Patents

Literature

35results about How to "Avoid smoky" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

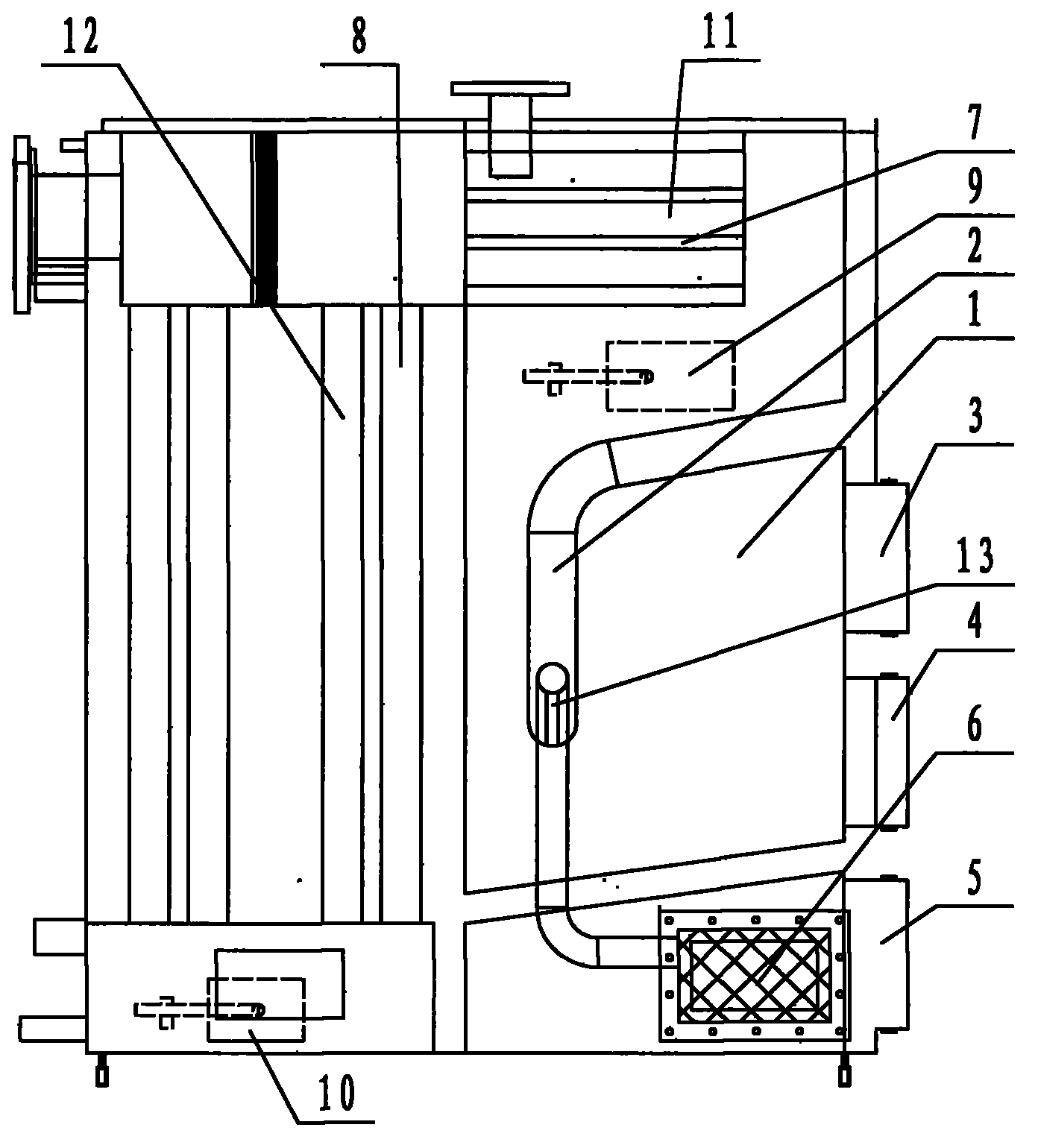

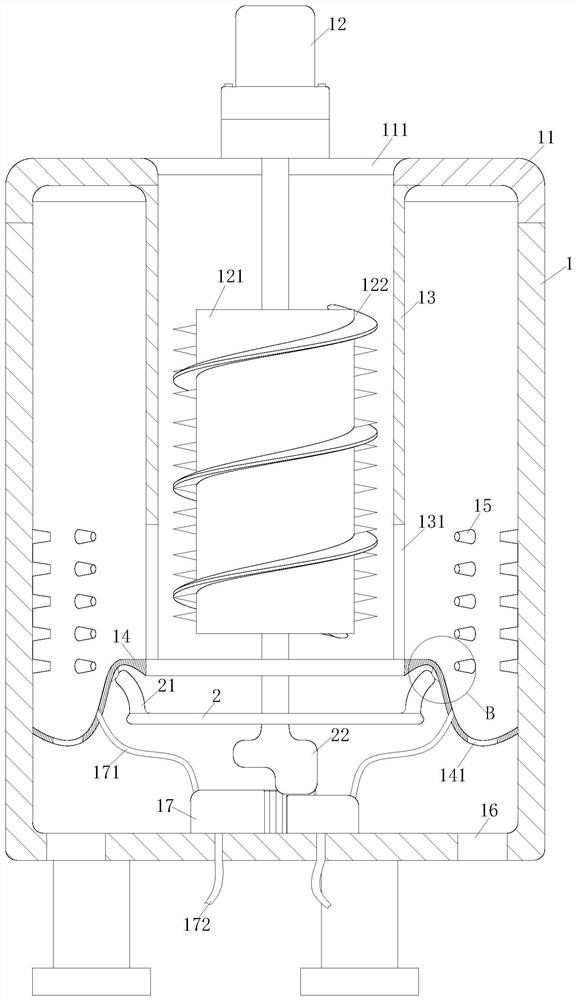

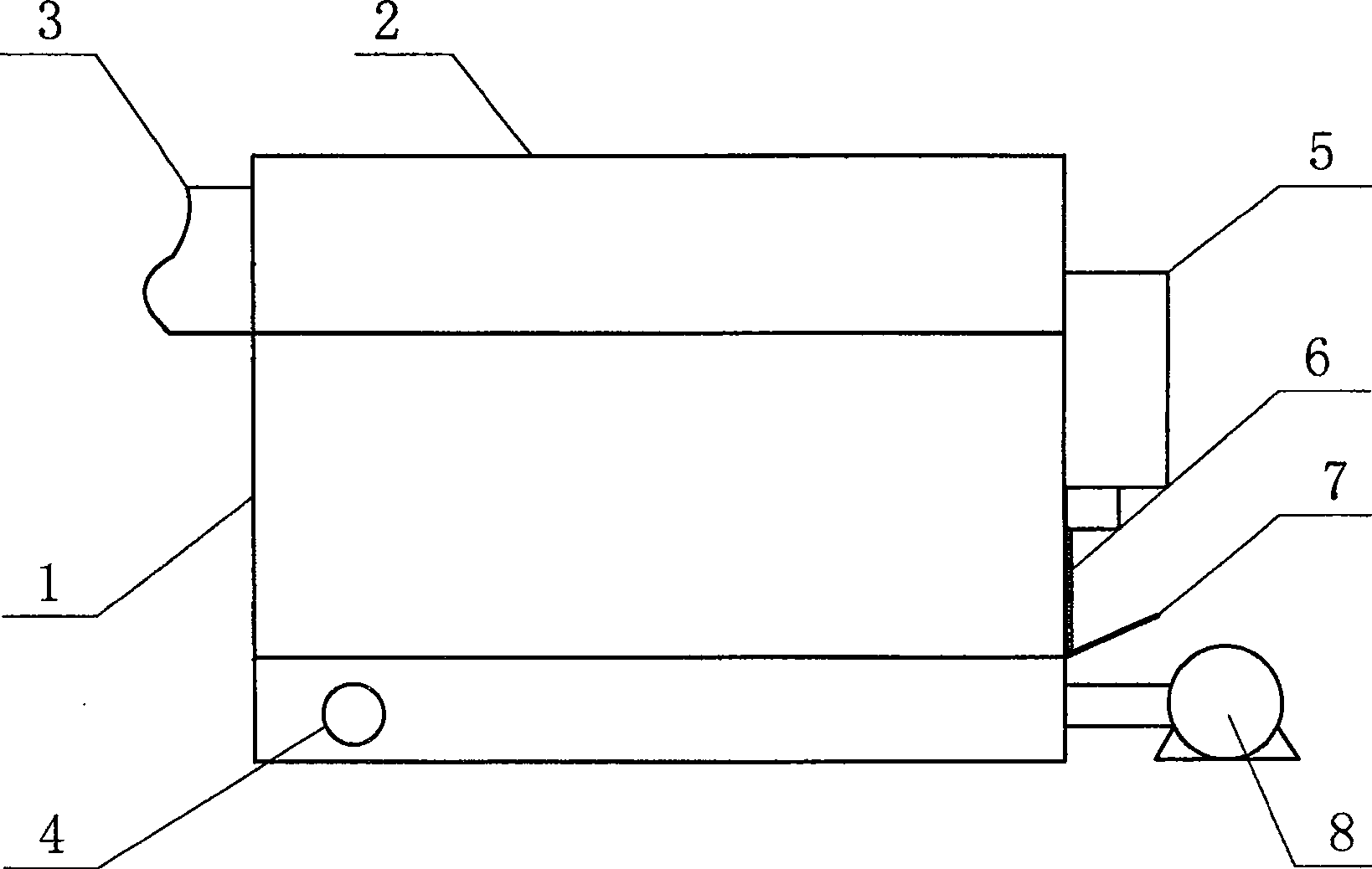

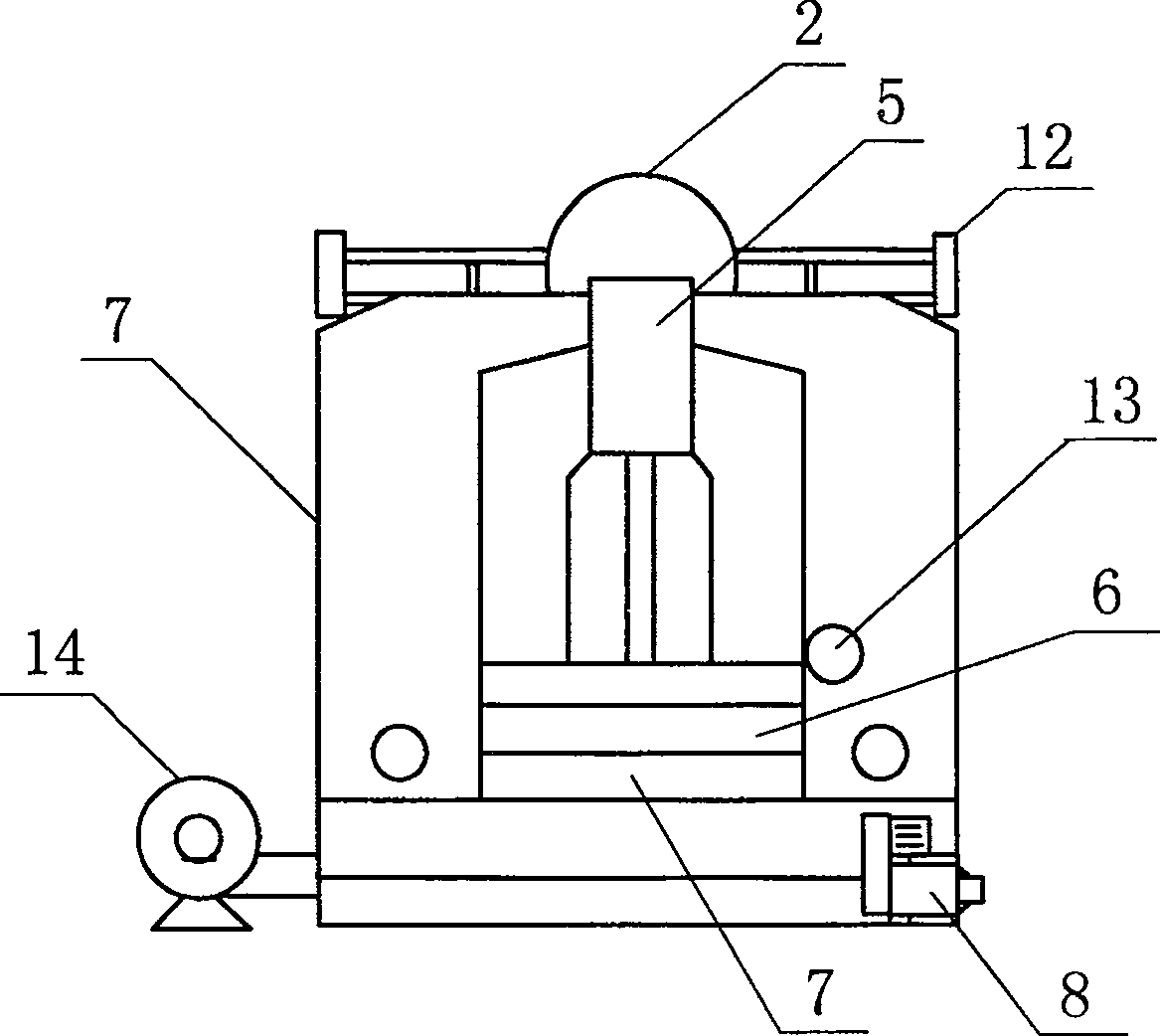

High-efficiency energy-saving emission-reduction circulating fluid bed organic heat carrier boiler

InactiveCN101545676AImprove combustion efficiencyImprove adaptabilityFluidized bed combustionStorage heatersAir preheaterHeat carrier

