Preparation method of carbon-containing micro-electrolysis material

An electrolytic material and micro-electrolysis technology, applied in the field of micro-electrolytic material preparation, can solve the problems of low added value of reduction products, shortened process flow, low product quality, etc., to improve comprehensive utilization effect, benefit the environment, and large specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

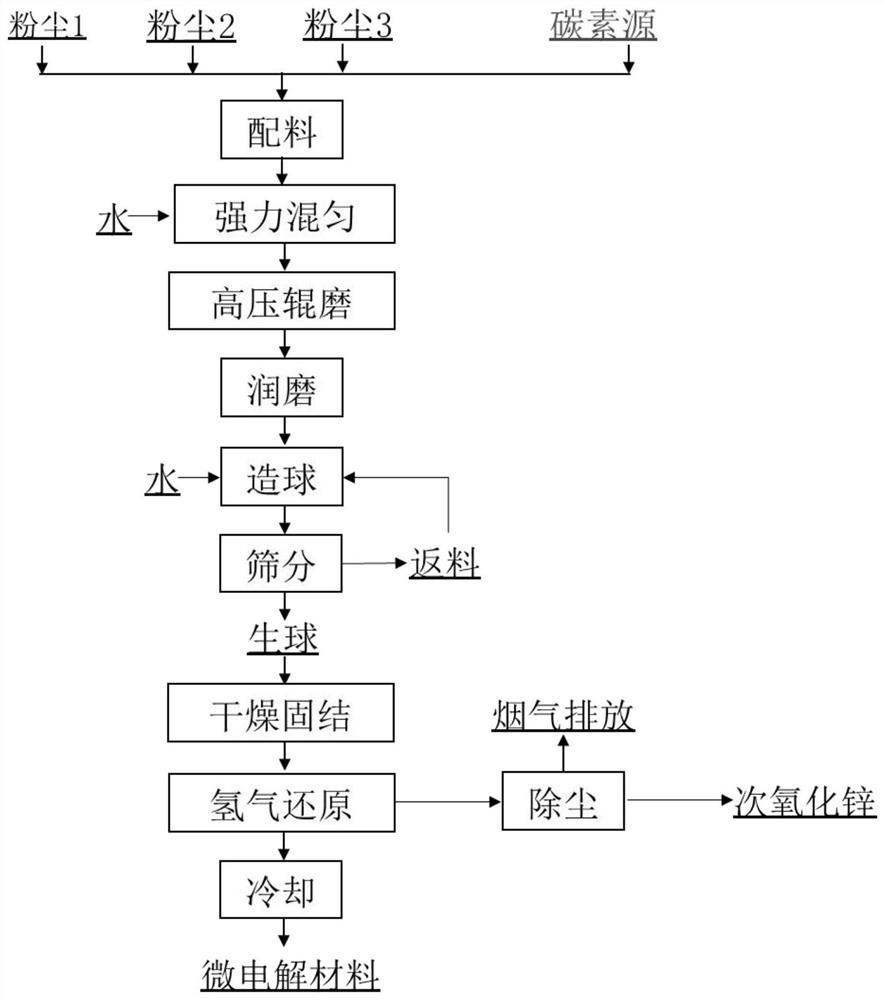

[0042] The invention provides a preparation method of carbon-containing micro-electrolytic material, comprising the following steps:

[0043] (1) Mix blast furnace dust, electric furnace dust, steel-making converter dust, graphite and 0.5% composite binder (35% of bentonite, 35% of sodium humate and 30% of polyacrylamide) , so that the iron-carbon mass ratio is controlled to 5:1;

[0044] (2) vigorously stirring the obtained mixed material, the stirring speed is 1500rpm, and the stirring time is 3min; then, the high-pressure roller mill is successively carried out, and the high-pressure roller mill has a moisture content of 7% and a roller mill pressure of 1.0N / mm 2 , the grinding time is 2min;

[0045] (3) Add the pretreated material to the disc pelletizing machine for pelletizing, the pelletizing time is 11 minutes, the moisture content of the green pellet is controlled at about 12.5%, and the particle size of the green pellet is controlled at 16-20 mm; the drop strength of...

Embodiment 2

[0050] The invention provides a preparation method of carbon-containing micro-electrolytic material, comprising the following steps:

[0051] (1) Mix blast furnace dust, electric furnace dust, steel-making converter dust, graphite and 1.0% composite binder (35% of bentonite, 35% of sodium humate and 30% of polyacrylamide) , so that the iron-carbon mass ratio is controlled to be 10:1;

[0052] (2) vigorously stirring the obtained mixed material, the stirring speed is 1500rpm, and the stirring time is 3min; then, the high-pressure roller mill is successively carried out, and the high-pressure roller mill moisture is 7.5%, and the roller mill pressure is 1.0N / mm 2 , the grinding time is 3min;

[0053] (3) Add the pretreated material to the disc pelletizing machine for pelletizing, the pelletizing time is 12min, the moisture content of the green pellet is controlled at about 12.5%, and the particle size of the green pellet is controlled at 16-20 mm; the drop strength of the prepa...

Embodiment 3

[0058] The invention provides a preparation method of carbon-containing micro-electrolytic material, comprising the following steps:

[0059] (1) Mix blast furnace dust, electric furnace dust, steel-making converter dust, graphite and 1.5% composite binder (35% of bentonite, 35% of sodium humate and 30% of polyacrylamide) , so that the iron-carbon mass ratio is controlled to be 15:1;

[0060] (2) vigorously stirring the obtained mixed material, the stirring speed is 2000rpm, and the stirring time is 3min; then, high-pressure roller milling is performed successively, and the high-pressure roller milling moisture is 7.5%, and the roller grinding pressure is 1.0N / mm 2 , the grinding time is 3min;

[0061] (3) Add the pretreated material to the disc pelletizing machine for pelletizing, the pelletizing time is 12min, the moisture content of the green pellet is controlled at about 12.5%, and the particle size of the green pellet is controlled at 16-20 mm; the drop strength of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| burst temperature | aaaaa | aaaaa |

| burst temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com