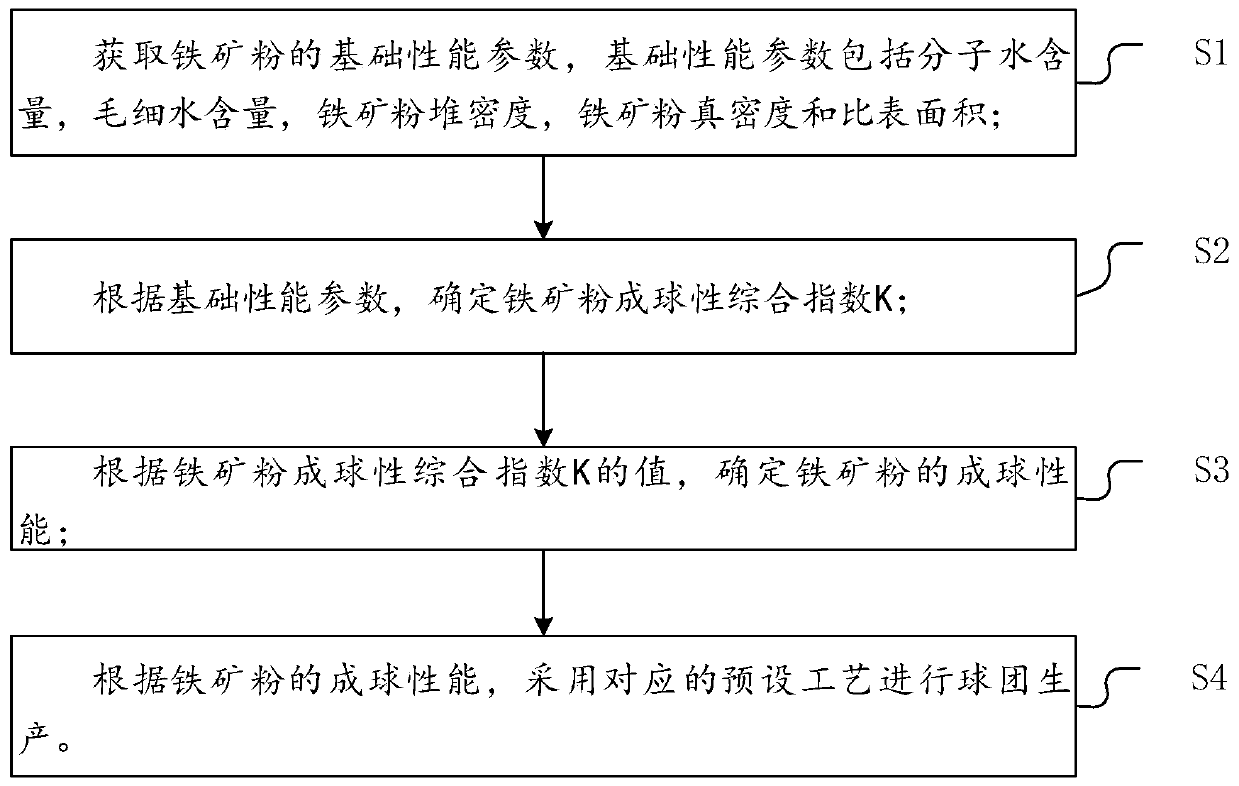

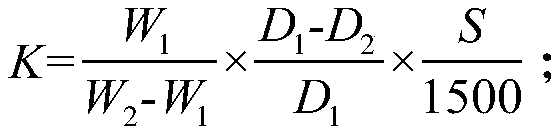

Control method of pellet production

ActiveCN111560515AAccurate judgment of ball formationImprove green ball qualityMining engineeringCapillary water

The invention discloses a control method of pellet production. The method comprises the steps that basic performance parameters of iron ore powder are obtained, and the basic performance parameters comprise molecular water content, capillary water content, iron ore powder bulk density, iron ore powder true density and specific surface area; a comprehensive index K of iron ore powder pelletizationis determined according to the basic performance parameters; the pelletizing performance of the iron ore powder is determined according to the value of the comprehensive index K of the iron ore powderpelletization; and a corresponding preset process for pellet production is adopted according to the pelletizing performance of the iron ore powder. According to the above control method, the pelletizing performance of the iron ore powder can be judged more accurately, so that the corresponding preset process is adopted to control the pellet production, and the quality of fresh pellets of pelletsis significantly improved.

