Patents

Literature

56results about How to "Improve ball forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite additive for preparing hematite concentrate pellet and application thereof

A composite additive for preparing hematite concentrate pellets comprises the following components: humic acid, calcium peroxide, and paigeite. During application, the composite additive is added which has a mass percent of 0.5%-1.6% of the total mass of the hematite concentrates, and the finished product pellets are obtained by pelletization, preheating, and roasting. Compared with pellets prepared by traditional technology, the hematite pellets prepared by the composite additive of the invention have improved falling strength of the green pellets, and compression strength of the finished product pellets; the preheating temperature and roasting temperature suitable for the pellets are reduced; both the preheating time and roasting time are shortened; the TFe grade is increased by 0.8%-1.2%. The composite additive of the invention has reasonable component ratios, is easy to process and manufacture, has a low using amount and a low residual amount, can significantly improve the pelletability of hematite concentrates which are difficult to be palletized, can improve the green pellet quality, has good heat stability, and can effectively reduce the preheating and roasting temperatures and shorten the preheating and roasting time of hematite concentrates. The composite additive of the invention is applicable to the production of oxidized pellets by hematites, and is especially applicable to the production of oxidized pellets by specularites. The composite additive of the invention is applicable to large-scale industrial production.

Owner:CENT SOUTH UNIV

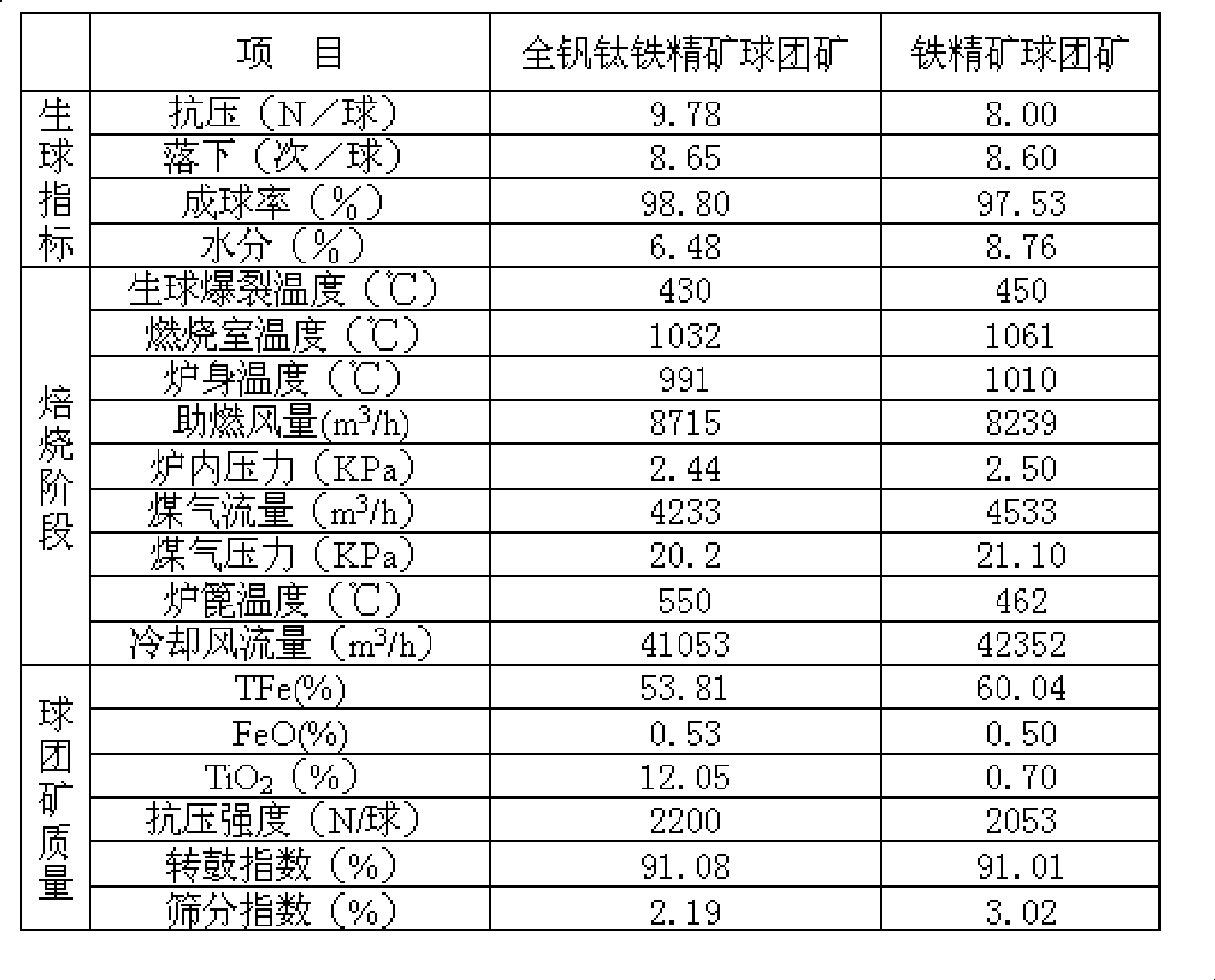

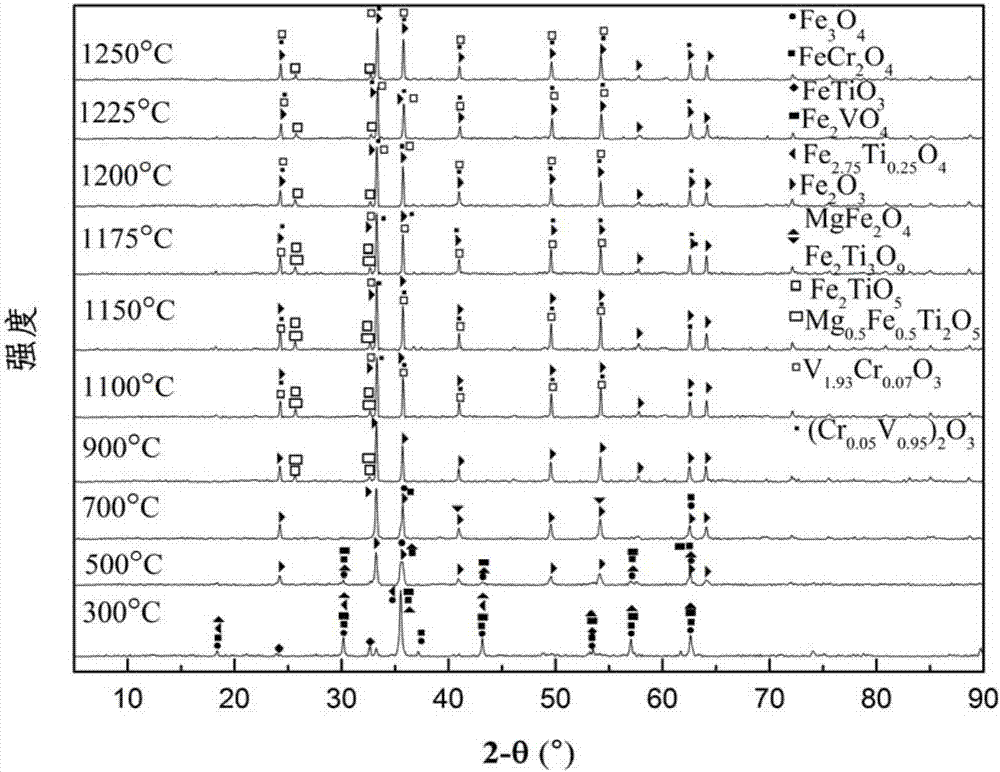

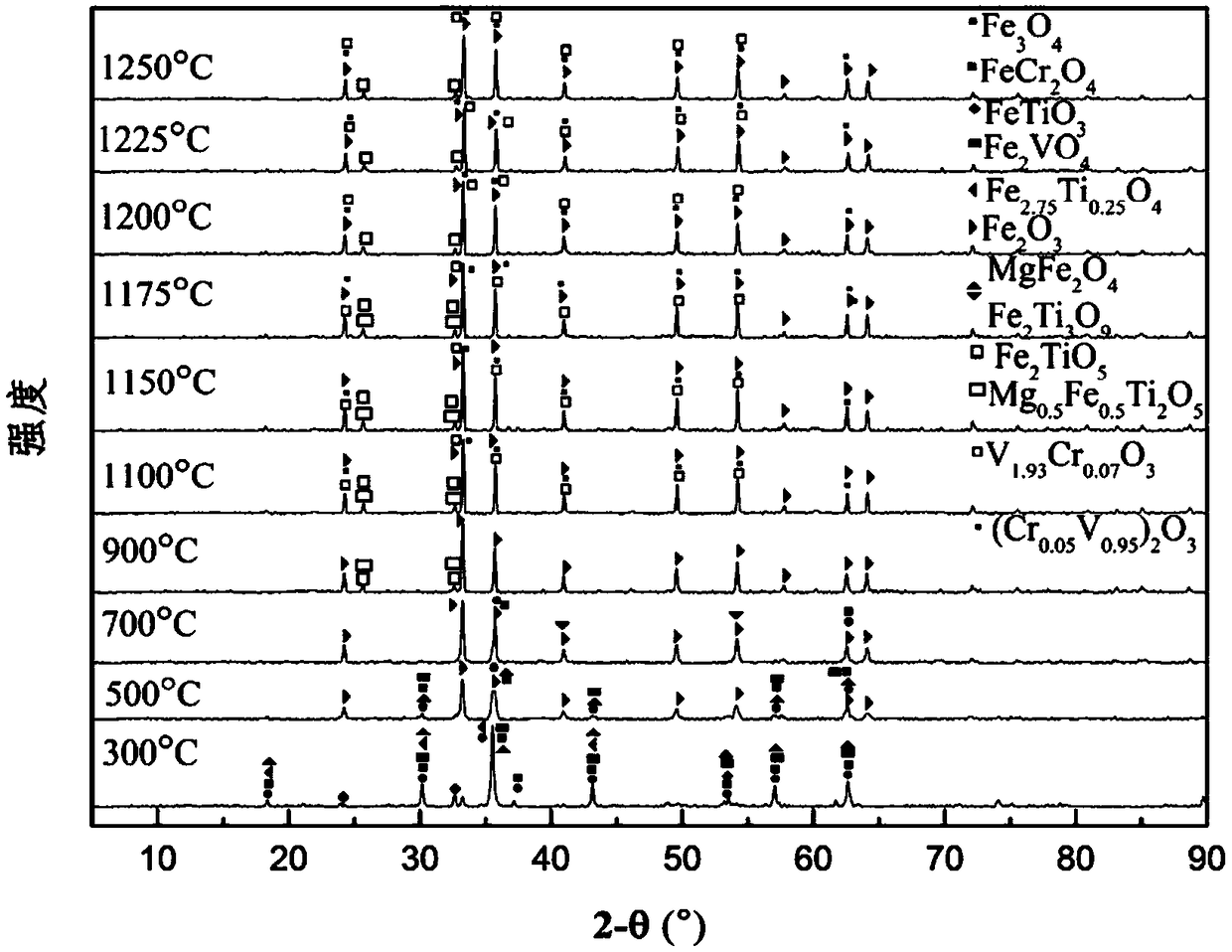

Application of shaft furnace in baking full-vanadium ferrotitanium ore concentrate pellet ore

InactiveCN101418371AHigh compressive strengthMeet strength requirementsShaft furnaceSodium BentoniteBlast furnace smelting

The invention relates to application of a shaft furnace to the roasting of full vanadium titanium iron ore concentrate pellet, which belongs to the technical field of the preparation method for the pellet. According to the method, the full vanadium titanium iron ore concentrate and 1.0 to 1.4 percent of bentonite are taken as raw materials which are used to prepare the full vanadium titanium iron ore concentrate pellet through even mixing, damp milling, pelletizing, drying and roasting, wherein the roasting temperature is 1,000 to 1,050 DEG C, and the roasting time is 30 to 60 minutes. The compressive strength of the full vanadium titanium iron ore concentrate pellet obtained by the method reaches 2,200N / piece. The pellet can be directly used for blast furnace smelting and also be used as a furnace protecting product during the blast furnace smelting of common ore.

