Low NOx emission variable cross-section circulating fluidized bed staged combustion boiler system and method

A circulating fluidized bed and staged combustion technology, applied in fluidized bed combustion equipment, combustion methods, staged combustion, etc., can solve problems such as reducing carbon content, achieve high carbon conversion rate, facilitate carbon conversion rate, and low NOx The effect of the original discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation examples.

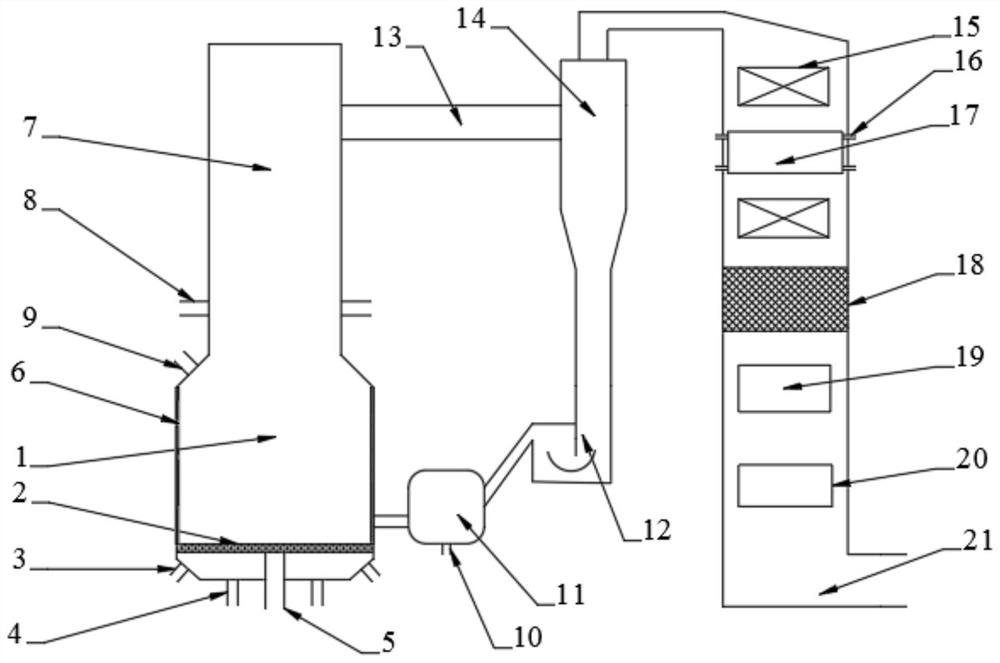

[0039] Such as figure 1 As shown, a low NOx emission variable cross-section circulating fluidized bed staged combustion boiler system of the present invention includes a fuel-rich combustion chamber 1, a fast fluidized combustion chamber 7, a fluidized bed activation chamber 11, a CO catalytic oxidation device 18 and a boiler Ontology other equipment.