Owner:SHOUGANG CORPORATION

Preparation method of high-chromium high-vanadium type vanadium-titanium ore pellets

The invention relates to a preparation method of high-chromium high-vanadium type vanadium-titanium ore pellets. The invention relates to a preparation method of vanadium-titanium ore pellets. With existing high-chromium high-vanadium type vanadium-titanium ore pellet preparation technologies, pellet superfusion is possible to occur, and pellet caking or nodulation are possible to occur, such that the quality of finished pellet product is influenced. The invention aims at solving the problem. The preparation method of the high-chromium-high vanadium type vanadium-titanium ore pellets comprises the steps of material blending, mixed drying, palletizing, green pellet screening, and shaft furnace roasting. Vanadium content of vanadium-titanium powder in the vanadium-titanium pellets is higher than 4.5%, such that a requirement by blast furnace vanadium-titanium smelting is satisfied. The high-chromium-high vanadium type vanadium-titanium ore pellet preparation method provided by the invention is used for preparing vanadium-titanium ore pellets.

Owner:HEILONGJIANG JIANLONG IRON & STEEL

A kind of iron ore pelletizing device

ActiveCN107794366BImprove yieldGuaranteed energy consumptionUltimate tensile strengthEnergy consumption

The invention discloses an iron ore pellet balling device. The device comprises an ore powder bin containing ore powder, an ore powder belt arranged below the ore powder bin, a first balling disc connected with the ore powder belt and a second balling disc arranged below the first balling disc. Ore powder falls onto the ore powder belt from the interior of the ore powder bin. Ore powder is conveyed into the first balling disc under the action of the ore powder belt, and green balls with the first weight are generated under the action of the first balling disc. Ore powder, not generating greenballs, in the first balling disc and the green balls with the first weight enter the second balling disc, and green balls with the second weight are generated under the action of the second balling disc. The technical effects that the ore return rate in the pellet balling process is greatly reduced, the yield is increased, the surface quality and strength of the green balls are improved, and energy consumption is reduced are achieved.