Owner:攀钢集团成都钢铁有限责任公司

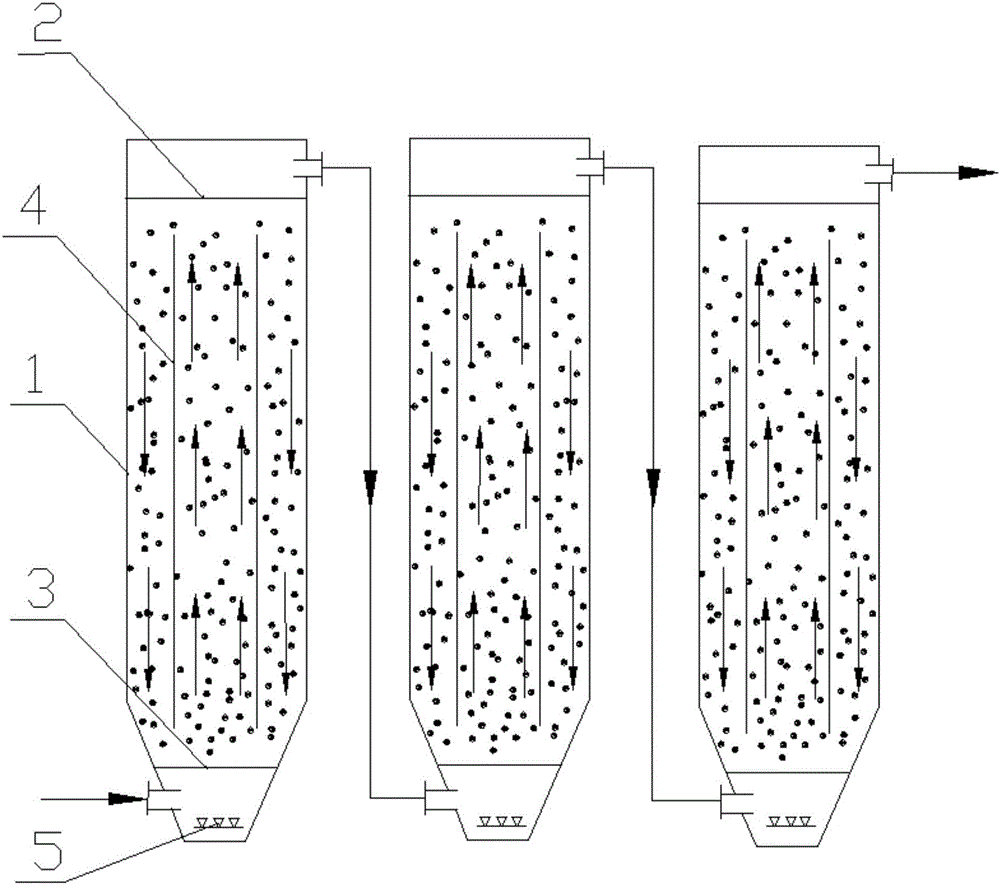

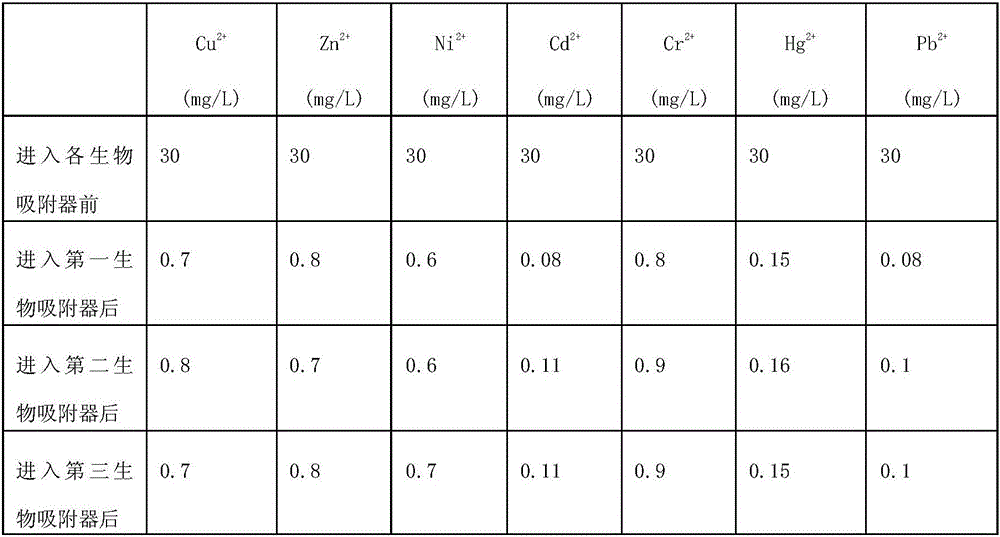

Waste water treatment agent and application thereof

ActiveCN105734037AImprove decomposition abilityImprove ball formingFungiBacteriaPeristaltic pumpPhosphate

The invention discloses a waste water treatment agent. The waste water treatment agent is prepared by using the following steps: 1, mixed fermenting, culturing and collecting pseudomonas pseudoalcaligenes and saccharomyces cerevisiae thalli; 2, mixing polyvinyl alcohol, calcium alginate, acrylyl and water according to a mass ratio of (6-15):(0.5-1.5):(3-5):100 to obtain a polyvinyl alcohol hydrosol, and adding the collected pseudomonas pseudoalcaligenes and saccharomyces cerevisiae thalli into the polyvinyl alcohol hydrosol to form a mixed solution; 3, adding the mixed solution into a saturated boric acid solution containing N'-methylene bisacrylamide CaSO4 by using a peristaltic pump to form a gel bead, cooling and unfreezing the gel bead, then cooling and unfreezing the gel bead again, placing in phosphate with the mass concentration of 0.2-0.5 g / L to obtain an immobilized cell bead with a spherical appearance and an internal porous mesh structure. The invention also discloses a method for treating waste water by using the treatment agent. Different heavy metals are well adsorbed.

Owner:湛江市粤绿环保科技有限公司

Preparation method of fresh water composite microorganism base modifier

The invention discloses a preparation method of a fresh water composite microorganism bottom modifier. The preparation method comprises the steps of preparation of a fermentation culture medium, fermentation, adsorption and crosslinking. The method comprises the following specific steps: firstly, mixing bran powder, corncob powder, starch wastewater and a fermentation synergist to obtain the fermentation culture medium; introducing a mixed bacterial solution of rhodococcus erythropolis, saccharomyces cerevisiae and bacillus subtitles for fermentation culture, and purifying to obtain a microbial flocculant; then, adsorbing sesame straw activated carbon, enzymatic liquid, the microbial flocculant and a microbial preparation; performing crosslinking with a crosslinking agent to obtain the fresh water composite microorganism base modifier. The preparation method has the beneficial effects of easiness and feasibility, higher yield and productive rate of polysaccharides in a preparation process, higher mechanical strength and stability of a final product, and higher mass transfer performance and pelletizing performance. The fresh water composite microorganism base modifier modifies culturing sewage through the three strong effects of fluctuation, enzymatic degradation and microbial degradation, and has the advantages of comprehensive biodegradability, high security, nontoxicity, harmlessness and freeness from secondary pollution.

Owner:金华市呗力水产养殖技术有限公司

Preparation method of low-temperature solidified metallurgical pellets

The invention belongs to the field of comprehensive utilization of metallurgical residue resources and specifically relates to a preparation method of low-temperature solidified metallurgical pellets.In order to solve the problems that when steel and iron scrap powder are adopted for making pellets, the generated pellets are poor in forming performance, low in sintering intensity, likely to be pulverized and the like. The provided preparation method of the low-temperature solidified metallurgical pellets includes the following steps of a, taking and weighing vanadium titano-magnetite concentrates, steel and iron scraps and a compound bonding agent according to a mass ratio of (28-65):(34-68):(2-4), adding water, uniformly mixing the mixture, and conducting pelleting to obtain raw pellets;b, drying the raw pellets obtained in step a until the moisture content is lower than or equal to 1%, and obtaining dry pellets; c, preheating the dry pellets and conducting sintering to obtain finished pellet products. The preparation method is simple in operation, the prepared pellet products are high in strength, MFe of the finished pellet products is 55-58%, the compressive strength of each pellet is 2,600-3,100 N, the drum index is 90.0-93.5%, and the production cost is low. The new method is provided for comprehensive utilization of the steel and iron scrap powder, and obvious economicbenefits are obtained.

Owner:PANZHIHUA UNIV +1

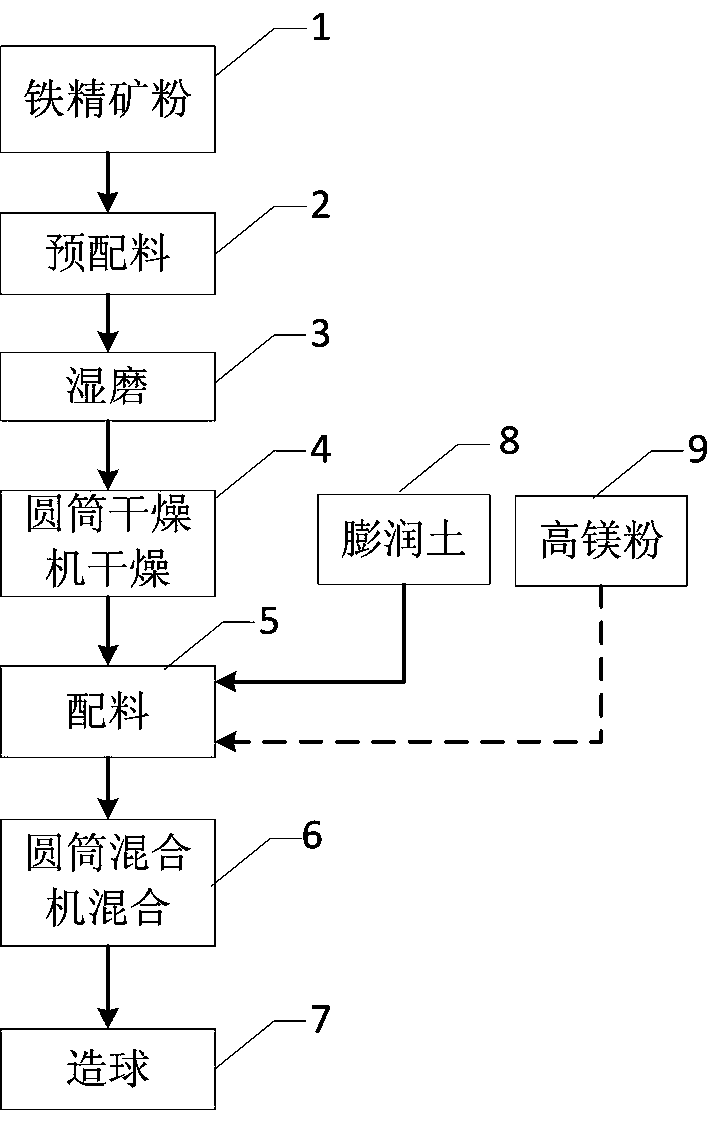

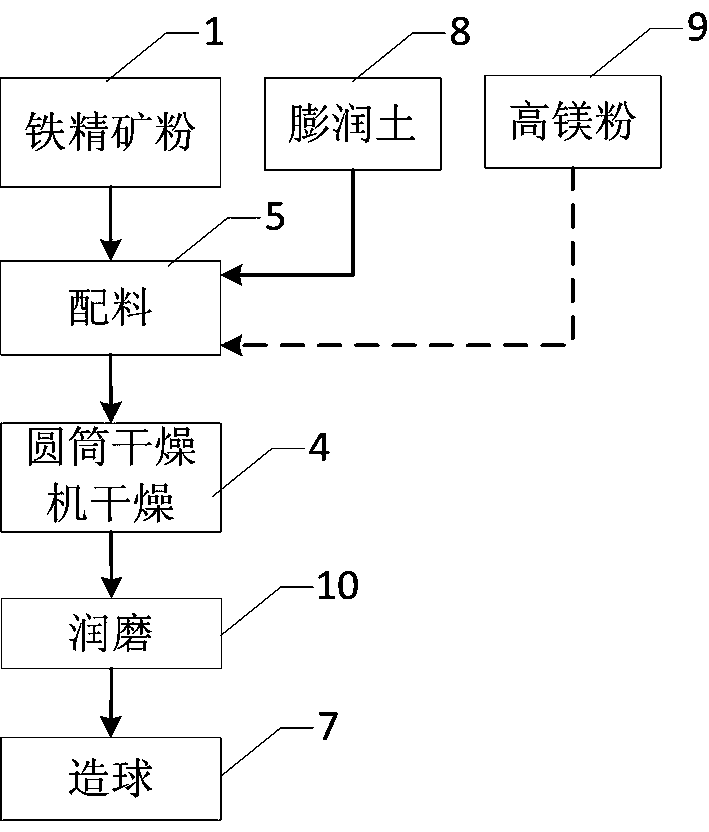

Iron mine pellet raw material preparation method facilitating efficient pelletizing

