Coal gasification boiler by reverse coal combustion

A hot water boiler and coal gasification technology, applied in the combustion chamber, combustion method, combustion equipment and other directions, can solve the problems of insufficient working water flow, insufficient heat recovery, and high impurity content, so as to reduce heat loss and chemical pollution. The effect of combustion heat loss, overall appearance of the boiler, and low pollutant discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

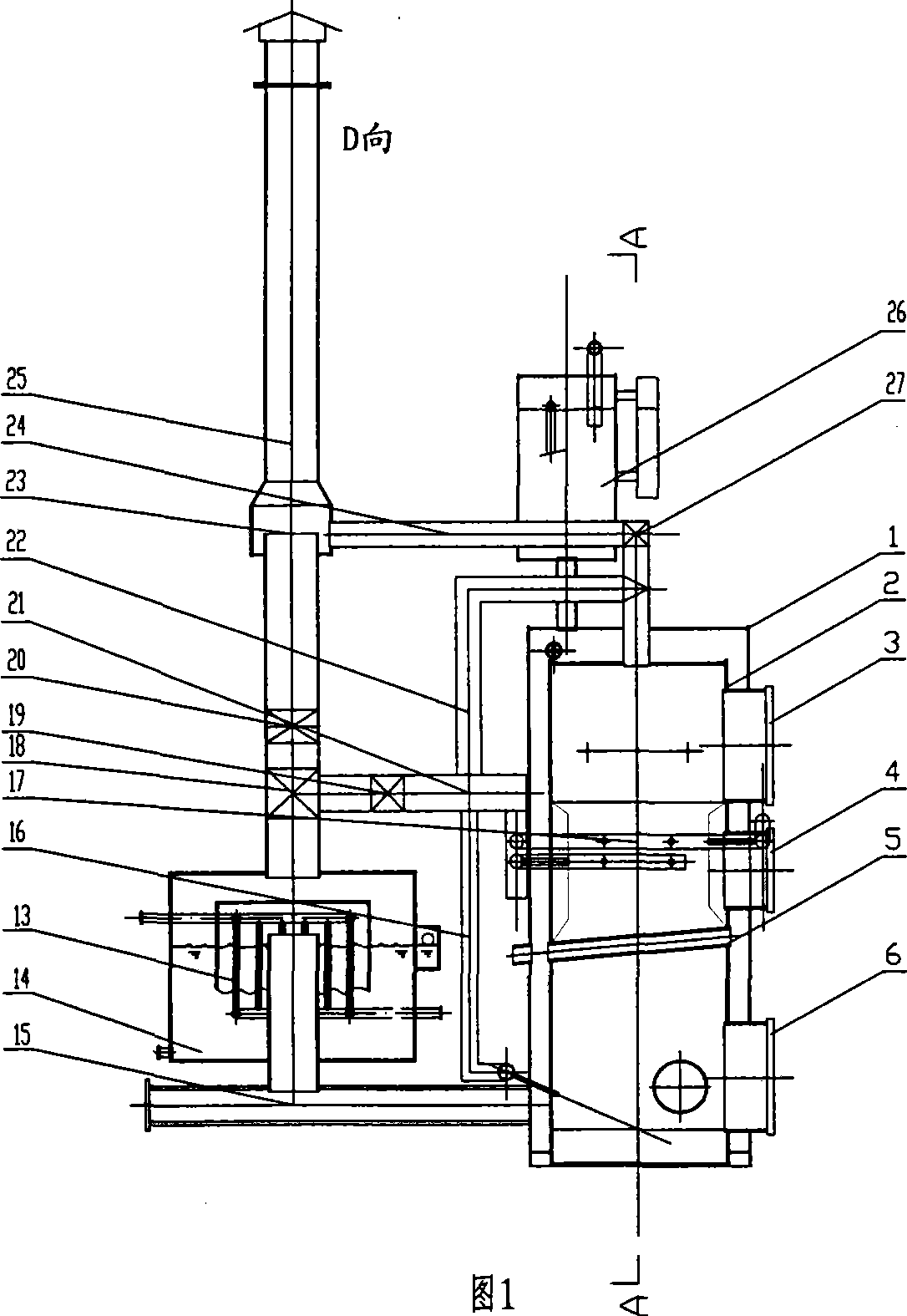