Owner:SHOUGANG CORPORATION

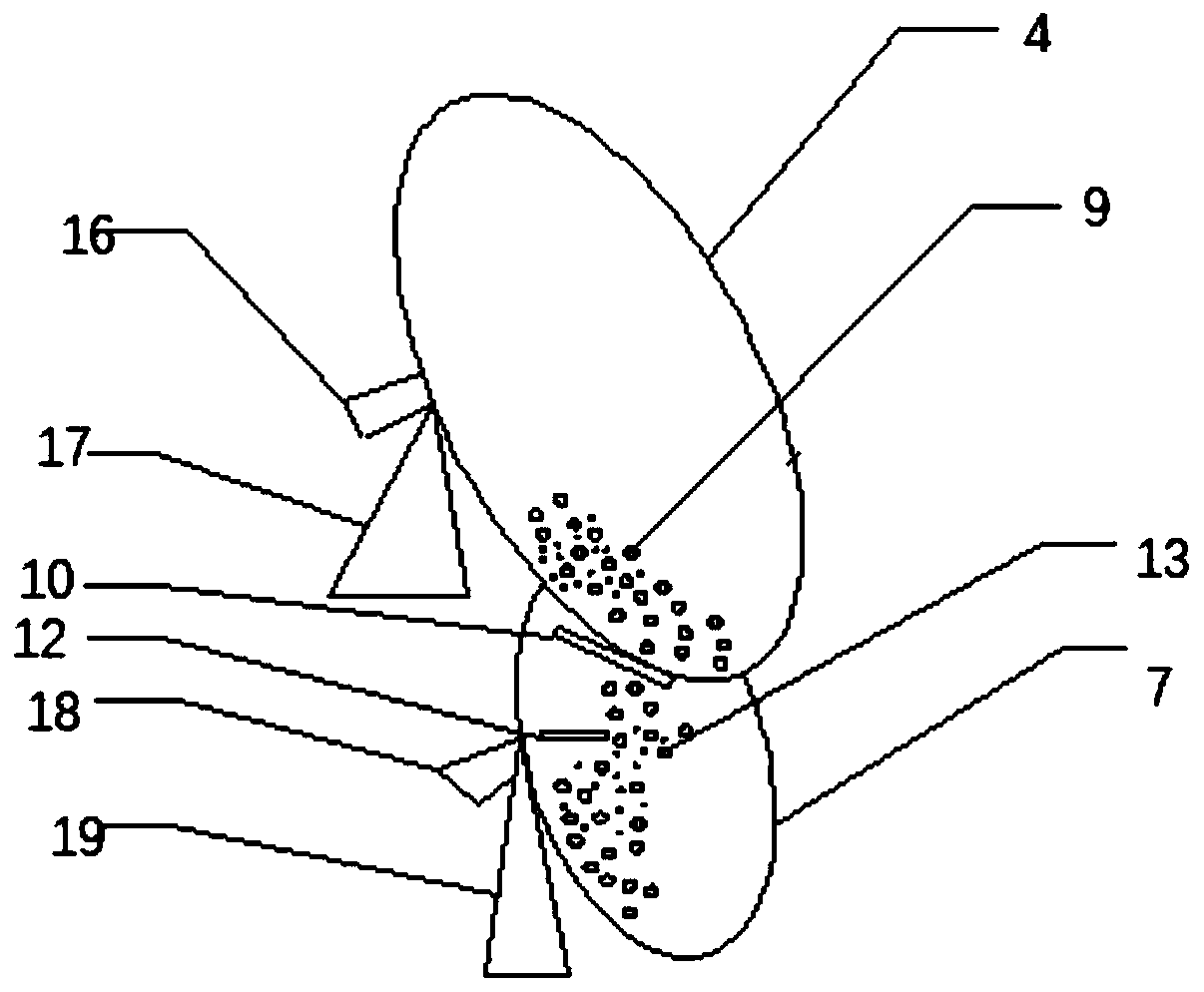

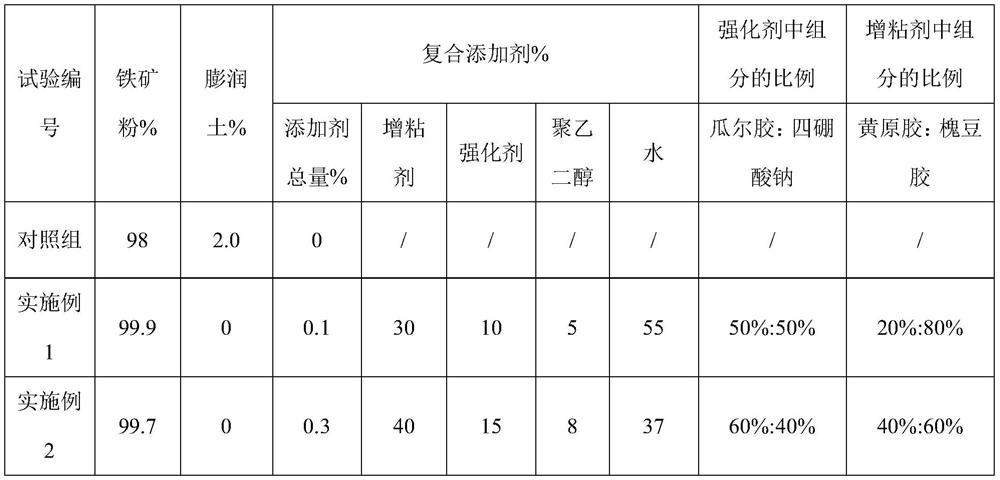

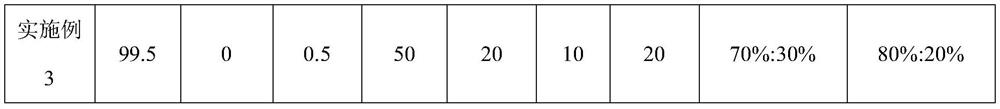

A composite additive for iron ore pellets and iron ore pellets

The invention belongs to the technical field of iron ore pellets, and mainly relates to a compound additive for iron ore pellets and iron ore pellets. In terms of mass percentage, the compound additive for iron ore pellets of the present invention ranges from 30% to 30%. 50% of the tackifier, 10% to 20% of the strengthening agent, 5% to 10% of polyethylene glycol, and the rest are water, which are prepared according to the proportions of the various components, and then uniformly mixed. This additive is mixed into iron ore powder in a certain proportion, fully mixed, and pelletized in a disc pelletizer, and then the green pellet strength is tested. This additive can effectively improve the falling strength and compressive strength of green balls and improve the quality of green balls.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