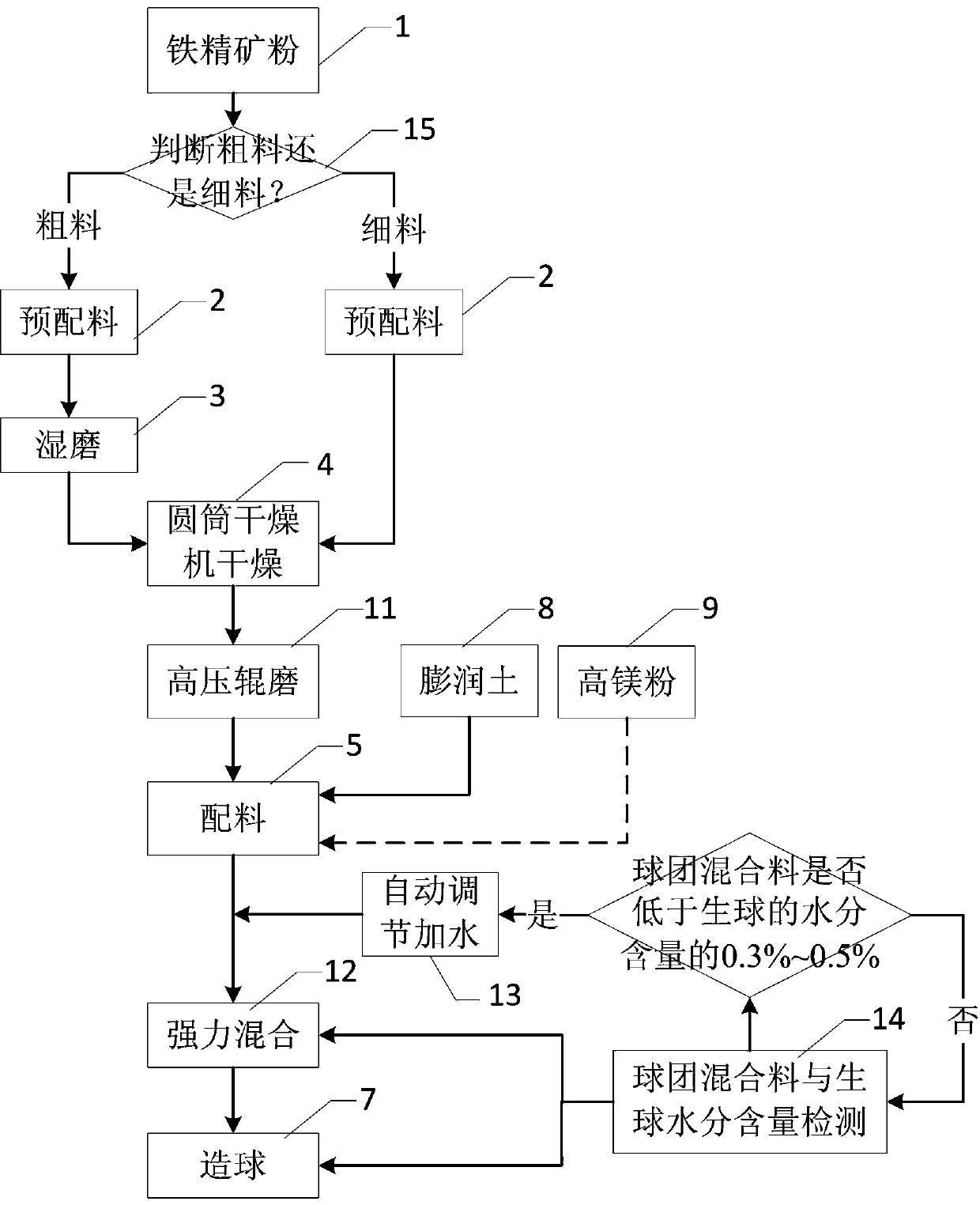

The invention relates to the field of research of pellet mine manufacturing techniques of the iron and steel metallurgy industry, in particular to an iron mine pellet raw material preparation method facilitating efficient pelletizing. The method includes the steps that whether iron concentrate fines are coarse materials or fines is judged, if the iron concentrate fines are the coarse materials, the iron concentrate fines are subjected to wet grinding after pre-dosing; the iron concentrate fines are dried and smashed by a high pressure rolling mill; the iron concentrate fines after smashing aremixed with bentonite and the like to obtain a pellet mixture through intensive mixing; the pellet mixture enters a pelletizer to be subjected to pelletizing to obtain pelletizing green-balls; and thewater content of the pelletizing mixture before entering the pelletizer and the water content of the pelletizing green-balls are separately detected, the pelletizing mixture before entering the pelletizer is automatically regulated and intensively mixed with water, and the pelletizing mixture water content range is controlled below 0.3%-0.5% of the green-ball suitable water content. According tothe iron mine pellet raw material preparation method facilitating efficient pelletizing, the technical problem that the water content of production raw materials is difficult to control in the preparation process is solved, and the strength and the production efficiency of pelletizing green-balls are improved.

Owner:ANYANG IRON & STEEL

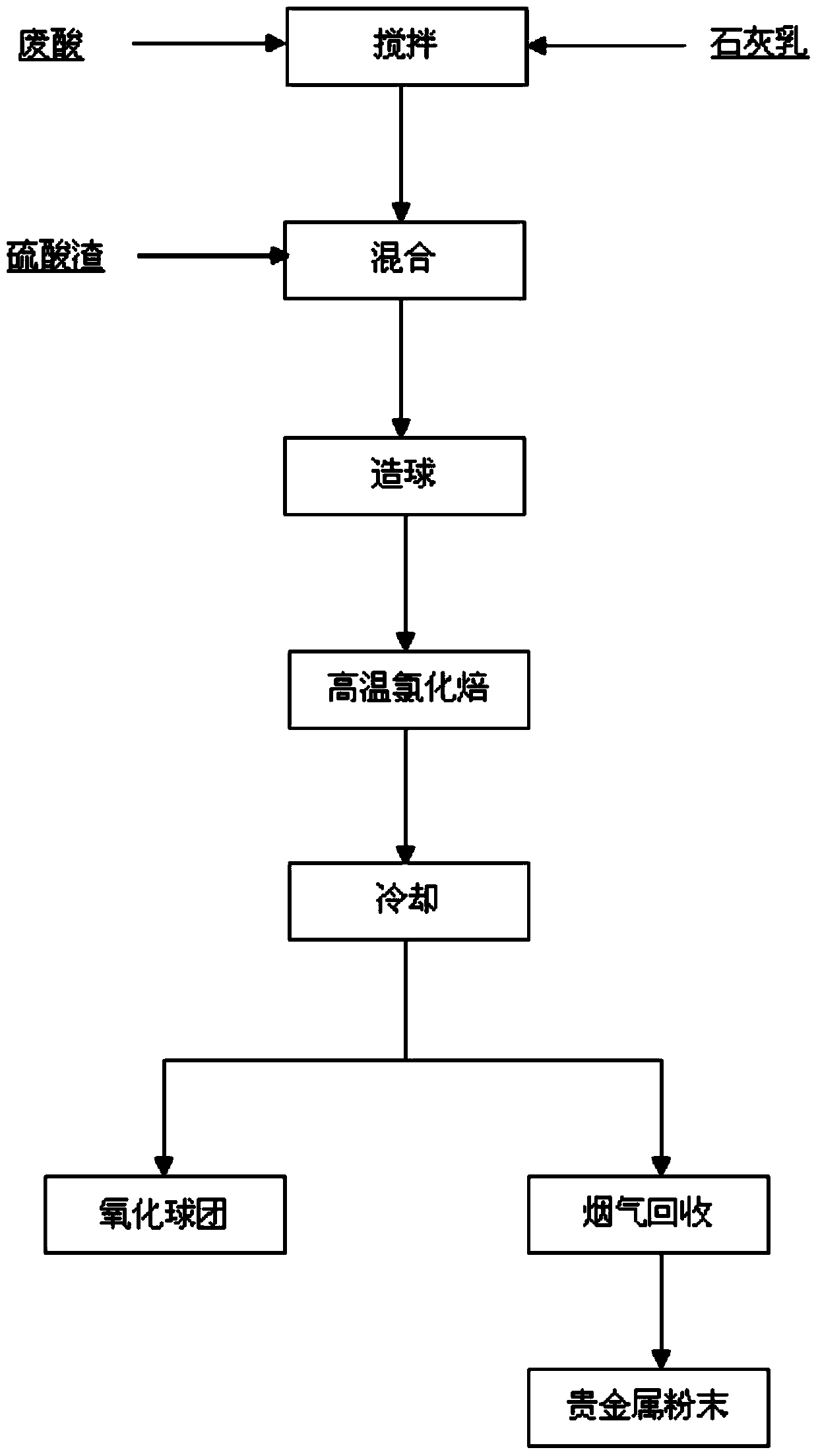

Treatment method for realizing comprehensive utilization of industrial acid pickling waste liquid and sulfate slag

ActiveCN104046781AReduce manufacturing costSmall specific surface areaProcess efficiency improvementMuffle furnaceSlag

The invention discloses a treatment method for realizing comprehensive utilization of industrial acid pickling waste liquid and sulfate slag, which comprises the following steps: neutralizing acid pickling waste acid to obtain an iron-based chlorinating agent; adding the iron-based chlorinating agent into sulfate slag, mixing, and then granulating; and performing high-temperature chlorination roasting through a muffle furnace to obtain high-grade oxidized pellets, and simultaneously recovering metal chloride in flue gas to obtain rare precious metal powder which mainly comprises gold, silver, copper, zinc, lead and other valuable metal. According to the treatment method disclosed by the invention, the acid / base neutralization method and the high-temperature chlorination roasting method are combined, and the chloride in the steel rolling acid pickling waste liquid is converted into the chlorinating agent required for high-temperature chlorination roasting, so that the chloride in the waste liquid is effectively used as the valuable metal chlorinating agent, and the valuable metal is recovered, thereby solving the environmental problem and lowering the production cost.

Owner:TIANJIN YIBAI GUANGTONG CULTURE MEDIA DEVCO

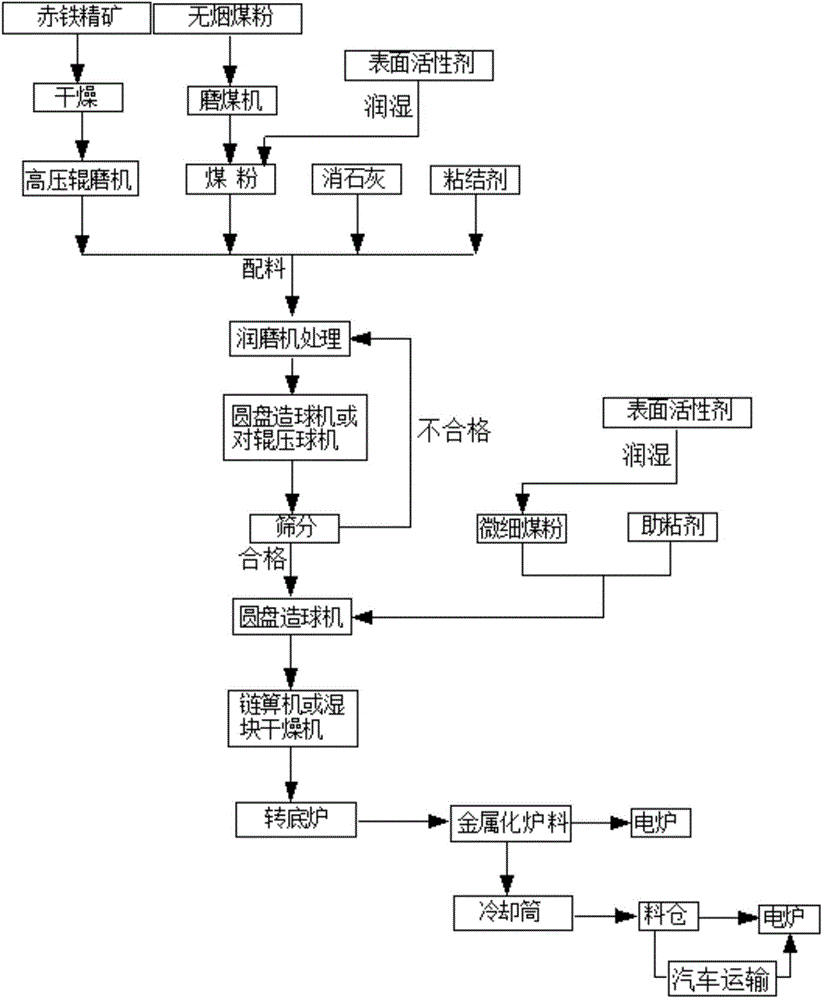

Technology for producing metal furnace burden for high-quality electric furnace by coal-based method

The invention discloses a technology for producing a metal furnace burden for a high-quality electric furnace by a coal-based method, and belongs to the field of direct iron ore concentrate reducing technologies. The technology comprises the following steps: (1) blending: drying hematite concentrates, then performing mechanical activation, grinding anthracite powder, and blending and mixing the hematite concentrates, the anthracite powder, slaked lime and an adhesive; (2) balling or ball pressing: balling or pressing the mixed raw materials in the step (1) to obtain pellets or blocks; (3) mixture wrapping: wrapping the produced pellets or blocks with a layer of mixture consisting of the anthracite powder, the slaked lime and polyacrylamide powder; (4) drying and reduction: drying the pellets or blocks wrapped with the mixture in the step (3), and then putting the pellets or blocks into a rotary hearth furnace. The metal furnace burden produced by the technology can directly meet the requirement on electric furnace production and is used for partially replacing waste steel for the electric furnace.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Leadless tin-base soft solder

InactiveCN101134272AGood ball formingImprove surface qualityWelding/cutting media/materialsSoldering mediaElectronic industryMaterials science

The no-lead Sn-base soft solder for preparing BGA tin ball consists of Ag 1.1.5-5.0 wt%, Cu 0.3-0.9 wt%, RE 0.001-0.2 wt%, Ge 0.001-0.2 wt%, and Sn for the rest. Or, it consists of Ag 2.1.5-5.0 wt%, Cu 0.3-0.9- wt%, RE 0.001-0.2 wt%, Ge 0.001-0.2 wt%, Bi 0.05-1.5 wt%, and Sn for the rest. The present invention is suitable for no-lead assembling and packaging in electronic industry.

Owner:ZHEJIANG ASIA GENERAL SOLDERING & BRAZING MATERIAL

Method for preparing pyritic slag pellet raw material and method for preparing green pellets

ActiveCN101597686AFully moistenedImprove ball formingProcess efficiency improvementSlagCapillary action

The invention provides a method for preparing a pyritic slag pellet raw material, which comprises the following steps: a) performing primary mixing on pyritic slag and water to prepare a mixture of which the water content is between 1 and 13 weight percent; b) performing ageing treatment on the mixture; and c) performing secondary mixing on the aged mixture, water and other iron-containing raw materials to prepare the pellet raw material. When the mixture is subjected to the ageing treatment, the water content in the mixture can fully moisten the pyritic slag, so that the capillary action of micropores of the pyritic slag can be better exerted to improve the ballability of the mixture. When green pellets are prepared from the pellet raw material comprising the mixture, the green pellets meeting technological requirements are prepared under the action of a binder and pores of the pellet raw material.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Method for pre-treating iron ore concentrates

InactiveCN101967554AImprove surface activityImprove ball formingGrain treatmentsSodium BentonitePre treatment

The invention provides a method for pre-treating iron ore concentrates, which comprises the following steps of: crushing the iron ore concentrates by adopting ball-milling and crushing the treated iron ore concentrates by adopting high-pressure roller-milling to increase the specific surface area of the iron ore concentrates to be 1,300 to 1,600 cm<2> / g. As the iron ore concentrates are pre-treated by adopting the ball-milling and the high-pressure roller milling, the method enhances the surface activity of red iron ore concentrate particles, improves the hydrophilicity of the surfaces of the iron ore concentrate particles, the pelleting performance of the concentrates, the pelleting intensity and the quality of pellet ore, reduces the volume of addition of bentonite, rises the cracking temperature and provides high-quality charging materials for blast furnace iron making.

