A composite additive for iron ore pellets and iron ore pellets

A composite additive and iron ore pellet technology, which is applied in the field of iron ore pellets, can solve the problems of iron grade decline in pellet ore, affecting energy consumption and output of blast furnace smelting, etc., so as to reduce the return rate, reduce return rate, Effect of improving ball forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below by embodiment, the present invention is further described:

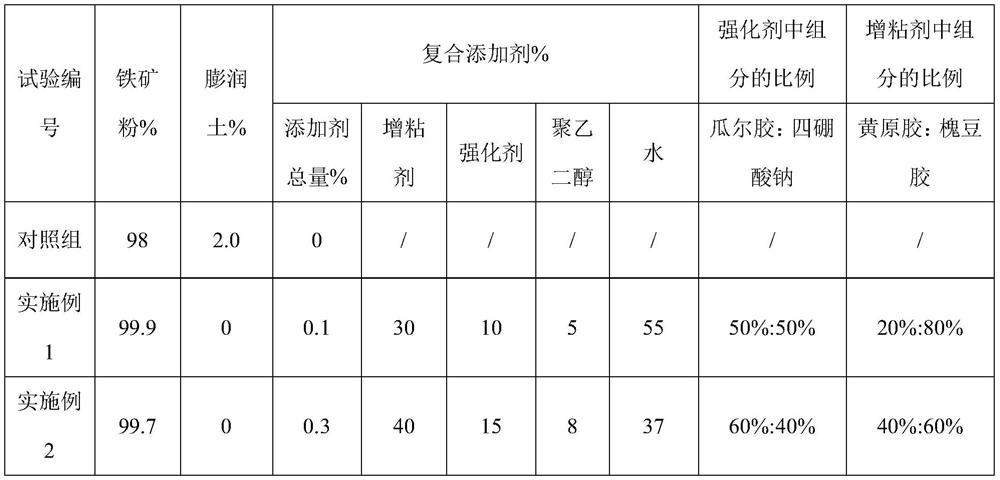

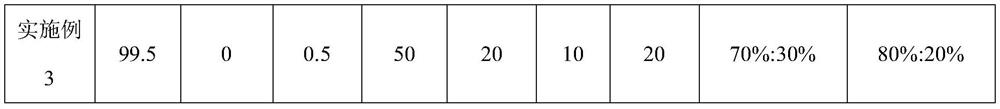

[0022] The composite additive for iron ore pellets of the present invention, in terms of mass percentage, is mixed with water by 30%-50% of tackifier, 10%-20% of strengthening agent and 5%-10% of polyethylene glycol. production. The tackifier is made of xanthan gum and locust bean gum in the ratio of (20% to 80%): (80% to 20%); the strengthening agent is made of guar gum and boron-containing compounds (20% to 40%) : (80% to 60%) ratio.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com