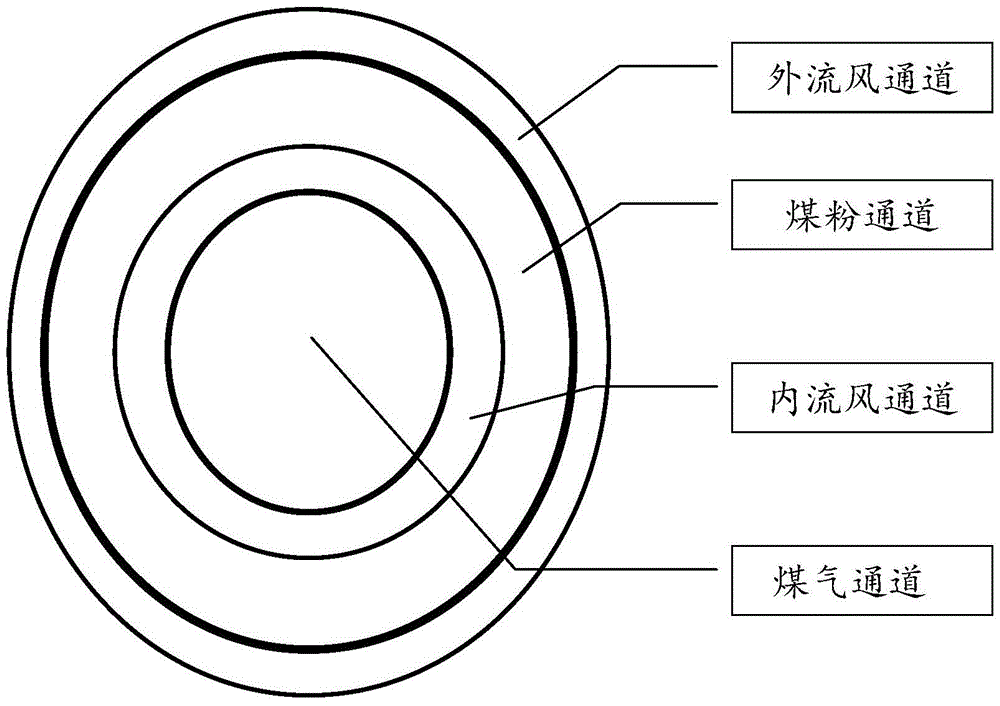

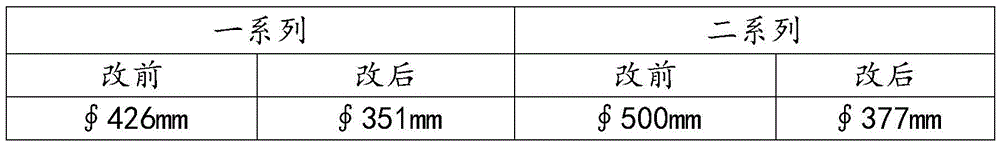

Ring formation control method through adding fine powder into rotary kiln oxidized pellets

InactiveCN105603183ASolve serious technical problems of loopingHigh specific surface areaCombustorHigh pressure

The invention relates to the technical field of iron and steel smelting, in particular to a ring formation control method through adding fine powder into rotary kiln oxidized pellets. The ring formation control method includes: utilizing a high-pressure roller milling system to perform high-pressure roller milling on the fine powder, adding the fine powder after roller milling in the process of producing the rotary kiln oxidized pellets, wherein specific surface area of the fine powder after roller milling is greater than that of the fine powder before roller milling; according to a sequence from inside to outside, sequentially arranging four passages of a main gun burner of a rotary kiln to be a coal gas passage, an inner flow air passage, a coal powder passage and an outer flow air passage; increasing pressure of a burning fan of the main gun burner. By using the ring formation control method, pelleting performance of the fine powder can be improved, and probability of ring formation in the kiln can be lowered.