Owner:武钢集团有限公司

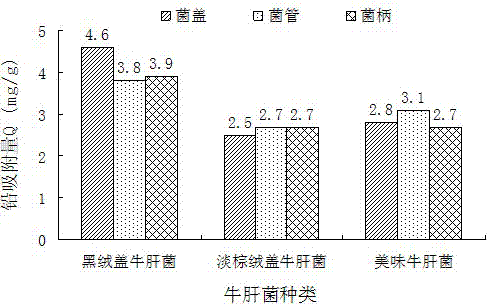

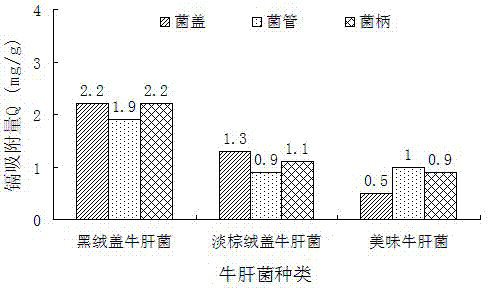

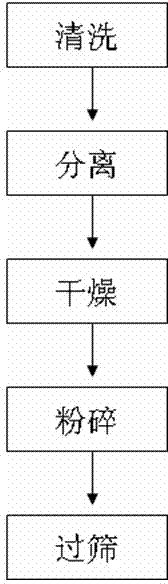

Heavy metal biological adsorbent and preparation method thereof

InactiveCN102921388ASimple preparation processFast preparation processOther chemical processesWater/sewage treatment by sorptionSpecific adsorptionChemical engineering

The invention discloses a heavy metal biological adsorbent and a preparation method of the heavy metal biological adsorbent. The biological adsorbent takes boletes as main ingredients and is prepared in the following steps that the boletes of various types and parts are selected, cleaned, separated, dried, smashed, sieved and the like. The biological adsorbent can be used for specific adsorption of heavy metal in various media, and is simple and fast in technology, low in equipment requirement and cost, simple and convenient to use, and high in adsorption efficiency.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI +1

Novel binder for metallurgical pellets

The invention belongs to metallurgical raw materials and pretreatment technology, and in particular relates to a novel binder for metallurgical pellets. The novel binder for the metallurgical pellets consists of the following components in part by weight: 100 parts of natural calcium-based bentonite, 2 to 5 parts of sodium carbonate and 1.1 to 2.0 parts of sodium cellulose, wherein the natural calcium-based bentonite is natural calcium-based bentonite with montmorillonite content of more than 54 percent. The preparation method comprises the following steps of: adding 2 to 5 weight parts of sodium carbonate into 100 weight parts of natural calcium-based bentonite for sodium treatment, drying until the moisture content is below 12 percent, performing ore grinding until the ore with granularity of less than 43 microns is over 90 percent, adding 1.1 to 2.0 weight parts of sodium cellulose, and stirring and uniformly mixing to prepare the novel binder for the metallurgical pellets. The pellet forming property of green pellets can be effectively improved, the cracking temperature of the green pellets is improved, the metallurgical property of pellet ore is improved, and the binder has the effects of increasing the yield and reducing the consumption for the production of the pellet ore.

