System and method for increasing drying capacity of medium-speed coal mill based on medium-temperature flue gas extraction

A coal mill and furnace smoke technology, which is applied in the field of thermal power generation, can solve the problems of large investment in low-temperature cold furnace smoke pipeline layout, increase in furnace smoke pressure head, and decrease in boiler efficiency, so as to achieve less influence of furnace negative pressure fluctuations and reduce raw material consumption. The effect of concentration of emission and renovation scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

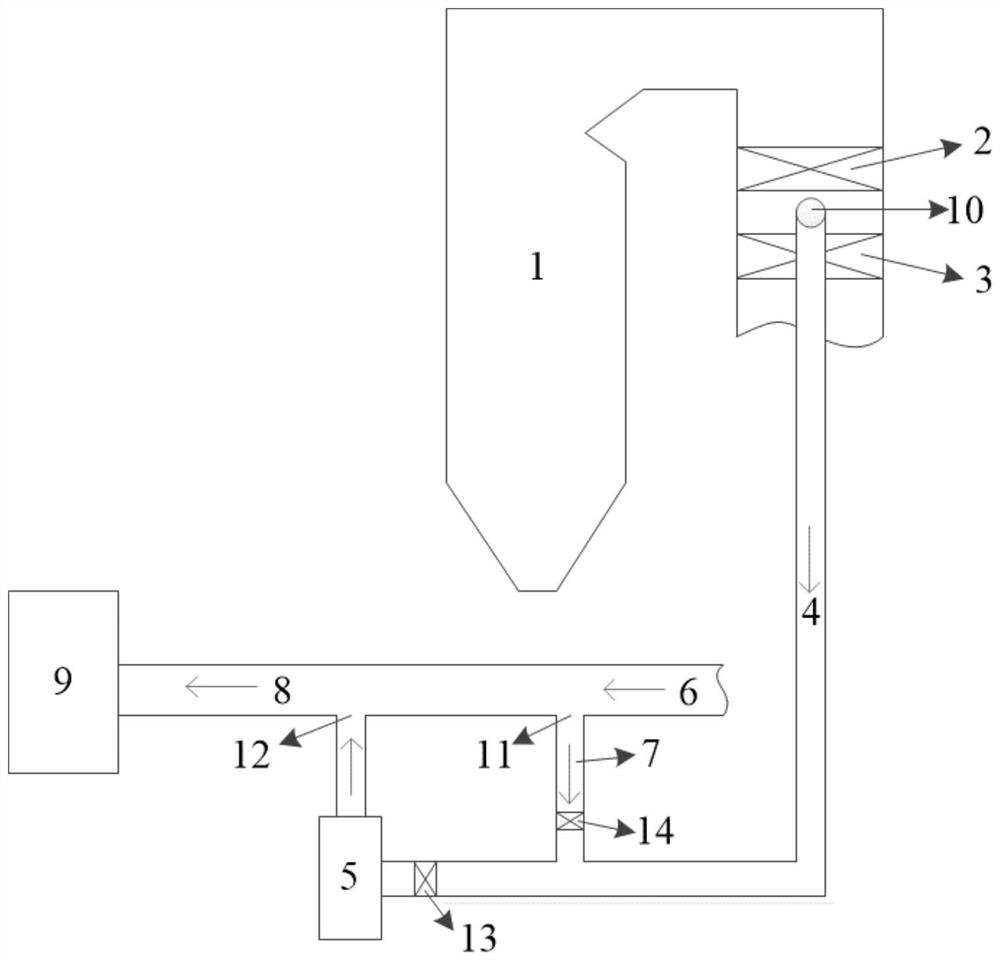

[0029] see figure 1 , a system provided by the present invention based on pumping medium-temperature furnace smoke to increase the drying output of medium-speed coal mills, mainly includes a pulverized coal boiler 1; a medium-temperature furnace smoke exhaust port 10; a flue gas bypass 4; a furnace smoke booster fan 5; Upstream hot primary air pipeline 6 ; hot primary air bypass pipeline 7 ; downstream hot primary air pipeline 8 .

[0030] When medium-temperature furnace fume is used to increase the drying output of medium-speed coal mills, through the flue gas bypass technology and the hot primary air bypass technology, the medium-temperature furnace fume at a suitable temperature is extracted from the outlet flue of the low-temperature superheater through the flue gas bypass , after the pressure head is raised by the furnace smoke booster fan, it is introd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com