Slag cooling system for reducing amount of boiler circulating ash and working method

A technology of circulating ash and cold slag, applied in the field of cold slag system, can solve the problems of complex mechanical system structure, poor sealing effect, easy leakage of circulating water, etc., and achieve the effect of high heat transfer efficiency, reasonable structure and stable heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

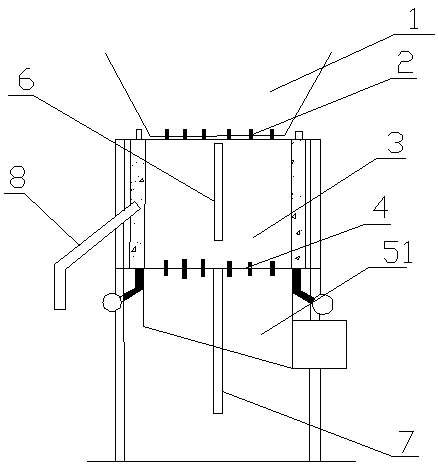

[0018] A slag cooling system for reducing boiler circulating ash, which consists of: a combustion chamber 1, a cooling chamber 3, and an air chamber 5, the combustion chamber is connected to the cooling chamber, and the cooling chamber is connected to the Air chamber connection.

Embodiment 2

[0020] 2. According to the cooling slag system for reducing boiler circulating ash amount described in Embodiment 1, the combustion chamber air distribution plate 2 is installed inside the combustion chamber, the hot slag pipe 6 is installed inside the cooling chamber, and the cooling chamber air distribution plate 2 is installed inside the combustion chamber. plate 4, an overflow port 8 is installed outside the cooling chamber, and a cold slag pipe 7 is installed in the air chamber.

Embodiment 3

[0022] According to the slag cooling system for reducing boiler circulating ash amount described in embodiment 1 or 2, the surrounding cooling chamber is composed of water-cooled wall heating surfaces, and the overflow port is connected with the water-cooled wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com