Owner:ANSTEEL GRP MINING CO LTD

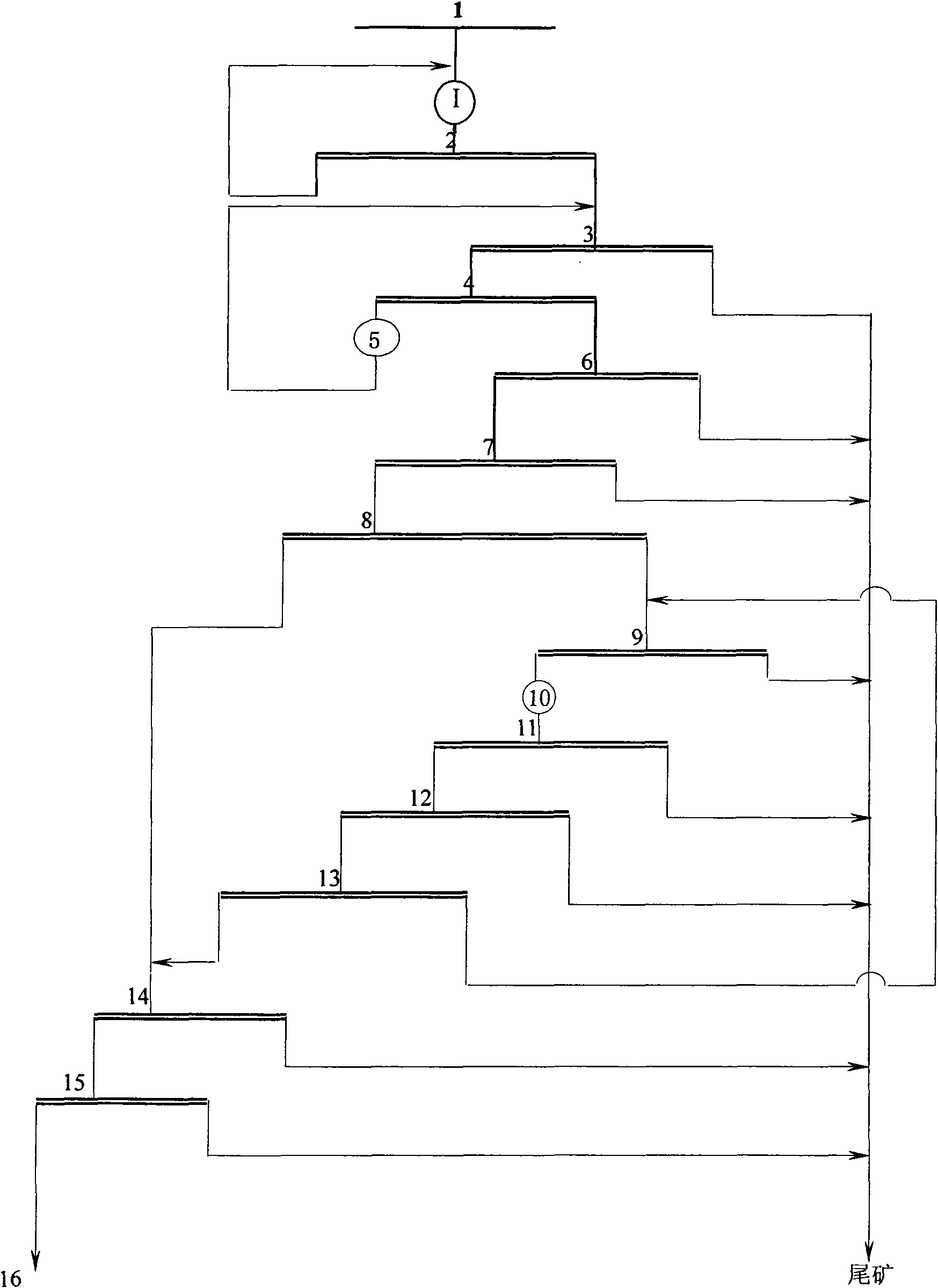

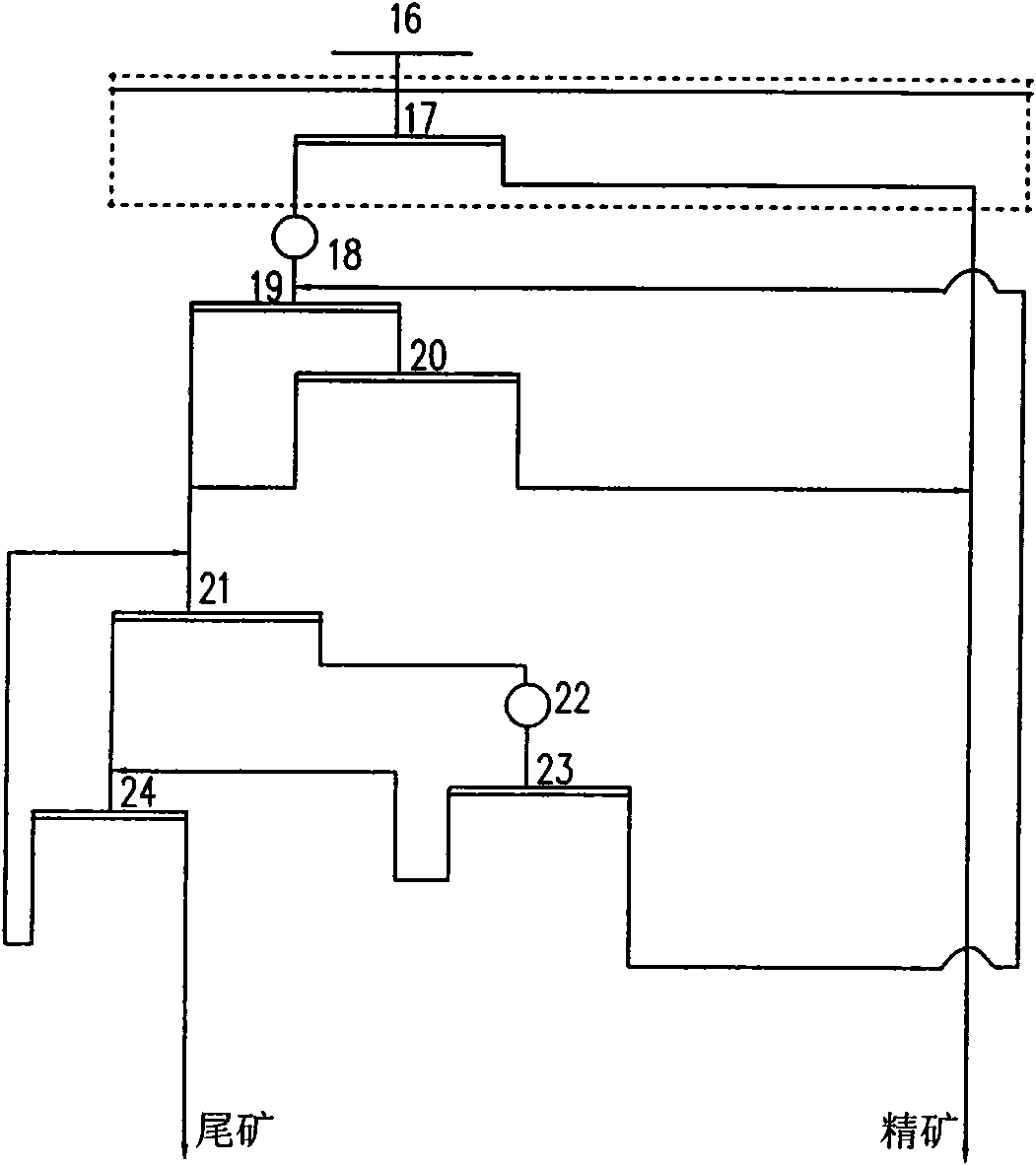

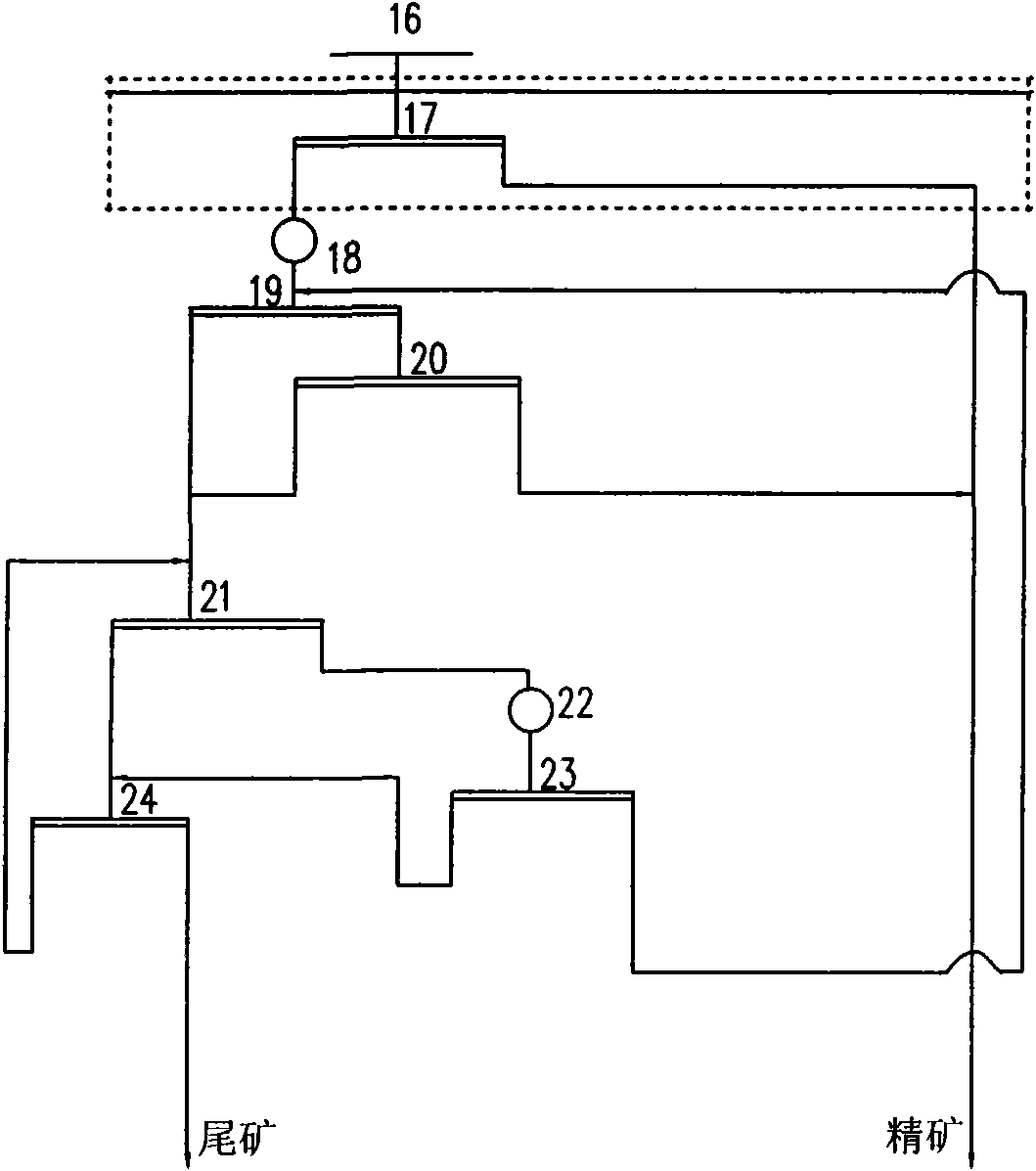

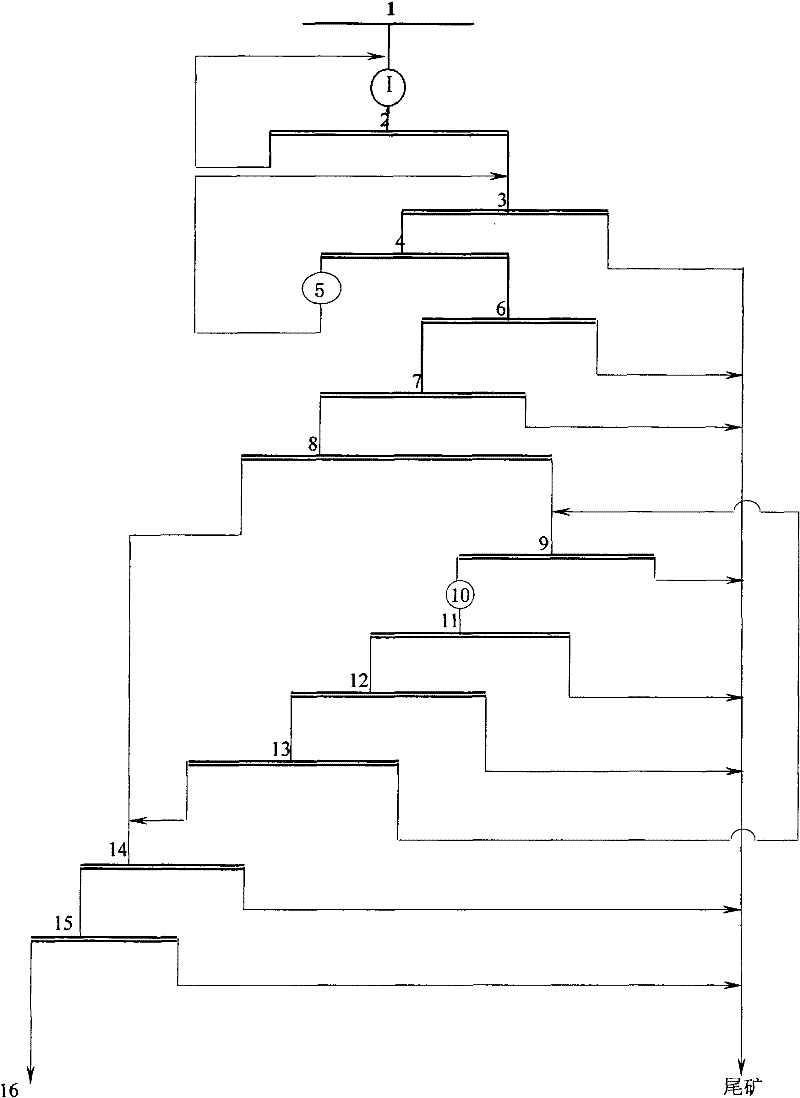

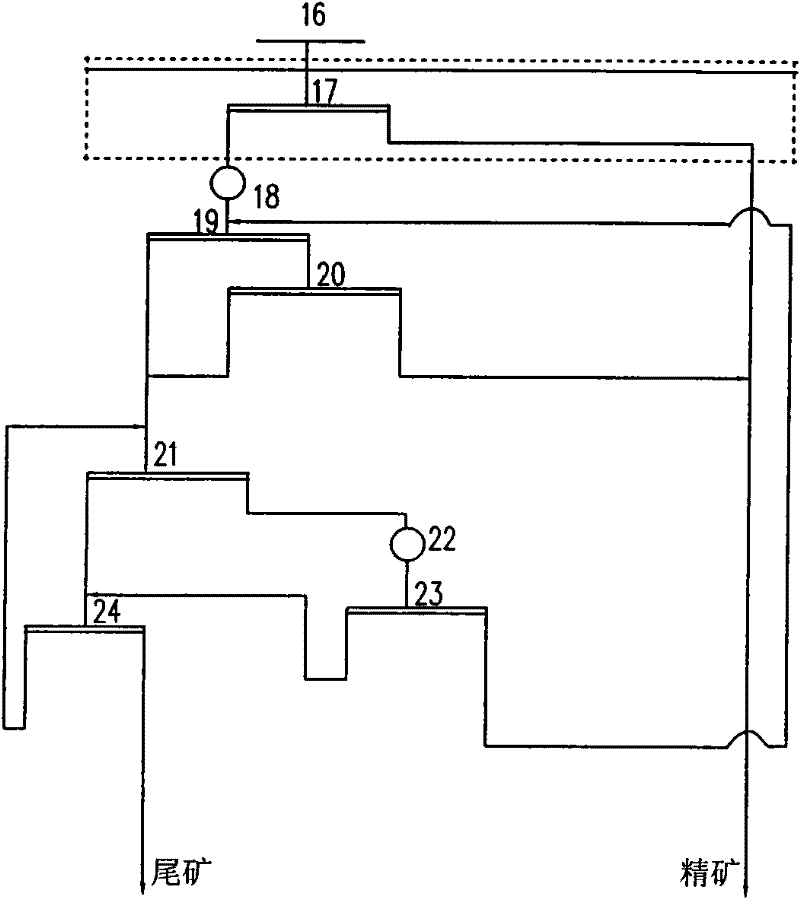

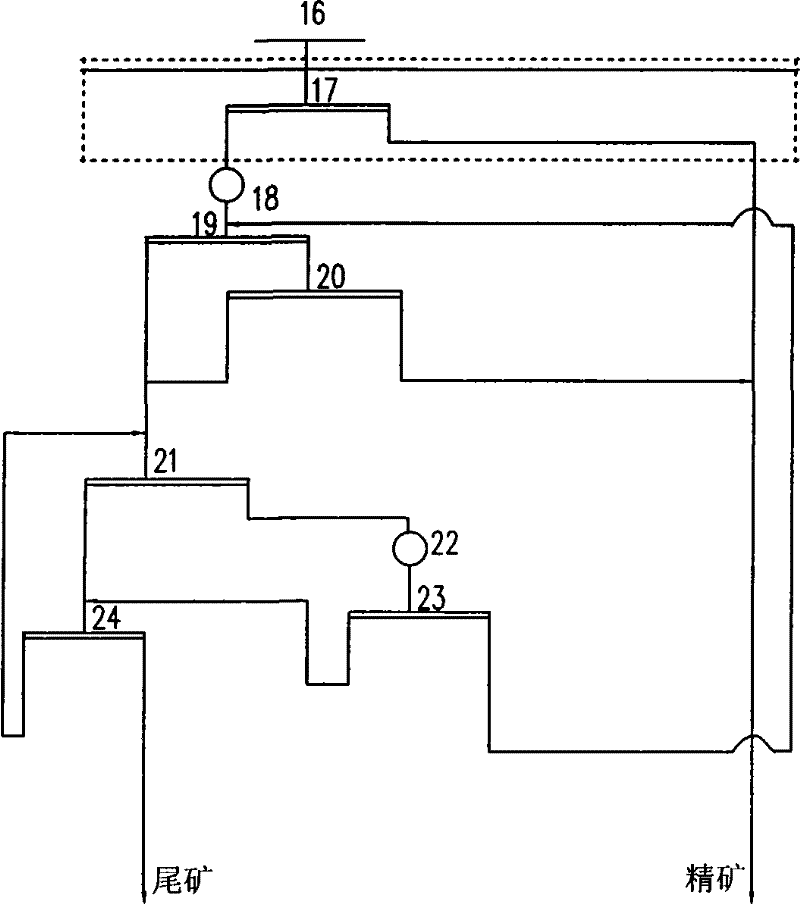

Magnetic separation column-anion reverse flotation optimizing beneficiation new process

The invention relates to a magnetic separation column-anion reverse flotation optimizing beneficiation new process belonging to the technical field of beneficiation. The magnetic separation column-anion reverse flotation optimizing beneficiation new process comprises the following steps of: obtaining magnetic concentrates by adopting the conventional magnetic separation process; processing the magnetic concentrates by adopting a magnetic separation column, wherein the magnetic separation column selects two products, i.e. an overflow product and a sand setting product; obtaining qualified concentrates by controlling the ascending water and the ore discharge quantity of the sand setting product; also continuously carrying out a flotation regrinding process on magnetic separation column overflows; discarding tailings; enabling the qualified concentrates and magnetic separation column concentrates to be merged into final concentrates. The invention increases a magnetic separation column selection process before reverse flotation aiming at the problems of high cost, environmental pollution, and the like in the traditional magnetic separation-reverse flotation process, thereby effectively reducing the pressure of flotation; the invention obtains 20 percent of the qualified concentrates in advance before the flotation, thereby reducing the flotation ore quantity by 20 percent; and in addition, the invention also reduces the cost of a flotation procedure by 30 yuan / t, thereby obviously enhancing the economic benefits.

Owner:ANSTEEL GRP MINING CO LTD

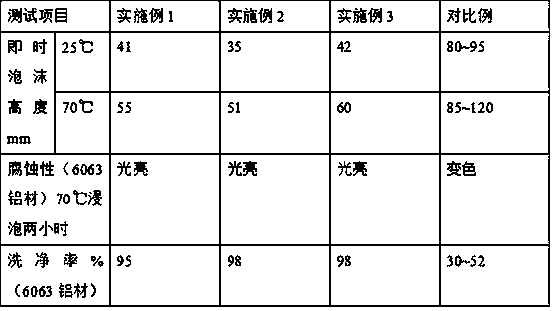

Preparing method for steel component wax solvent

The invention discloses a preparing method for a steel component wax solvent, and belongs to the field of wax solvents. Paraffin thirsty bacteria are mainly cultivated and can metabolize, so that a biological surface active agent, an organic solvent and other substances with surface activity are generated, meanwhile, polyvinyl alcohol is utilized as a carrier, and after an additive is added in a water solution of the polyvinyl alcohol, gelatinization happens, and accordingly, microorganisms are embedded and fixed in the gel network; and sodium alginate is added so that ballability of the carrier can be improved; the carrier surface property can be improved through calcium alginate generated through the reaction of the sodium alginate and calcium salt, the gel strength is improved, and accordingly, the microorganisms are more effectively protected; and the calcium alginate can be diffused in the gel network along with proceeding of the reaction, the carrier structure is further optimized, growing and breeding of the microorganisms are facilitated, and accordingly, the dewaxing effect of the wax solvent is further enhanced. The preparing method solves the problems that due to a current existing wax solvent, the original color of the surface of a steel component is prone to being corroded, and the wax solvent is single in dewaxing function.

Owner:闫博文

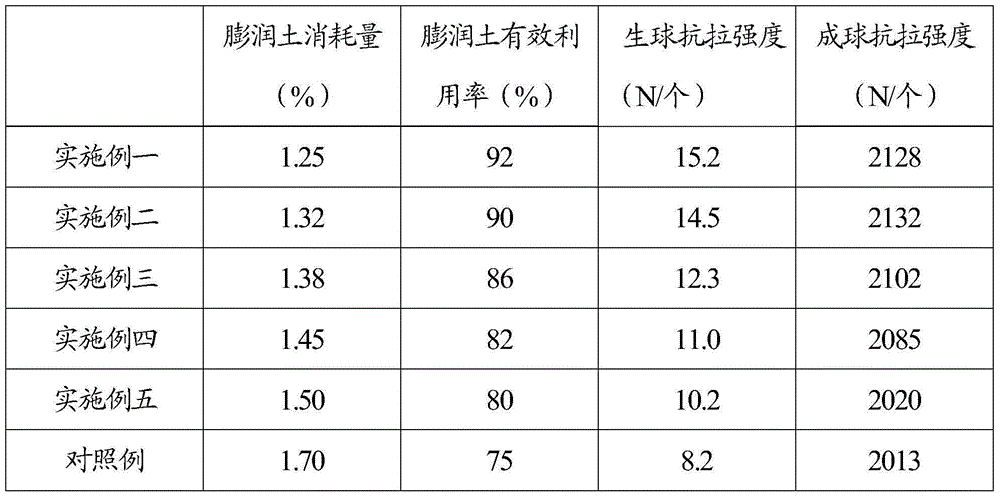

Pelletizing method for reducing bentonite consumption

The invention discloses a pelletizing method for reducing bentonite consumption. Bentonite is adopted as a binding agent. The pelletizing method comprises the steps of mixing, pelletizing, drying and preheating and roasting. In the step of mixing, a mixture of Qing Gangping concentrate powder with the weight ratio of 50%-70% and XiChang South concentrate powder with the weight ratio of 30%-50% is adopted as pelletizing concentrate powder; and during mixing, water is firstly added to the bentonite to wet the bentonite, and then the bentonite is mixed with the pelletizing concentrate powder to form mixed powder. The bentonite is fully expanded through selective treatment on concrete powder raw materials and control over parameters in the bentonite mixing step, the concentrate power is in full contact with the bentonite, the effective utilization rate of the bentonite is improved, and therefore pelletizing quality is improved.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

Reinforced concrete internal curing high-water-absorption microsphere material and preparation method thereof

The invention provides an enhanced concrete internal curing high-water-absorption microsphere material and a preparation method thereof. The enhanced concrete internal curing high-water-absorption microsphere material is prepared from the following raw materials: nano silicon dioxide, chitosan, glutaraldehyde, Arabic gum, methacrylic acid, glacial acetic acid, cumene hydroperoxide, ferrous chloride and sodium ethoxide. By improving the transition area of the cement paste and the aggregate and modifying the microstructure in the cement-based material, the porosity is reduced, and the mechanicalproperty is improved. The whole preparation process flow is relatively simple, professional technicians do not need to operate and guide, and only the operation is carried out according to the description of the invention. The strength, durability, service life and the like of cement concrete are obviously improved by the reinforced concrete internal curing high-water-absorption microsphere prepared by the method disclosed by the invention.

