Large-diameter silicon crystal growth device

A growth device and silicon crystal technology, applied in the direction of crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of not reaching the comprehensive economic benefits of the enterprise, not being recognized and popularized by the market, and high operating and production costs. Facilitates growth, increases thermal insulation, improves the effect of airflow guides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

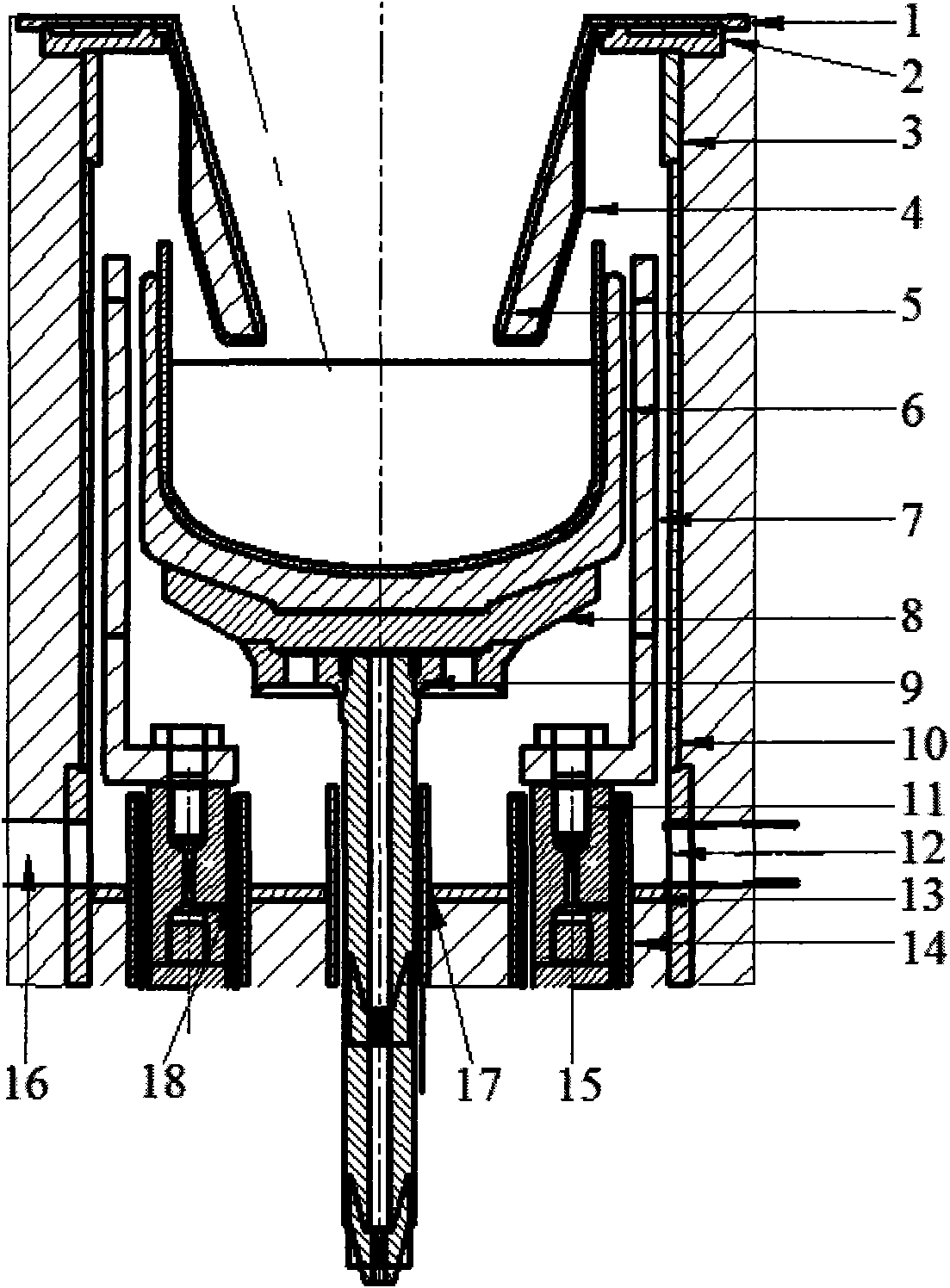

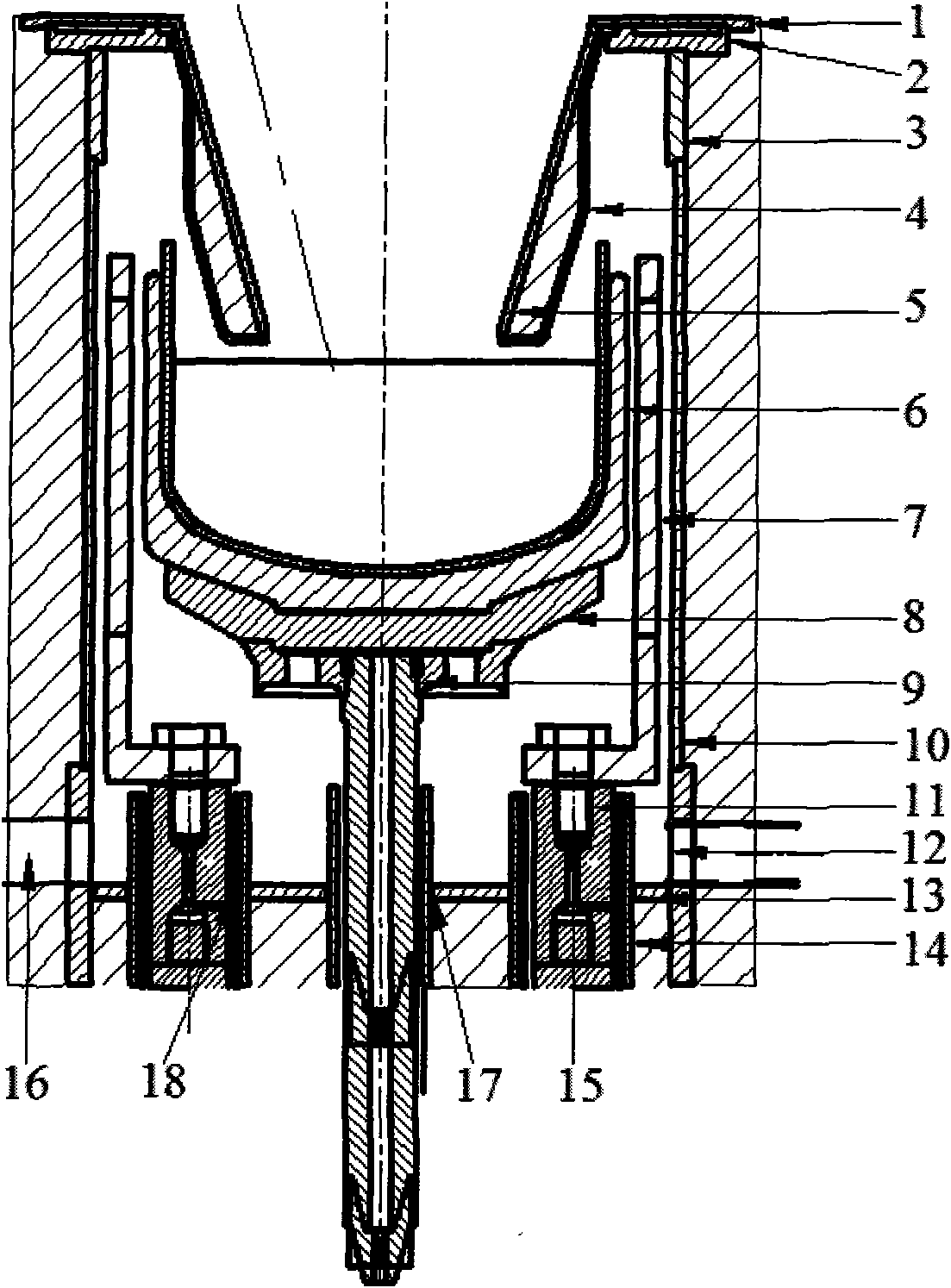

[0033] The furnace bottom insulation structure of the present invention includes a furnace bottom retaining ring 12 and a furnace bottom pressing sheet 13, and a graphite carbon felt is arranged under the furnace bottom retaining ring 12 and the furnace bottom pressing sheet 13.

[0034] The insulation of the furnace bottom adopts the measures of graphite carbon felt isolation, and the graphite carbon felt is filled under the furnace bottom retaining ring 12 and the furnace bottom pressing sheet 13 to increase the heat preservation of the lower part of the furnace body; increase the gap between the lower furnace body retaining ring and the briquetting block, Graphite carbon felt enhances the effect of heat preservation.

Embodiment 2

[0036] The air guide system of the present invention is provided with an air guide device, and the air guide device adopts a double-layer structure, that is, an outer guide tube 4 and an inner guide tube 5 .

[0037] The double-layer diversion structure is adopted to further improve the heat insulation effect.

Embodiment 3

[0039] Graphite carbon felt is filled between the outer guide tube 4 and the inner guide tube 5 of the present invention.

[0040] The gap between the inner and outer layers of the heat guide tube is increased, carbon felt is filled between the outer guide tube 4 and the inner guide tube 5, and the slope angle of the outer guide tube is changed to increase the heat radiation reflection effect of the guide tube and reduce heat dissipation .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com