Application of shaft furnace in baking full-vanadium ferrotitanium ore concentrate pellet ore

A technology for vanadium ilmenite concentrate and pellets, applied in shaft furnaces, furnaces, furnace types, etc., can solve the problems of not being widely used, FeO content and compressive strength reduction, etc. The effect of increasing ball rate and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

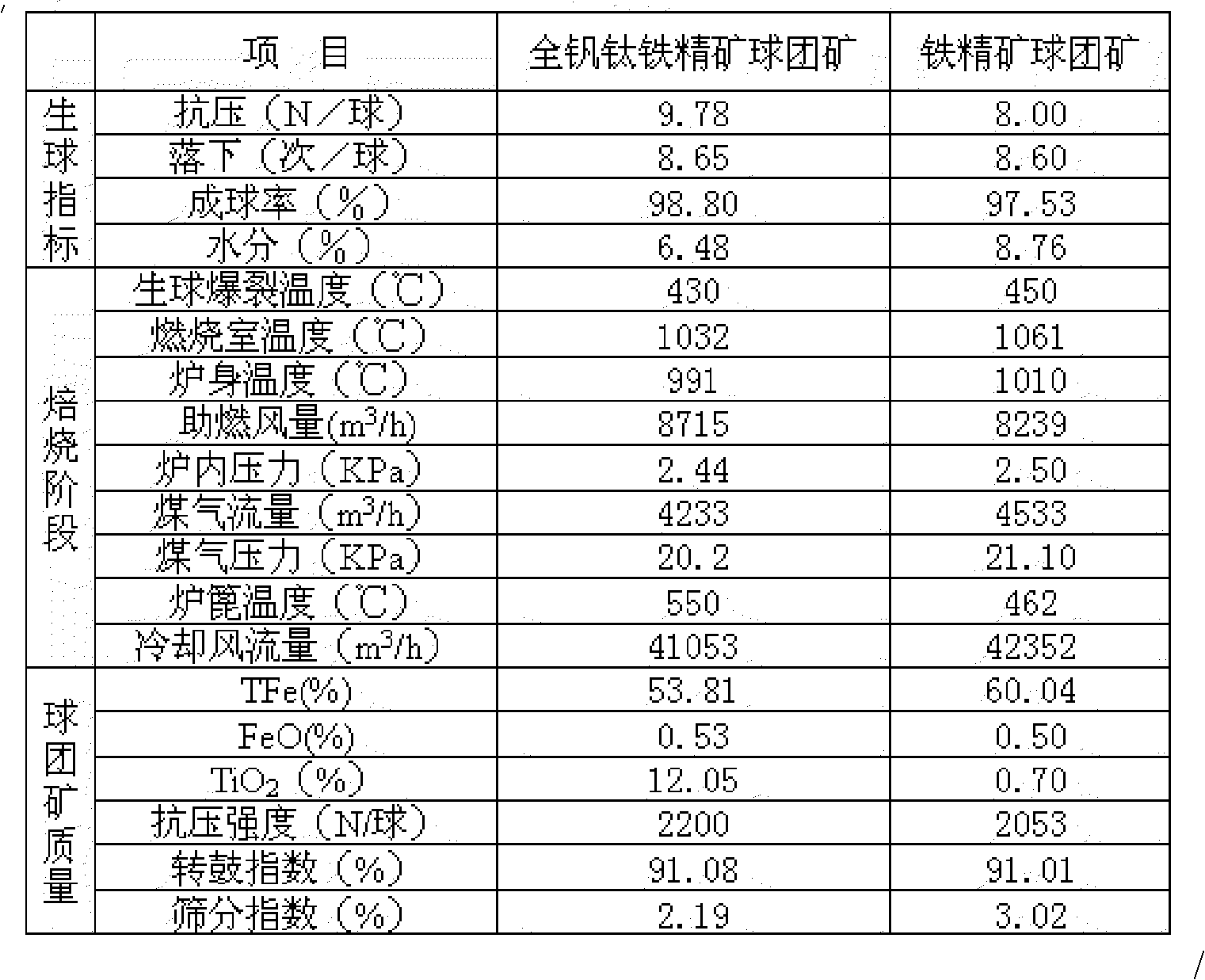

Embodiment 1

[0026] The raw materials (full vanadium ilmenite concentrate and bentonite in a ratio of 98.8:1.2) are automatically batched by an electronic belt scale, and then transported by a belt into a drum drying mixer for mixing and dehydration. After mixing and dehydration The moisture content of the mixture is 5%, and then sent to the moistening mill for moistening and grinding, so that the particle size of the raw material is 200 mesh, and the particle size is increased by about 10%, and then enters the disc pelletizing machine for pelletizing. The size of the disc pelletizing machine is Φ6000×700mm ( Side height), rotation speed 8r / min, inclination angle 46.5°, the way of adding water is to add water to the upper and lower parts of the pelletizing disc at the same time, and the amount of water added is 1-2% of the weight of raw materials. The properties of the green pellets obtained are shown in Table 3.

[0027] After the green balls are screened by the sieving machine, the green ...

Embodiment 2

[0033] After the raw materials (full vanadium ilmenite concentrate and bentonite in a ratio of 98.8:1.2) are automatically batched by an electronic belt scale, they are transported by a belt into a drum drying mixer for mixing and dehydration. After mixing and dehydration The moisture content of the mixture is 5.2%, and then it is sent to the moistening mill for moistening and grinding, so that the particle size of the raw material -200 mesh increases by about 10%, and then enters the disc pelletizing machine for pelletizing. The size of the disc pelletizing machine is Φ6000×700mm (Side height), speed 8r / min, inclination angle 46.5°, the water addition system of the disc pelletizer is connected to a bypass system to connect to the sludge tank, and the converter sludge slurry is sent to the pelletizing disc by a pump, and pelletized in the disc Spray converter sludge slurry with 2-4% weight of raw material instead of water when making pellets.

[0034] After the green balls are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com