Movable scraper optimum control for cleaning balling pan bottom

An optimized control and pelletizing disk technology, which is applied in the direction of granulation in the rotating disk/pan, can solve the problems of low output of a single disk pelletizing machine, unclean and thorough cleaning of the bottom of the disk, and unreasonable partitioning of large and small raw pellets. Achieve the effect of improving the operation rate of the ball disc, improving the ball forming rate and reasonable distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Below in conjunction with accompanying drawing, the present invention will be further described:

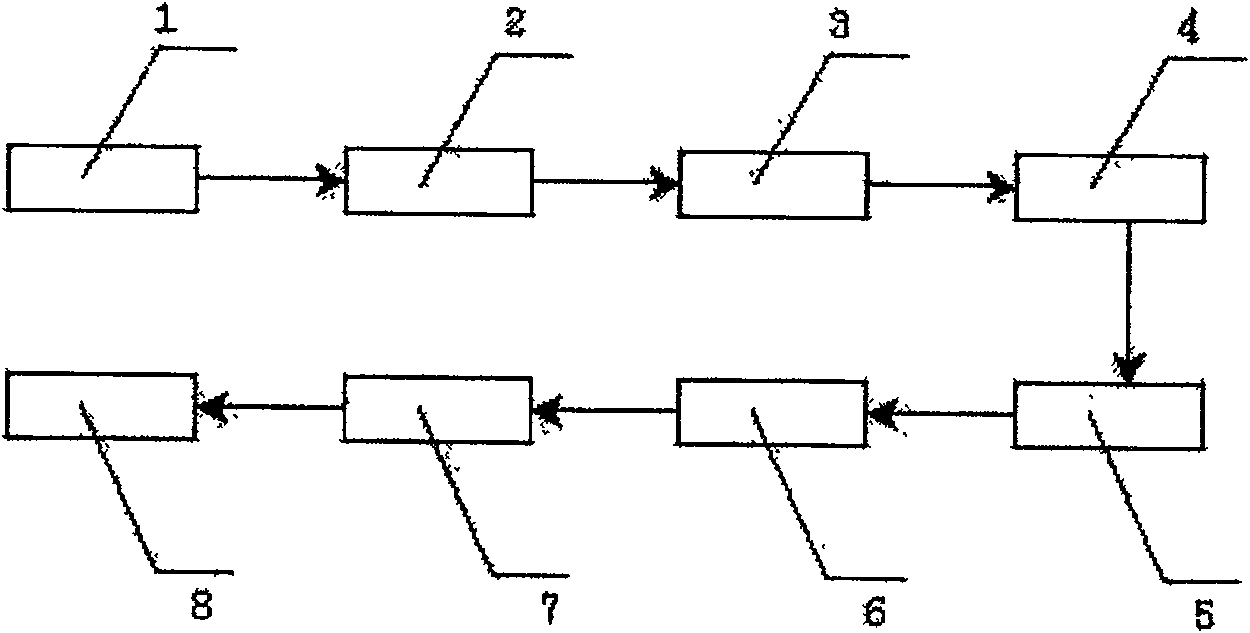

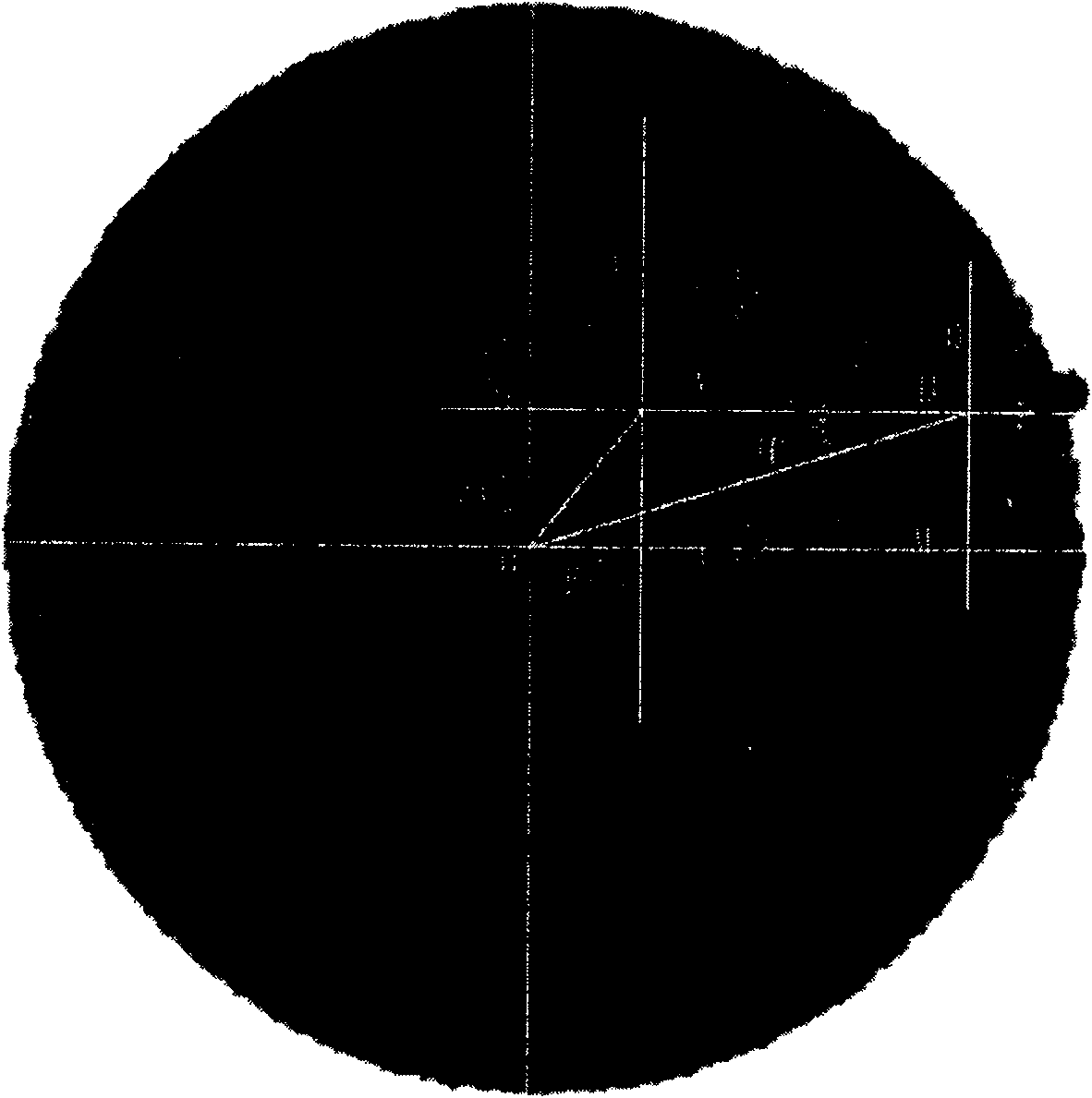

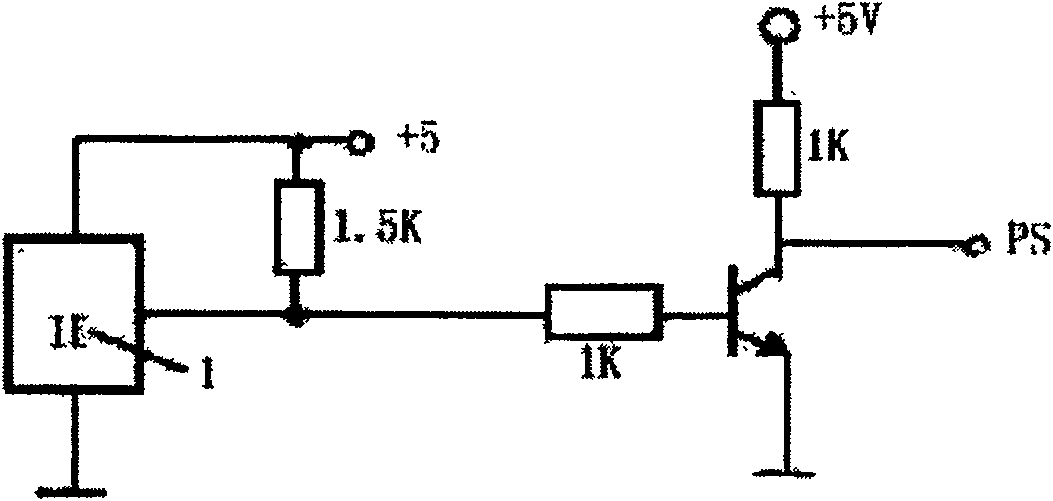

[0040] A kind of movable scraper optimization control for cleaning the bottom of the pelletizing disc, such as figure 2 As shown, the movable scraper is arranged above the disc pelletizer and consists of 2 movable scrapers, and each movable scraper has 7 movable scrapers. In this embodiment, the Hall integrated sensor [1] is installed on the disc pelletizing machine to be optimally controlled, the Hall integrated sensor [1] is connected to the pulse signal amplifier [2], and the pulse signal amplifier [2] is connected to the counter [3] connect. According to the angular velocity ω of the disc pelletizing machine displayed by the counter [3], a mathematical model of the trajectory curve of each active scraper tool is established, and then a mathematical model of the trajectory curve density and a coverage index mathematical model of each active scraper tool are establishe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com