Owner:CHANGAN UNIV

Vanadium-titanium alkaline pellet production method

The invention discloses a vanadium-titanium alkaline pellet production method. The vanadium-titanium alkaline pellet production method comprises the following steps: S1, mixing 80 parts by weight of limestone powder with 20 parts by weight of bentonite to prepare alkaline bentonite; S2, adding 4-6 parts by weight of magnesia bentonite into 100 parts by weight of iron ore powder, adding 1.3-1.5 part of bentonite, and adding 0.2 part by weight of magnesia bentonite as a material mixture; S3, uniformly mixing the material mixture through a mixer; S4, transporting alkaline bentonite into a circular disc pelletizer, adding the material mixture and water, and pelletizing to obtain fresh pellets, wherein the diameters of the fresh pellets are 1-20 mm; and S5, sequentially performing screening, drying, pre-heating, roasting, kiln head distributing, kiln head cooling and ring cooler cooling on the fresh pellets, thereby obtaining vanadium-titanium alkaline pellets. The vanadium-titanium alkaline pellet production method improves pelletizing and pellet-forming performance, is beneficial for green pellet roasting, improves a condition that powder is much and atmosphere is poor in a roasting process, can achieve the mass production target in a chain-grate machine-rotary kiln pellet production process, and only reduces yield ratio design ability by about 15%.

Owner:承德信通首承科技有限责任公司

Method for preparing pellet by pre-treating high titanium type vanadium-titanium magnetite

The invention relates to a method for preparing a pellet by pre-treating high titanium type vanadium-titanium magnetite. The method comprises the following steps of carrying out fine ball milling pretreatment on the high titanium type vanadium-titanium magnetite by using an ore milling device, so as to enable the proportion of the particle size, which is less than 75 microns, of magnetite powder to be greater than 85 to 95 percent; drying, so as to enable the moisture of the high titanium type vanadium-titanium magnetite powder to be less than or equal to 1.3 percent; dry-mixing the dried magnetite powder and bentonite for 15min to 20min, and subsequently, spraying water, and wet-mixing for 15min to 20min; putting a wet-mixed raw material in a condition of 25 to 30 DEG C, braising the material for 25min to 35min, then putting into a pelletizer, and preparing a green pellet with a diameter of 10mm to 12.5mm; drying the green pellet; afterwards, roasting, and raising the temperature of the pellet to 800 to 900 DEG C according to a temperature rise rate of 10 to 12 DEG C per minute; afterwards, raising the temperature to 1,140 to 1,180 DEG C according to a temperature rise rate of 4 to 6 DEG C per minute, and roasting for 10min to 15min; subsequently, lowering the temperature according to a temperature fall rate of 5 to 8 DEG C per minute, taking out after the temperature is fallen to 300 DEG C, and carrying out air cooling. The method provided by the invention can be used for effectively improving the pelletizing performance and the pelletizing speed of the high titanium type vanadium-titanium magnetite, is used for enabling the strength of the green pellet to be best, moreover, is lower in roasting temperature and shorter in time, can be used for meeting the requirement of the compression strength of a mature pellet, and is used for obviously improving the production efficiency of the pellet of the high titanium type vanadium-titanium magnetite.

Owner:NORTHEASTERN UNIV LIAONING

Magnetic whole-cell catalyst, preparation method and method for producing biodiesel

The invention discloses a magnetic whole-cell catalyst, a preparation method and a method for producing biodiesel. The preparation method includes the steps that firstly, pseudomonas mendocina cells are cultured and collected; secondly, SiO2-Fe3O4 nanoparticles are taken and added into a sodium alginate solution, the bacterial cells obtained in the first step are added after uniform stirring, and a mixed solution is obtained after uniform mixing; thirdly, the mixed solution is added into a sterile CaCl2 aqueous solution drop by drop under the stirring condition, still standing is carried out, magnetic microspheres are attracted out through a magnet and cleaned, and the magnetic whole-cell catalyst is obtained. The particle diameter of the prepared magnetic whole-cell catalyst is 2-6 mm, biological activity is high, and stability is good. In a biodiesel preparation reaction system, the magnetic whole-cell catalyst can be directly separated and extracted through the magnet and repeatedly used. The catalyst is easy to recycle, stable, easy to operate, moderate in condition, high in adaptability and safety and capable of reducing production cost of the biodiesel.

Owner:TIANJIN UNIV

Titanium concentrate pretreatment method and titanium concentrate pelletizing method

The invention discloses a titanium concentrate pretreatment method and a titanium concentrate palletizing method. The methods aim at solving the problem that the palletizing performance of existing titanium concentrates is poor. By the adoption of the technical scheme, the titanium concentrate pretreatment method includes the steps that firstly, raw materials are prepared; the content of water of selected titanium concentrates is adjusted, the water mass accounts for 20%-40% the total mass of the titanium concentrates and water, and wet titanium concentrates are obtained; wet grinding is conducted, wet grinding is conducted on the wet titanium concentrates through a ball grinding mill, wet grinding is divided into two stages, the grinding material in the first stage is steel balls of three models, the grinding material in the second stage is steel forgings, and finally filtering is conducted; and the wet-ground titanium concentrates and the serous fluid are filtered, and finished fine grain titanium concentrates are obtained. By the adoption of the titanium concentrate pretreatment method, the specific surface area of the titanium concentrates is increased to 50 cm<2> / g to 600 cm<2> / g from 150 cm<2> / g generated before treatment, and the palletizing performance is improved greatly. Bentonite and water are added to the finished fine grain titanium concentrates, palletizing is conducted, the drop strength of manufactured balls ranges from 5 times to 8 times, and the requirement for the quality of the balls in the titanium concentrate palletizing and oxidizing roasting processes can be met.

Owner:PANGANG GROUP TITANIUM INDAL +1

A method for pretreating high-titanium vanadium-titanium magnetite to prepare pellets

The invention relates to a method for pretreating high-titanium vanadium-titanium magnetite to prepare pellets, which includes the following steps: using grinding equipment to perform fine ball milling pretreatment on high-titanium vanadium-titanium magnetite; drying; and drying the dried vanadium-titanium magnetite. Dry mix the mineral powder and bentonite, then spray water to wet mix; place the wet mixed raw materials at 25 to 30°C for simmering and then put them into a pelletizing machine to prepare green balls; dry the green balls; then roast them. The pellets are heated to 800-900°C; then, the temperature is raised to 1140-1180°C for roasting; then, the temperature is lowered to 300°C, then taken out and air-cooled. The method of the present invention effectively improves the ball-forming performance and ball-forming speed of high-titanium vanadium-titanium magnetite, so that the strength of green balls can be optimized, and the roasting temperature is low and the time is short, so that it can meet the requirements of compressive strength of cooked balls. The production efficiency of high-titanium vanadium-titanium magnetite pellets is significantly improved.

