Heavy metal biological adsorbent and preparation method thereof

A biosorbent, heavy metal technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of long time, high cost, complicated operation, etc., to improve the adsorption effect, low equipment requirements , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

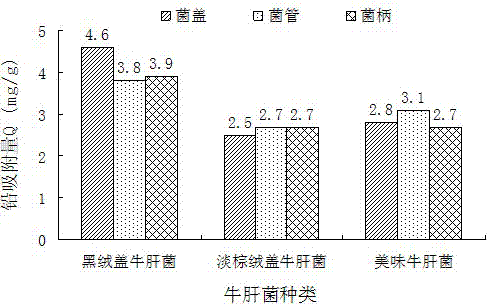

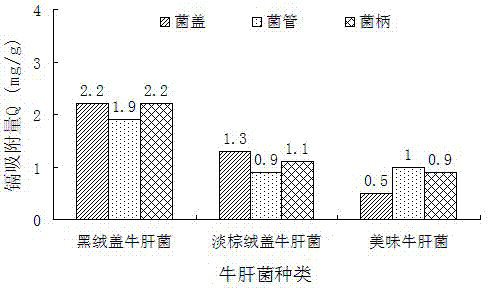

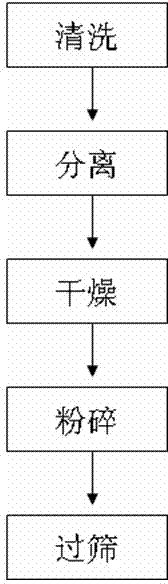

[0051] (1) Preparation of bacteria powder

[0052] Take the black velvet cap boletus, wash it with deionized water; put it in a constant temperature drying box, and dry it at 50±2°C until it reaches a constant weight; after cooling, put it in a pulverizer and grind it to make a corresponding dry Bacteria powder: Sieve the obtained bacteria powder through 80-mesh, 100-mesh, 120-mesh, 150-mesh and 300-mesh sampling sieves for particle size classification, and obtain particle sizes of 150-200 μm, 125-150 μm, 100-125 μm and 4 kinds of adsorbent powders of 50-100μm.

[0053] (2) Adsorption test

[0054] Take four 250 mL clean Erlenmeyer flasks with stoppers, and add 25 mL of lead solution with a concentration of 100 mg / L (1000 mg / L lead standard solution GSB 04-1742- 2004 diluted 10 times), respectively weighed 500 mg of the above-mentioned boletus powder and added them to the triangular flask (each bottle corresponds to a boletus powder in a particle size range), and another 4 c...

Embodiment 2

[0058] Get the boletus powder 500 mg of 150-200 μ m particle size prepared in Example 1 and 200 μ L concentration is the polyethylene solution of 5 mg / mL and mix evenly, be placed in the mold that cross section is circular, adopt hand-operated hydraulic press at 0.5 The pressure was maintained at MPa for 10 seconds, and the sample was withdrawn from the mold to obtain a circular cake of adsorbent.

[0059] Take 2 adsorbent discs prepared by the above method and place them in 25 mL of lead solution and cadmium solution with a concentration of 100 mg / L respectively. After 1 hour of adsorption, take out the adsorbent discs and measure the filtrate with an atomic absorption spectrophotometer. The concentration of heavy metal ions remaining in C f , and simultaneously determine the initial concentrations of metal ions in the prepared lead and cadmium solutions C i , with three replicates for each treatment. And formula 1 and formula 2 were used to calculate the respective ads...

Embodiment 3

[0062] Take the black velvet cap boletus, wash it with deionized water; put it in a constant temperature drying box, and dry it at 50±2°C until it reaches a constant weight; after cooling, put it in a pulverizer and grind it to make a corresponding dry Bacteria powder: Sieve the obtained bacteria powder with 80-mesh and 300-mesh sampling sieves to obtain adsorbent powder with a particle size of 50-200 μm. Using the same method as the adsorption test in Example 1, it was measured that the adsorption capacity to lead was 4.3 mg / g, and the adsorption rate was 86%; the adsorption capacity to cadmium was 2.2 mg / g, and the adsorption rate was 44%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com