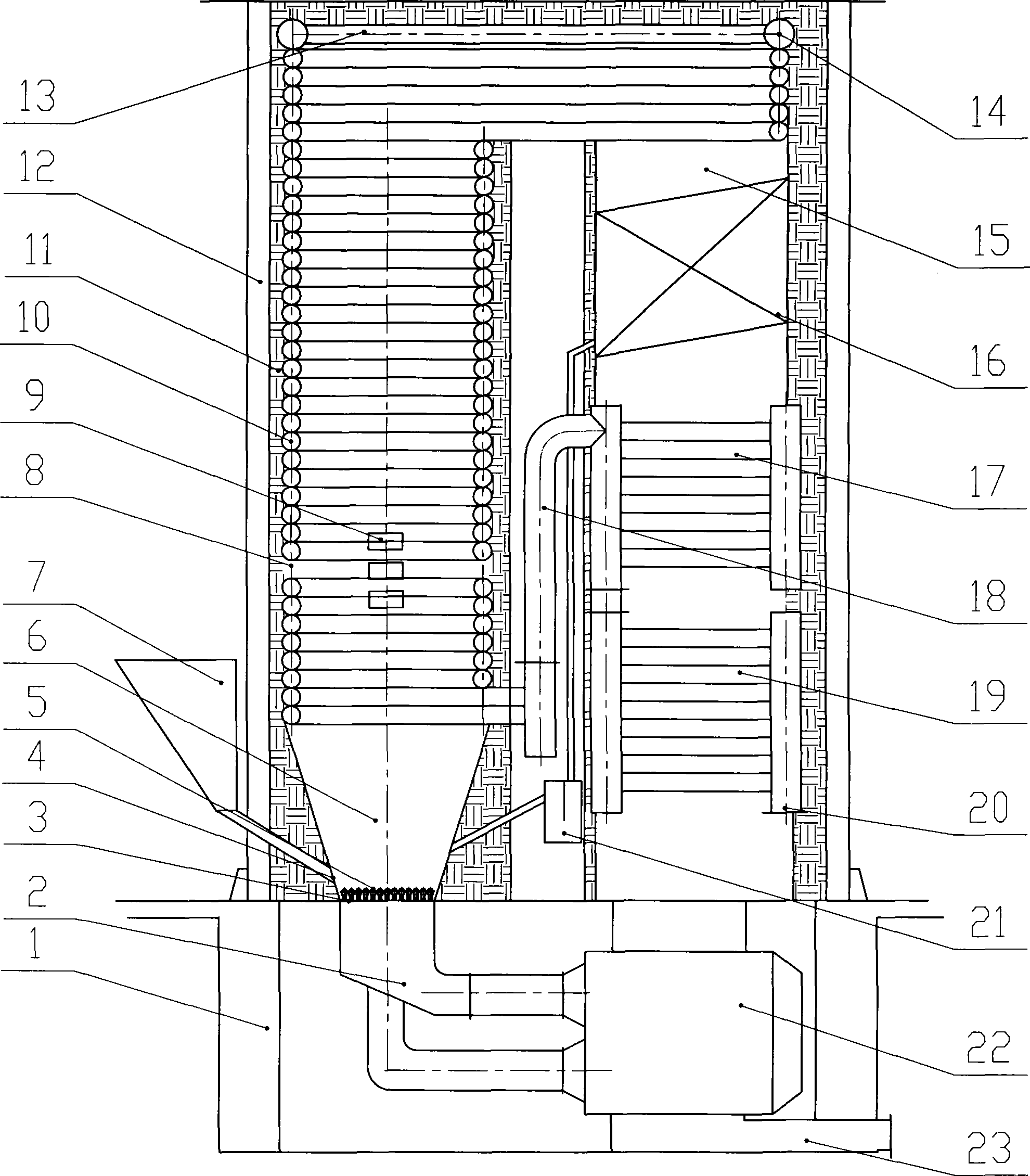

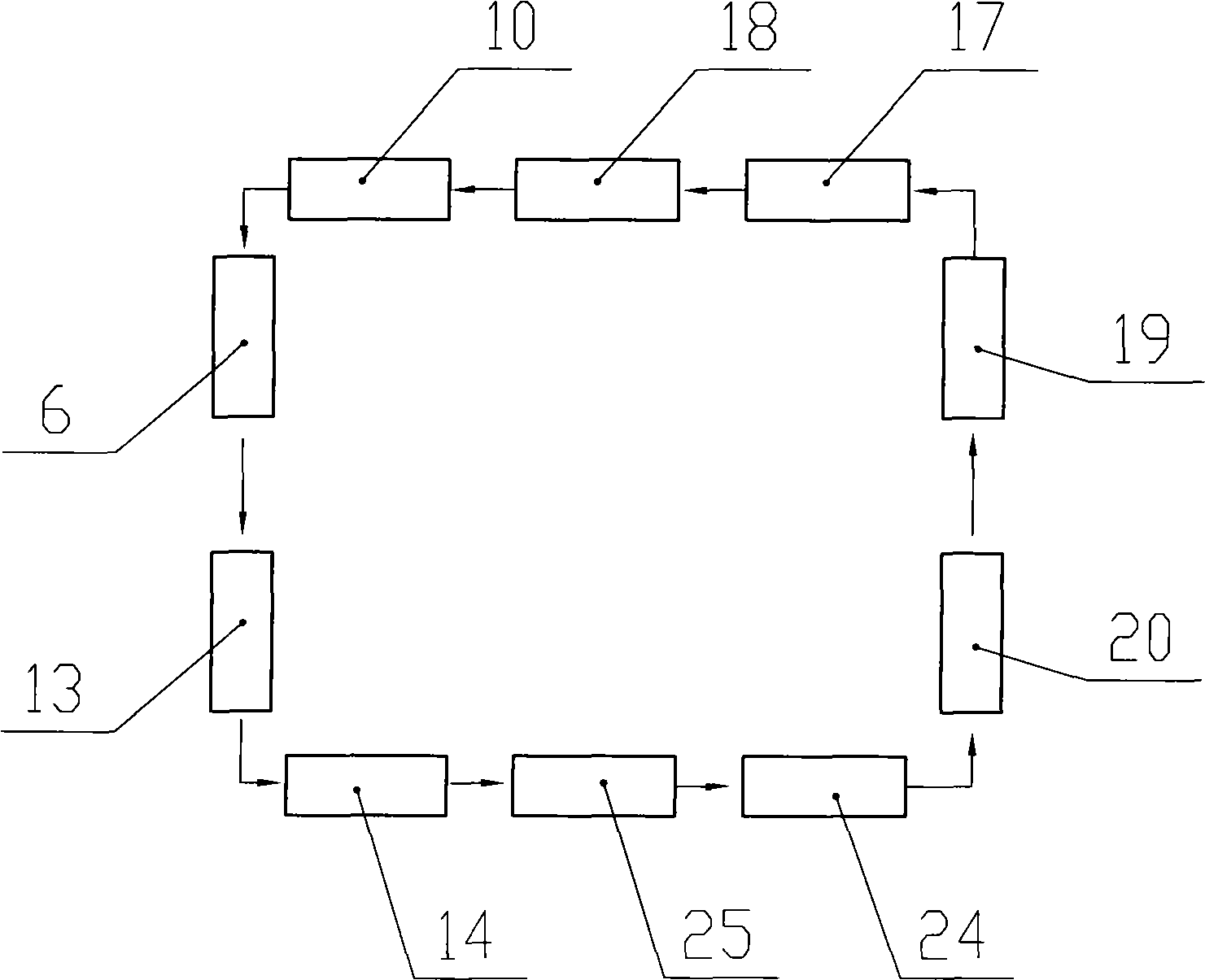

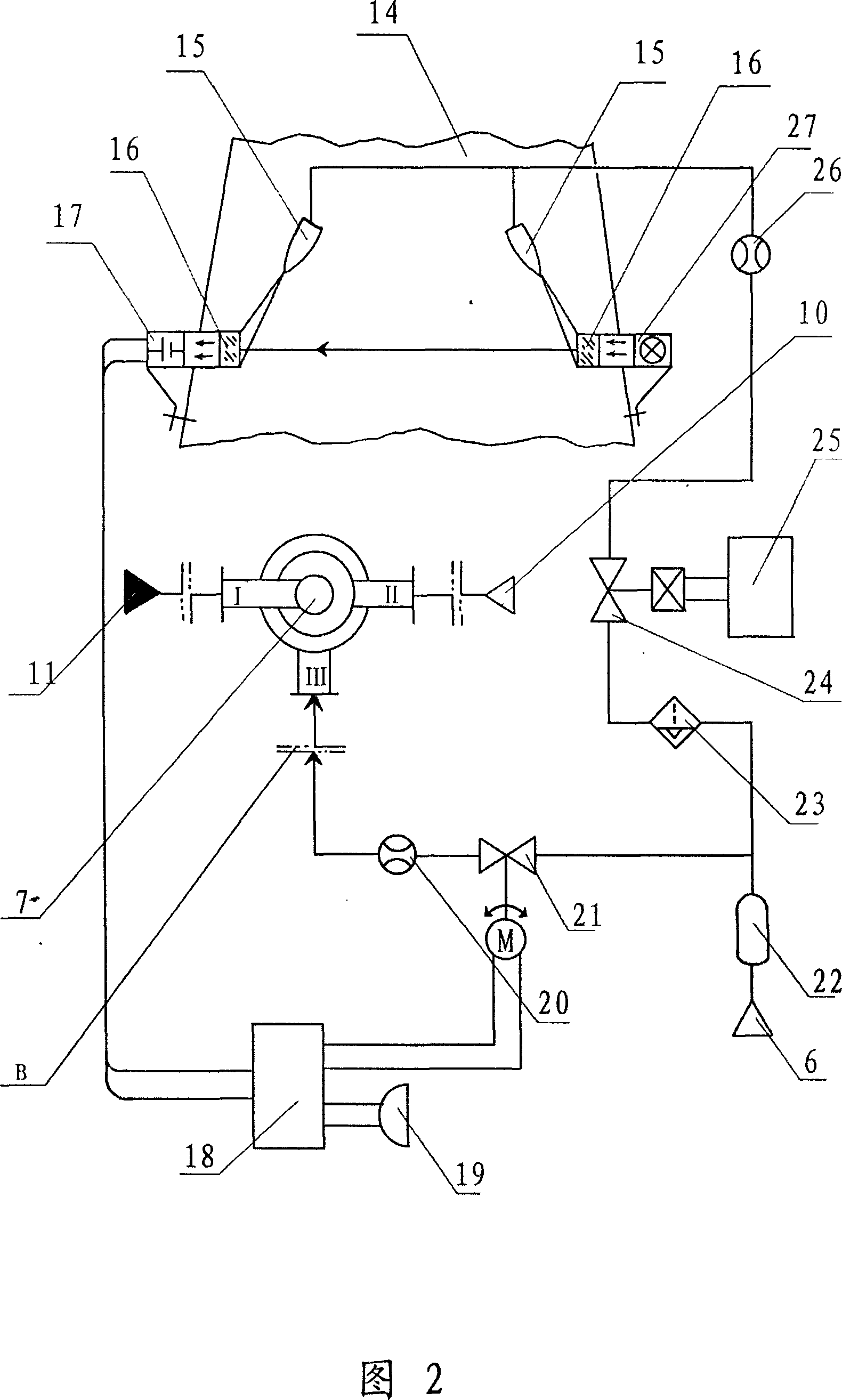

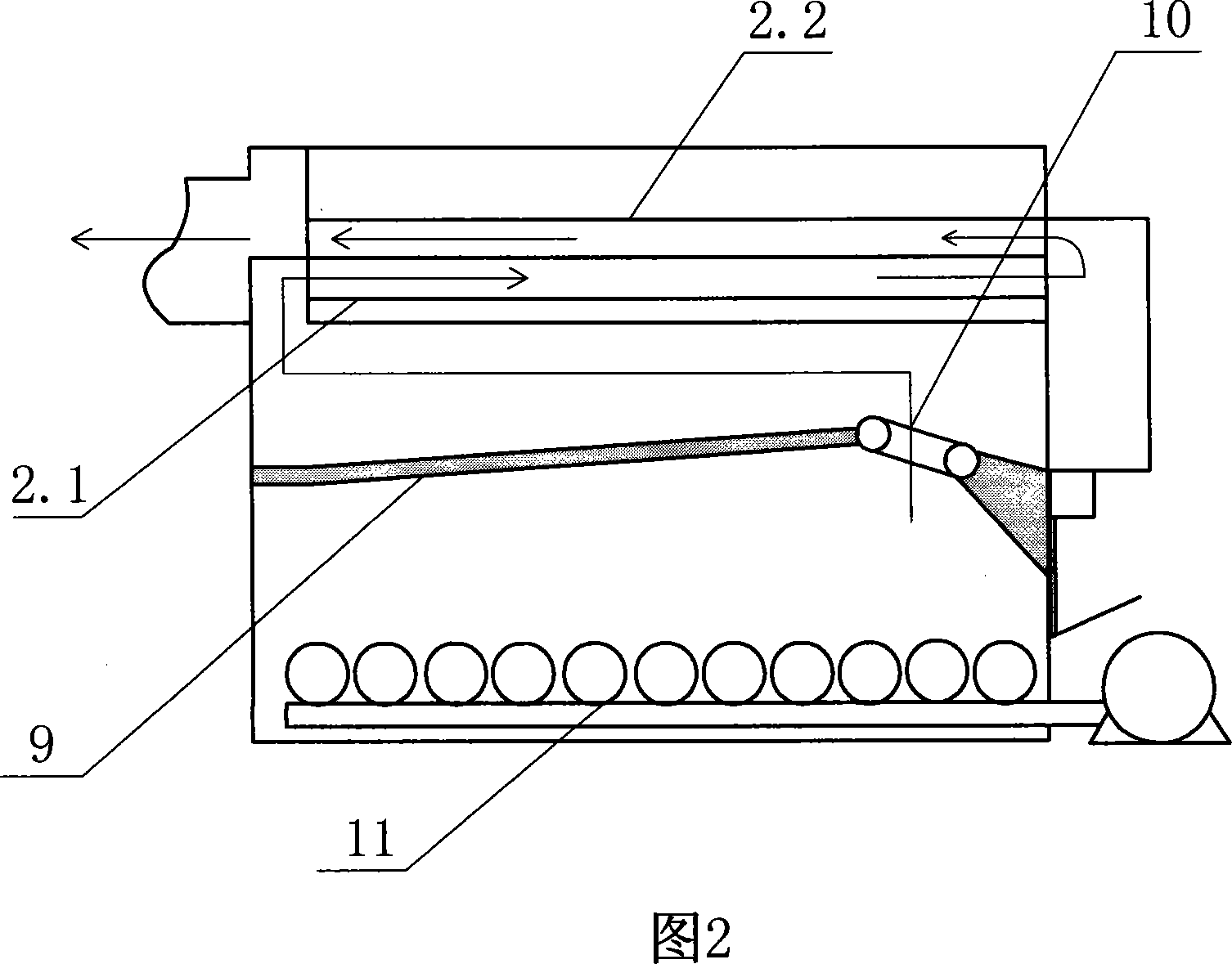

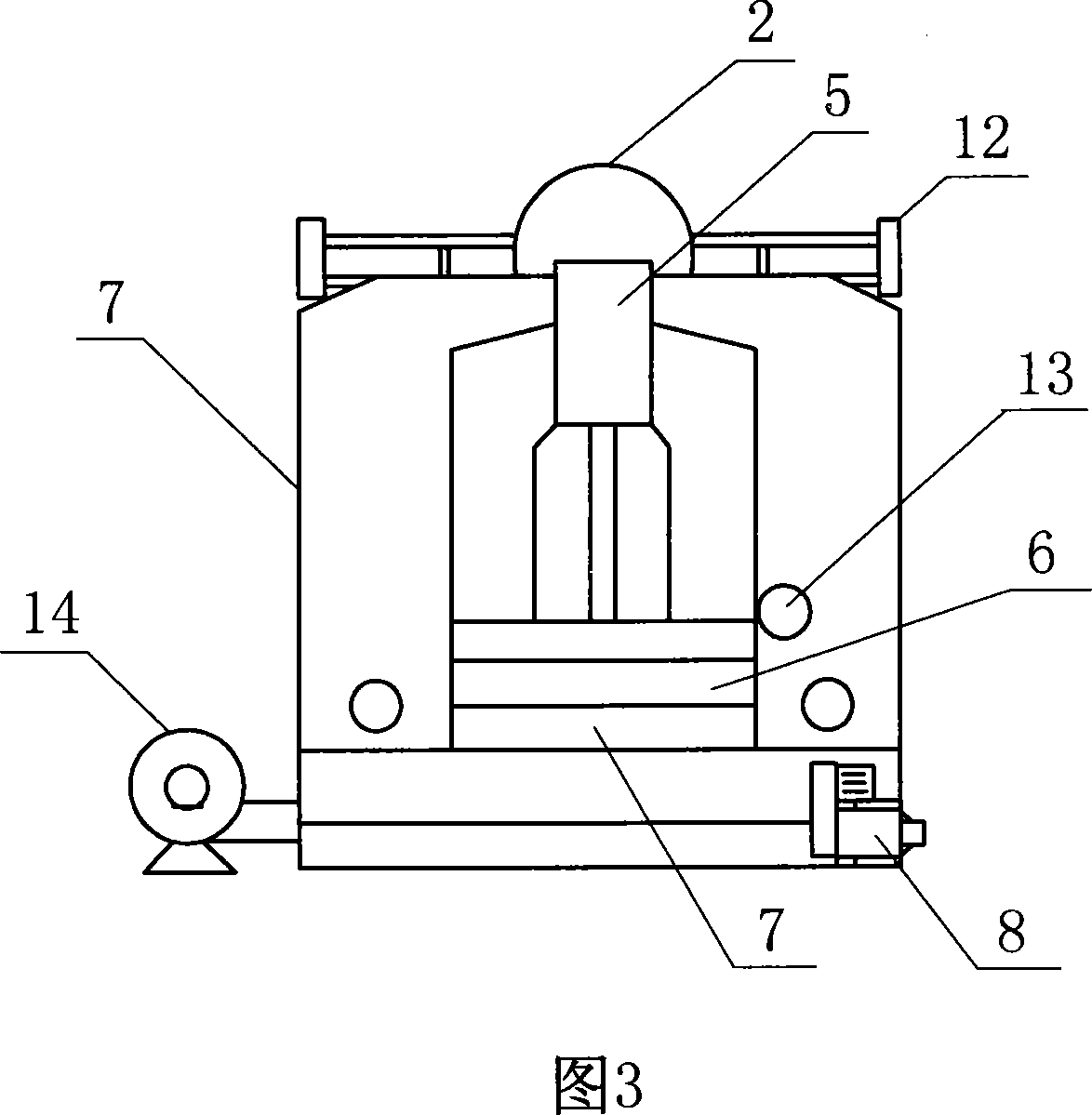

The invention discloses a high-efficiency energy-saving emission-reduction circulating fluid bed organic heat carrier boiler which comprises a boiler base, a coal scuttle and a heat medium circulation pump, wherein a boiler body formed by steel racks and insulation fire-resistant layers from outside to inside is arranged on the upside of the boiler base; a hearth and a flue the top parts of which are communicated are arranged in the boiler body in parallel; a top part heating surface and a square plate radiation heating pipe bundle are arranged on the upper part of the hearth from top to bottom; a secondary wind nozzle is arranged in a clearance of coil pipes; the lower part of the hearth is provided with a grid plate, a wind cap and an equipressure wind box; the flue is sequentially provided with an outlet container, a cyclone separating device, a high-temperature convection pipe bundle, a low-temperature convection pipe bundle and an air preheater; the flue is communicated with a smoke outlet arranged on the underside through the air preheater; the cyclone separating device is communicated with the hearth by a pipeline through a back feeder; the high-temperature convection pipe bundle is communicated with the square plate radiation heating pipe bundle by a middle linkage box; the low temperature convection pipe bundle is communicated with the heat medium circulation pump; and the heating surface is communicated with a heat device by the outlet container. The invention protects the environment, saves energy and has long service life.

