Reinforced concrete internal curing high-water-absorption microsphere material and preparation method thereof

A technology of internal and high water absorption in concrete, applied in the field of building materials, can solve the problems of concrete strength decline, achieve the effects of reducing porosity, increasing liquid absorption rate, and promoting early hydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The present embodiment provides a kind of reinforced concrete interior maintenance superabsorbent microsphere material, and in parts by weight, comprises following raw material to make: 8% nano-silica, 20% chitosan, 30% pentadiene Aldehyde, 5% gum arabic, 25% methacrylic acid, 3.3% glacial acetic acid, 0.5% cumene hydroperoxide, 0.2% ferrous chloride, 8% sodium ethoxide.

[0042] The preparation method of the reinforced concrete internal maintenance superabsorbent microsphere material of the present embodiment, the method specifically includes the following steps:

[0043]Step 1, taking each raw material by formula weight;

[0044] Step 2, dispersing the nano-silica in water, configuring it into a nano-silica suspension with a mass concentration of 3%, and stirring;

[0045] In step 2, the stirring adopts magnetic stirring, and the stirring time is 20 min.

[0046] Step 3, diluting the glacial acetic acid with water into a dilute glacial acetic acid solution with a ma...

Embodiment 2

[0061] The present embodiment provides a kind of reinforced concrete internal maintenance superabsorbent microsphere material, in parts by weight, comprising the following raw materials: 9% nano silicon dioxide, 18% chitosan, 25% pentadiene Aldehyde, 4.4% gum arabic, 30% methacrylic acid, 5% glacial acetic acid, 0.4% cumene hydroperoxide, 0.2% ferrous chloride, 8% sodium ethoxide.

[0062] The preparation method of the reinforced concrete inner-cured superabsorbent microsphere material in this embodiment is the same as the preparation method of the reinforced concrete inner-cured superabsorbent microsphere material in Example 1.

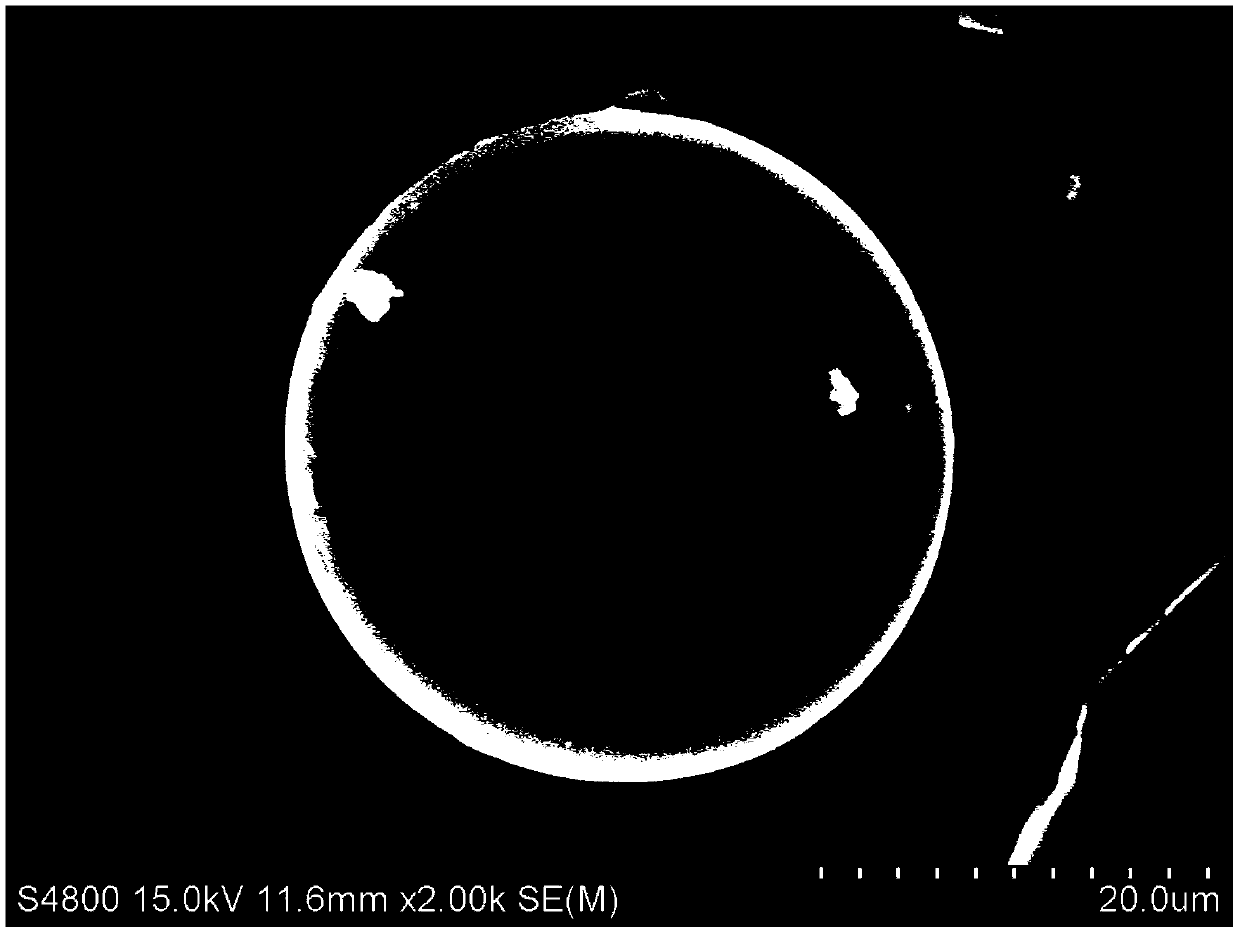

[0063] The SEM image of the reinforced concrete internal maintenance superabsorbent microsphere material obtained in this embodiment is as follows figure 1 shown. When in use, directly add the superabsorbent microspheres in the reinforced concrete together with cement to the mixing equipment for mixing, the dosage is 1.8% of the cement dosage, and t...

Embodiment 3

[0065] The present embodiment provides a kind of reinforced concrete internal maintenance superabsorbent microsphere material, and in parts by weight, comprises the following raw materials to make: 10% nano silicon dioxide, 19% chitosan, 28% pentadiene Aldehyde, 4% gum arabic, 27% methacrylic acid, 3.3% glacial acetic acid, 0.5% cumene hydroperoxide, 0.2% ferrous chloride, 8% sodium ethoxide.

[0066] The preparation method of the reinforced concrete inner-cured superabsorbent microsphere material in this embodiment is the same as the preparation method of the reinforced concrete inner-cured superabsorbent microsphere material in Example 1.

[0067] The SEM image of the reinforced concrete internal maintenance superabsorbent microsphere material obtained in this embodiment is as follows figure 1 shown. When in use, directly add the superabsorbent microspheres in the reinforced concrete together with cement to the mixing equipment for mixing, the dosage is 0.25% of the cement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com