High-strength recycled concrete and preparation method thereof

A recycled concrete, high-strength technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc. Reduced impact, reduced disposal costs, increased viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

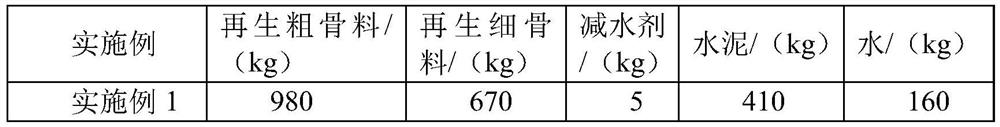

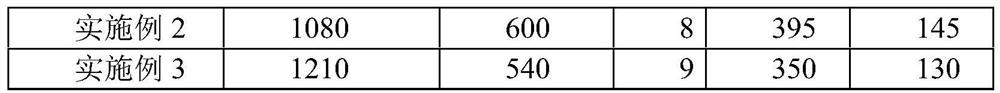

Examples

preparation example 1

[0050] Step 1: Sorting, crushing, and magnetically separating waste concrete to obtain waste concrete block a with a particle size of less than 40 mm;

[0051] Step 2: Stir-fry the waste concrete block a at 180°C for 24 hours, and then soak it in water at 25°C for 3 days, then stir continuously for 8 hours to obtain the waste concrete block b;

[0052] Repeat step 2 3 times until the particle size of the waste concrete block b is less than 25mm, to obtain the waste concrete block c;

[0053] Step 3: After raising the temperature of the waste concrete block c to 190°C, add molten styrene-butadiene rubber, stir until the waste concrete block c is covered with molten styrene-butadiene rubber, and then sprinkle cement so that the waste concrete blocks do not stick together, and obtain Abandoned concrete block d;

[0054] Step 4: Sieve the waste concrete block d, wherein the waste concrete block e whose particle size ranges from 5-20 mm and is continuously graded is recycled coars...

preparation example 2

[0056] Step 1: Sorting, crushing, and magnetically separating waste concrete to obtain waste concrete block a with a particle size of less than 40 mm;

[0057] Step 2: Stir-fry the waste concrete block a at 200°C for 22 hours, soak in water at 20°C for 3 days, and stir continuously for 10 hours to obtain the waste concrete block b;

[0058] Repeat step 2 3 times until the particle size of the waste concrete block b is less than 25mm, to obtain the waste concrete block c;

[0059] Step 3: After raising the temperature of the waste concrete block c to 180°C, add molten styrene-butadiene rubber, stir until the waste concrete block c is covered with molten styrene-butadiene rubber, and then sprinkle cement so that the waste concrete blocks do not stick together, and obtain Abandoned concrete block d;

[0060] Step 4: Sieve the waste concrete block d, wherein the waste concrete block e with a particle size range of 5-20 mm and continuous gradation is recycled coarse aggregate, wit...

preparation example 3

[0062] Step 1: Sorting, crushing, and magnetically separating waste concrete to obtain waste concrete block a with a particle size of less than 40 mm;

[0063] Step 2: Stir the waste concrete block a at a temperature of 210°C for 18 hours, put it into water at 22°C for 4 days, and stir continuously for 12 hours to obtain the waste concrete block b;

[0064] Repeat step two 2 times until the particle size of the waste concrete block b is less than 25mm to obtain the waste concrete block c;

[0065] Step 3: After raising the temperature of the waste concrete block c to 150°C, add molten styrene-butadiene rubber, stir until the waste concrete block c is covered with molten styrene-butadiene rubber, and then sprinkle cement so that the waste concrete blocks do not stick together, and obtain Abandoned concrete block d;

[0066] Step 4: Sieve the waste concrete block d, wherein the waste concrete block e whose particle size ranges from 5-20mm and is continuously graded is recycled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com