Owner:SHANDONG SHENGWEI BOILER

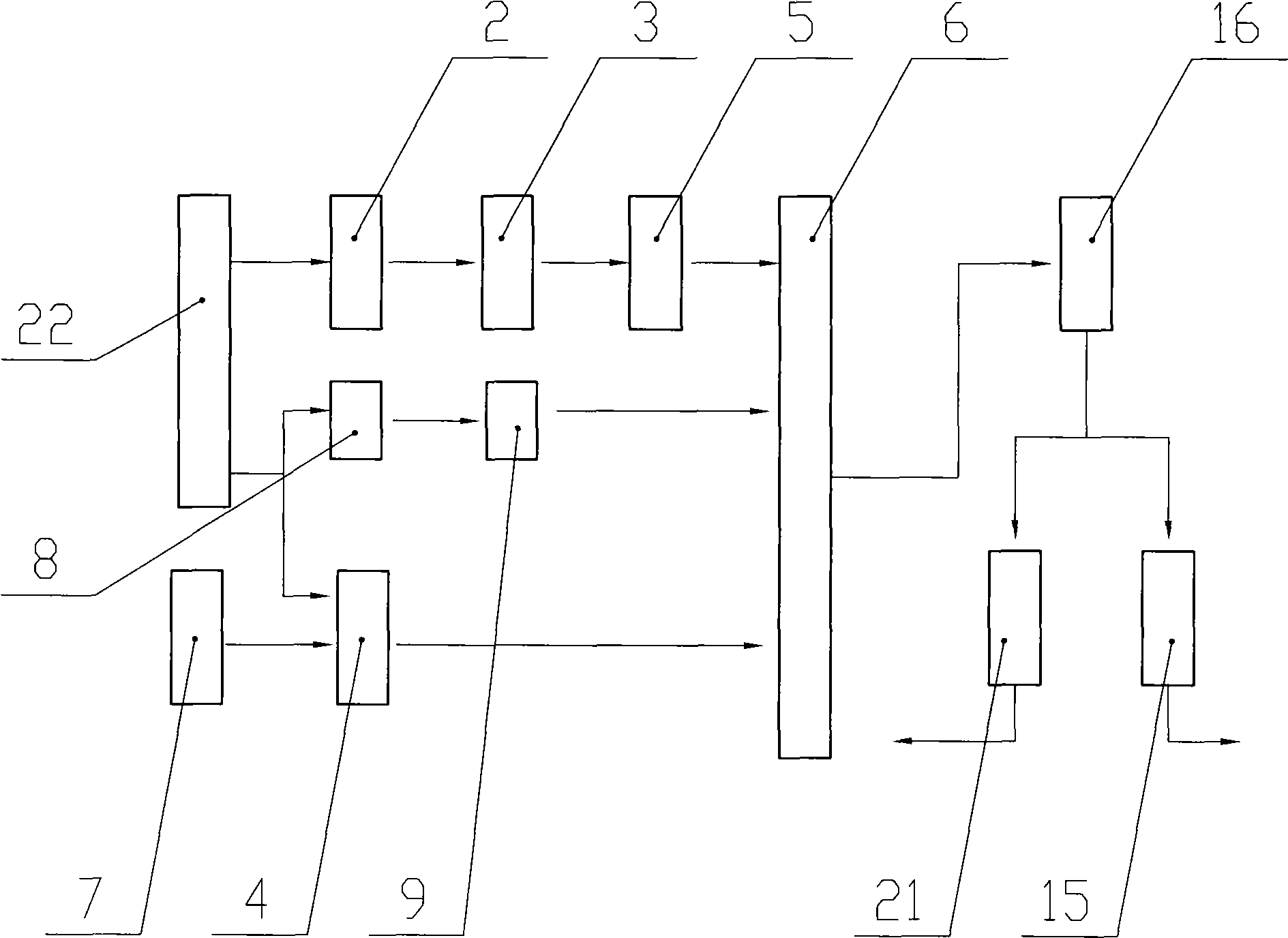

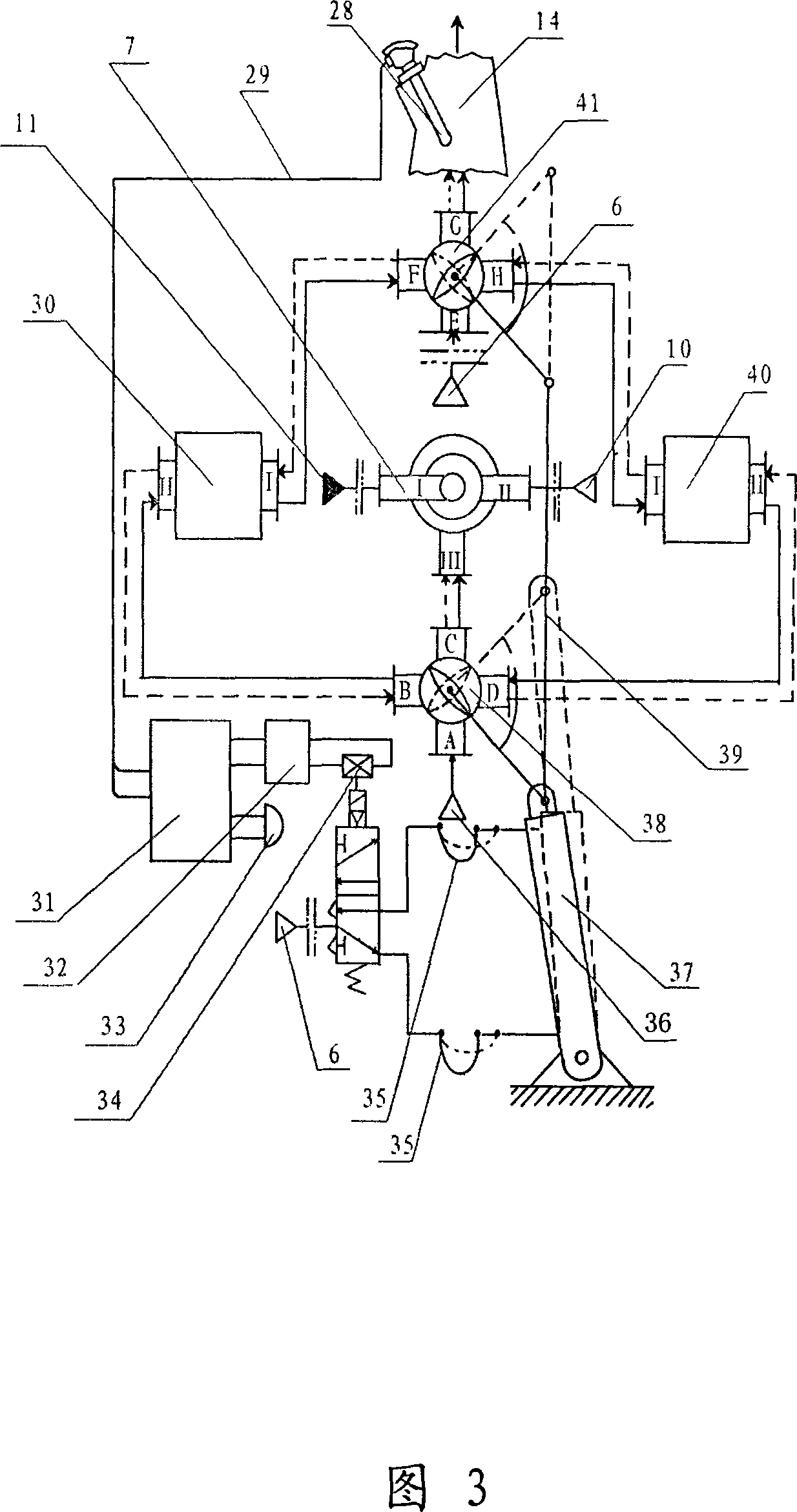

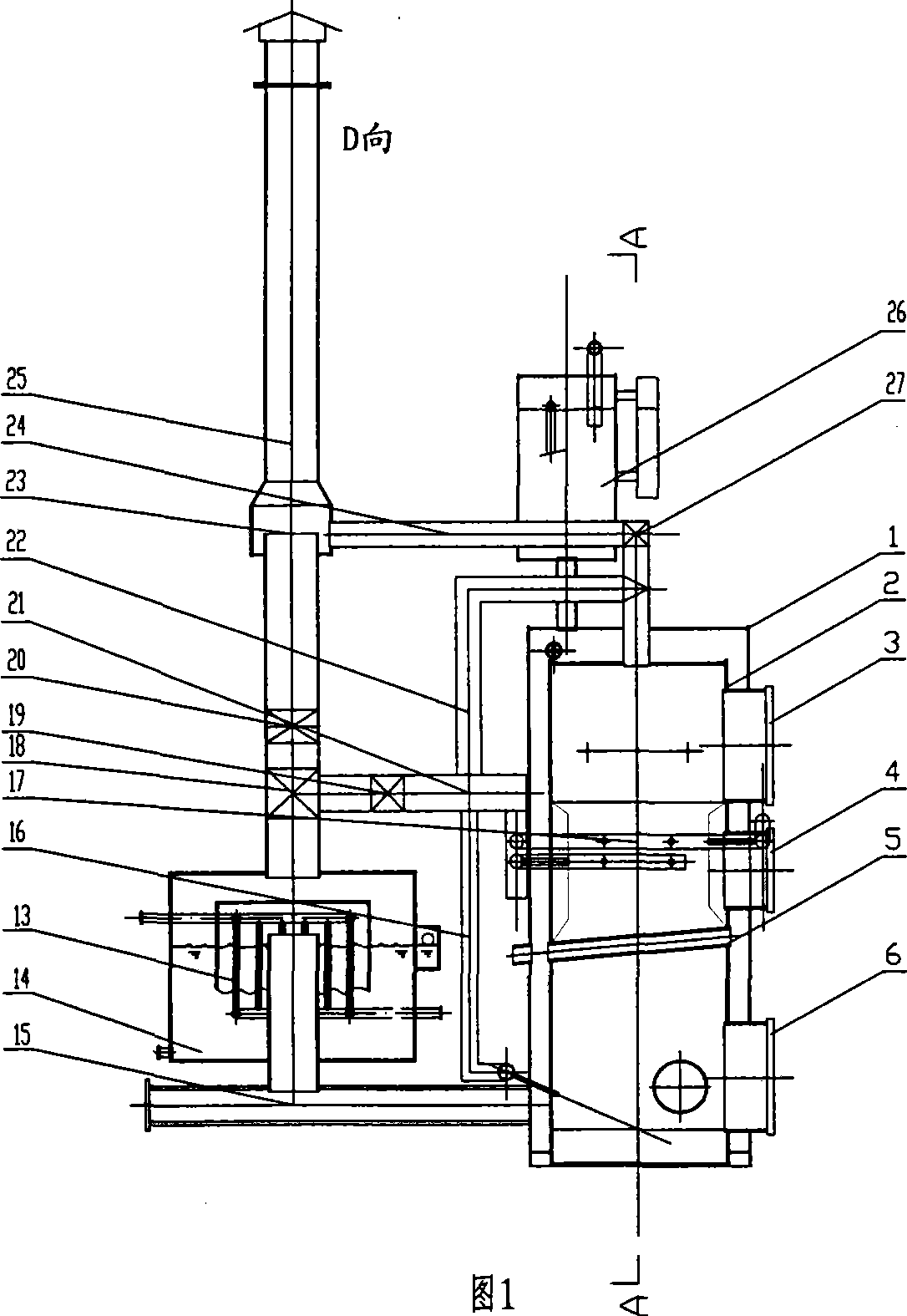

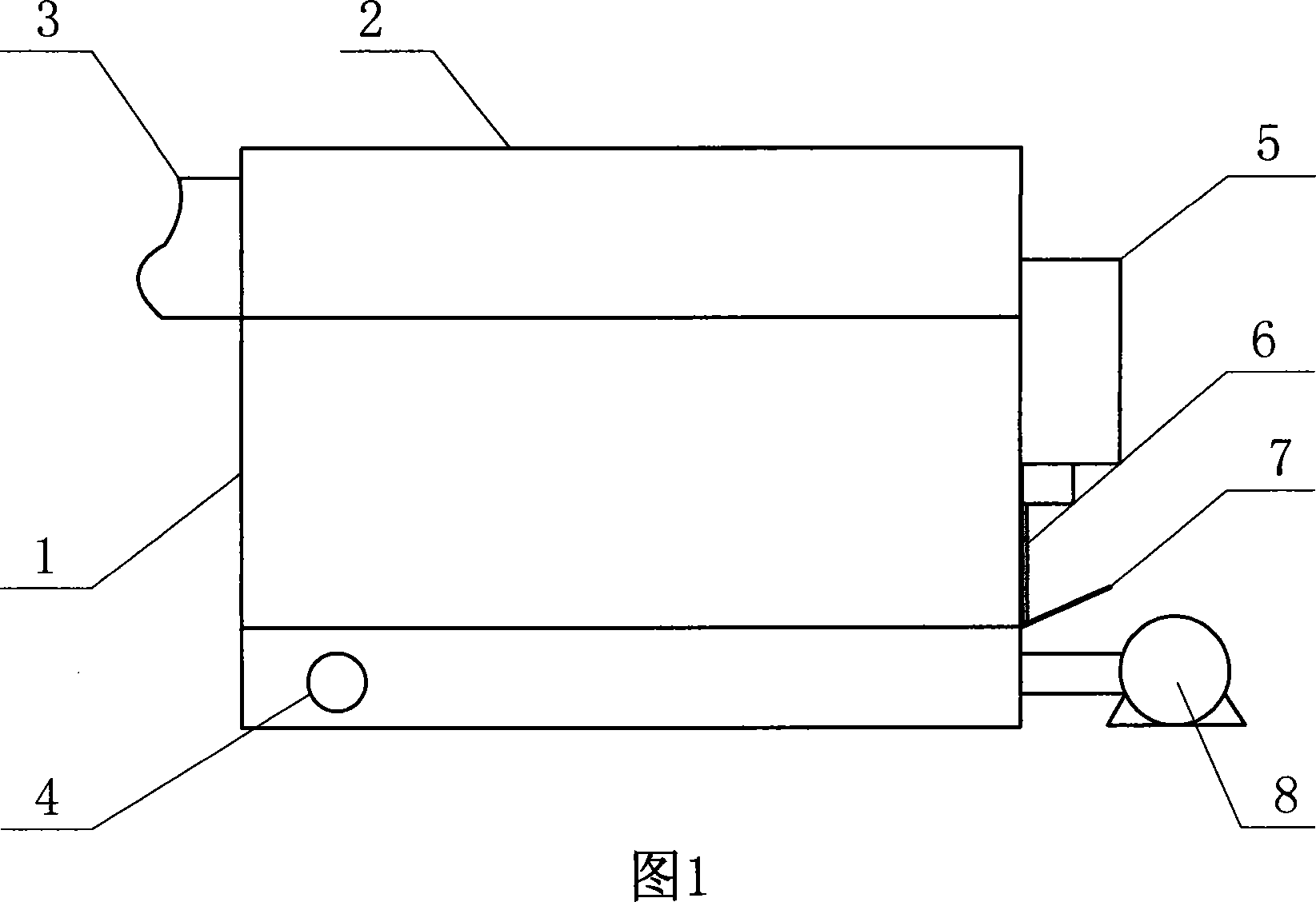

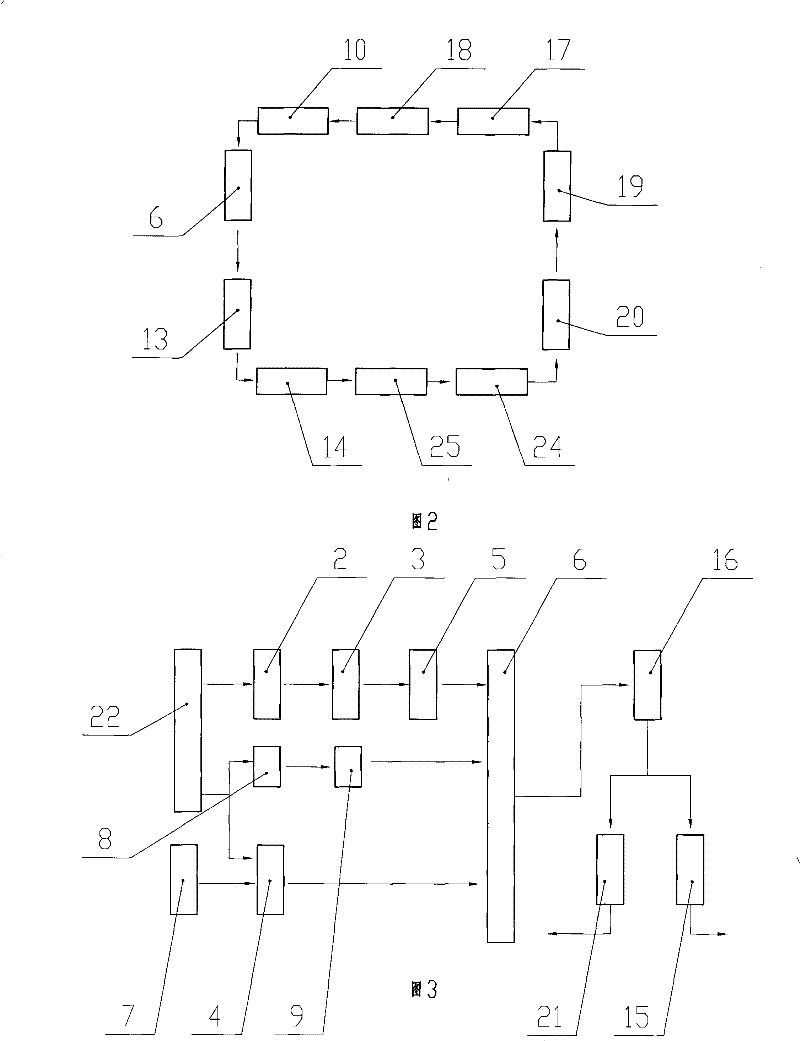

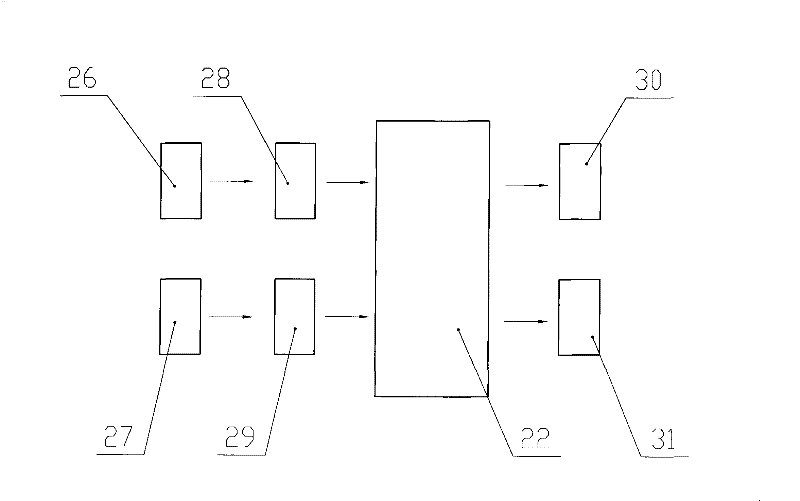

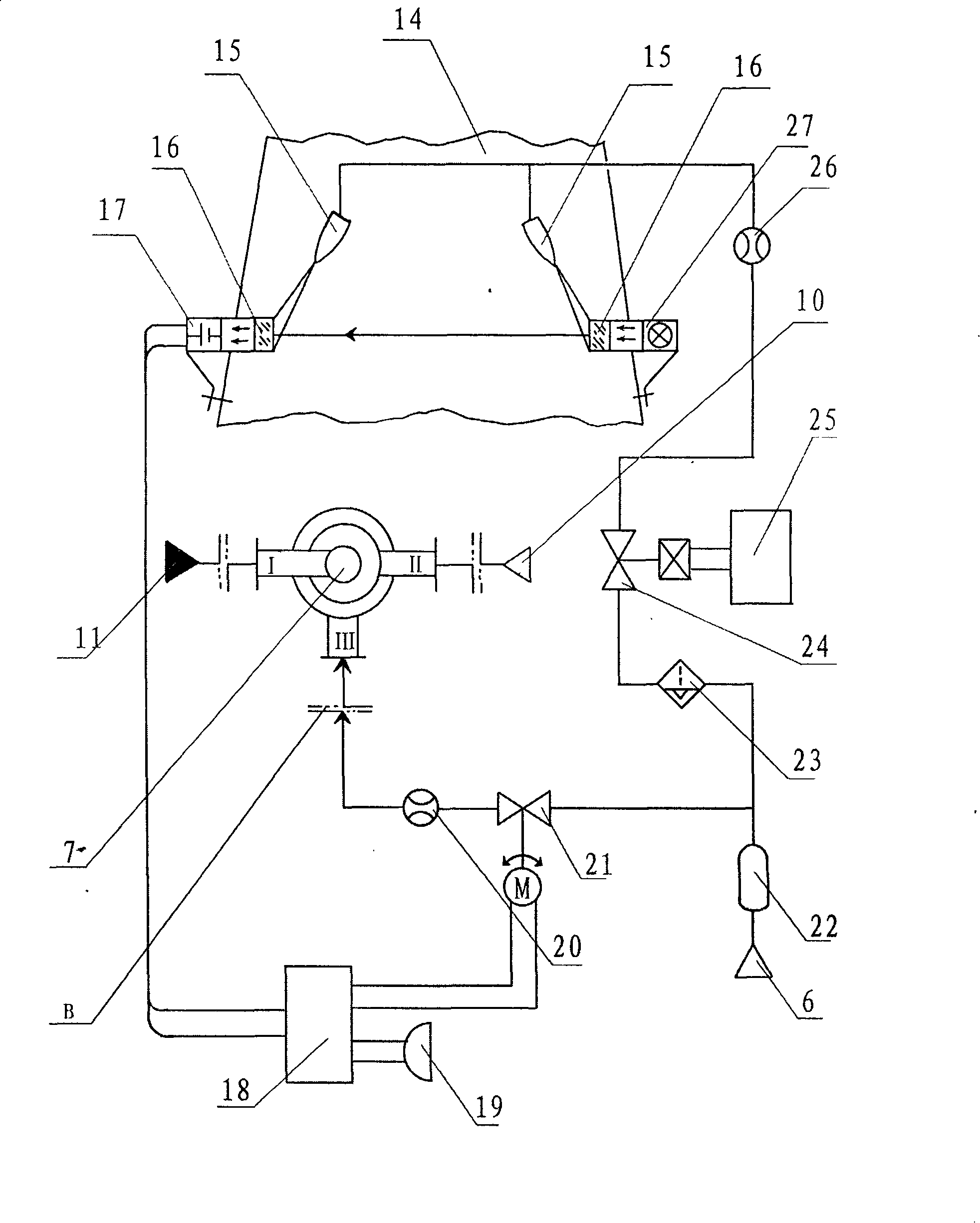

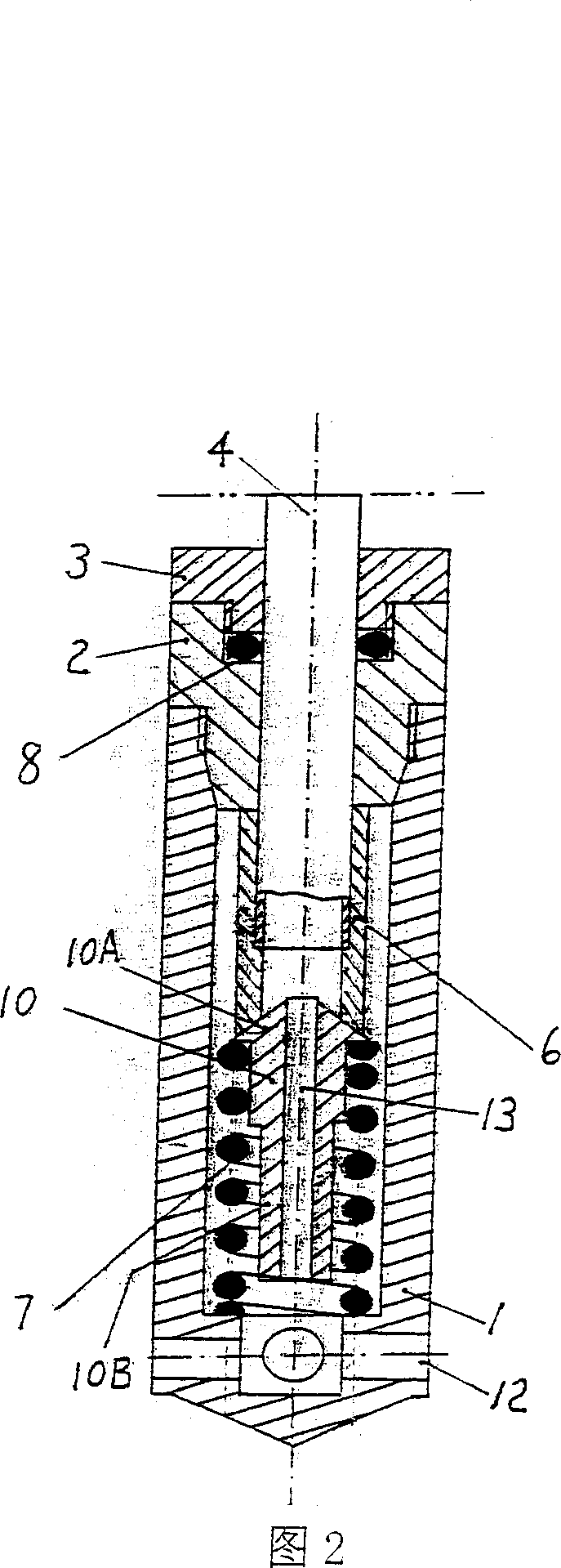

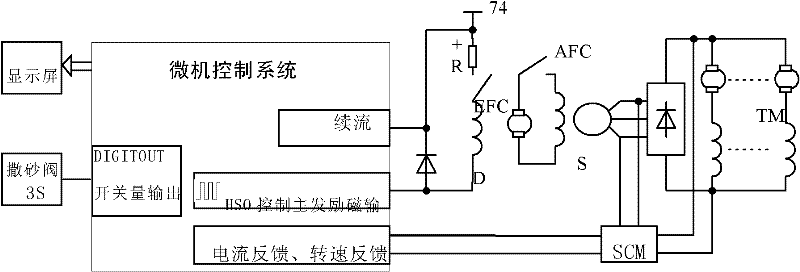

Automatic observing and controlling method for roasting heat accumulating type steel ladle and the device using the method

InactiveCN101121200AImprove roast qualityPrevent from being baked throughCasting safety devicesVolumetric Mass DensitySmoke

The present invention discloses an automatic measurement and control method for the heating regenerative ladle comprising an automatic measurement and control method for ladle internal lining, an automatic measurement and control method for the smoke and dust density in the flue exhaust and an automatic measurement and control method for flue exhaust temperature. The present invention also discloses an automatic measurement and control method for the heating regenerative ladle comprising an automatic measurement and control method for ladle internal lining, an automatic measurement and control method for the smoke and dust density in the flue exhaust and an automatic measurement and control method for flue exhaust temperature; the present invention can ensure the sufficient burning of fuel and the heating quality of the ladle; the present invention can thoroughly remove the defect that the smoke and dust will pollute the environment and the energy-saving effect is obvious.

