Magnetic whole-cell catalyst, preparation method and method for producing biodiesel

A whole-cell catalyst and biodiesel technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of difficult removal of by-products, difficult recovery of esterification products, and unimmobilized cells, etc., to achieve improved Effects of spheroidization and stability, improvement of recyclability, and improvement of catalytic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

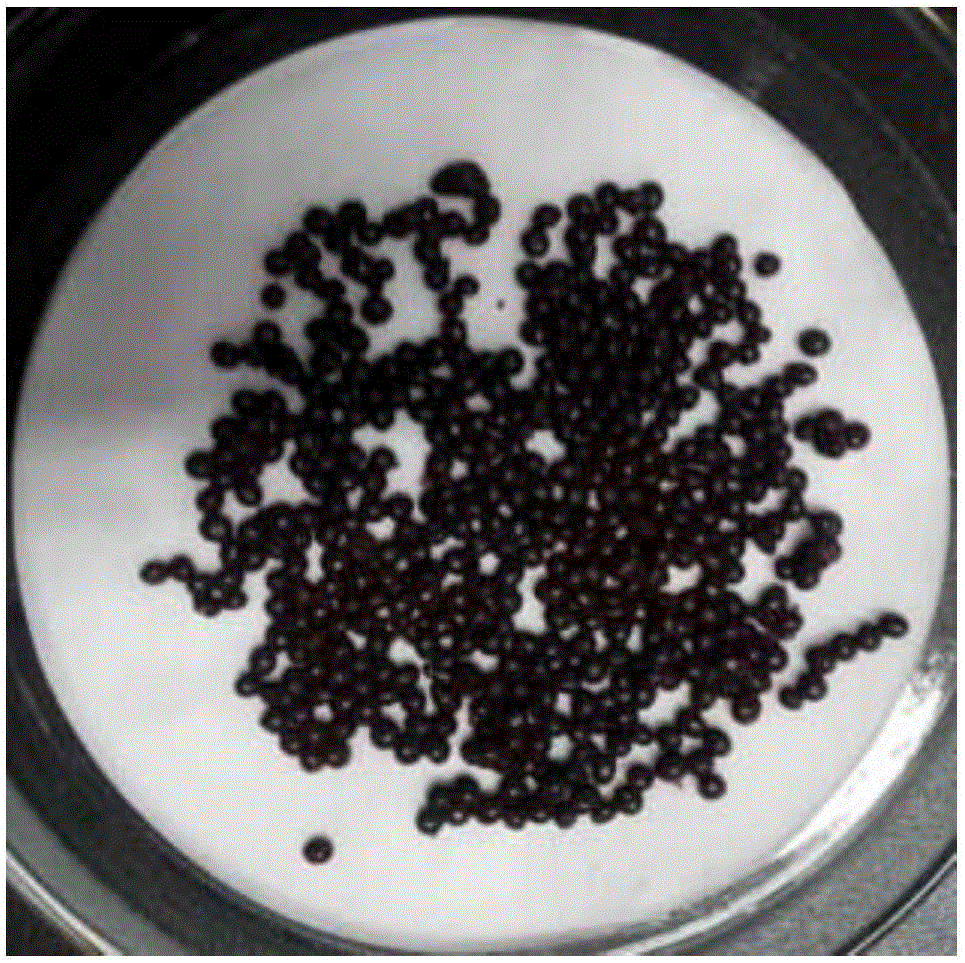

Image

Examples

Embodiment 1

[0031] A method for preparing a magnetic whole-cell catalyst, comprising the steps of:

[0032] (1) Inoculate Pseudomonas mendocina (hereinafter referred to as Pseudomonas mendocina) with the preservation number of CGMCCNo.7644 into 100mLLB medium, cultivate it at 35°C and 160r / min for 20h, and then cultivate it at 9000r / min Centrifuge for 12 minutes, discard the supernatant, and collect Pseudomonas mendoza cells;

[0033] (2) Proportionally, take 1gSiO 2 -Fe 3 o 4 The nanoparticles are added to 70mL of 3% sodium alginate solution by mass percentage, stirred evenly, and then the bacterial cells obtained in step (1) are added, and the mixed solution is obtained after mixing; the solvent of the sodium alginate solution is 1M Sodium hydroxide aqueous solution;

[0034] (3) The mixed solution obtained in step (2) is dripped dropwise into 150 mL of 1.5 mol / L sterile CaCl under stirring conditions with a syringe with an inner diameter of 1.36 mm. 2 In the aqueous solution, the ...

Embodiment 2

[0036] A method for preparing a magnetic whole-cell catalyst, comprising the steps of:

[0037] (1) Inoculate Pseudomonas mendoza into 125mL LB medium, culture at 30°C and 150r / min for 24h, centrifuge at 7000r / min for 15min, discard the supernatant, and collect Pseudomonas mendoza cells;

[0038] (2) Proportionally, take 0.5gSiO2 -Fe 3 o 4 Add nanoparticles into 50mL of 2.5% sodium alginate solution by mass percentage, stir evenly, then add the bacterial cells obtained in step (1), and mix to obtain a mixed solution; the solvent of the sodium alginate solution is 0.5% M sodium hydroxide aqueous solution;

[0039] (3) The internal diameter of the dropper that the mixed solution that step (2) obtains is 1.19mm is dripped dropwise into 180mL1mol / L sterile CaCl under stirring condition 2 In the aqueous solution, the stirring rate is 200r / min. After the dropwise addition of the mixed solution is completed, let it stand for 3 hours, suck out the magnetic microspheres with a magne...

Embodiment 3

[0043] A method for preparing a magnetic whole-cell catalyst, comprising the steps of:

[0044] (1) Inoculate Pseudomonas mendoza into 150mL LB medium, culture at 28°C and 140r / min for 30h, centrifuge at 10000r / min for 10min, discard the supernatant, and collect Pseudomonas mendoza cells;

[0045] (2) Proportionally, take 1.5gSiO 2 -Fe 3 o 4 Add nanoparticles into 100mL of 3.5% sodium alginate solution by mass, stir evenly, then add the bacterial cells obtained in step (1), and mix to obtain a mixed solution; the solvent of the sodium alginate solution is 1.5% M sodium hydroxide aqueous solution;

[0046] (3) The mixed solution obtained in step (2) is dripped dropwise into 200mL2mol / L sterile CaCl under stirring conditions with a syringe with an inner diameter of 1.54mm. 2 In the aqueous solution, the rate of stirring is 400r / min. After the dropwise addition of the mixed solution is completed, let it stand for 1.5h, suck out the magnetic microspheres with a magnet, and was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com