Method for preparing pellet by pre-treating high titanium type vanadium-titanium magnetite

A technology of vanadium-titanium magnetite and high-titanium type is applied in the field of pretreatment of high-titanium type vanadium-titanium magnetite to prepare pellets, which can solve the problems of decreased green pellet strength, long preheating time, pellet quality, etc. The effect of slowing down the rate of water evaporation, reducing the amount of water loss, and improving the performance of the ball

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

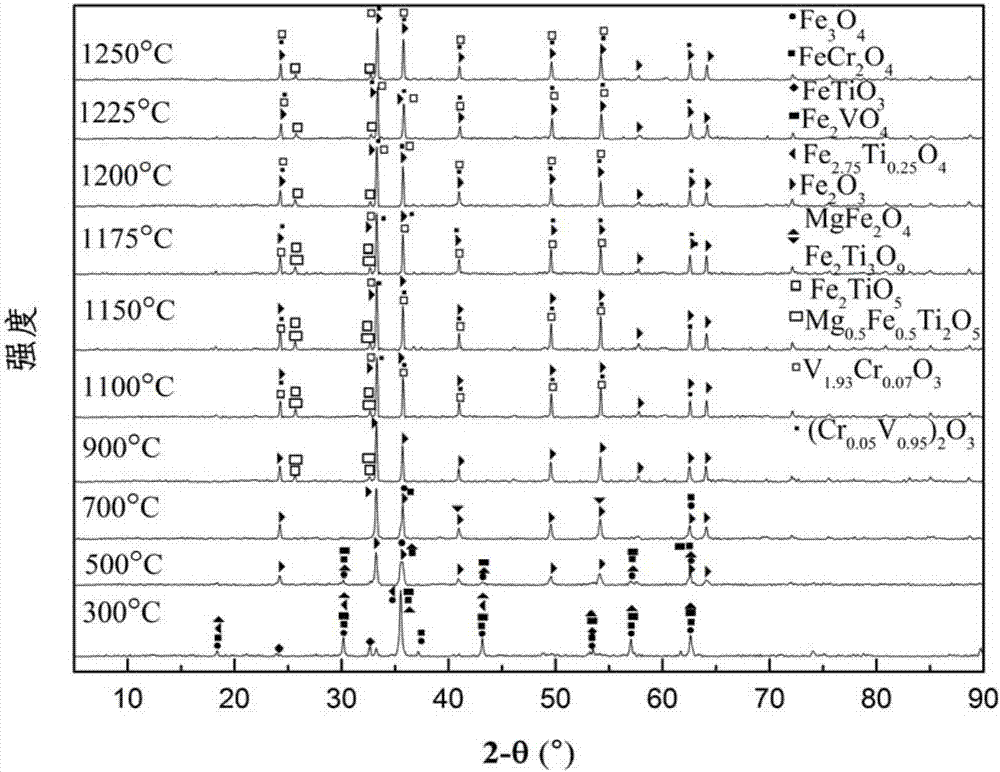

Image

Examples

Embodiment 1

[0045] A method for preparing pretreated high-titanium type vanadium-titanium magnetite pellets, the method comprising:

[0046] 1. Pretreatment

[0047] Take high-titanium vanadium-titanium magnetite and finely grind high-titanium vanadium-titanium magnetite in conical ball mill, horizontal ball mill or dry slag ball mill and other grinding equipment to obtain high-titanium vanadium-titanium magnet Mineral powder. Among them, the parameters of the conical ball mill are: the grinding capacity is 4kg, the rotating speed is 90r / min, the grinding concentration is 65% to 75%, the ball loading capacity is 10kg, and the ball milling time is 1 to 60min; the parameters of the horizontal ball mill are: The ore quantity is 2-5kg, the speed is 35-55r / min, the ball milling time is 1-60min, and the ball loading capacity is 25kg; the parameters of the dry-type mineral powder ball mill are: the grinding quantity is 2-5kg, the speed is 30-45r / min, The ball milling time is 1-60 minutes, and ...

Embodiment 2

[0072] A method for pretreating high-titanium vanadium-titanium magnetite to prepare pellets, the present embodiment is based on embodiment 1, and the specific operation steps are as follows:

[0073] 1. Pretreatment

[0074] Take 4kg of high-titanium vanadium-titanium magnetite in a conical ball mill with a rotating speed of 90r / min, a grinding concentration of 70%, a ball loading capacity of 10kg, and a ball milling time of 30min.

[0075] After grinding, the particle size distribution of the high-titanium vanadium-titanium magnetite was measured by wet sieving, and 92% of the particles had a particle size smaller than 75 μm.

[0076] 2. Raw material drying

[0077] The pretreated high-titanium vanadium-titanium magnetite was dried in a draft drying oven at a temperature of 108°C for 2 hours, and the moisture content of the dried high-titanium vanadium-titanium magnetite was measured to be 1.13%.

[0078] 3. Mixing stage

[0079] Add 0.6% of its weight of calcium-based be...

Embodiment 3

[0094] This embodiment is on the basis of embodiment 1, concrete operation is as follows:

[0095] 1. Pretreatment

[0096] Take 5 kg of high-titanium vanadium-titanium magnetite in a horizontal ball mill with a rotating speed of 40 r / min, a ball loading capacity of 25 kg, and a ball milling time of 25 min.

[0097] After grinding, the particle size distribution of the high-titanium vanadium-titanium magnetite was measured by wet sieving, and 86% of the particles had a particle size smaller than 75 μm.

[0098] 2. Raw material drying

[0099] The pre-grinded high-titanium vanadium-titanium magnetite and 0.7% by weight of hydrogen-based bentonite were dried in a draft drying oven at 105°C for 2.1 hours, and the water content of the iron ore was measured to be 1.15%.

[0100] 3. Mixing stage

[0101] Add hydrogen-based bentonite to high-titanium vanadium-titanium magnetite powder for 18 minutes of dry mixing. After the dry mixing is completed, use a high-pressure sprayer to e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com