Owner:江苏兴利来特钢有限公司

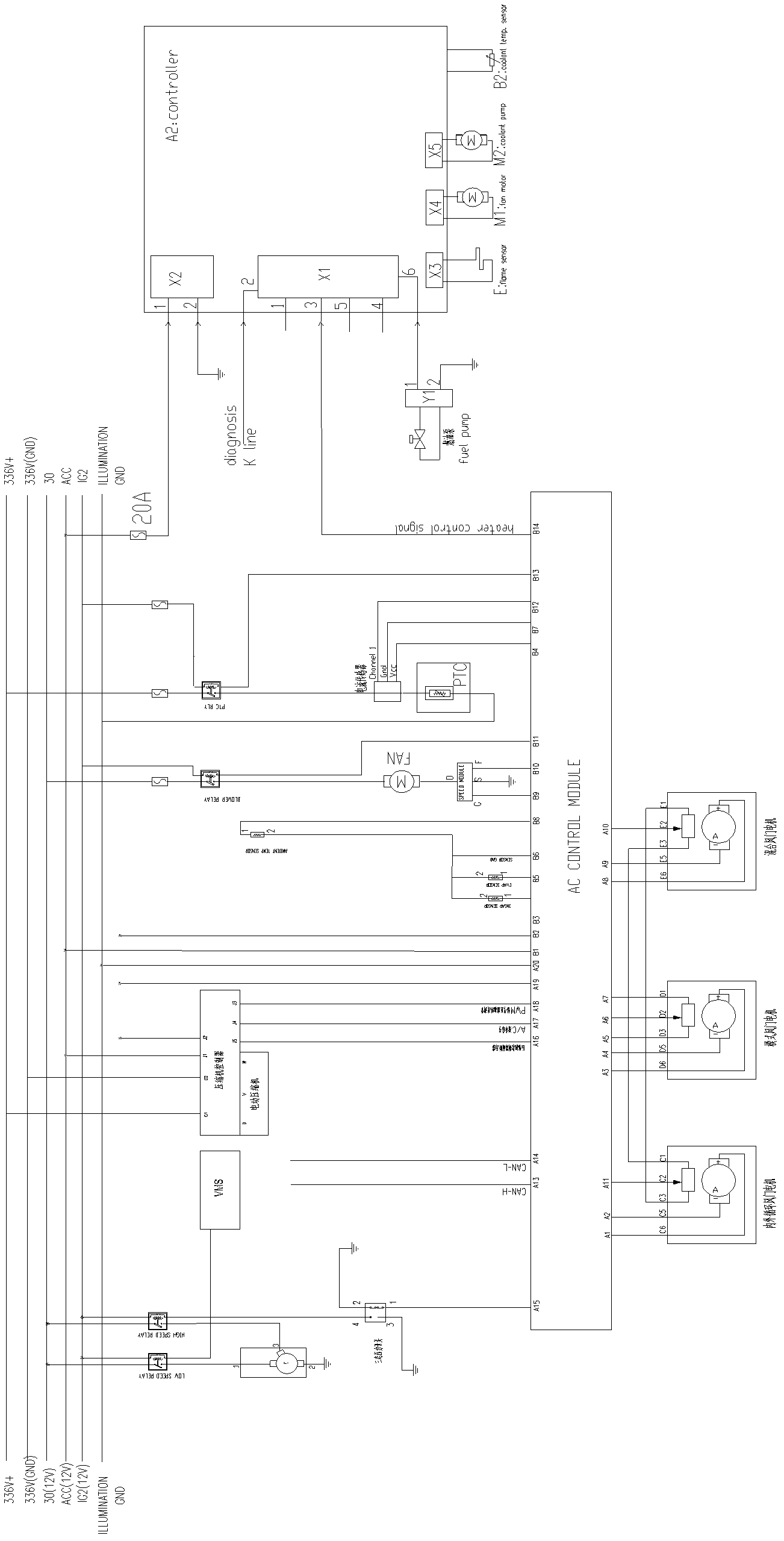

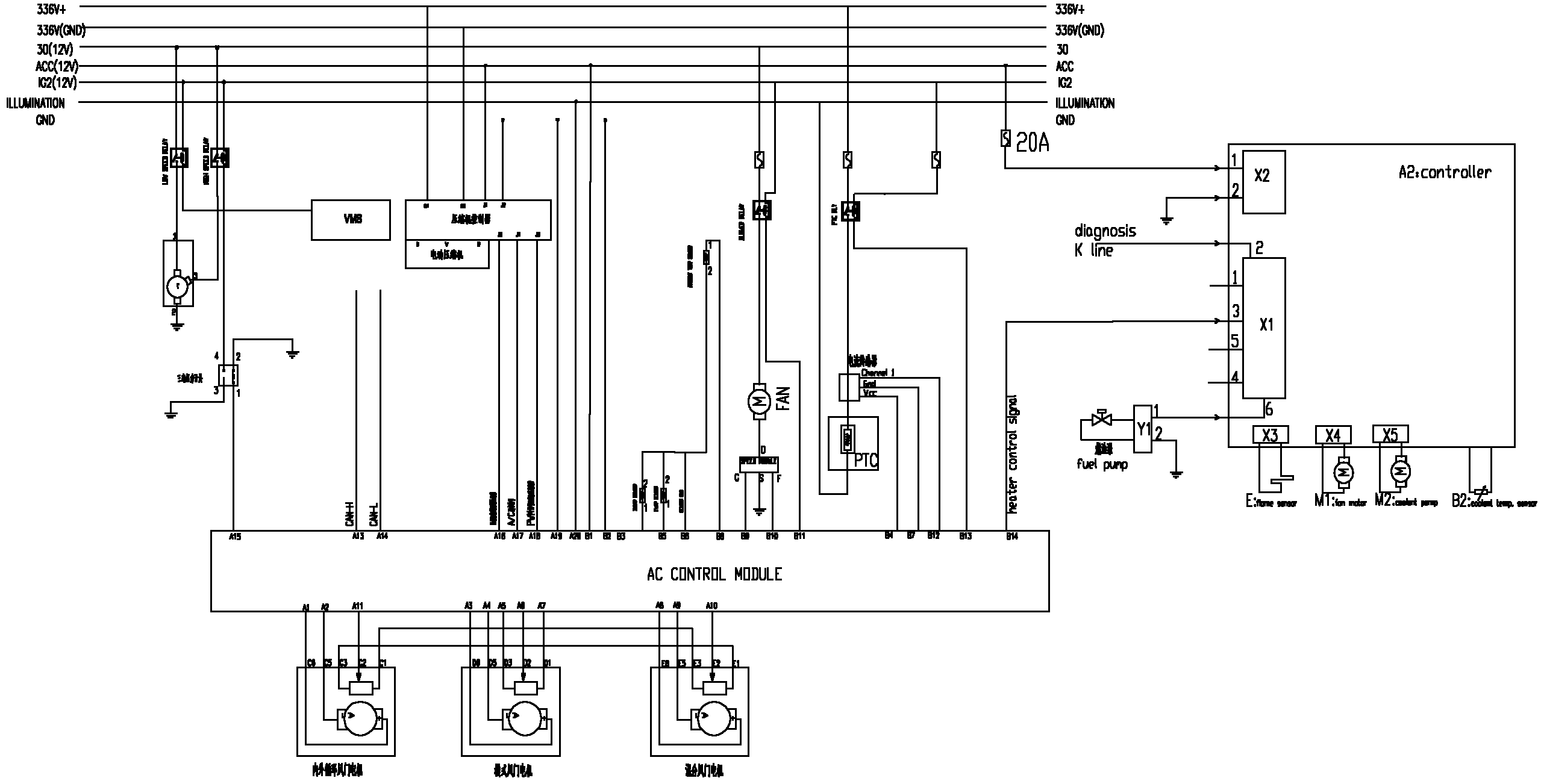

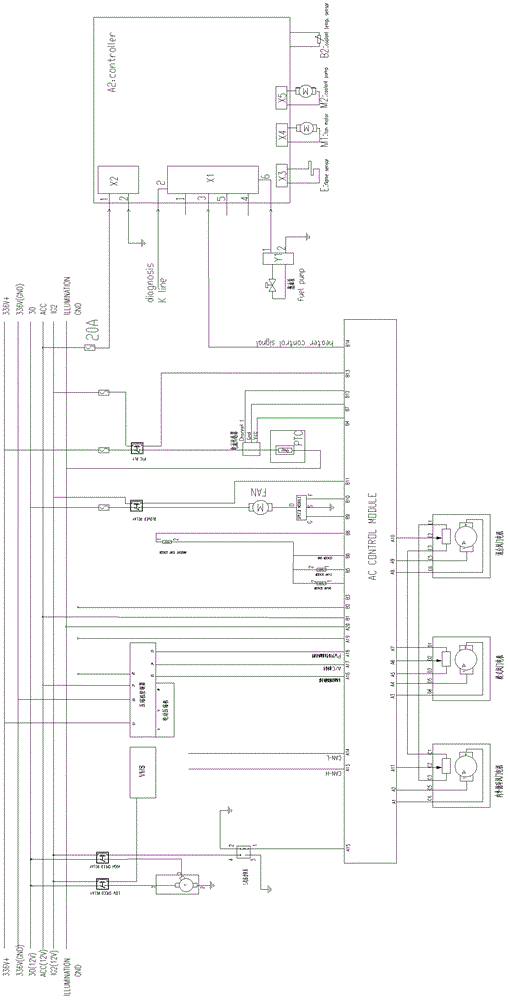

Air conditioning control panel system of electrombile and control method thereof

ActiveCN102501814AControl start and stopAvoid smokyAir-treating devicesVehicle heating/cooling devicesFuel oilEngineering

The invention relates to an air conditioning control panel system of an electrombile and a control method thereof. The air conditioning control panel system of the electrombile comprises an air conditioning control panel, a positive temperature coefficient (PTC) heating element and a fuel oil heater, wherein the PTC heating element and the fuel oil heater are installed on a finished electrombile and used for heating the finished electrombile. The air conditioning control panel is in control connection with the PTC heating element and the fuel oil heater and used for judging whether the PTC heating element or the fuel oil heater is assembled on the finished electrombile and for sending out corresponding start-up information to start up the PTC heating element or the fuel oil heater.

