Method and system for preparing metallized pellet

A technology for metallizing pellets and pellets, applied in the fields of energy and metallurgy, can solve the problems of worsening the ventilation of the charge, reducing the life of the rotary hearth furnace, and eroding the bottom materials of the furnace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

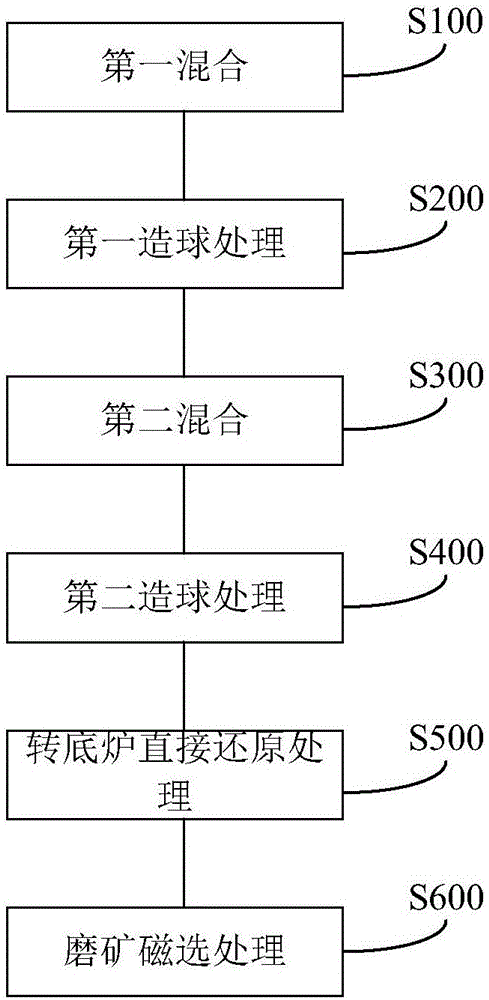

Method used

Image

Examples

Embodiment 1

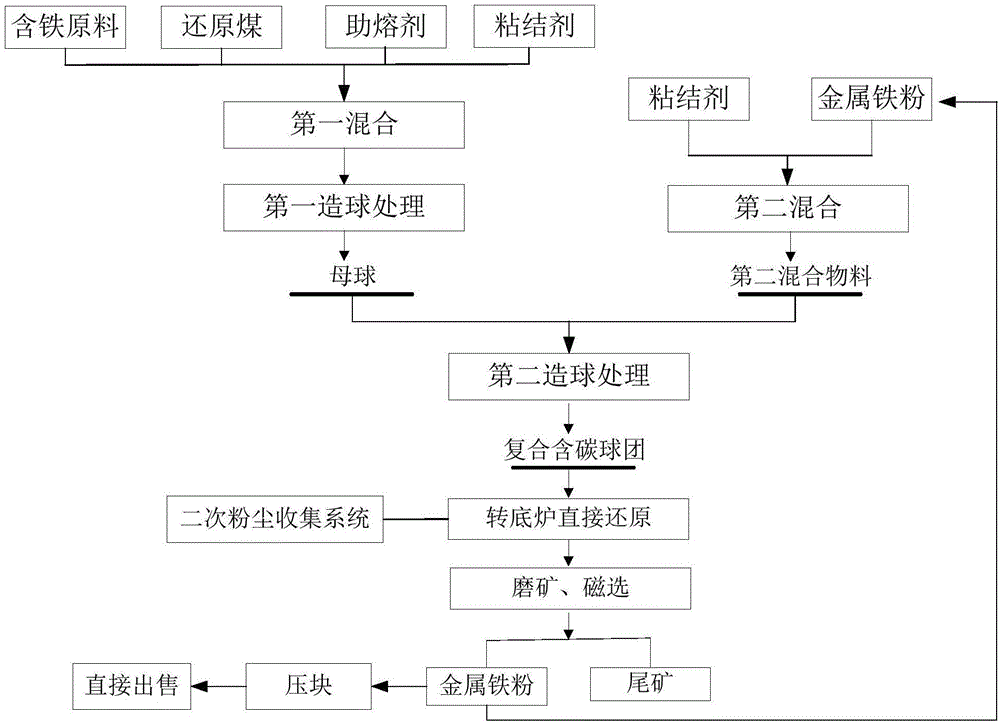

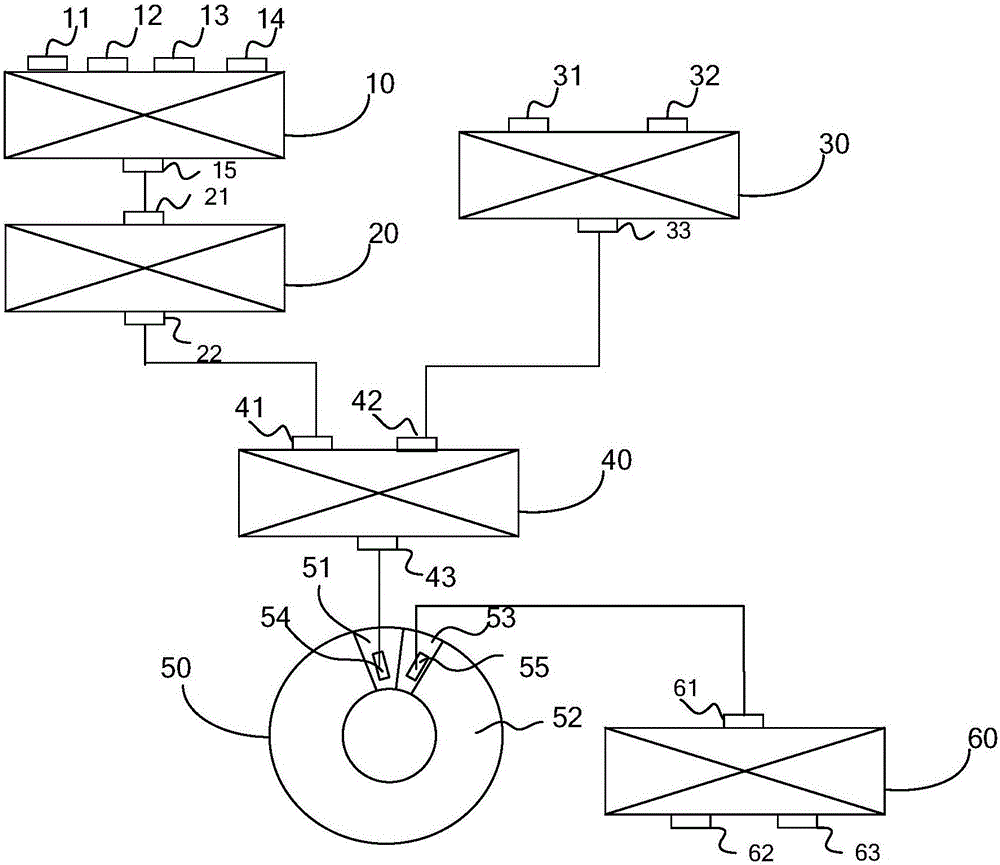

[0067] (1) Mix copper smelting slag (TFe is 41%, Zn is 2.7%) with reduced coal, sodium carbonate, and bentonite. The mixing ratio is 100:27:3:4, and the carbon-oxygen ratio is 1.8. The first mixture The raw materials are pelletized to obtain cue balls. The particle size of the pellets is in the range of 10 to 14. The unqualified pellets are screened and returned to the moistening mill, and re-enter the feeding area of the first pelletizing process. Mix metal iron powder (with a particle size of 0.074mm~0.1mm) and binder at a ratio of 100:5. After mixing, use the cue ball as the cue ball to enter the second ball making process, and wrap the second mixture evenly On the surface of the cue ball, composite carbon-containing pellets are obtained, and the qualified particle size of the composite carbon-containing pellets is 12-16 mm.

[0068](2) Evenly distribute the composite carbon-containing pellets into the rotary hearth furnace for direct reduction, the thickness of the pavin...

Embodiment 2

