Preparing method for steel component wax solvent

A technology for dewaxing water and parts, which is applied in the field of preparation of iron and steel parts dewaxing water, can solve the problems of single wax dewaxing function and corrosion of wax dewaxing water, and achieves the improvement of wax removal effect, rust prevention ability and surface property improvement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

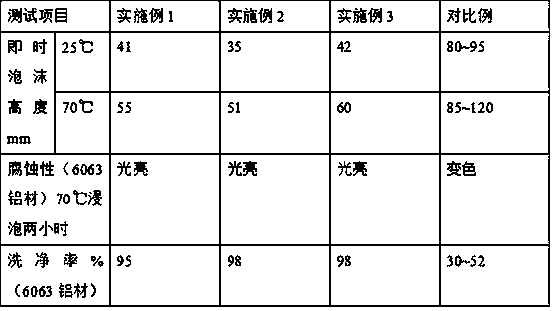

Examples

preparation example Construction

[0017] A preparation method of wax removal water for iron and steel parts, the preparation method comprises the steps of:

[0018] (1) Crush the rapeseed meal and pass through a 50-60 mesh sieve to obtain the sieved product. According to the mass ratio of 1:7-8, mix the sieved product and 0.8mol / L acetic acid solution, stir evenly, and then place In a constant temperature oscillator, the rotation speed is 180~200 r / min, and the vibration extraction is performed at a temperature of 70~80°C for 1~2h to obtain an extract, and the extract is centrifuged at 5000~6000r / min for 8~10min , to obtain the supernatant, crush the pomelo peel to obtain the crushed product, mix water, hydrochloric acid, and the crushed product at a mass ratio of 10~15:10~15:1, and heat and reflux at a temperature of 70~80°C for 1~ 2h, after cooling, filter to obtain a filtrate, and concentrate the filtrate to obtain a concentrate;

[0019] (2) In parts by weight, take 70~80 parts of water, 2~3 parts of sodi...

Embodiment 1

[0022] The additive is boric acid.

[0023] The emulsifier is alkylphenol ethoxylate.

[0024] A preparation method of wax removal water for iron and steel parts, the preparation method comprises the steps of:

[0025] (1) Crush the rapeseed meal and pass through a 50-mesh sieve to obtain the sieved product. According to the mass ratio of 1:7, mix the sieved product and 0.8mol / L acetic acid solution, stir evenly, and then place it in a constant temperature oscillator In the medium, the rotation speed is 180r / min, and the vibration extraction is carried out at a temperature of 70°C for 1h to obtain the extract solution, which is centrifuged at 5000r / min for 8min to obtain the supernatant, and the pomelo peel is crushed to obtain the crushed product , according to the mass ratio of 10:10:1, mix water, hydrochloric acid, and pulverized matter, heat and reflux at a temperature of 70° C. for 1 hour, filter after cooling to obtain a filtrate, and concentrate the filtrate to obtain ...

Embodiment 2

[0029] The additive is borax.

[0030] The emulsifier is alkylphenol ethoxylate.

[0031] A preparation method of wax removal water for iron and steel parts, the preparation method comprises the steps of:

[0032] (1) Crush the rapeseed meal and pass through a 60-mesh sieve to obtain the sieved product. According to the mass ratio of 1:8, mix the sieved product and 0.8mol / L acetic acid solution, stir evenly, and then place it in a constant temperature oscillator In the medium, the rotation speed is 200r / min, and the vibration extraction is carried out at a temperature of 80°C for 2h to obtain the extract solution, which is centrifuged at 6000r / min for 10min to obtain the supernatant, and the grapefruit peel is crushed to obtain the crushed product , according to the mass ratio of 15:15:1, mix water, hydrochloric acid, and pulverized matter, heat and reflux at a temperature of 80° C. for 2 hours, filter after cooling to obtain a filtrate, and concentrate the filtrate to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com