Owner:NORTHEASTERN UNIV LIAONING

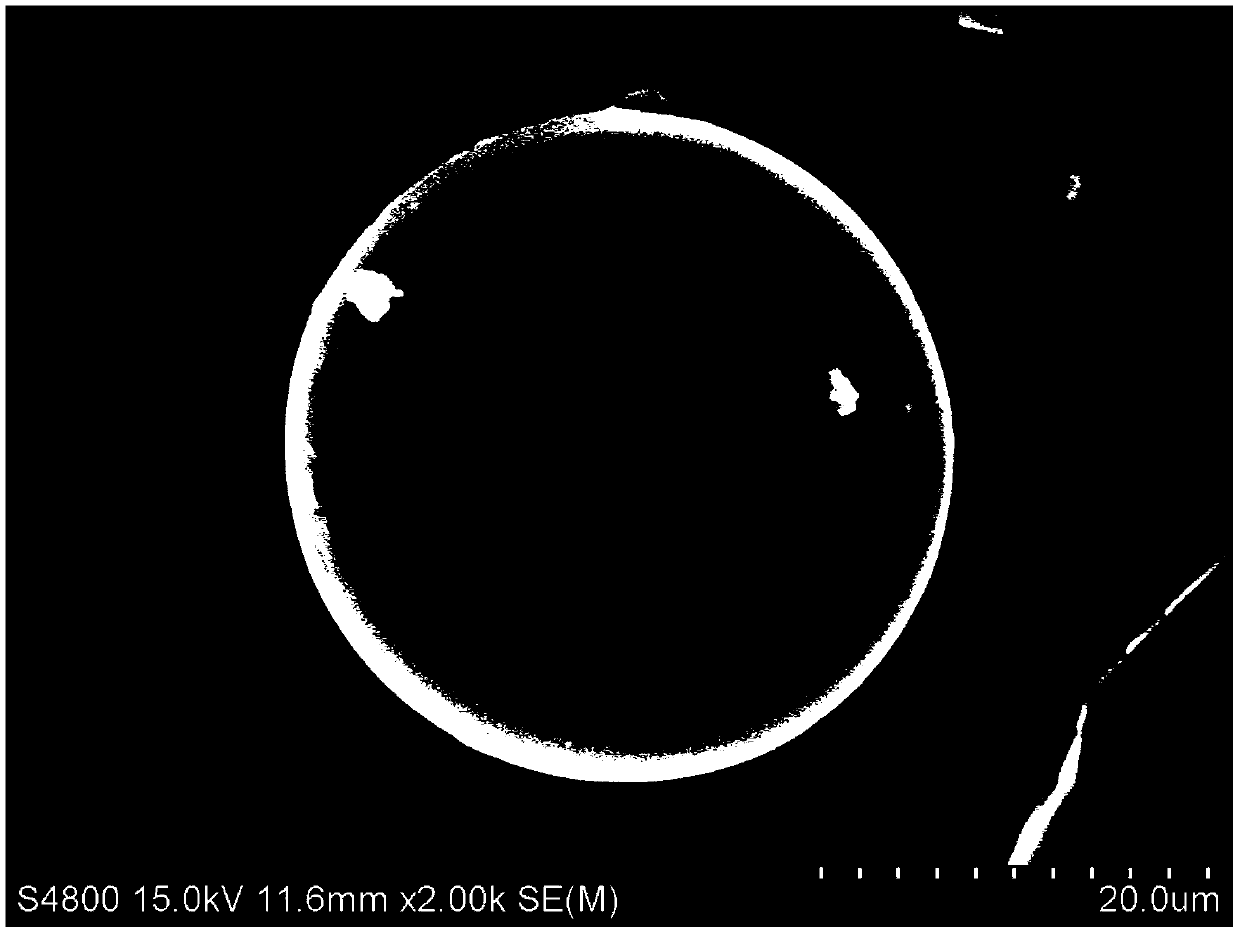

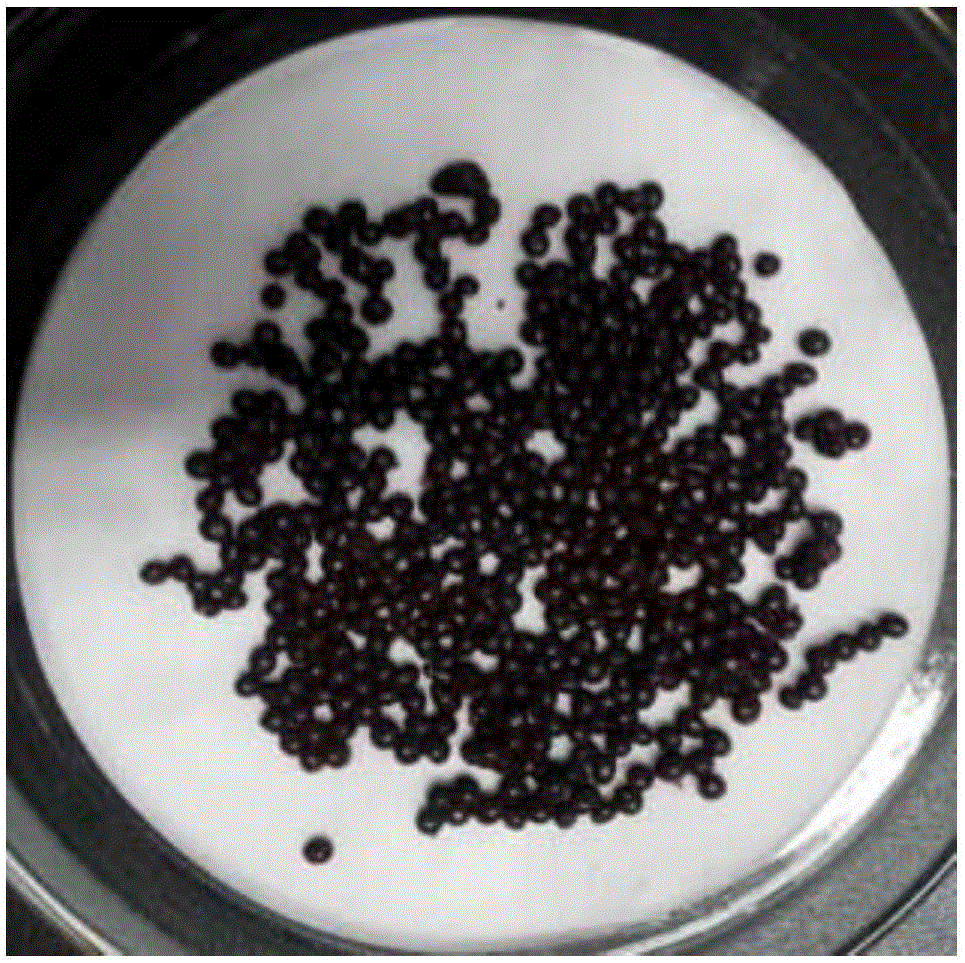

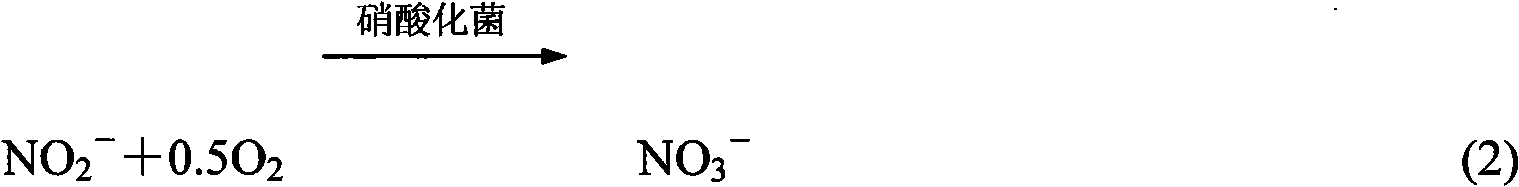

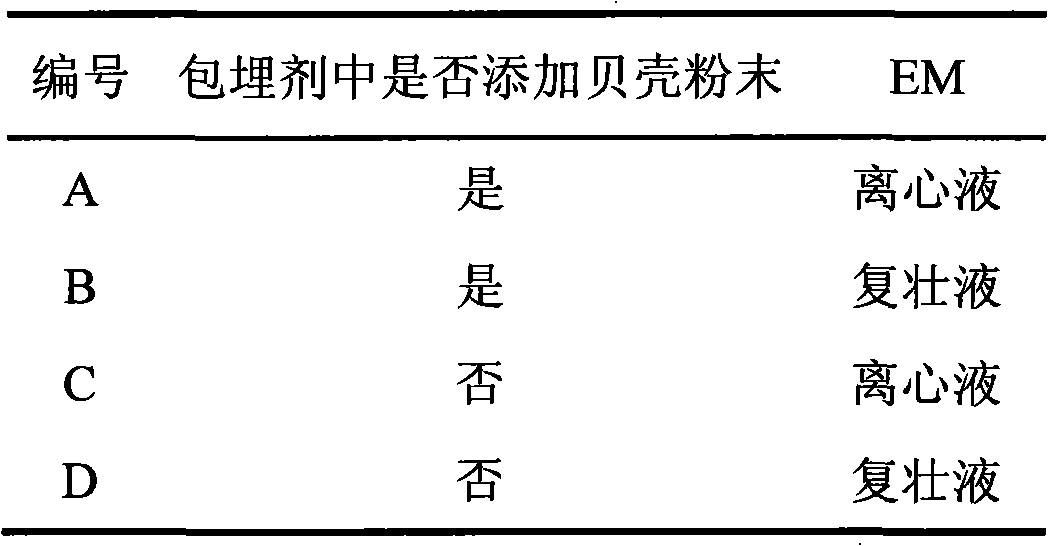

Preparation of embedding immobilized effective microorganism gel bead

InactiveCN101475931BImprove ball formingHigh strengthMicroorganism based processesOn/in organic carrierEffective microorganismPolyvinyl alcohol

A preparation method of embedding immobilized effective microorganism gel pellets relates to a microbial cell immobilization method for saprobe denitrification, specifically to a method taking polyvinyl alcohol and sodium alginate as the embedding agent, calcium chloride and boric acid as a cross linker and shell powder as additives to embed the effective microorganism. The invention provides a preparation method of embedding immobilized effective microorganism gel pellets which can not only effectively resolve the defects in the preparation and use process of the gel pellet, but also can effectively improve the biological denitrification effect by taking the effective microorganism as embedding thalli. The method includes: mixing uniformly the embedded agents and additives, dissolving inwater, completely dissolving and mixing uniformly and then cooling to below 40 DEG C, mixing with the centrifuged effective microorganism concentrated bacterium liquor, stirring, and then adding intothe cross-linker to form the gel pellets.

Owner:XIAMEN UNIV

Process for immobilizing enzyme/microbe with polyvinyl alcohol

InactiveCN1137991CSolve the problem of agglomerationImprove ball formingProtozoaCross-linkWater baths

A process for preparing immobilized enzyme microbe with polyvinyl alcohol includes such steps as mixing polyvinyl alcohol, sodium algate and acrylamide with water, water-bath heating until full dissolving, then cooling to obtain solution of polyvinyl alcohol, mixing it with enzyme / microbe suspension according to a certain proportion, preparing solution of cross-linking agent by adding saturated boric acid solution to the mixture of calcium chloride and N,N'-methanobiacrylamide, dripping the said mixed solution to the solution of cross-linking agent to form white spherial particles, immersing for several hr, and washing with physiological brine. Its advantages are high mechanical strength and long service life.