[0072] (1) Mix zinc slag (TFe is 22%, Zn content is 16%, lead content is 4%) and reduced coal, the mixing ratio is 100:21, the carbon-oxygen ratio is 2.2, and the first mixed material is made Balls are obtained to obtain cue balls. The particle size of the pellets is in the range of 10 to 14. The unqualified pellets are screened and returned to the moistening mill, and re-enter the feeding area of the first pelletizing process. Mix metal iron powder (with a particle size of 0.074mm to 0.1mm) and binder at a ratio of 100:5. After mixing, use the cue ball as the cue ball and enter the second ball making process, and wrap the second mixture evenly On the surface of the cue ball, composite carbon-containing pellets are obtained, and the qualified particle size of the composite carbon-containing pellets is 12-16 mm.

[0073] (2) Evenly distribute the composite carbon-containing pellets into the rotary hearth furnace for direct reduction. The thickness of the paving material is 5-...

Embodiment 3

[0077] (1) Mix zinc-containing dust (TFe is 45%, Zn is 3%, C is 4%) with reduced coal and bentonite, the mixing ratio is 100:24:4, the carbon-oxygen ratio is 1.8, and the first The mixed material is pelletized to obtain cue balls. The particle size of the pellets is in the range of 10 to 14. The unqualified pellets are screened and returned to the moist mill, and re-enter the feeding area of the first pelletizing process. Mix metal iron powder (with a particle size of 0.074mm to 0.1mm) and binder at a ratio of 100:5. After mixing, use the cue ball as the cue ball and enter the second ball making process, and wrap the second mixture evenly On the surface of the cue ball, composite carbon-containing pellets are obtained, and the qualified particle size of the composite carbon-containing pellets is 11-15mm.

[0078] (2) Evenly distribute the composite carbon-containing pellets into the rotary hearth furnace for direct reduction. The thickness of the material is 7 to 8 layers of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com