Circulating fluidized bed boiler capable of realizing ultra-low emission of nitrogen oxide and SO2

A circulating fluidized bed, nitrogen oxide technology, applied in the field of coal-fired boilers, can solve the problem that nitrogen oxides and carbon dioxide indicators cannot be further reduced, and achieve the effect of increasing cross-sectional area, reducing original emissions, and ultra-low emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail below in conjunction with accompanying drawing:

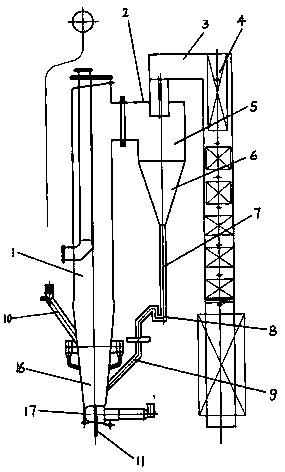

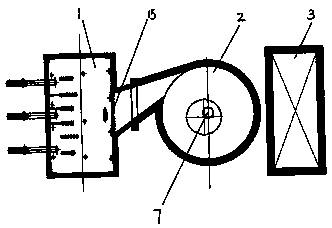

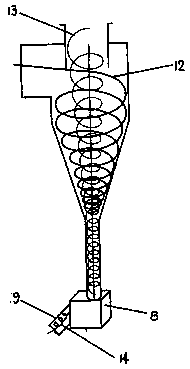

[0017] A circulating fluidized bed boiler that can realize ultra-low emissions of nitrogen oxides and SO2, including a furnace 1, a cyclone separator 2, and a tail shaft flue 3, the furnace 1 is a membrane water-cooled hearth, and in the tail shaft flue 3 A heating surface 4 is provided, and only one smoke outlet 15 is provided at the rear of the furnace 1, and a cyclone separator 2 is connected to the smoke outlet 15, and the cyclone separator 2 is composed of a cylindrical cylinder body 5 and a conical transition cylinder. The body 6, the return pipe 7 and the return box 8 are connected in sequence, and the return box 8 is connected with the lower section 9 of the return pipe, and the other end of the lower section 9 of the return pipe is connected with the bottom of the furnace 1, and the cyclone The separator 2 transports the high-temperature ash 12 with a particle size ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com