Owner:CHERY AUTOMOBILE CO LTD

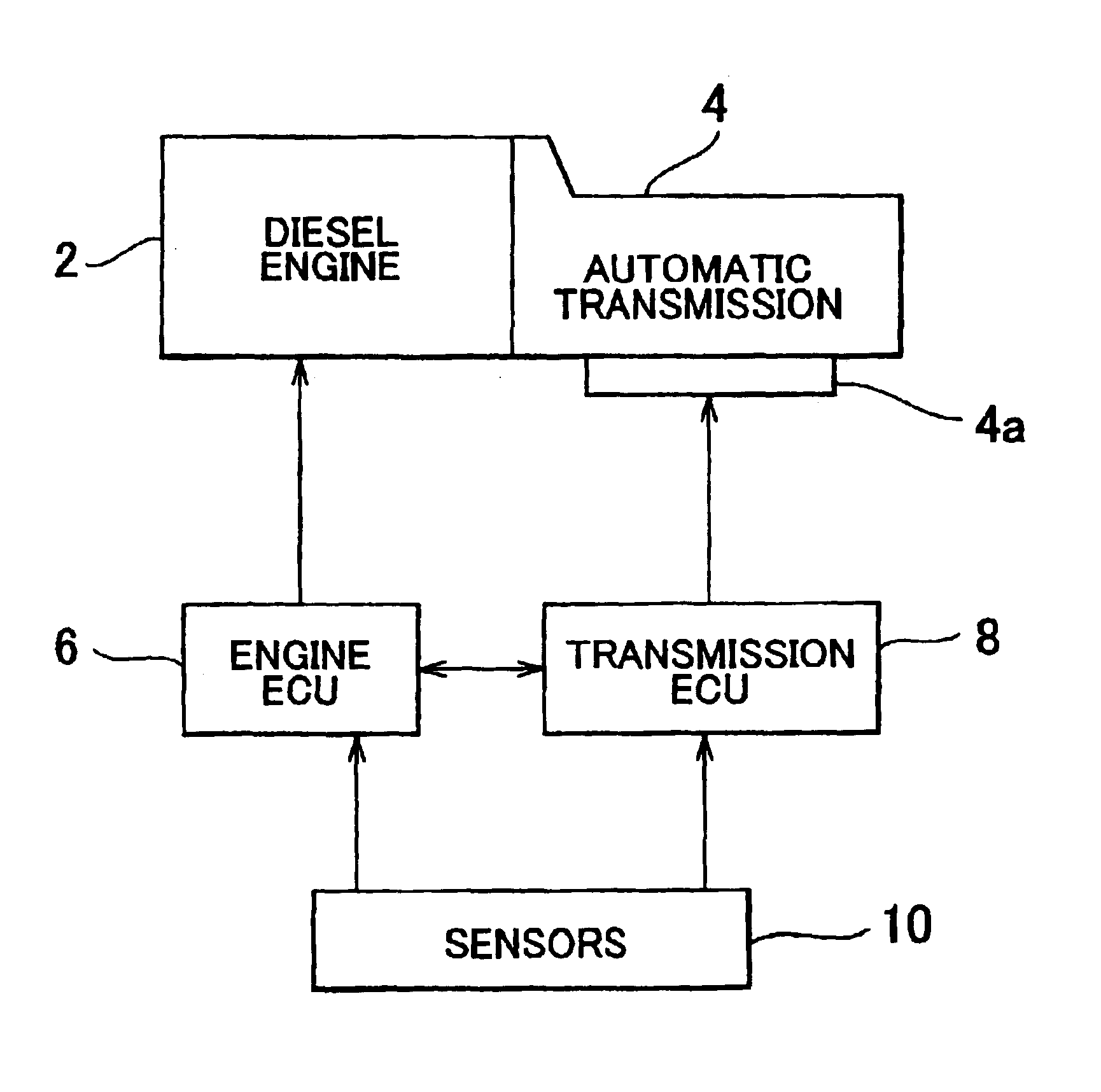

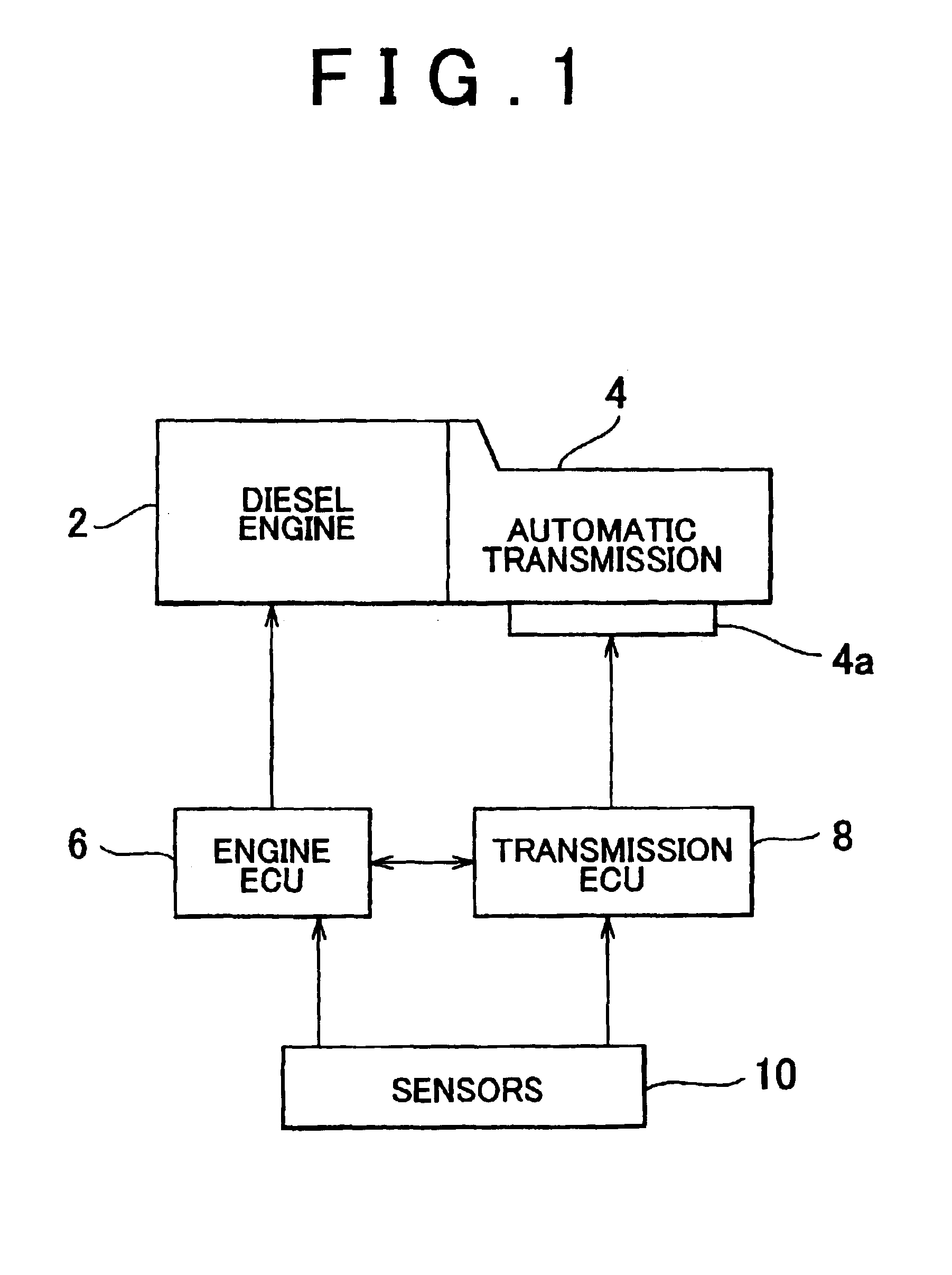

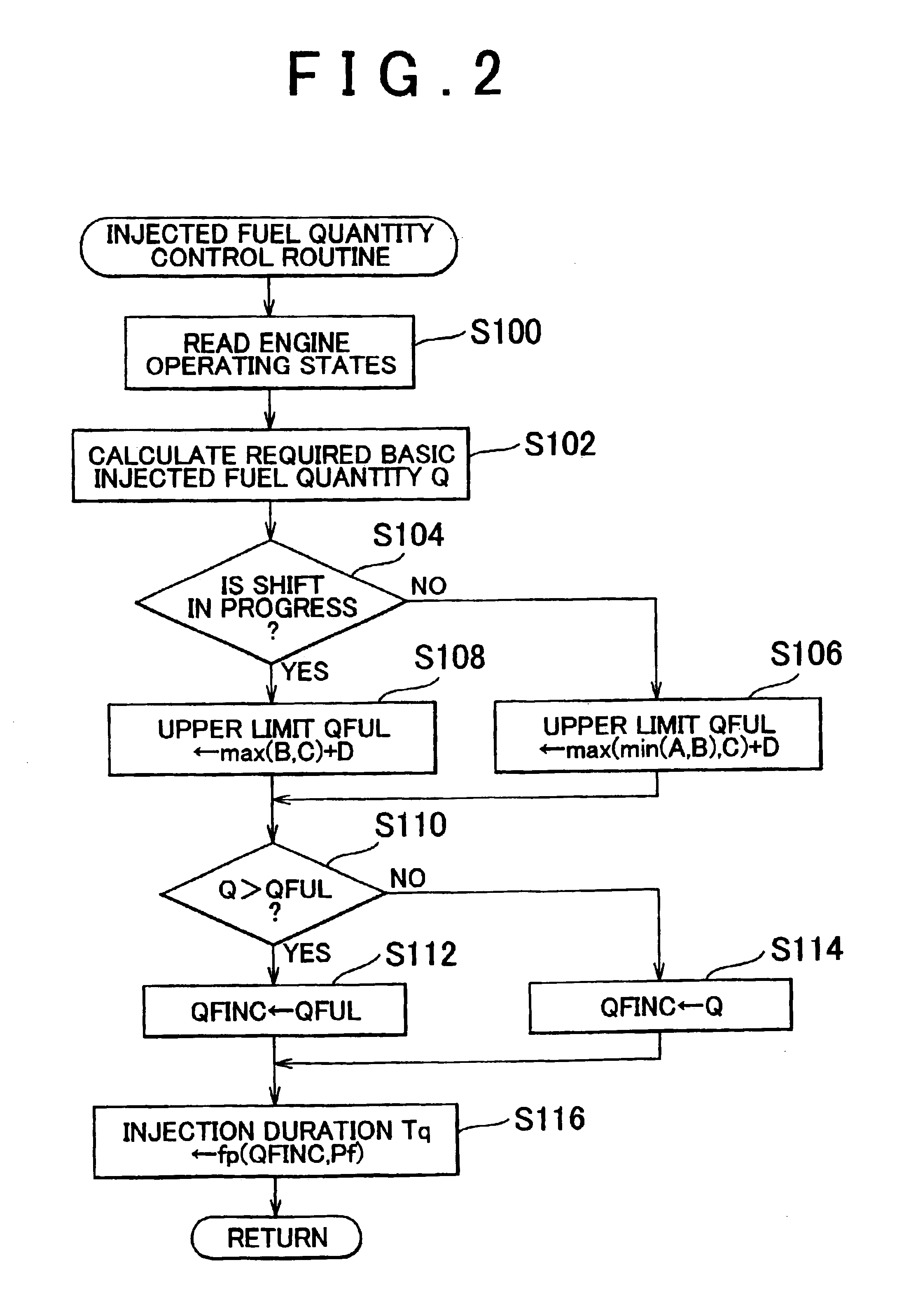

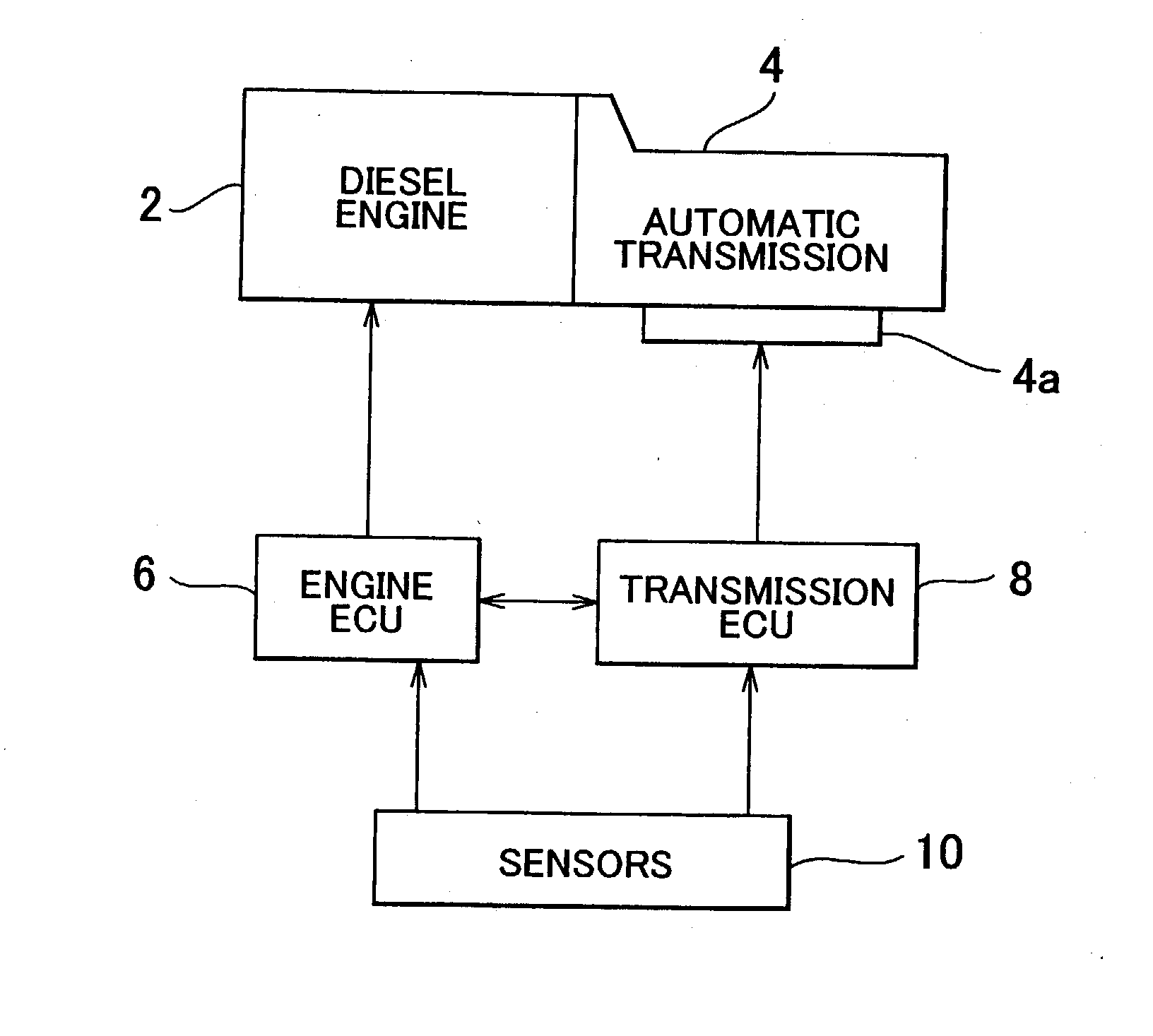

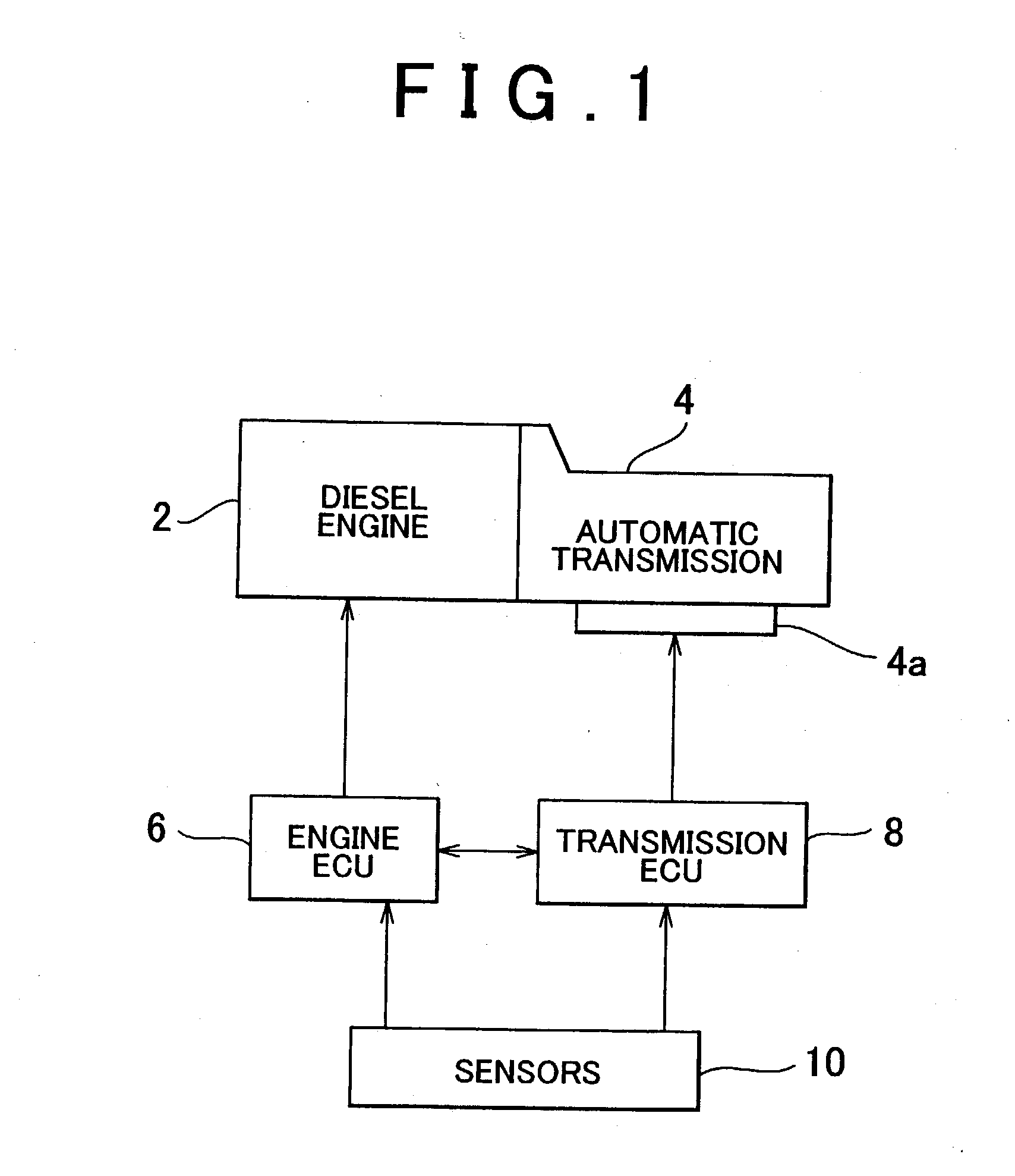

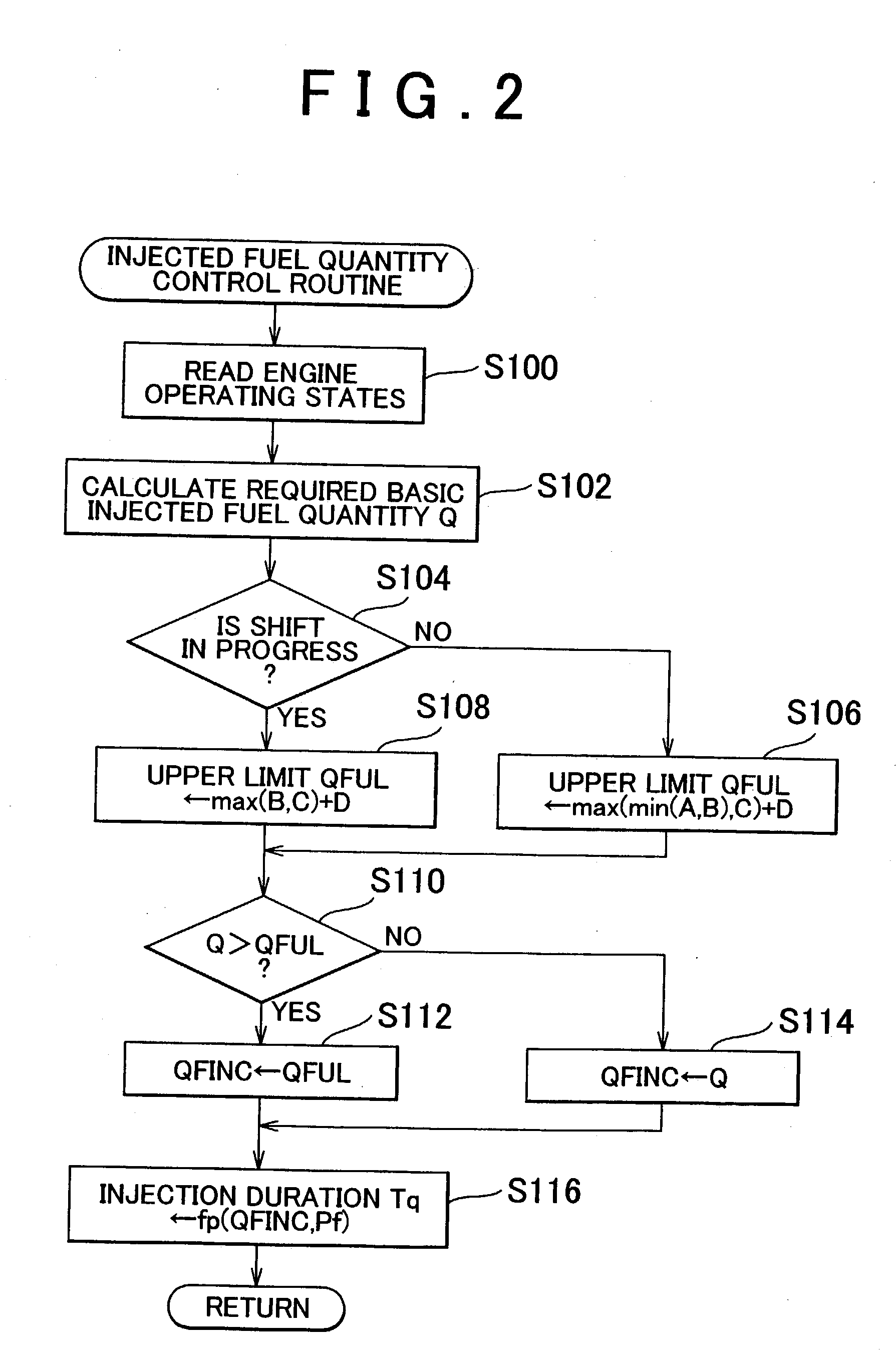

Method and apparatus for controlling diesel engine

InactiveUS6832150B2Reduce outputAvoid smokyAnalogue computers for vehiclesElectrical controlAutomatic transmissionDiesel engine

Owner:TOYOTA JIDOSHA KK

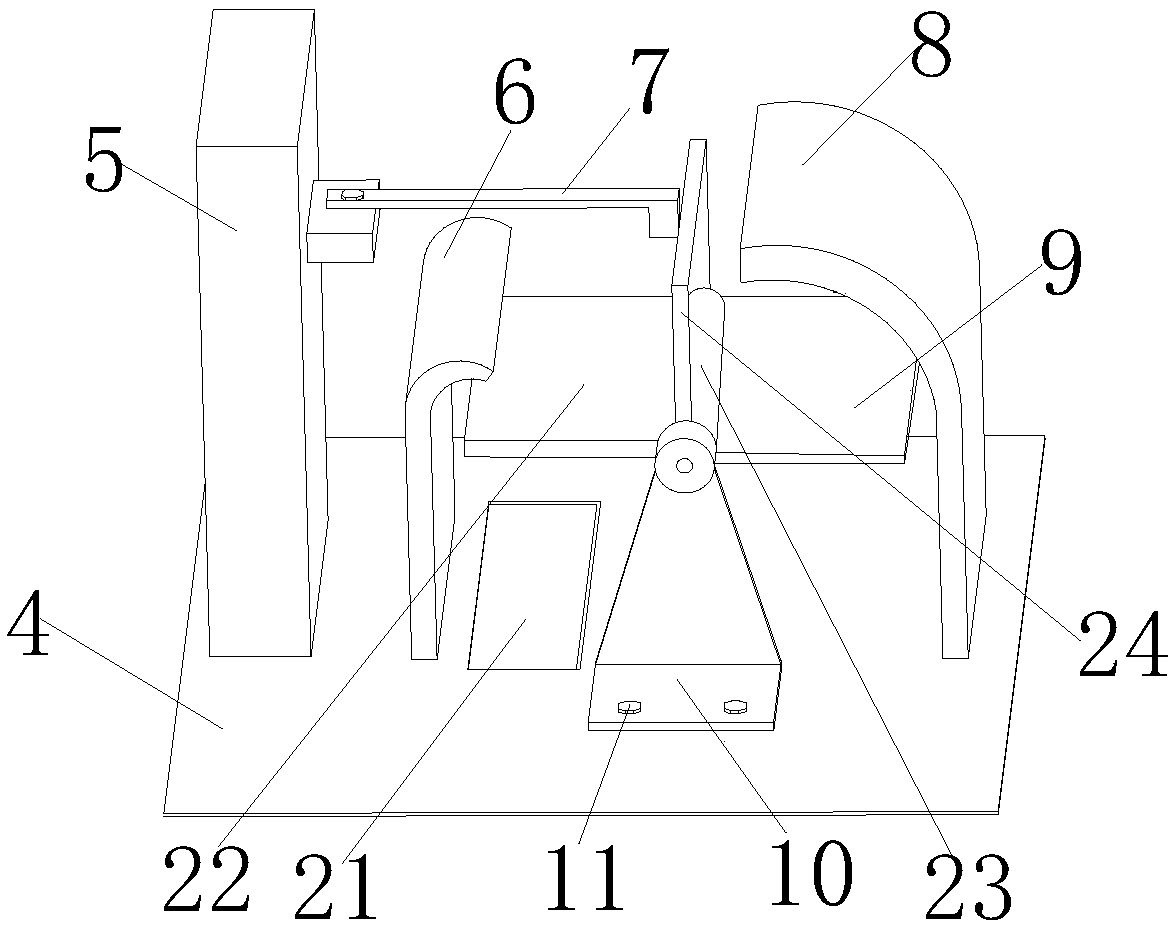

Hazardous waste burning rotary kiln

PendingCN107883383ANot easy to slideImprove wear and tearIncinerator apparatusCombustion chamberRefractory

The invention discloses a hazardous waste burning rotary kiln. The hazardous waste burning rotary kiln comprises a feeding device, a pushing device, a rotary kiln cylinder, a seal device, a kiln headash bucket, a secondary combustion chamber, a bearing device and a drive device; one end of the pushing device extends into one side of a kiln head of the rotary kiln cylinder, the side, extending into the rotary kiln cylinder, of the pushing device is higher than the other side, the lower portion of the feeding device is communicated with the side wall of the upper portion of a material cylinderof the pushing device, the rotary kiln cylinder is axially and horizontally arranged, a refractory material layer is arranged on the inner wall of the rotary kiln cylinder in an attached manner, and the thickness of the refractory material layer is evenly increased in the axial direction from kiln tail to kiln head. Through the technical scheme, the wear condition of the bearing device and the drive device below the rotary kiln cylinder can be avoided, the rotary kiln cylinder is not prone to sliding in the moving direction of materials, meanwhile, black smoke and tempering phenomena of the kiln head can be avoided, a burning system continuously and stably runs, and safety and reliability of the burning system can be ensured.