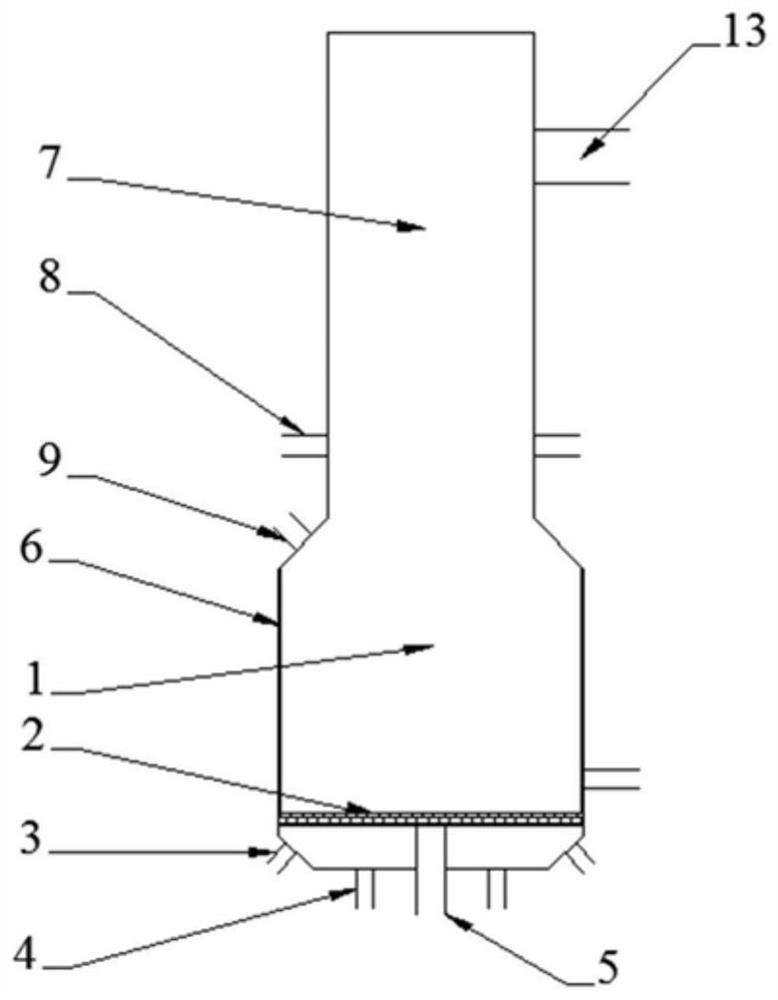

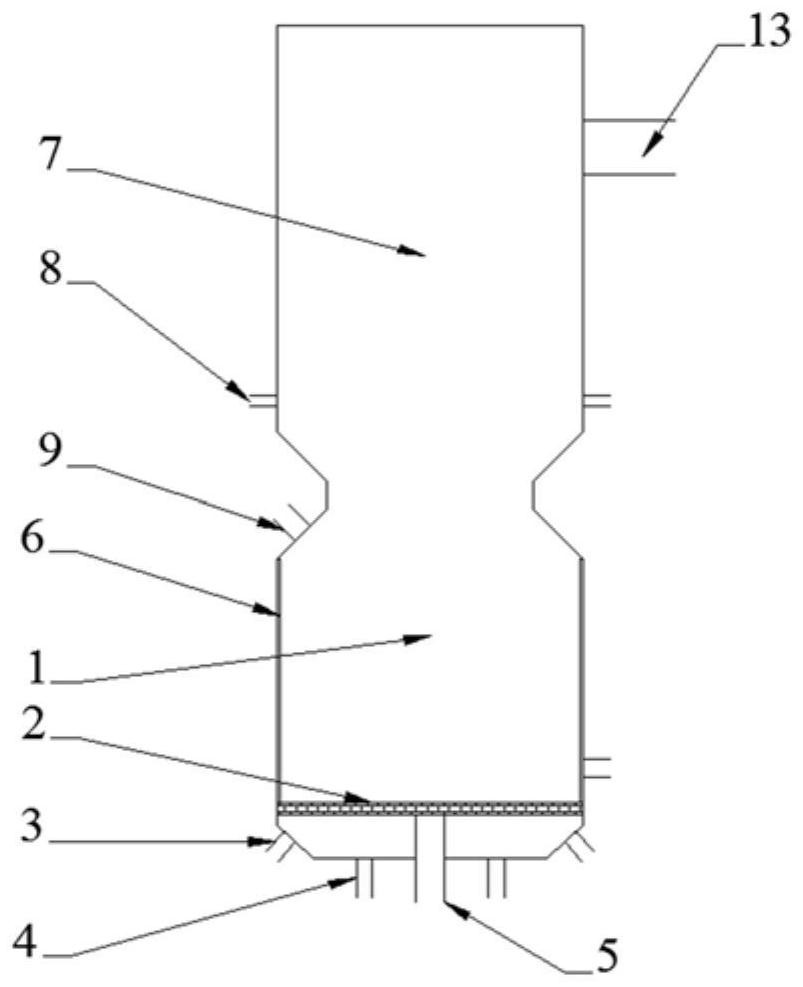

[0040] Such as figure 2 As shown, the variable-section furnace is divided into upper and lower parts. The lower furnace has a larger cross-sectional area and is a fuel-rich combustion chamber 1 ; the upper furnace has a smaller cross-sectional area and is a fast fluidization combustion chamber 7 . Other equipment of the boiler body also includes an adiabatic cyclone separator 14, a material return mechanism 12, a convection heating surface 15, a supplementary air combustion cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com