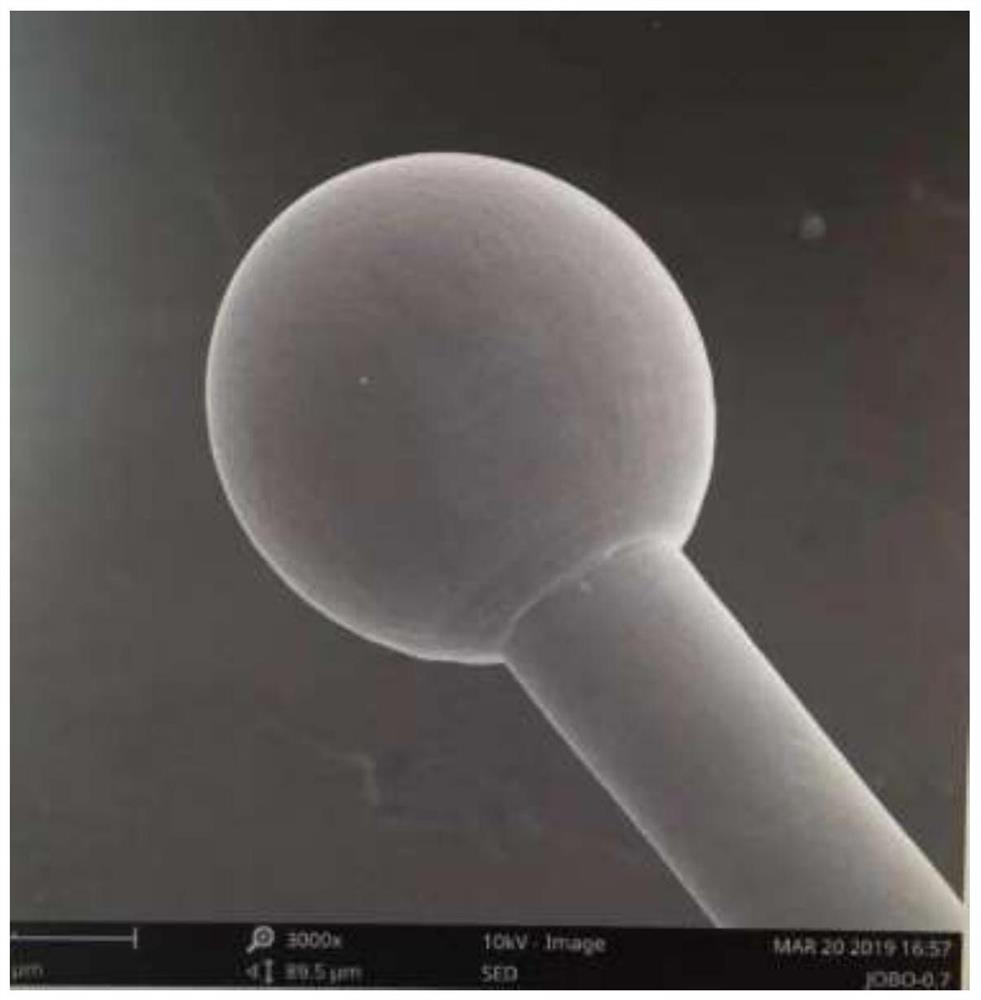

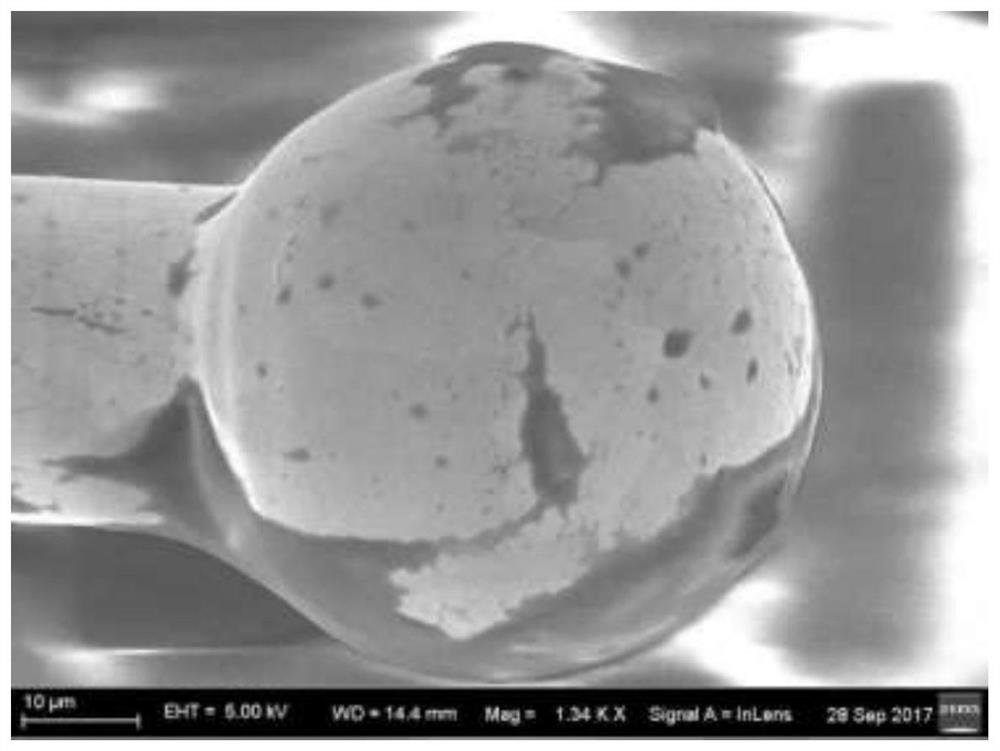

A kind of bonding silver wire material with high spheroidity and preparation method thereof

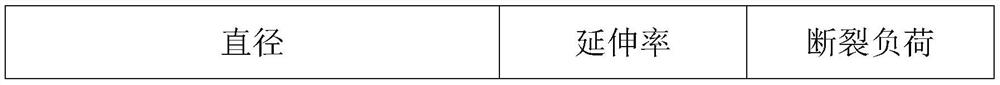

A ball forming and silver wire technology, which is applied in semiconductor/solid-state device manufacturing, circuits, electric solid-state devices, etc., can solve the problem of affecting the stability and work efficiency of components used, increasing production costs and use costs, and insufficient mechanical properties, etc. problems, to achieve the effect of improving chemical stability and mechanical properties, excellent ball forming, excellent elongation and breaking load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of preparation method of bonding silver wire material with high spheroidity:

[0032] 1) Pretreatment: Grind each metal substance into powder and sieve, then preheat to 50-60°C for vacuum drying, and use carbon monoxide to deoxidize the metal substance;

[0033] 2) Preparation of silver-nickel-calcium melt: take metallic silver 20% ± 0.2%, nickel 0.4% ± 0.04% and calcium 0.01% ± 0.001%, mix them into a silicon nitride crucible, adopt vacuum melting, and the vacuum pressure is 10 -2 ~10 -4 Pa, the initial melting temperature is raised to 780-810°C and maintained for 10-30 minutes, then raised to 900-950°C and maintained for 10-50 minutes, then raised to 1300-1400°C and maintained for 20-60 minutes, the whole process The heating rate is 110-350°C / h, and the silver-nickel-calcium melt is obtained after melting;