Owner:BEIJING GEOENVIRON ENG & TECH

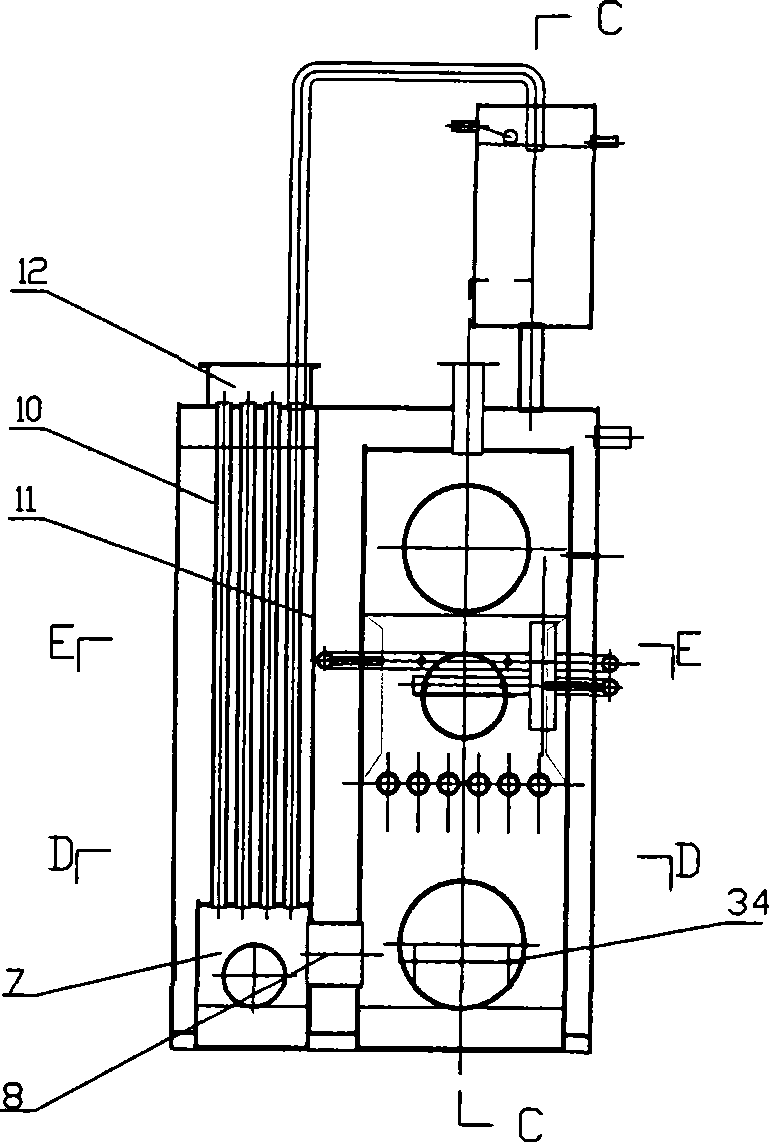

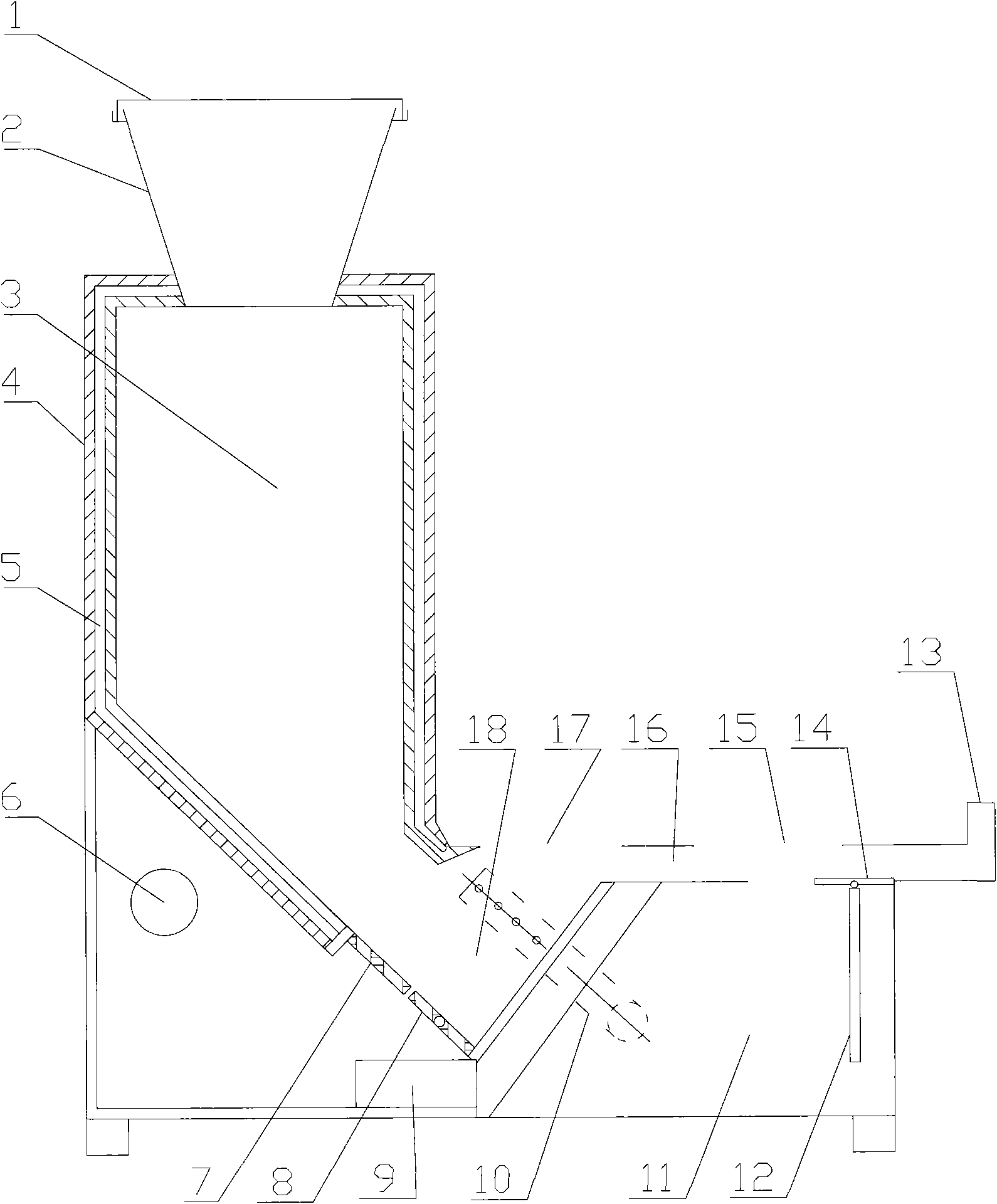

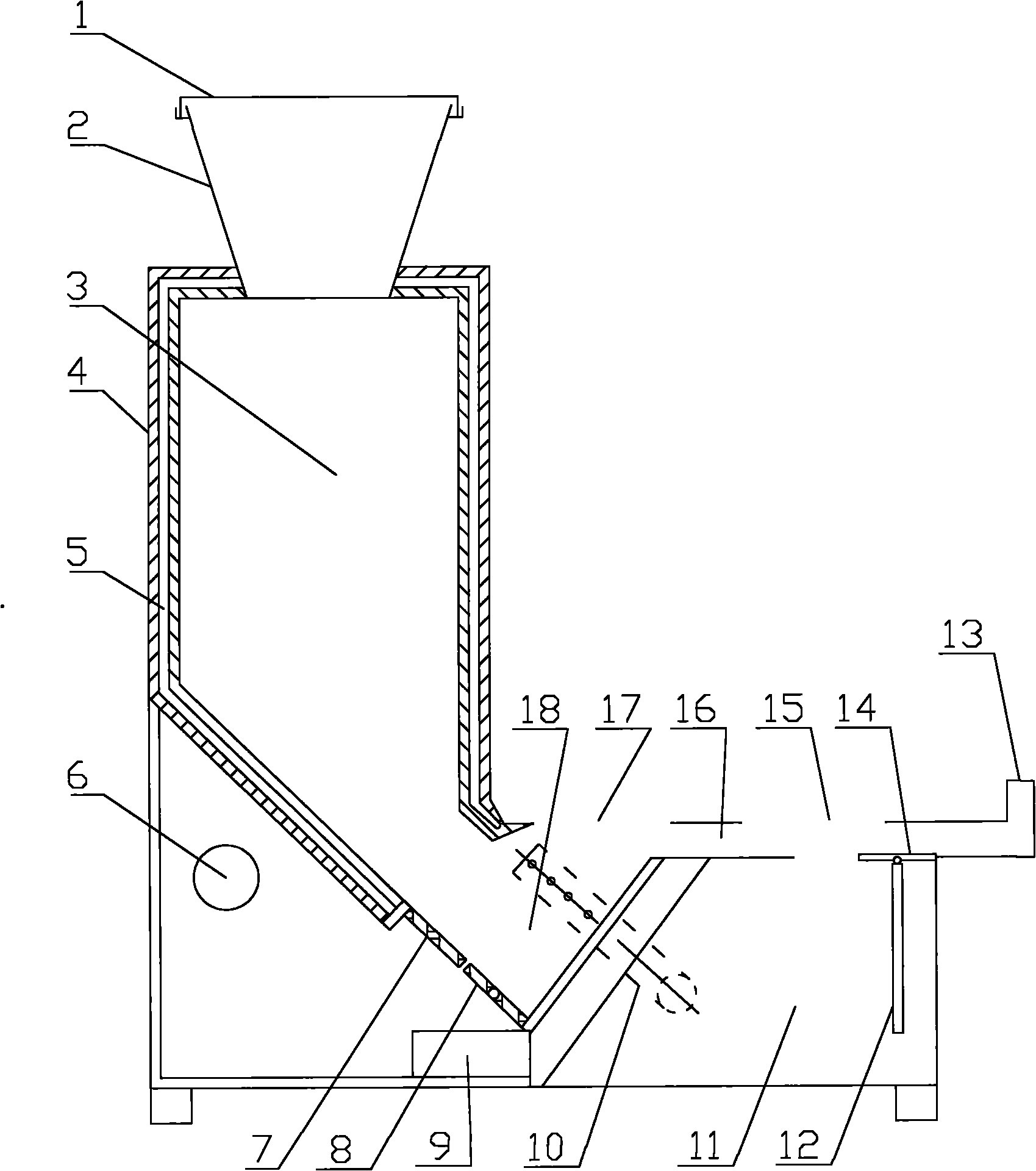

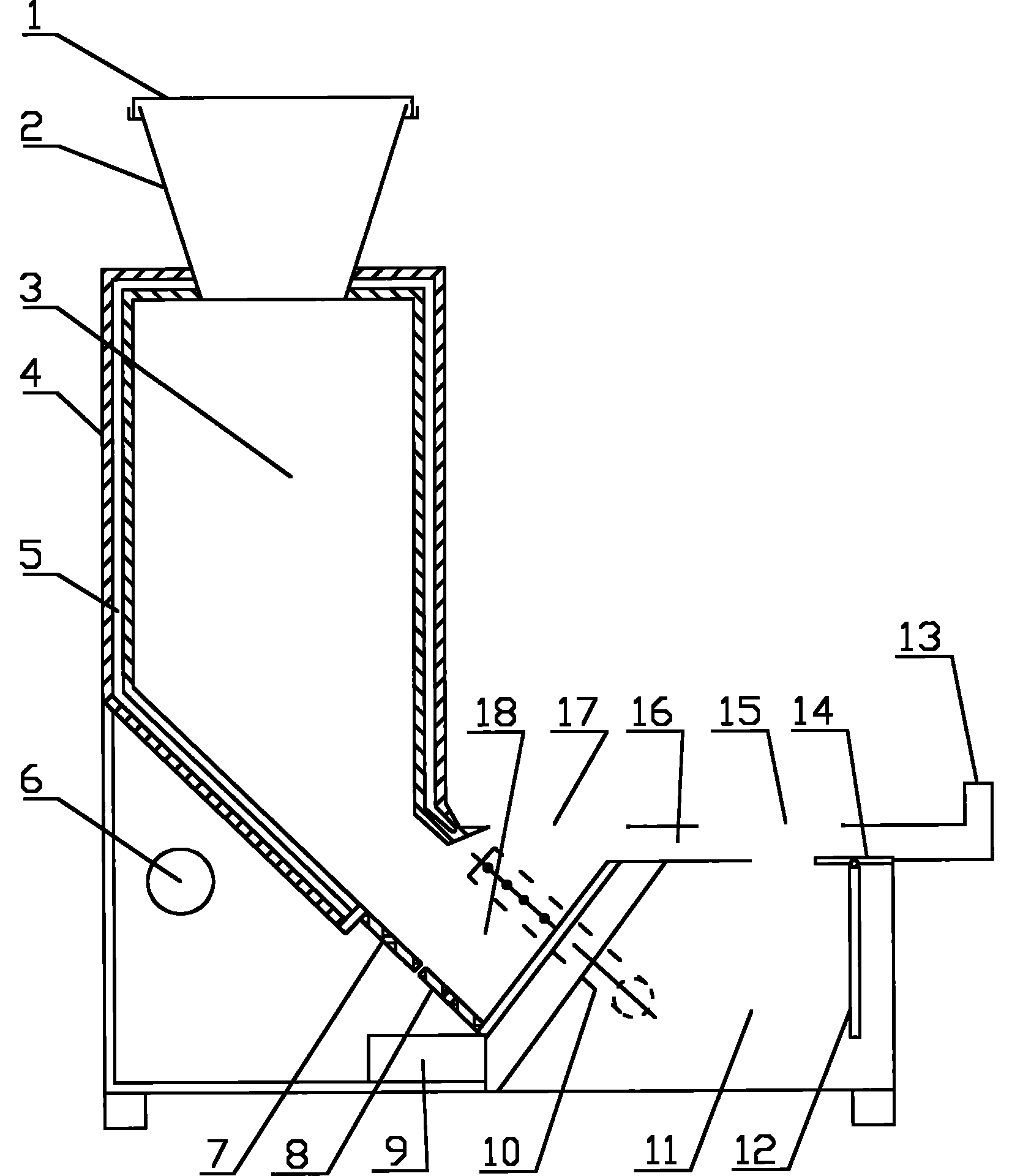

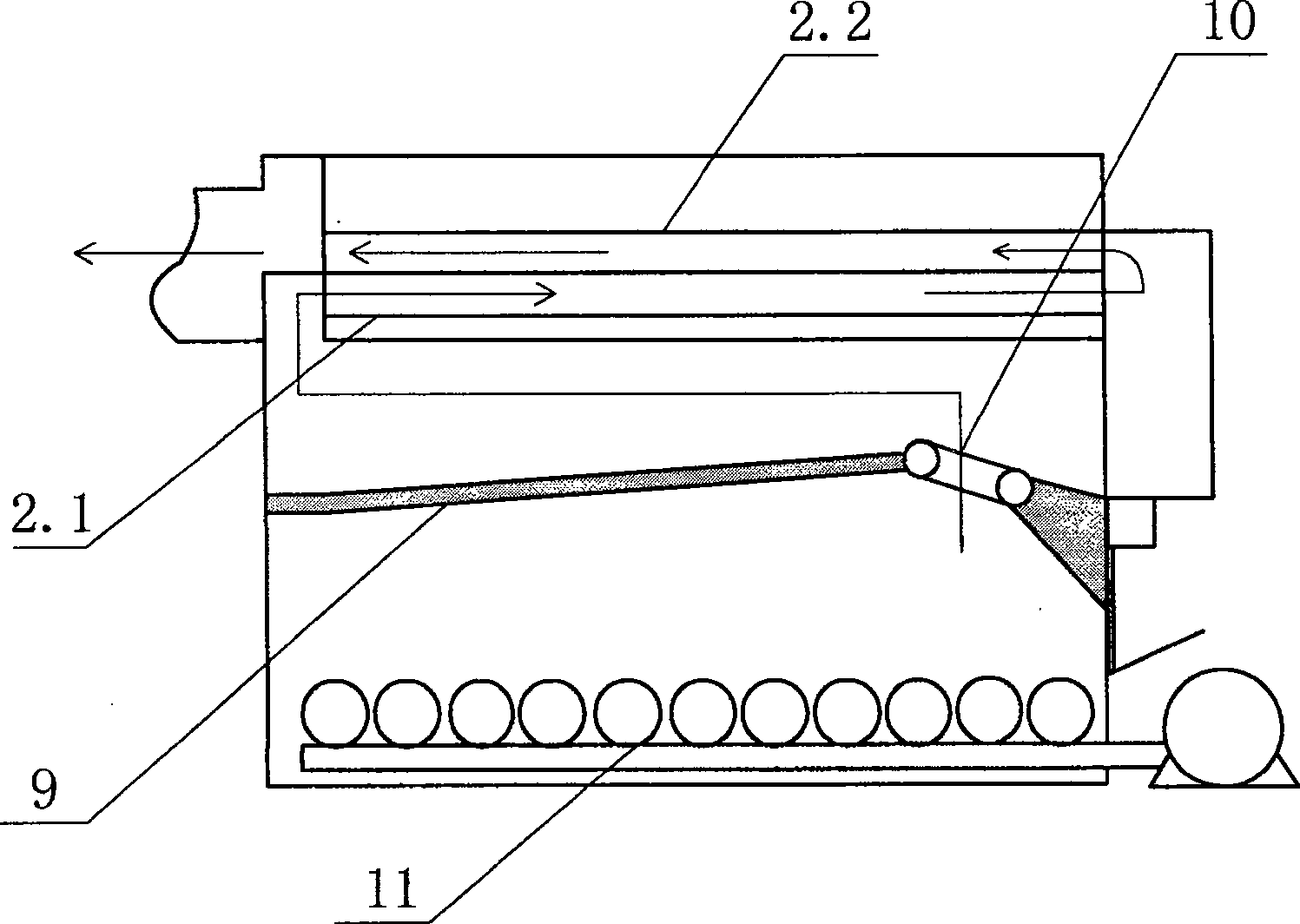

Combustion and smoke and dust removal method of small boiler combusting soft coal II and III

InactiveCN102798120AEmission reductionAvoid smokySolid fuel combustionIndirect carbon-dioxide mitigationEngineeringOxygen

The invention discloses a combustion and smoke and dust removal method of small boiler combusting soft coal II and III. The method comprises the following steps of: (1) combustion and smoke removal: in combustion work of a boiler, primary air enters a fire grate so as to combust coal in a hearth, fume generated in the combustion process in the hearth is blocked by a furnace arch arranged at the back of the hearth and negative pressure is formed at the same time; secondary air is opened automatically to feed air in the furnace arch so as to form an oxygen-enriched region at a furnace arch port, and smoke dust is combusted fully again at the furnace arch port; and (2) dust removal: the fume after combustion and smoke removal enters a first heat exchange region of the boiler to carry out heat exchange and sequentially enters a plurality of rows of vertical fume pipes in a second heat transfer region, wherein the fume enters a first vertical fume pipe from top to bottom, enters a second vertical fume pipe from bottom to top, enters a third vertical fume pipe top to bottom and so on, and dust of the fume in a circulation process falls into a dust cleaning opening. By the method provided by the invention, the small boil can achieve the effects of high-efficiency combustion and cleaning discharge when combusting soft coal II and III, and the heat efficiency of the boiler is improved.