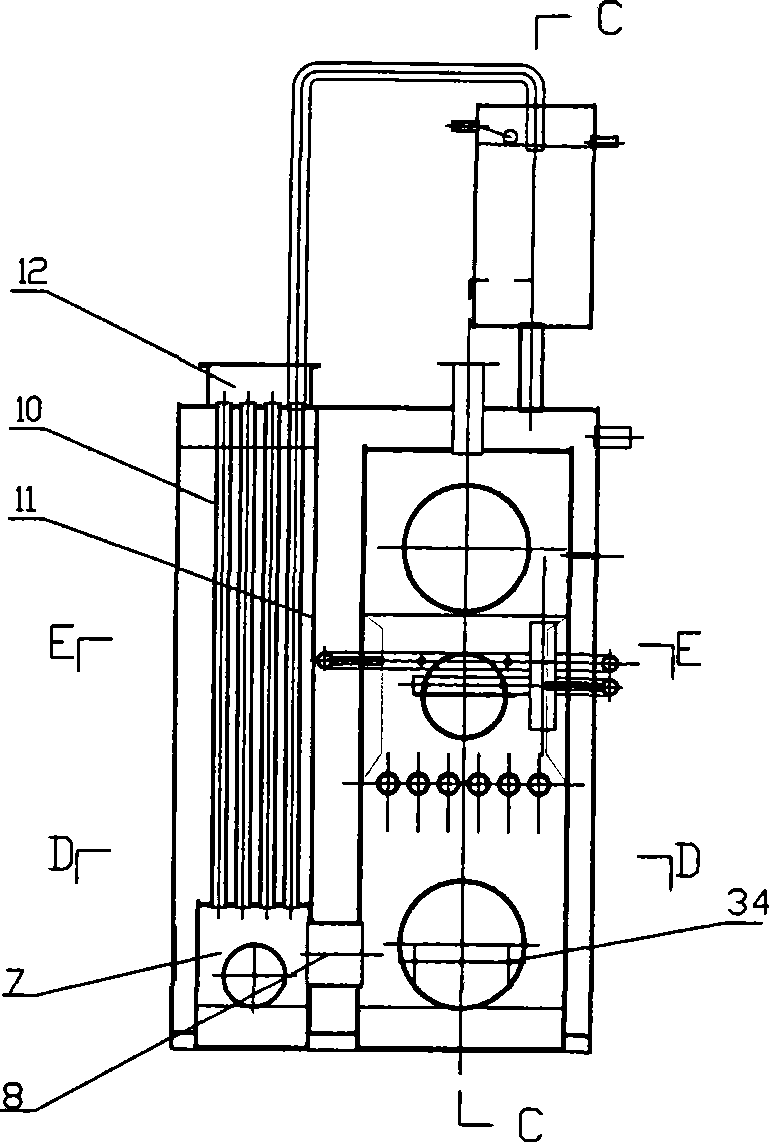

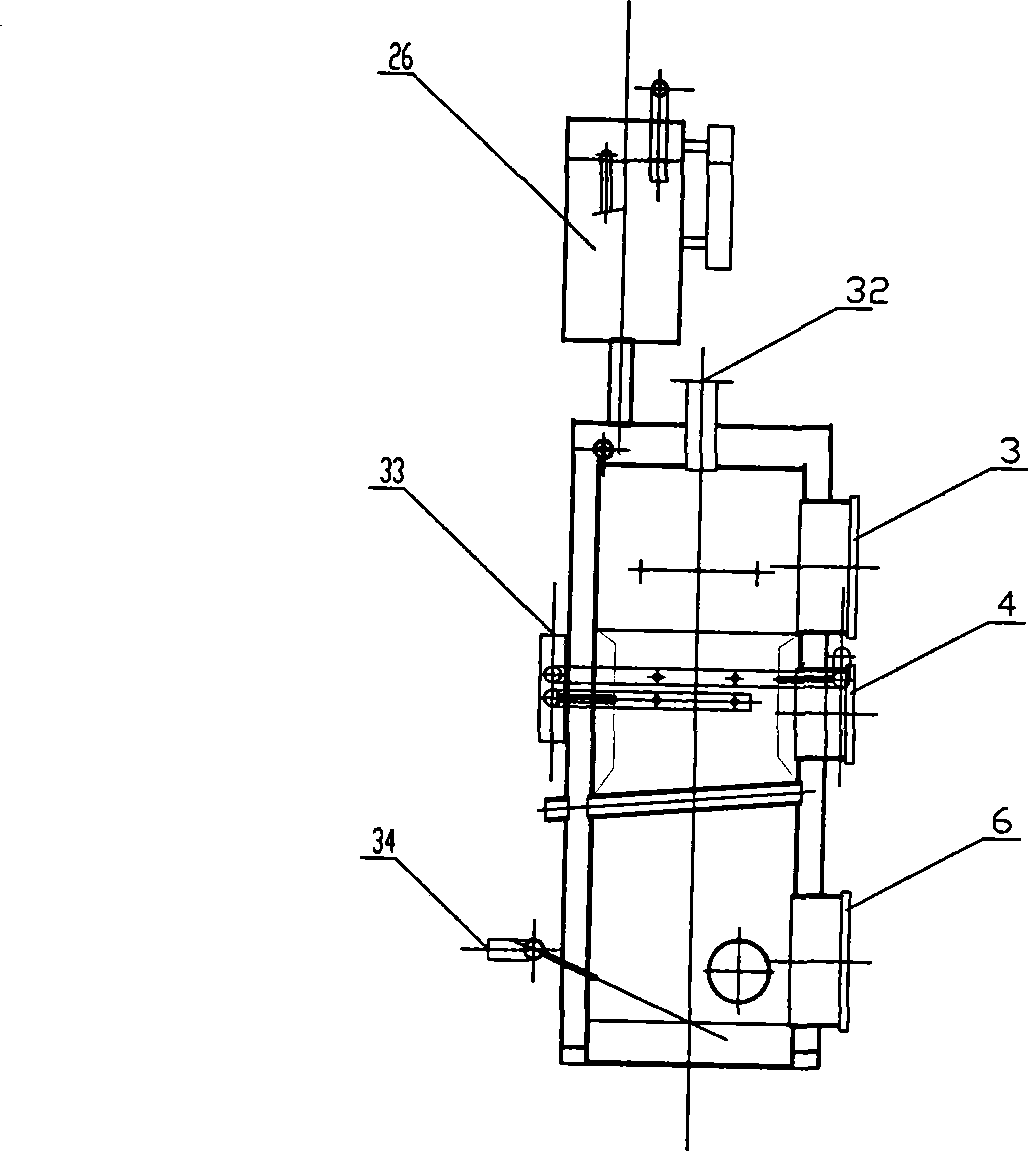

[0033] As shown in Figure 1, Figure 2, Figure 3a, and Figure 3b, the boiler includes: pot shell 1, furnace gall 2, coal feeding door (with micro positive pressure visible sealing furnace door) 3, fire control door (with micro positive pressure Pressure visible sealed furnace door) 4, fire grate 5, ash removal door (with slight positive pressure visible sealed furnace door) 6, lower flue gas diversion chamber (with a partition in the middle) 7, furnace and lower flue gas diversion chamber connecting flue 8, double-stroke flue pipe 9 of "∏" type process, partition 10 between the first water chamber and the second water chamber, partition 11 between the first and second water chambers and the furnace gall water chamber, upper The flue gas steering chamber 12 and 35 are the first water chamber smoke tube bundle, 36 is the second water chamber smoke tube bundle, the wet desulfurization dust collector 14, the buried pipe waste heat recovery device 13, and the buried pipe waste heat r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com