Counter current heat exchanging smoke-fire constant pressure boiler capable of saving energy and protecting environment

An energy-saving and environmentally friendly countercurrent heat exchange technology, which is applied to fluid heaters, water heaters, lighting and heating equipment, etc., to achieve the effects of reducing carbon emissions, reducing carbon emissions, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

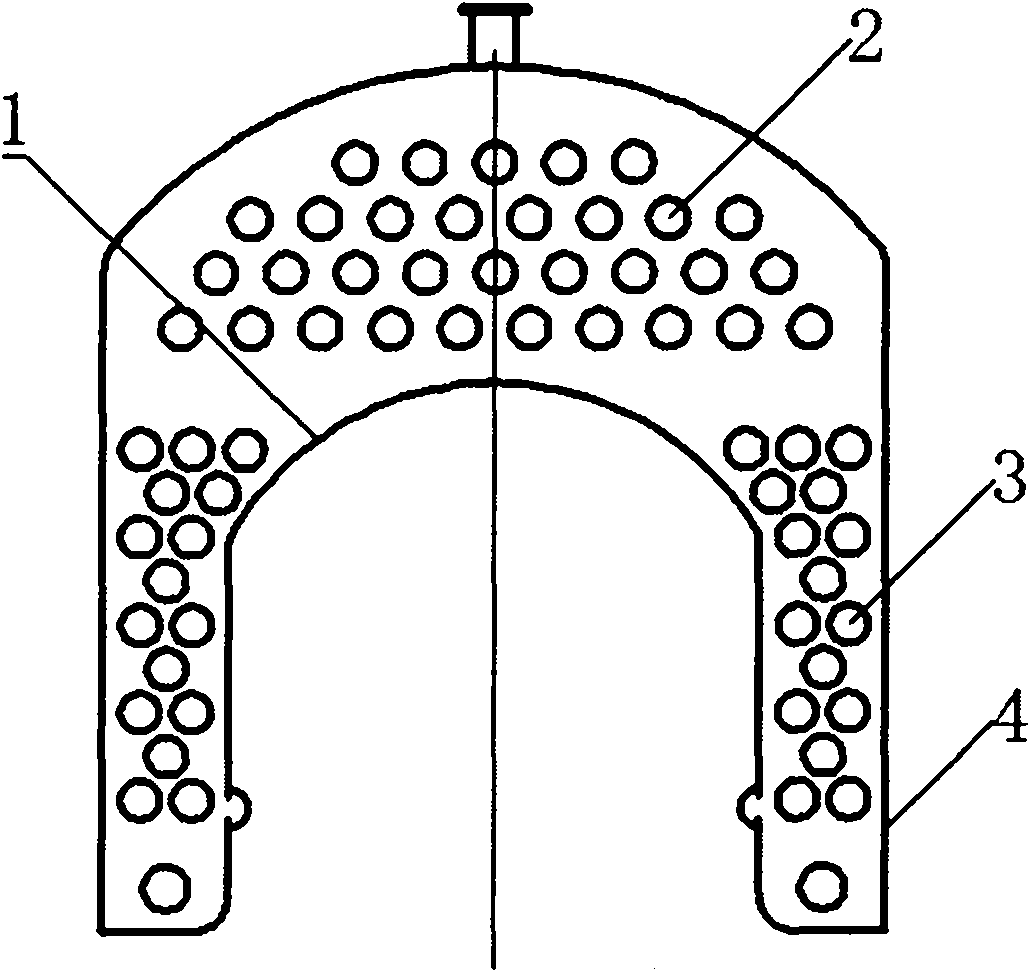

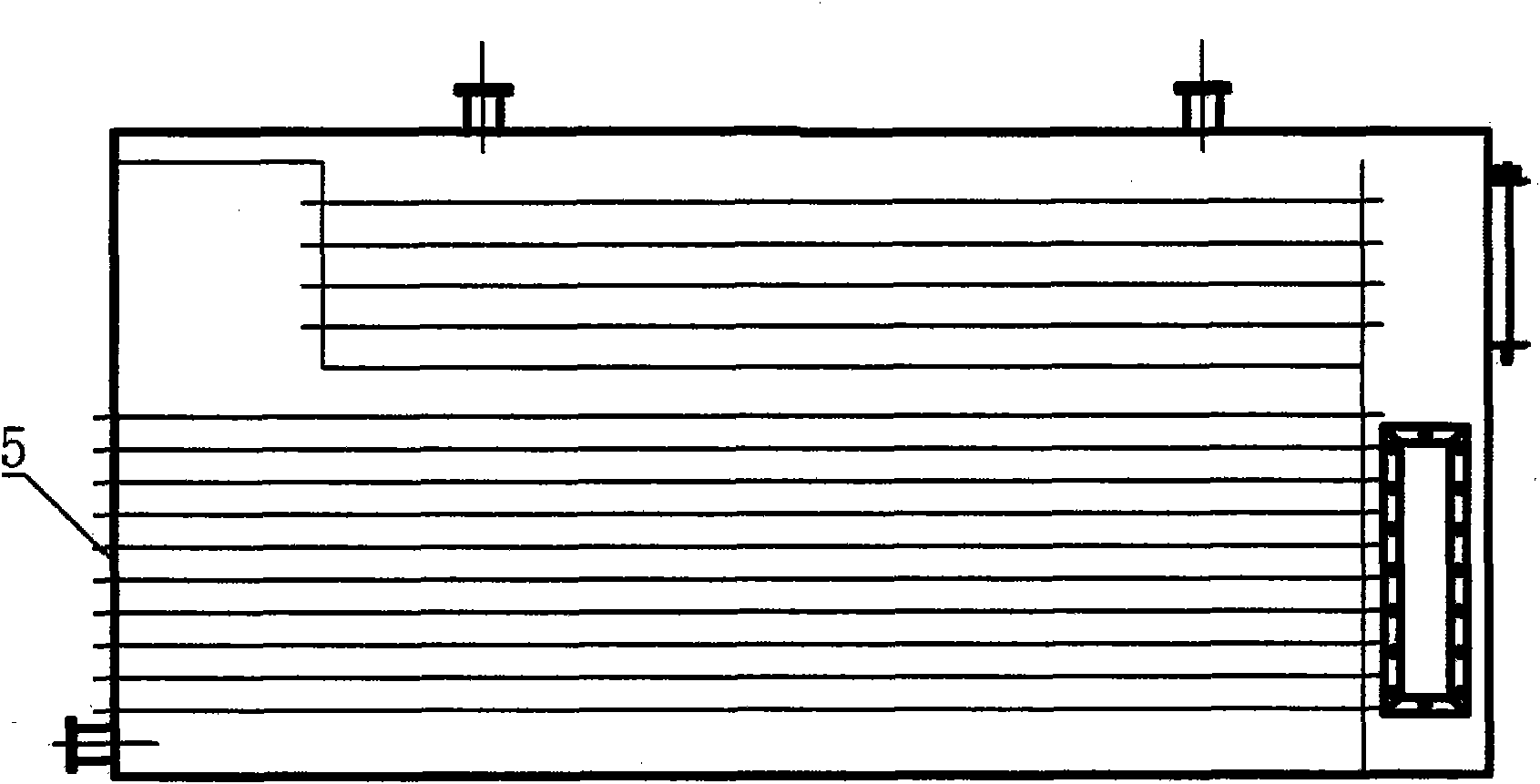