[0034] 3) Preparation of silver palladium lanthanum melt: take metallic silver 20% ± 0.2%, palladium 0.03% ± 0.004% and lanthanum 0.01% ± 0.001%, mix the...

Embodiment 2

[0041] A kind of preparation method of bonding silver wire material with high spheroidity:

[0042] 1) Pretreatment: Grind each metal substance into powder and sieve, then preheat to 50-60°C for vacuum drying, and use activated carbon to deoxidize the metal substance;

[0043] 2) Preparation of silver-nickel-calcium melt: take metallic silver 20% ± 0.2%, nickel 0.4% ± 0.04% and calcium 0.01% ± 0.001%, mix them into a silicon carbide crucible, adopt vacuum melting, and the vacuum pressure is 10 -2 ~10 -4 Pa, the initial melting temperature is raised to 780-810°C and maintained for 10-30 minutes, then raised to 900-950°C and maintained for 10-50 minutes, then raised to 1300-1400°C and maintained for 20-60 minutes, the whole process The heating rate is 110-350°C / h, and the silver-nickel-calcium melt is obtained after melting;

[0044] 3) Preparation of silver-palladium-lanthanum melt: take metallic silver 20% ± 0.2%, palladium 0.03% ± 0.004% and lanthanum 0.01% ± 0.001%, mix th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com