Owner:BEIJING SHOUGANG CO LTD

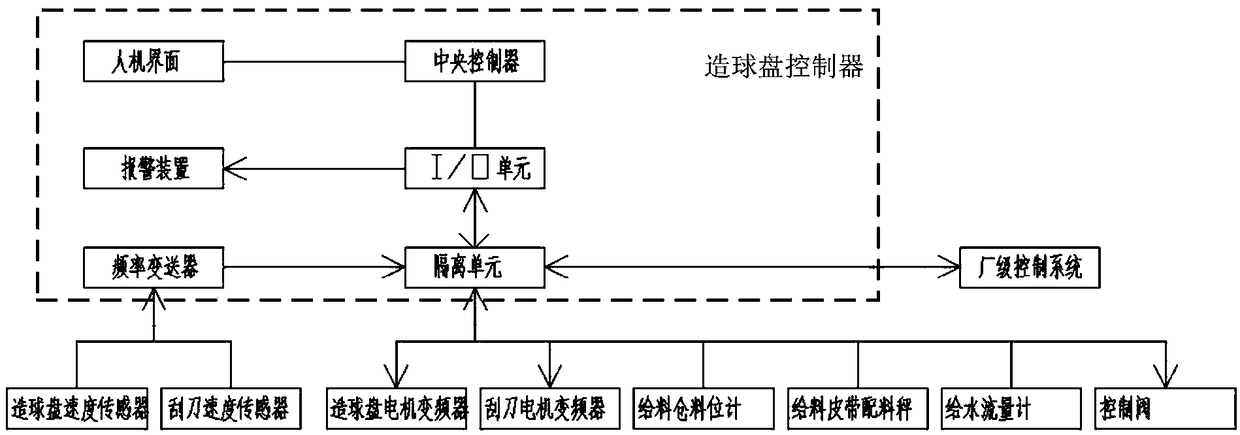

A system and method for controlling a pelletizing disc

A pelletizing disc control system and method belong to the technical field of automation of the metallurgical industry. The pelletizing disc control system comprises a pelletizing disc controller, a feed silo meter, a feeding belt batching scale, a water supply flowmeter, a control valve, a pelletizing disc speed sensor and a scraper speed sensor, wherein the sensors acquire data of feed silo material level L, pelletizing disc feed quantity W, supply pipe water addition F, control valve opening degree V, pelletizing disc rotational speed S and scraper rotational speed S1 and send the acquired data to an upper computer and the pelletizing disc controller; the upper computer performs linkage on L and feeding belt speed; the pelletizing disc controller performs linkage on F and W; and an operator can adjust S, S1 and F according to the pelletizing quality and displayed values. As operation of pelletizing discs are centralized on site, the pelletizing quality can be improved more visually and efficiently, and the production efficiency is improved; one person can operate multiple pelletizing discs to pelletize; and frequency signals susceptible to electromagnetic interference are converted into standard current signals which are then transmitted to the upper computer, so that the signal truth and accuracy are guaranteed.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Preparation method of refractory ball carbon-containing iron-containing dust pellets and its application in composite agglomeration process of iron ore powder

The invention discloses a preparation method of a difficult-to-make ball carbon-containing iron-containing dust pellet material and its application in the iron ore powder composite agglomeration process; Humic acid-modified bentonite is subjected to moist grinding or strong mixing, and then pelletized to obtain carbon-containing and iron-containing dust pellets; this method can make carbon-containing and iron-containing dust that is difficult to pellet into balls with high falling and compressive strength Agglomerates meet the requirements of the iron ore powder composite agglomeration process for the strength of dust green pellets; when the agglomerates are used in the iron ore powder composite agglomeration process, the ratio of iron-containing dust pellets can be significantly increased, and the composite The quality index of agglomerate products realizes efficient, reasonable and large-scale utilization of carbon-containing and iron-containing dust, achieves the purpose of saving secondary resources and protecting the environment, and meets the requirements of industrial production.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com