Control method of pellet production

A control method and pelletizing technology, which is applied in the field of iron and steel smelting, can solve the problems of inaccurate evaluation of iron ore powder pelletizing performance, poor quality of pellets, etc., and achieve the effect of improving the quality of pellets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

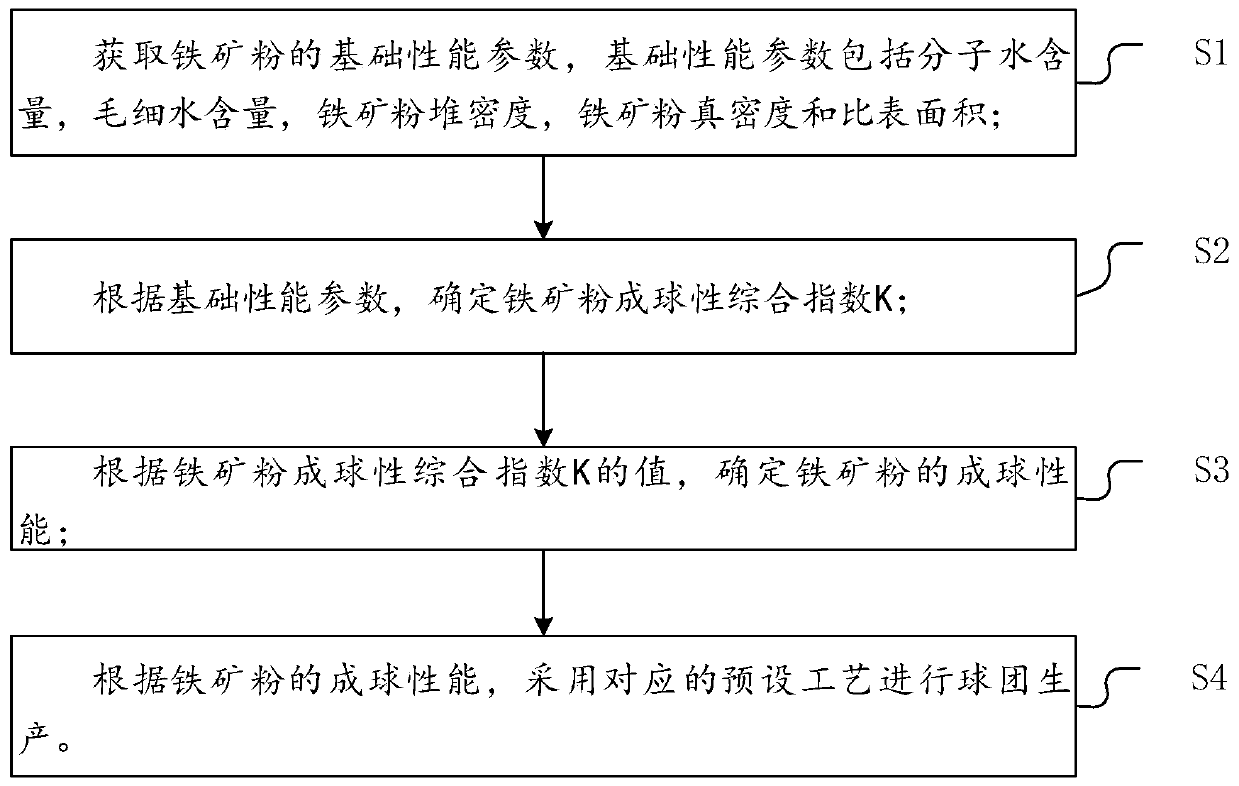

[0040] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

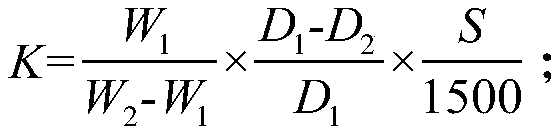

[0041] The calculation method of an existing ore powder spheroidizing index K is as follows:

[0042]

[0043] Among them, W f is the maximum molecular water content of mineral powder, %; W m is the capillary water content of mineral powder, %.

[0044] However, in actual production, the ball forming index calculated according to the above formula cannot accurately evaluate the quality of green balls after mineral powder is balled. In response to this problem, the inventor found that the reason is that the existing empirical formula only considered the influence of molecular water and capillary water of iron ore powder, but did not consider the impact of other basic powder propertie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com