Treatment method for realizing comprehensive utilization of industrial acid pickling waste liquid and sulfate slag

An industrial pickling and treatment method technology, applied in the direction of improving process efficiency, etc., can solve the environmental pollution of steel rolling pickling waste acid, etc., achieve the effects of high fineness, improve ball forming performance, and avoid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

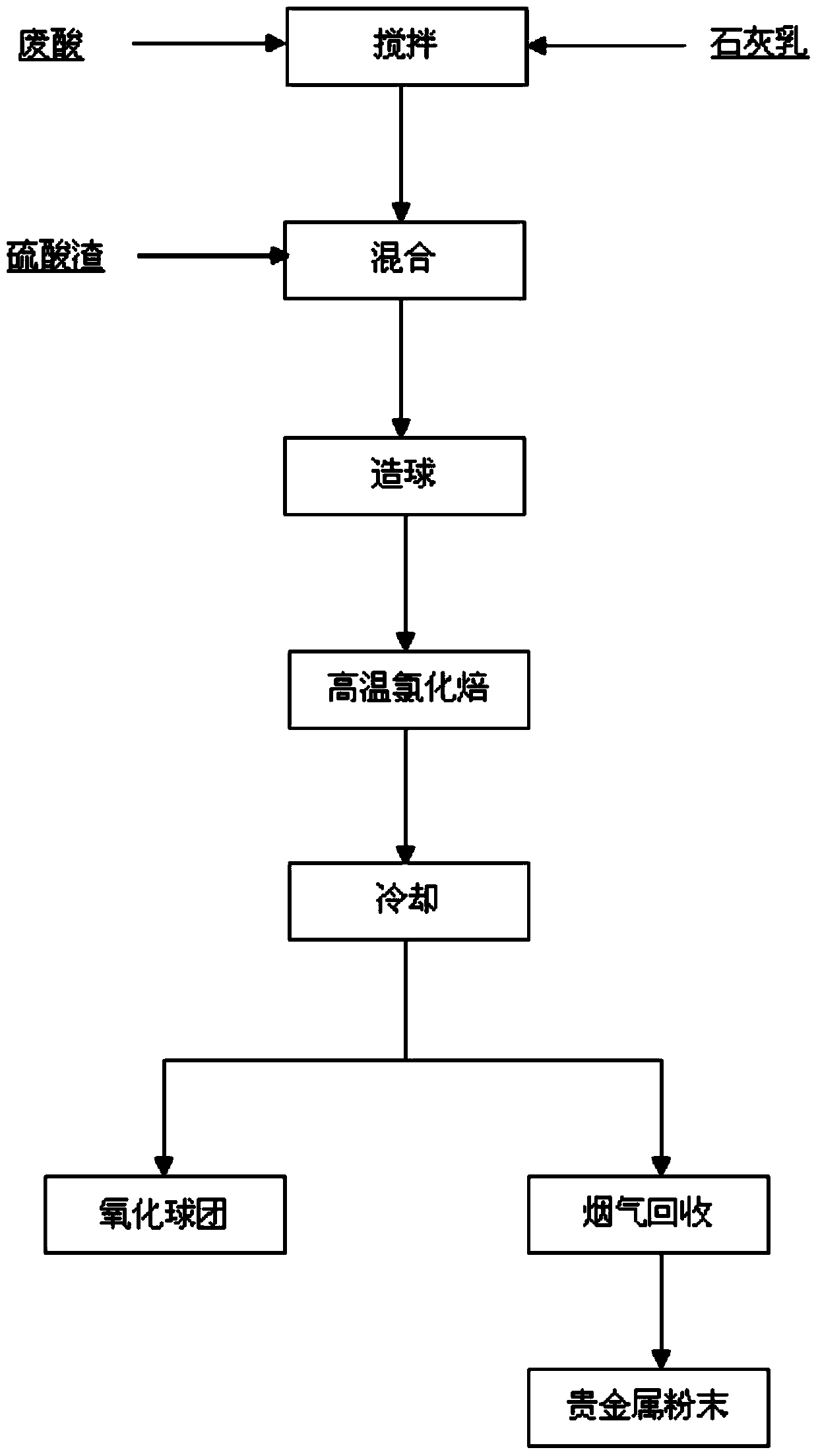

Image

Examples

Embodiment 1

[0042] Take 100mL of pickling waste liquid to be treated, add 120mL of lime emulsion, add 100 grams of anhydrous calcium chloride while stirring constantly, the reaction time is 30 minutes, and after the reaction, the iron-based solution with a chlorinating agent content of 15.23wt% is obtained. Chlorinating agent; calcium chloride is added to the iron-based chlorinating agent, and the content of the chlorinating agent in the iron-based chlorinating agent is 51.25wt%.

[0043] Mix the iron-based chlorinating agent prepared above and the sulfuric acid slag to be treated uniformly at a mass ratio of 1:4, and then pelletize on a disc granulator to obtain pellets with a particle size of 15-20 mm.

[0044] The pellets were put into a muffle furnace, chlorinated and roasted at a high temperature of 1050°C for 60 minutes, and cooled naturally to obtain oxidized pellets.

[0045] The oxidized pellets obtained in Example 1 are analyzed by X-ray fluorescence spectrum, and the obtained a...

Embodiment 2

[0047] Take 100mL of pickling waste liquid to be treated, add 100mL of lime emulsion, add 200 grams of anhydrous calcium chloride while stirring constantly, the reaction time is 30 minutes, and after the reaction, the iron-based chloride with a chlorinating agent content of 14.66% is obtained. Calcium chloride is added in the iron-based chlorinating agent, and the content of the chlorinating agent in the iron-based chlorinating agent is 53.66wt%.

[0048] The iron-based chlorinating agent prepared above and the sulfuric acid slag to be treated are mixed uniformly with the iron-based chlorinating agent and sulfuric acid slag according to the mass ratio of 1:6, and then pelletized on a disc granulator to obtain a particle size of 15 -20mm pellets.

[0049] Put the above-mentioned pellets into a muffle furnace, chlorinated and roasted at 1100°C for 60 minutes, and cooled naturally to obtain oxidized pellets.

[0050] The oxidized pellets obtained in Example 2 were analyzed by X-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com