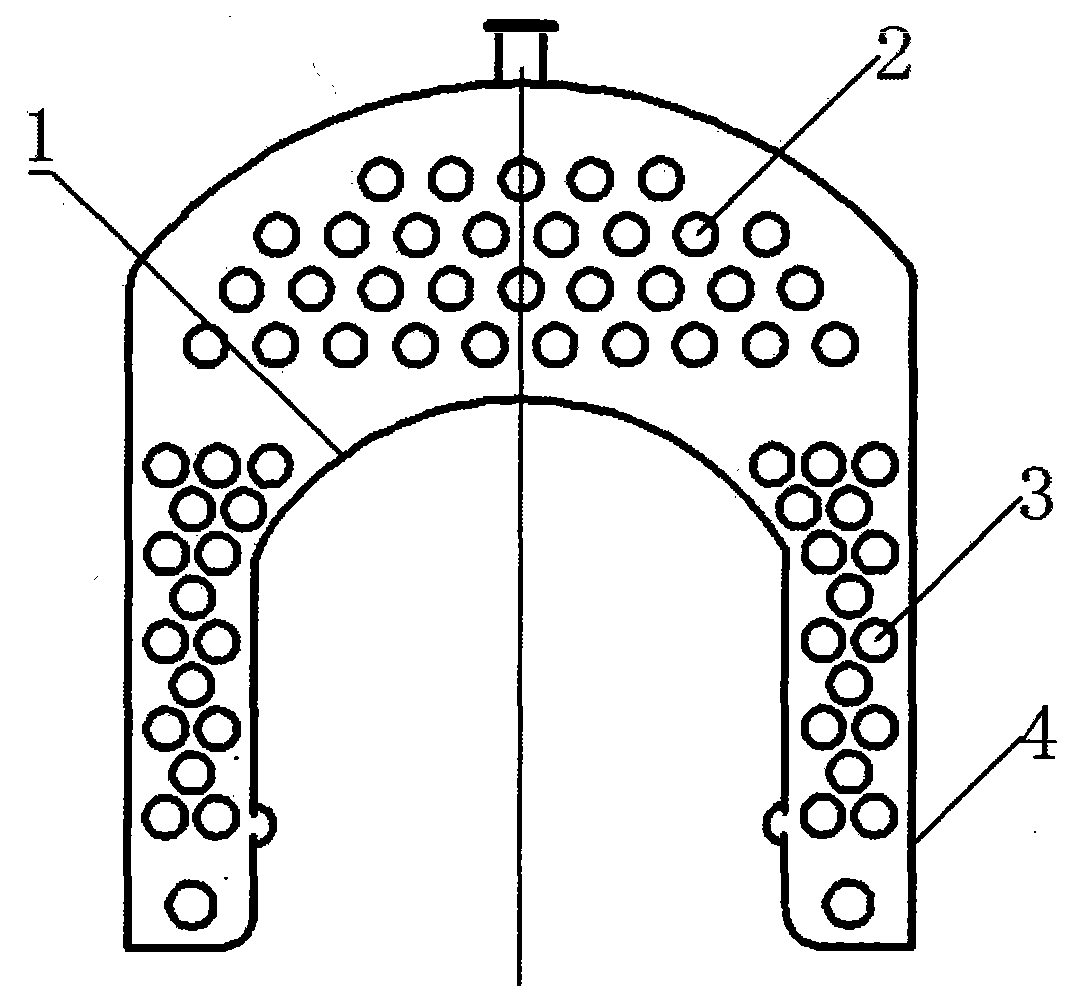

[0009] according to Figure 1-2 The specific structure of the present invention will be described in detail. The structure of the countercurrent heat exchange energy saving and environmental protection pyrotechnic tube atmospheric pressure boiler is as follows: Figure 1-2 shown. It consists of a furnace 1, an upper pyrotechnic tube 2, a lower pyrotechnic tube 3, a pot shell 4, and a tube plate 5. The high-temperature flue gas of the second pass passes through the upper pyrotechnic tube 2 in the pot shell for heat exchange, and then the lower flue gas of the third pass passes through the lower pyrotechnic tube 3 in the pot shell. After heat exchange, the flue gas is discharged out of the boiler body, completely changing the original downstream heat exchange method, realizing countercurrent heat exchange to save energy; reducing carbon dioxide emissions; adopting normal pressure design to reduce steel consumption, achieving energy saving and environmental protection purposes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com