Owner:TSINGHUA UNIV

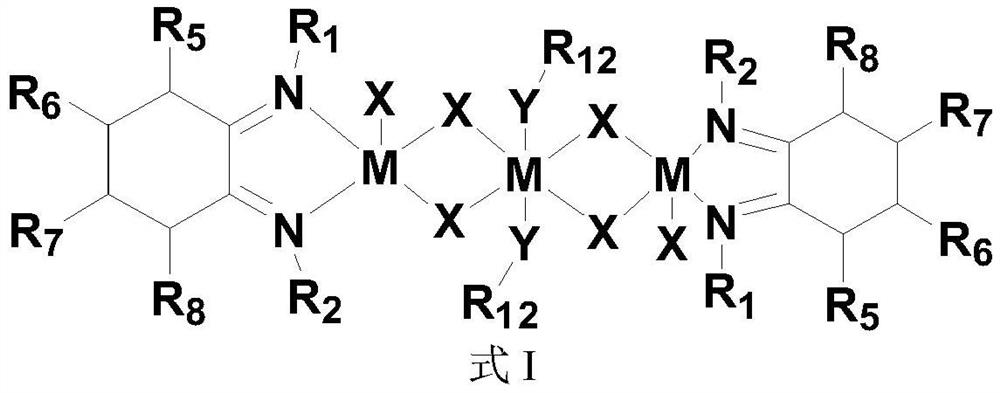

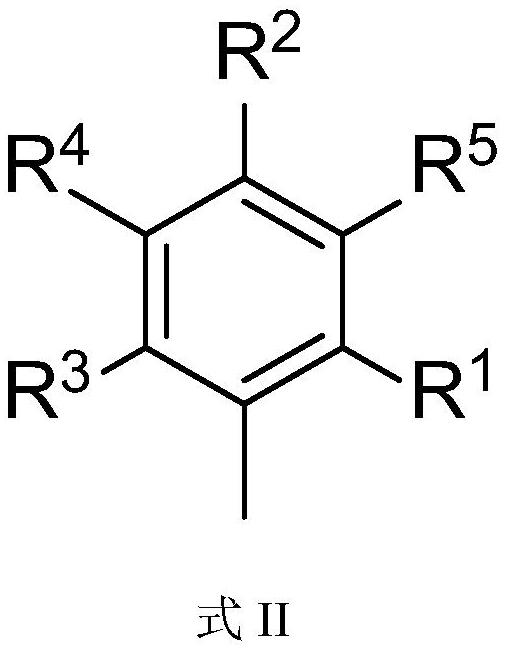

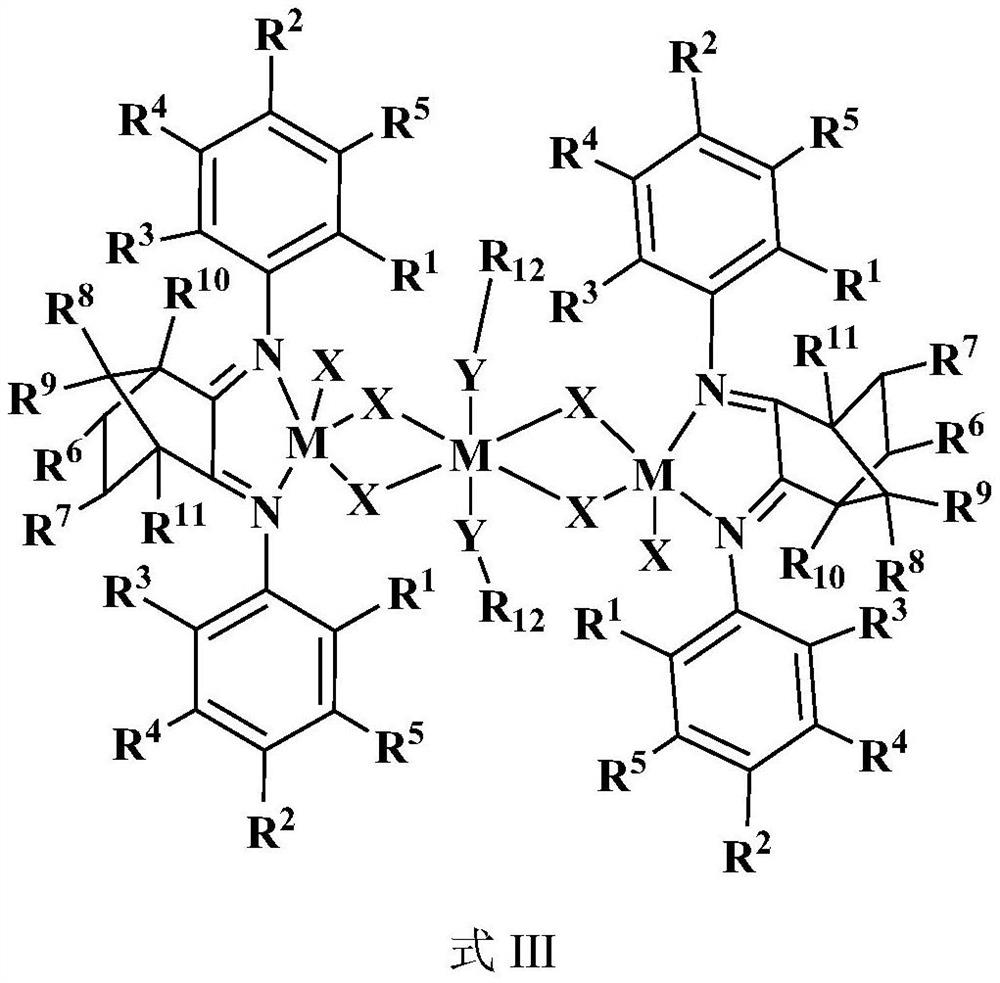

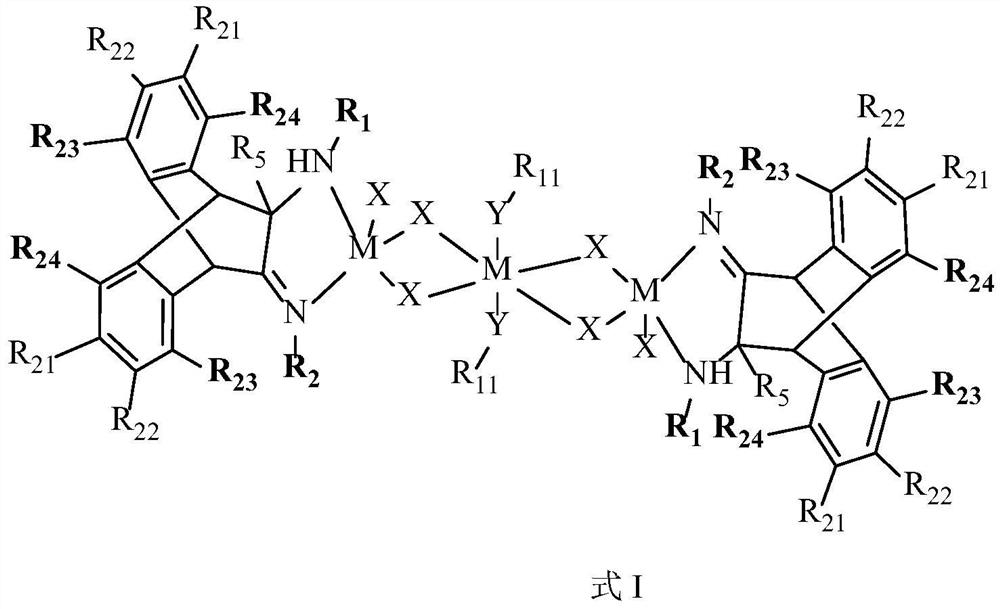

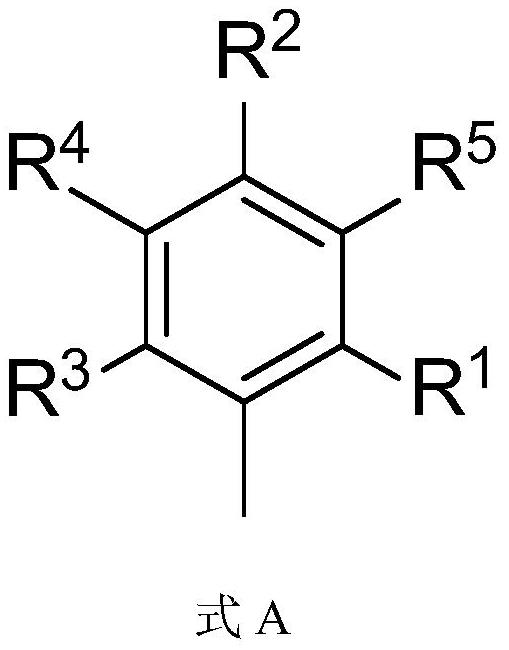

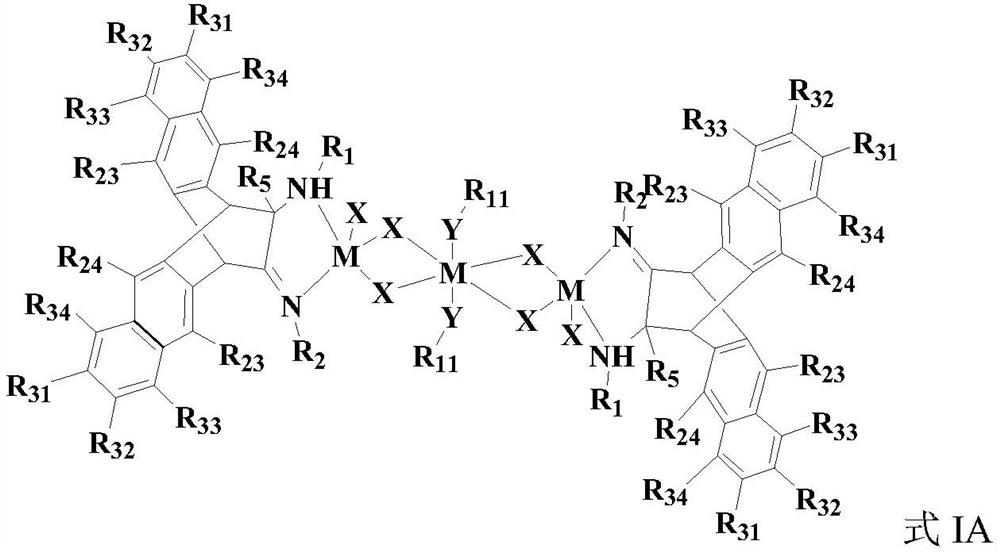

Preparation method of copolymer of olefin and unsaturated carboxylic acid

The invention relates to a preparation method of a copolymer of olefin and unsaturated carboxylic acid and the copolymer prepared by the method. The method comprises the step of polymerizing olefin and unsaturated carboxylic acid in the presence of a catalyst, an improver, an optional chain transfer agent and an improver, wherein the used catalyst comprises a diimine metal complex as shown in a formula I which is described in the specification. The spherical and / or sphere-like polymer prepared by the preparation method has a good prospect in industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Magnetic separation column-anion reverse flotation optimizing beneficiation new process

The invention relates to a magnetic separation column-anion reverse flotation optimizing beneficiation new process belonging to the technical field of beneficiation. The magnetic separation column-anion reverse flotation optimizing beneficiation new process comprises the following steps of: obtaining magnetic concentrates by adopting the conventional magnetic separation process; processing the magnetic concentrates by adopting a magnetic separation column, wherein the magnetic separation column selects two products, i.e. an overflow product and a sand setting product; obtaining qualified concentrates by controlling the ascending water and the ore discharge quantity of the sand setting product; also continuously carrying out a flotation regrinding process on magnetic separation column overflows; discarding tailings; enabling the qualified concentrates and magnetic separation column concentrates to be merged into final concentrates. The invention increases a magnetic separation column selection process before reverse flotation aiming at the problems of high cost, environmental pollution, and the like in the traditional magnetic separation-reverse flotation process, thereby effectively reducing the pressure of flotation; the invention obtains 20 percent of the qualified concentrates in advance before the flotation, thereby reducing the flotation ore quantity by 20 percent; and inaddition, the invention also reduces the cost of a flotation procedure by 30 yuan / t, thereby obviously enhancing the economic benefits.

Owner:ANSTEEL GRP MINING CO LTD

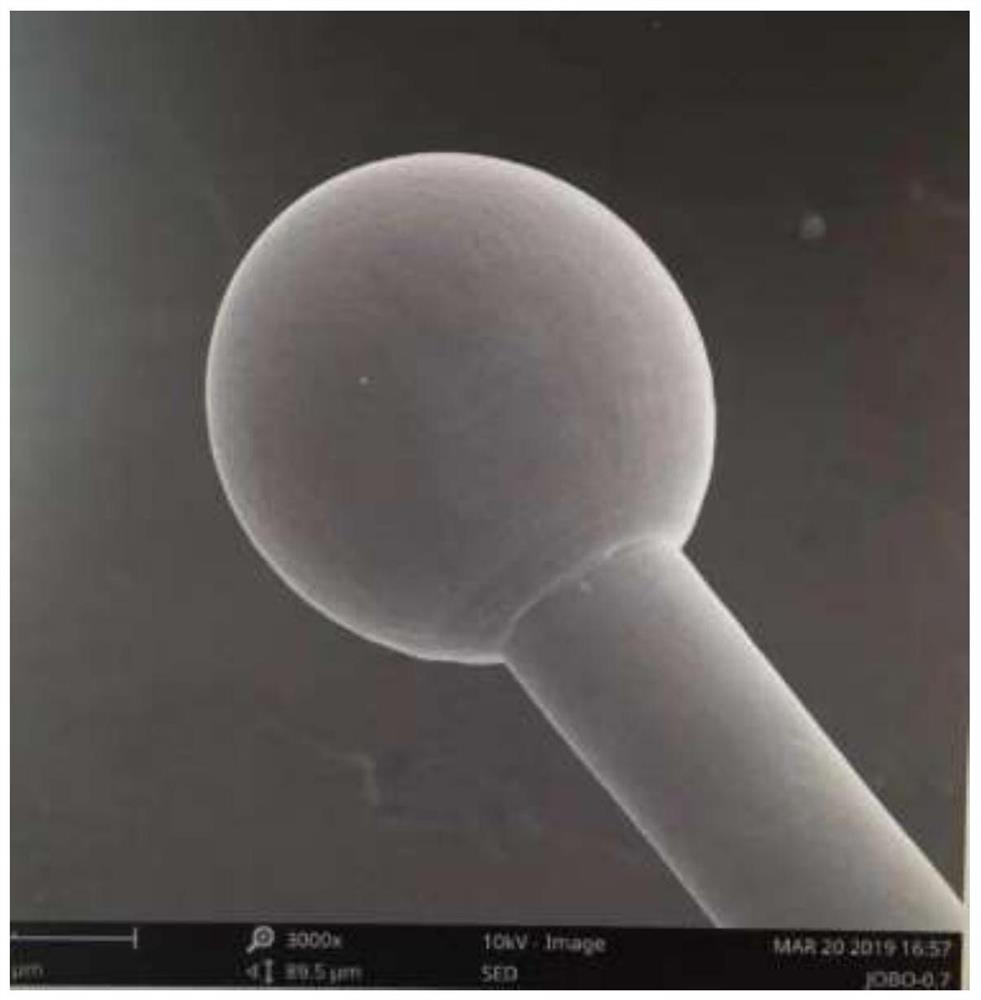

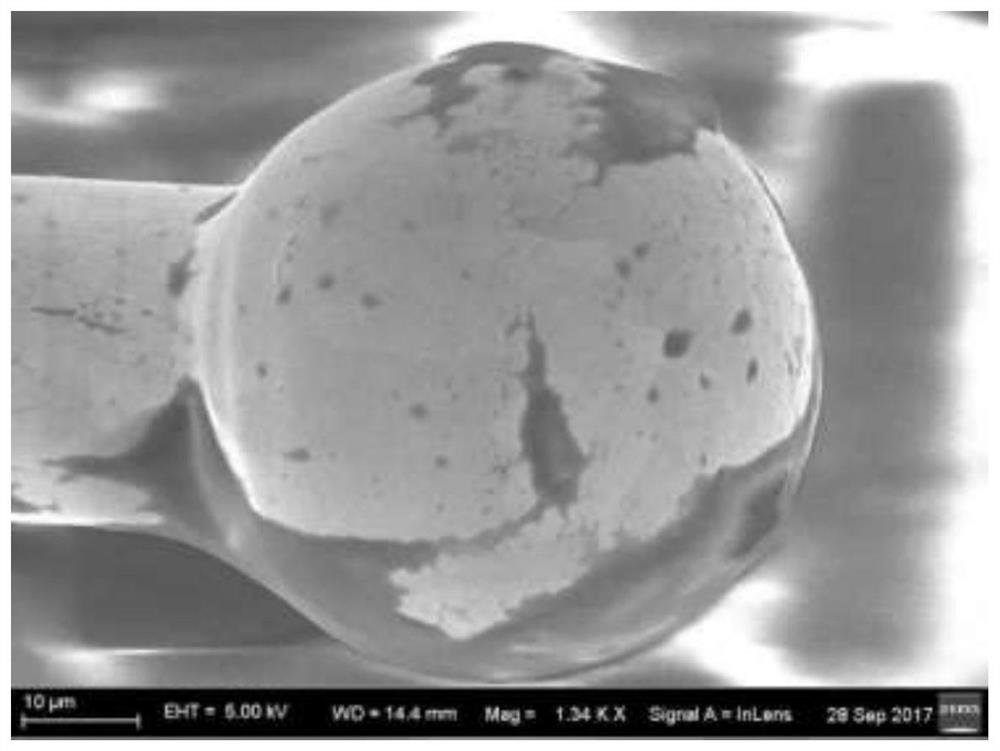

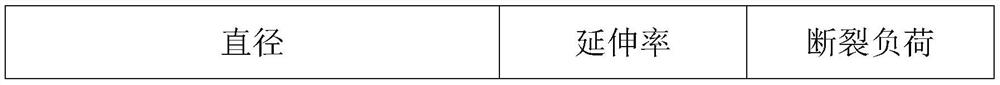

A kind of bonding silver wire material with high spheroidity and preparation method thereof

ActiveCN110699570BImprove ball formingHigh ballSemiconductor/solid-state device detailsSolid-state devicesIndiumCerium

The invention belongs to the technical field of bonding wire materials, and relates to a high spherical bonding silver wire material and a preparation method thereof. The composition of the material comprises silver 99%±0.2%, nickel 0.4%±0.04%, and cobalt 0.4% ±0.05%, calcium 0.01%±0.001%, copper 0.01%±0.001%, gold 0.03%±0.004%, palladium 0.03%±0.004%, lanthanum 0.01%±0.001% and lead 0.0025%±0.0005%, also including other trace amounts The elements include one or more of indium, cerium, yttrium, and selenium. The preparation method of the bonding silver wire material of the present invention makes each metal component melt and synthesizes separately by steps, so that the crystal grains of each component are fully matched during the synthesis process of the bonding silver wire material, and the spheroidization of the synthesized bonding silver wire is improved. , in order to improve the chemical stability and mechanical properties of the alloy wire material.

Owner:广东佳博电子科技有限公司

Method for preparing pyritic slag pellet raw material and method for preparing green pellets

ActiveCN101597686BFully moistenedImprove ball formingProcess efficiency improvementSlagCapillary action

The invention provides a method for preparing a pyritic slag pellet raw material, which comprises the following steps: a) performing primary mixing on pyritic slag and water to prepare a mixture of which the water content is between 1 and 13 weight percent; b) performing ageing treatment on the mixture; and c) performing secondary mixing on the aged mixture, water and other iron-containing raw materials to prepare the pellet raw material. When the mixture is subjected to the ageing treatment, the water content in the mixture can fully moisten the pyritic slag, so that the capillary action of micropores of the pyritic slag can be better exerted to improve the ballability of the mixture. When green pellets are prepared from the pellet raw material comprising the mixture, the green pellets meeting technological requirements are prepared under the action of a binder and pores of the pellet raw material.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Copolymer containing polar group and preparation method and application thereof

The invention relates to a preparation method of a polar group-containing copolymer and the polar group-containing copolymer prepared by the method. The preparation method of the polar group-containing copolymer comprises the following step: carrying out polymerization reaction on olefin and olefin alcohol in the presence of a catalyst, an improver and an optional chain transfer agent, wherein the used catalyst comprises an amino imine complex as shown in a formula I. The spherical and / or sphere-like polymer prepared by the preparation method has a good prospect in industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of high-efficiency composite bentonite for pelletizing

The invention relates to a high-efficiency composite bentonite for pellets, which consists of the following components in parts by weight: 60-80 parts of bentonite, 12-26 parts of organic cellulose, 5-10 parts of sodium carbonate, 7-14 parts of magnesium oxide, three 4-6 parts of diboron oxide, 5-11 parts of high-temperature explosion-proof agent. The organic cellulose is one or any mixture of carboxymethyl cellulose and hydroxymethyl cellulose. The high temperature anti-explosion agent is an anti-explosion fiber. Compared with the prior art, the beneficial effects of the present invention are: 1) instead of ordinary bentonite, the amount of bentonite binder is reduced from 1.7% to 1.2%; 2) compared with ordinary bentonite, it has the It has the characteristics of high strength and high pelletizing degree, which can increase the grade of finished ore (TFe) by about 0.6%, and reduce the content of SiO2 by about 0.8%; 3) adding magnesium oxide and boron trioxide can effectively reduce the roasting temperature; 4) can reduce the unit consumption , improve the ball forming of green balls, increase the burst temperature of green balls, and improve the metallurgical properties of pellets.

Owner:ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com