Power station boiler system and method for increasing tail fume temperature of power station boiler by integrating supplemental combustion for biomass gasification

A power plant boiler and biomass technology, applied in chemical instruments and methods, gasification processes, separation methods, etc., can solve problems such as environmental damage, low thermal efficiency, smoke and dust, save coal, improve unit efficiency, and reduce fly ash content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

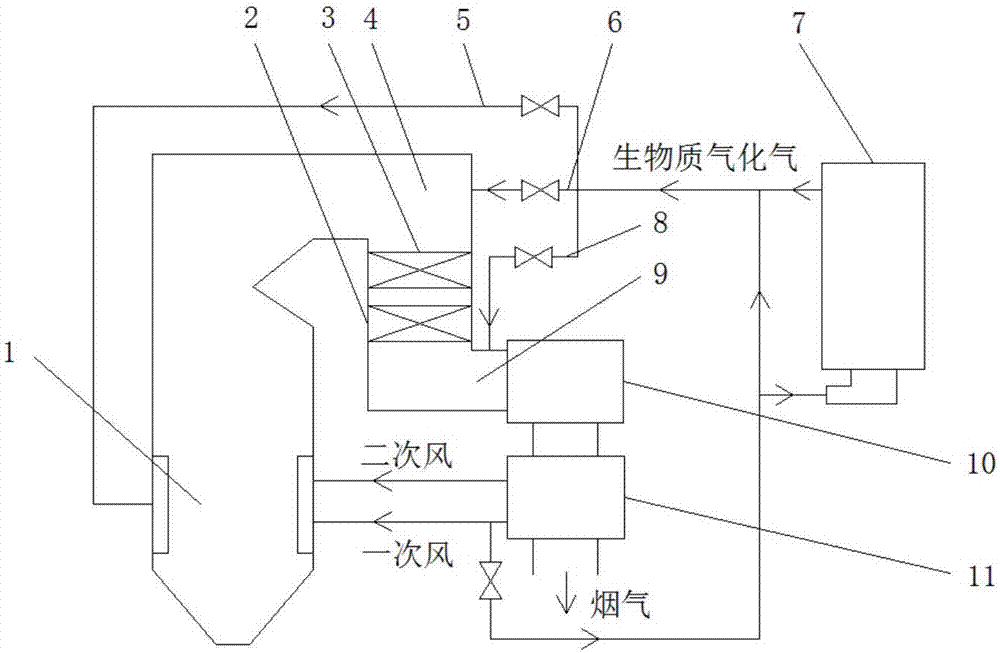

[0030] When the boiler is running under low load conditions, the gasification gas produced by the fixed-bed biomass gasifier 7 is sent to the economizer along the pipeline three 8 (the pipeline three in this embodiment is the above-mentioned first branch pipeline) In the rear flue 9, the biomass gasification gas is used for supplementary combustion to raise the flue gas temperature to a reasonable temperature, so as to ensure that the selective catalytic reduction flue gas denitrification system 10 can be put into safe and stable operation. At the same time, the heat exchange rate of the air preheater 11 is increased, the secondary air temperature is increased, the heat sent to the boiler is increased, the coal is saved, and it is beneficial to the combustion in the furnace and reduces the heat loss of incomplete combustion of solids.

[0031] As the load of the boiler increases, gradually reduce the supplementary combustion gas, and send the reduced gasification gas for supple...

example 2

[0037] When the boiler is operating under low load conditions, the gasification gas produced by the fixed-bed biomass gasifier 7 can be sent to the steering flue along the pipeline 2 6 (the pipeline 2 is the above-mentioned first branch pipeline in this embodiment). In chamber 4, biomass gasification gas is used for supplementary combustion to raise the smoke temperature to a reasonable temperature. Not only can it ensure the safe and stable operation of the selective catalytic reduction flue gas denitrification system 10, but also increase the heat transfer of the air preheater, and increase the heat transfer of the low-temperature superheater 3, so as to overcome the problem of lower superheated steam temperature at low load and improve Crew efficiency. The main difference between embodiment 2 and embodiment 1 is that: in embodiment 2, the gasification gas produced by the gasifier 7 is sent to the diverting smoke chamber 4, while in embodiment 1 the gasification gas produced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com