Pelletizing raw material loosening and blanking device and method

A material distributing device and loose material technology, which is applied in the field of loose material distributing device for pelletizing raw materials, can solve the problems of not achieving uniform material distribution, not achieving the effect of loose material, complicated device manufacturing, etc., and achieve sufficient pelletizing time , improve the dispersion, reduce the load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

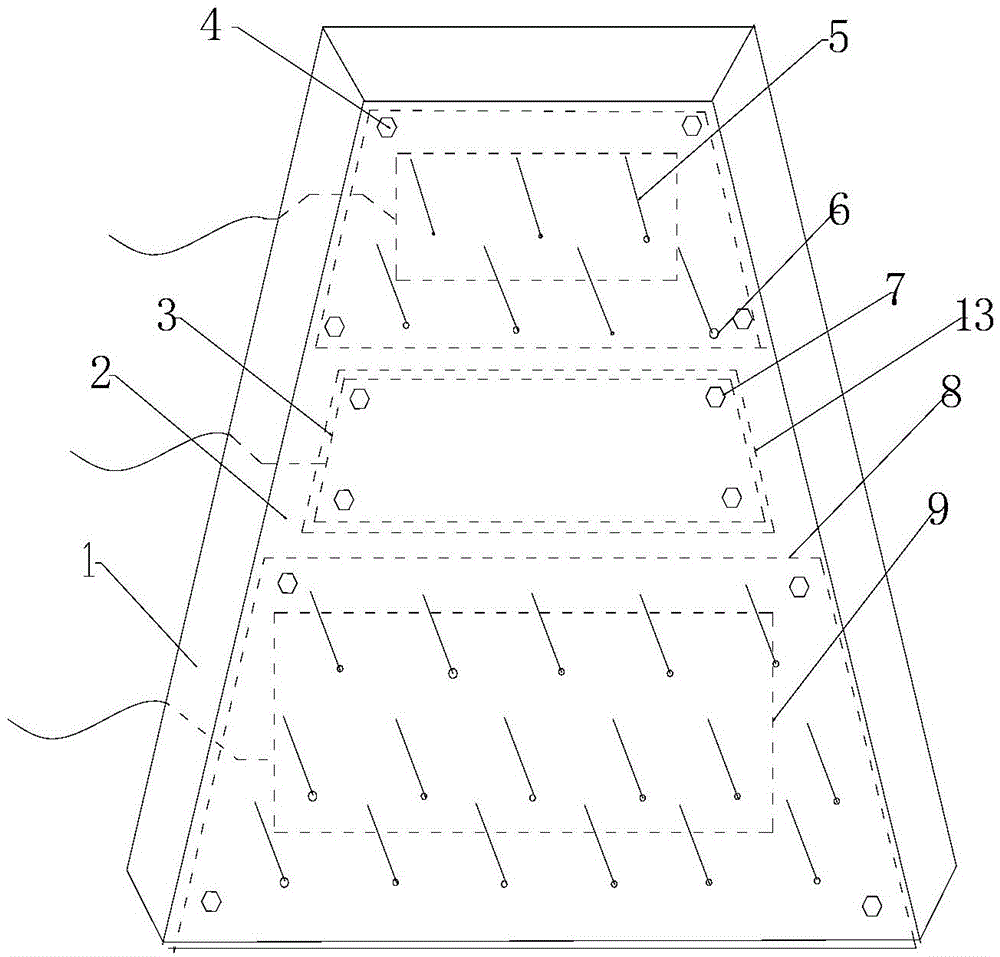

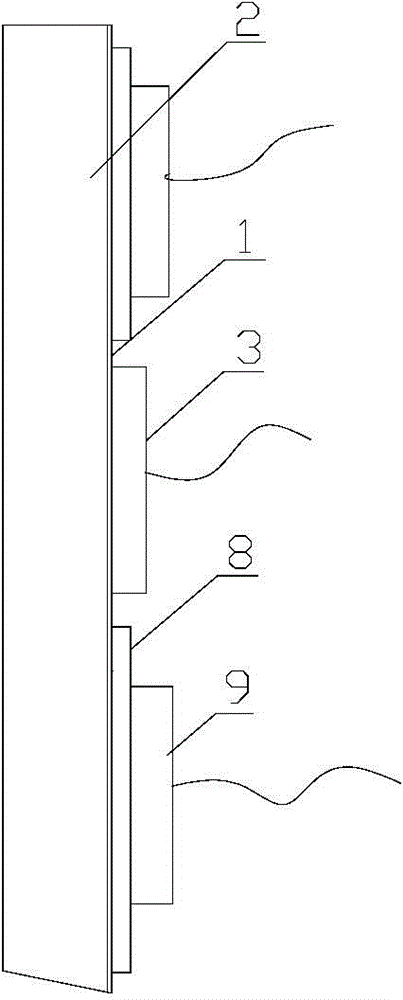

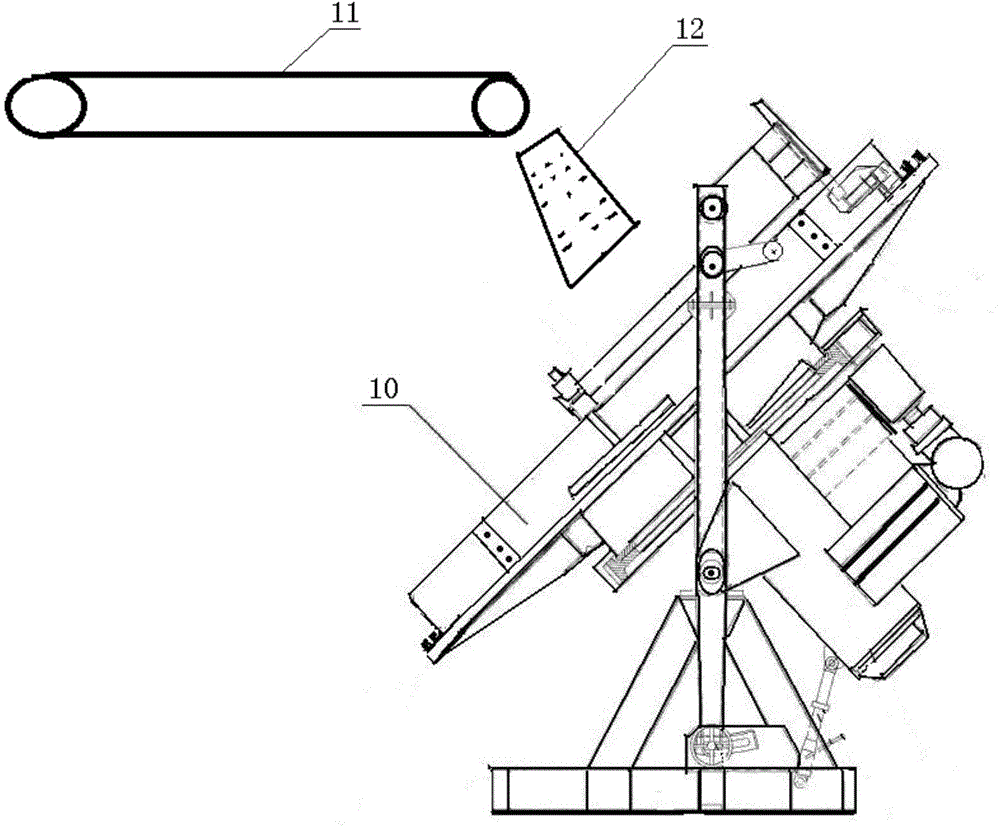

[0024] First, the bottom plate 2 of the loose material distributing device 12 is placed between the feed belt 11 and the disc pelletizer 10 with the narrow side on the top and the wide side on the bottom (see image 3 ), so that the angle between the upper surface of the bottom plate 2 and the horizontal plane of the feed belt 11 is 65°. After feeding, the pelletizing raw materials falling from the feeding belt 11 first fall on the bottom plate 2 of the loose material distributing device 12. Vibrate up and down at a vibration frequency of 40 times / min to loosen the pelletizing raw material on the bottom plate 2, and loosen the pelletizing raw material into mineral powder with uniform particle size. At the same time, the vibrating plate 3 vibrates continuously with an exciting force of 1900N and an amplitude of 1.5mm, and drives the bottom plate 2 to vibrate synchronously with it, so that the mineral powder dispersed on the bottom plate 2 is evenly distributed to the pelletizin...

Embodiment 2

[0026] First, the bottom plate 2 of the loose material distributing device 12 is placed between the feed belt 11 and the disc pelletizer 10 with the narrow side on the top and the wide side on the bottom (see image 3 ), so that the angle between the upper surface of the bottom plate 2 and the horizontal plane of the feed belt 11 is 70°. After feeding, the pelletizing raw materials falling from the feeding belt 11 first fall on the bottom plate 2 of the loose material distributing device 12. Vibrate up and down at a vibration frequency of 60 times / min to loosen the pelletizing raw material on the bottom plate 2, and loosen the pelletizing raw material into mineral powder with uniform particle size. At the same time, the vibration plate 3 vibrates continuously with an exciting force of 2500N and an amplitude of 2.5mm, and drives the bottom plate 2 to vibrate synchronously with it, so that the mineral powder dispersed on the bottom plate 2 is evenly distributed to the pelletizin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com