Magnetized water granulation process for sintering mixture based on electrostatic dispersion of powder fuel

A technology of sintering mixture and electrostatic dispersion, which is applied in the field of metallurgical energy saving and environmental protection, can solve the problems that the sticky material on the inner wall of the cylinder cannot be cleaned in real time, the stability of the mixing and granulation process system is poor, and the gas resistance is increased, so as to optimize the utilization of heat gradient, Solve the problem of material bonding and improve the effect of uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

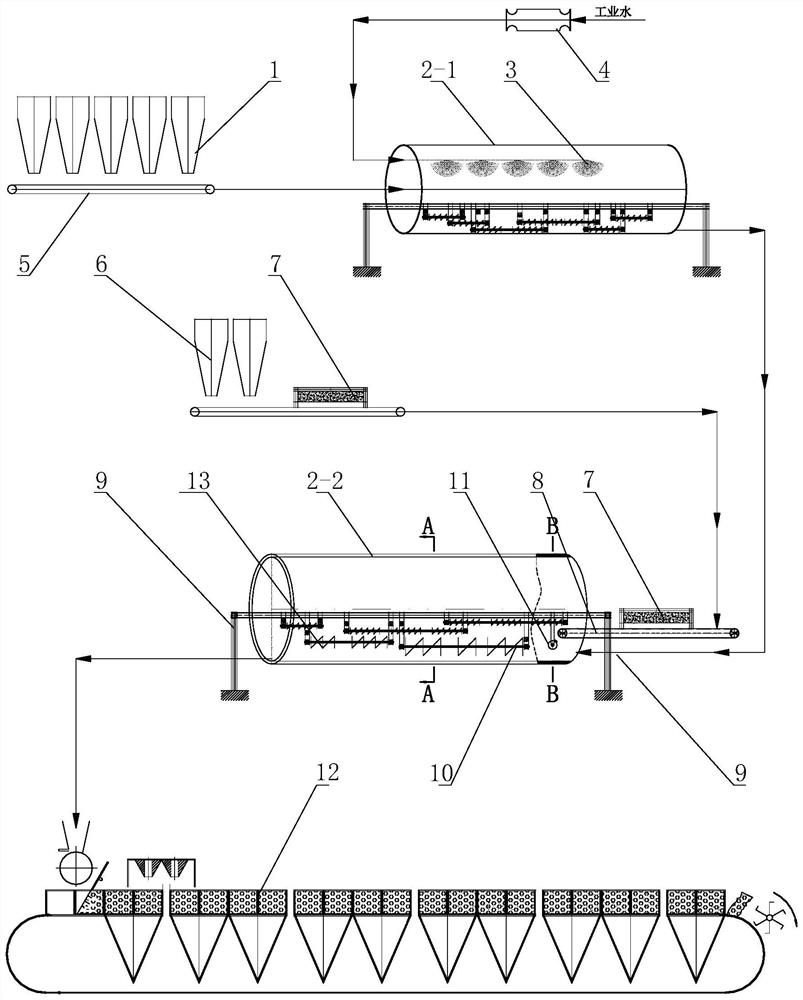

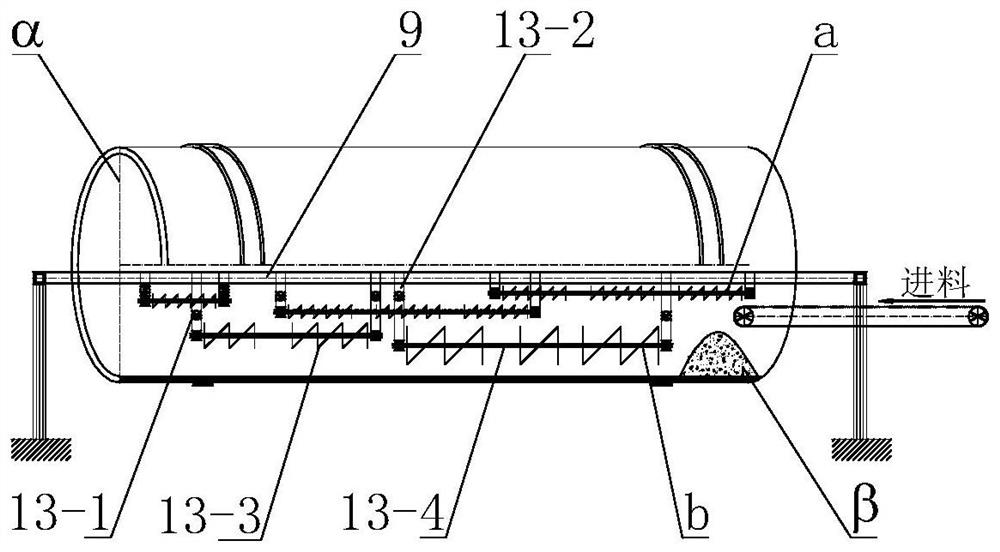

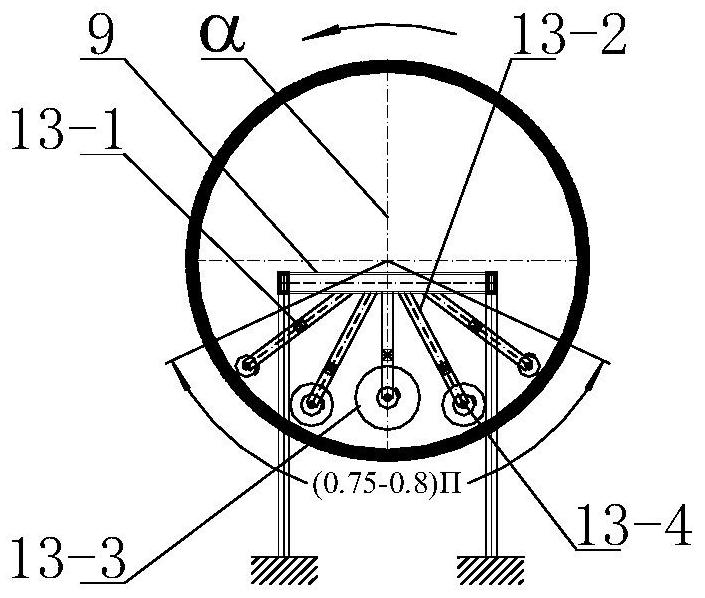

[0071] The following process of the present invention in conjunction with the accompanying drawings will be further explained:

[0072] as Figure 1 , in addition to solid fuel (such as coke powder or coal powder) all sintering raw materials (such as mineral powder and flux powder) into the primary mixer 2-1 for mixing granulation, while the industrial water by the industrial water magnetizer 4 treatment to form magnetized water through the pipeline into the primary mixer 2-1 in the nozzle 3 sprayed out to wet the sintered raw materials, using grading, sub-region to the primary mixer 2-1 into the magnetized water, specifically:

[0073]In the area of 10-20% of the length of the cylinder of the primary mixer inlet and 10-20% of the length of the discharge port, no water is added; in the β downstream of the blanking point and the distance from the blanking point is 10-20% of the length of the cylinder, the water spray begins, and 3 spray sections are set up in turn (magnetized wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com