Technology for producing metal furnace burden for high-quality electric furnace by coal-based method

A high-quality, coal-based technology, applied in furnaces, rotary drum furnaces, furnace types, etc., can solve the problem of raw pellets sticking to the bottom of the furnace or sticking to each other, the hydrophilicity and cohesiveness of rolling fuel Insufficient, limited production efficiency of metal charge and other problems, to achieve the effect of improving ball forming, improving ball forming performance and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

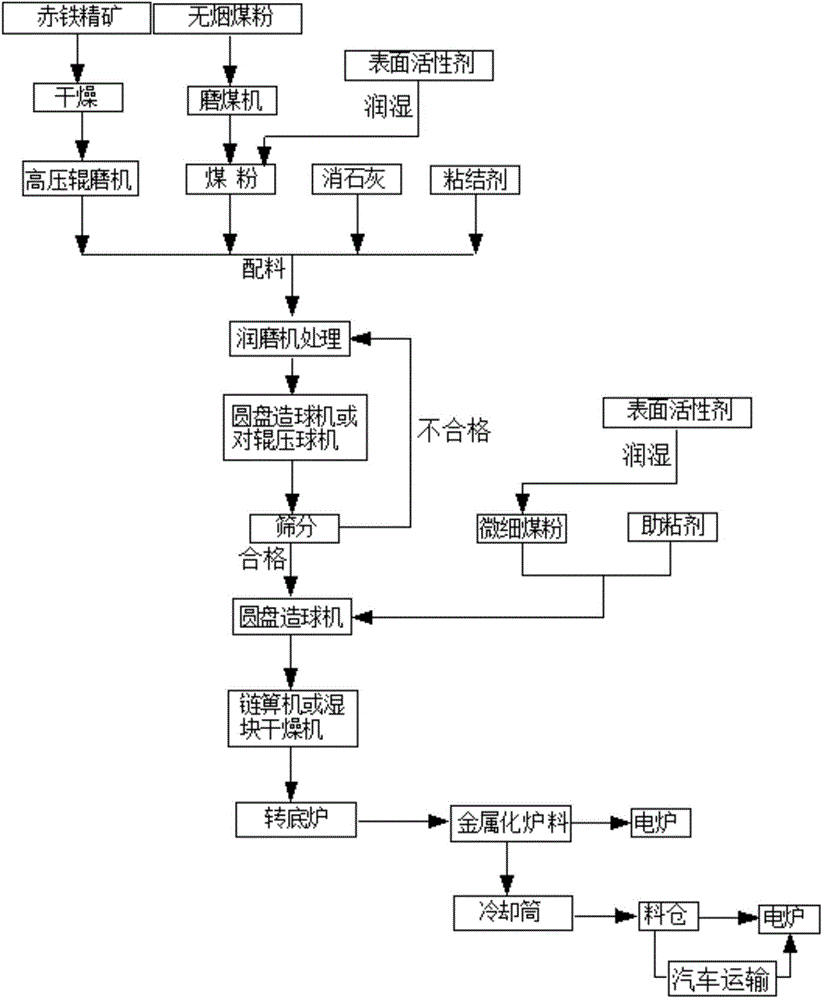

[0033] Such as figure 1 As shown, the coal-based method of this embodiment produces a high-quality metal charge for electric furnace, including the following steps.

[0034] (1) Ingredients: 81% by weight of hematite concentrate from Brazil, 17% by weight of anthracite clean coal from Anhui, and 2% by weight of slaked lime and binder. The above-mentioned hematite concentrate in Brazil satisfies TFe≥66%, SiO 2 ≤2.5%, the content of harmful elements S and P is less than 0.01%, and the particle size -200 mesh accounts for more than 85% of the requirements. The above-mentioned anthracite clean coal in Anhui satisfies C 固 ≥82.5%, S≤0.35%, Ash≤10% requirements. Firstly, the water in the high-grade low-silicon hematite concentrate is dried to 5% by a cylinder dryer, and then mechanically activated by a high-pressure roller mill, which performs static pressure grinding on the hematite concentrate. A large number of cracks are produced on the surface of hematite concentrate particl...

Embodiment 2

[0040] The coal-based method of this embodiment produces high-quality metal charge for electric furnaces, including the following steps.

[0041] (1) Ingredients: 81% by weight of hematite concentrate from Brazil, 17% by weight of anthracite clean coal from Anhui, and 2% by weight of slaked lime and binder. The above-mentioned hematite concentrate in Brazil satisfies TFe≥66%, SiO 2 ≤2.5%, the content of other harmful elements S and P is less than 0.01%, and the particle size -200 mesh accounts for more than 85% of the requirements. The above-mentioned anthracite clean coal in Anhui satisfies C 固 ≥82.5%, S≤0.35%, Ash≤10% requirements. Firstly, the water content in the high-grade low-silicon hematite concentrate is dried to 8% by a cylinder dryer, and then mechanically activated by a high-pressure roller mill. The high-pressure roller mill performs static pressure grinding on the hematite concentrate. A large number of cracks are produced on the surface of hematite concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com