Owner:青岛艳阳天环保有限公司

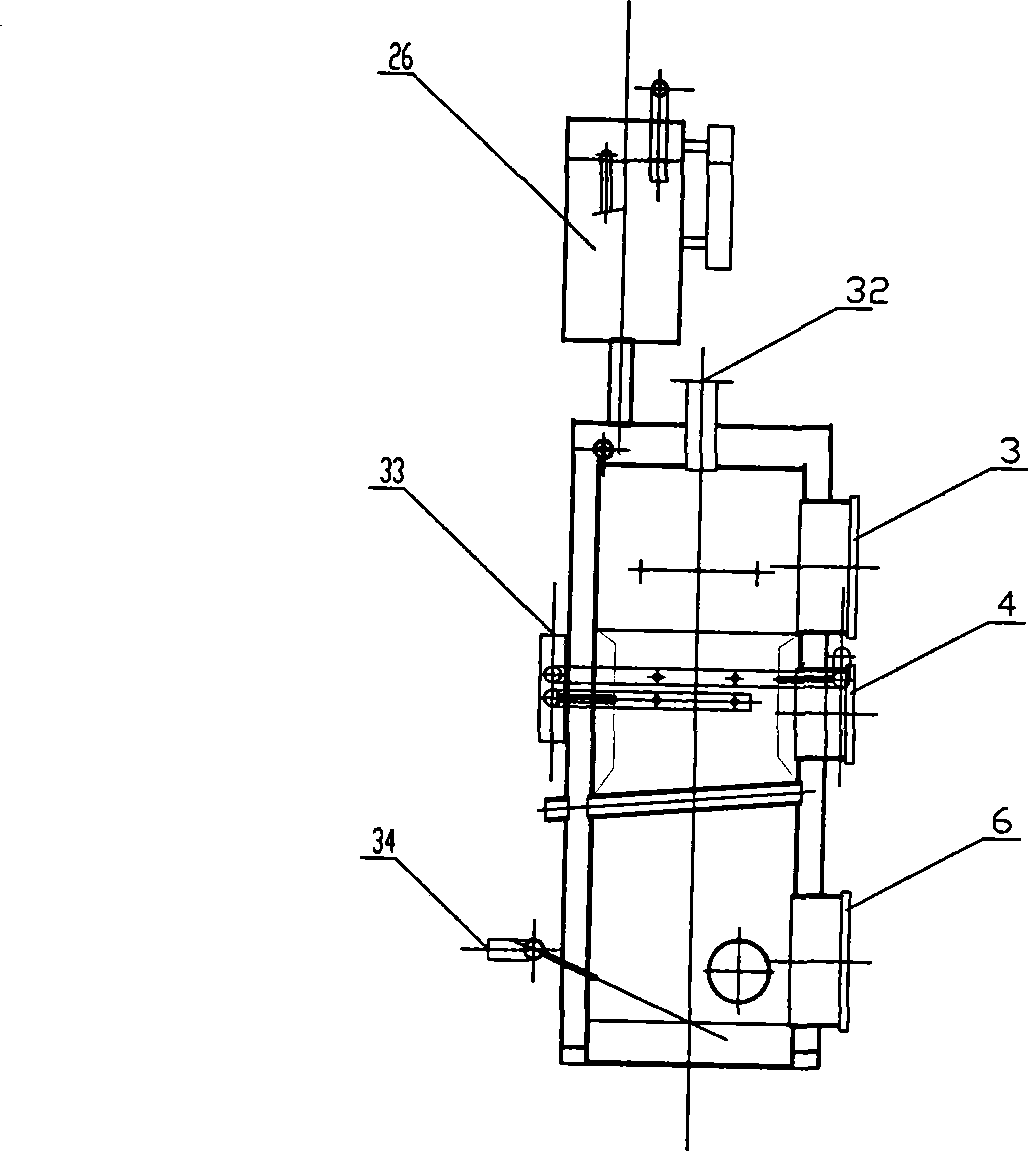

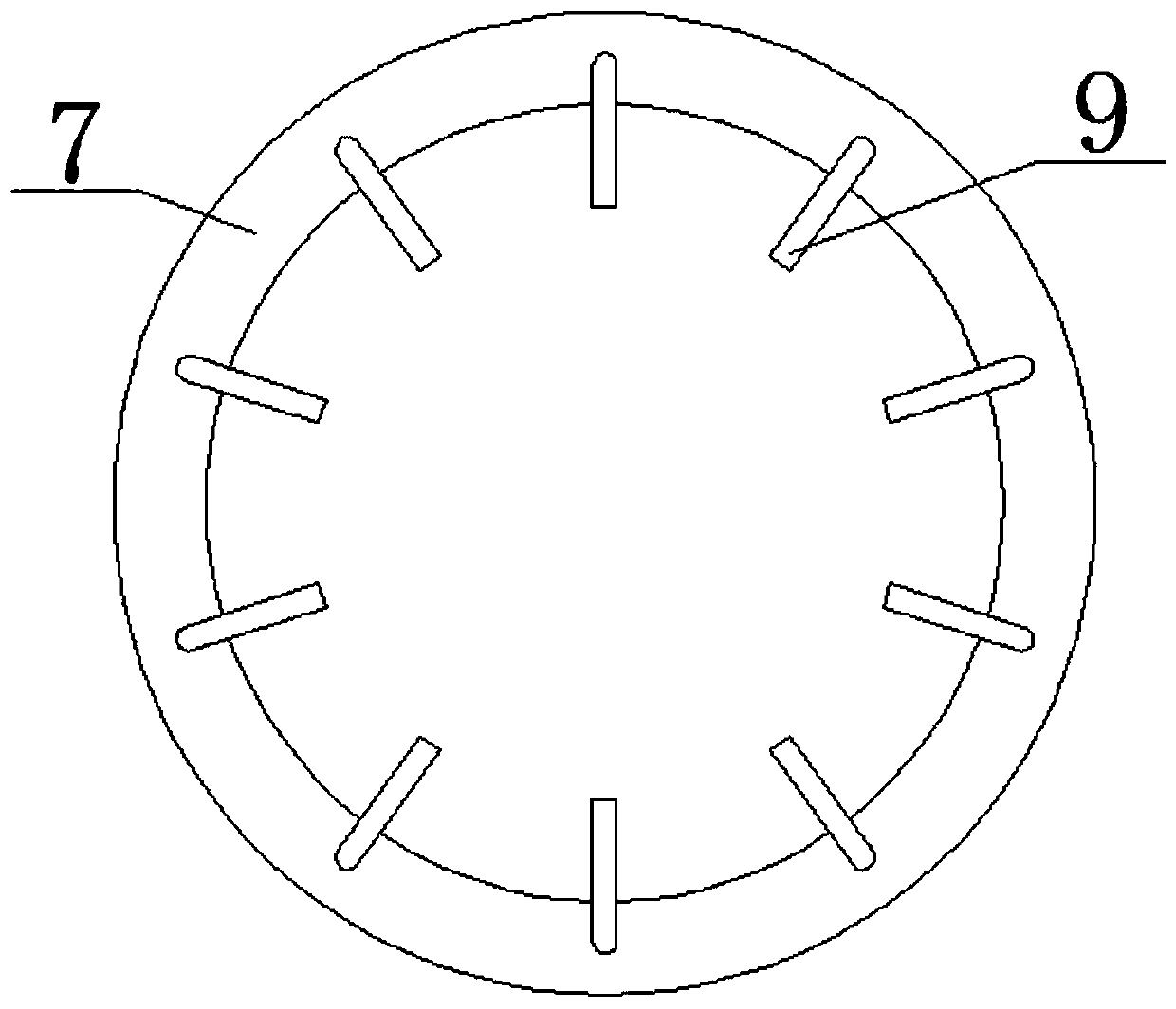

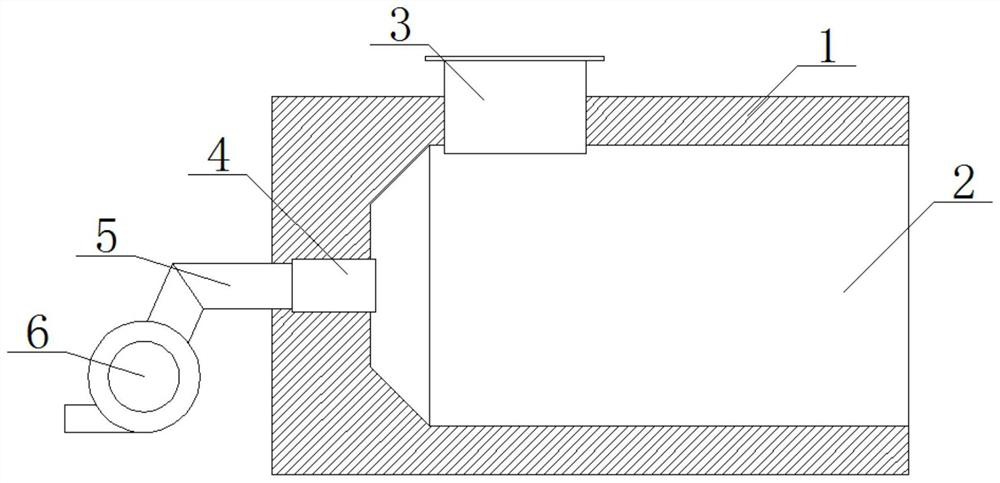

Coal gasification boiler by reverse coal combustion

InactiveCN101382294AEfficient and clean combustionBurn fullyIndirect carbon-dioxide mitigationAir/fuel supply for combustionAutomatic controlBoiler furnace

The invention discloses a novel gasification counter-heating water boiler, which comprises a boiler shell, a boiler furnace, a fire grate, a coal door, a poke door, an ash door, a smoke channel, a chimney and an automatic control device, and is characterized in that: the coal door, the poke door and the ash door are all visible sealed furnace doors with micro positive pressure, and the novel gasification counter-heating water boiler further comprises a circumferential multipoint air distributing device, a wet desulfurizing dust remover of a built-in pipe burying afterheat recycling device, and a smoke gas afterheat recycling air heater. The novel gasification counter-heating water boiler has the advantages of less equipment investment, low running cost, automated operation, 85 percent of the boiler thermal efficiency, low pollutant discharge and boiler modularization, and can be widely used in places needing small-scale heat supply such as residential houses, bath centers, factories, hotels, government agencies and the like.

Owner:QINHUANGDAO JIEMEI BOILERS MFG

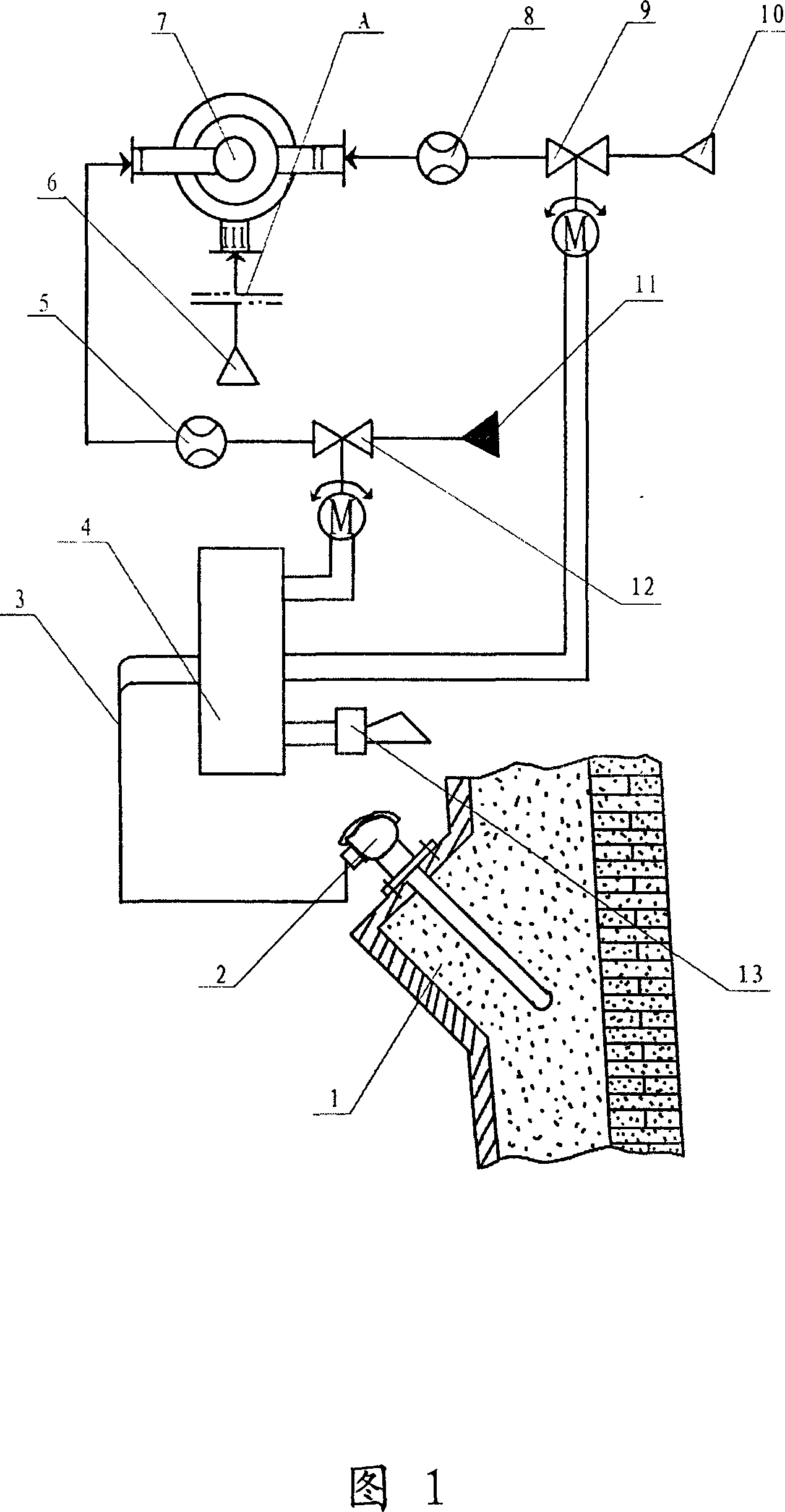

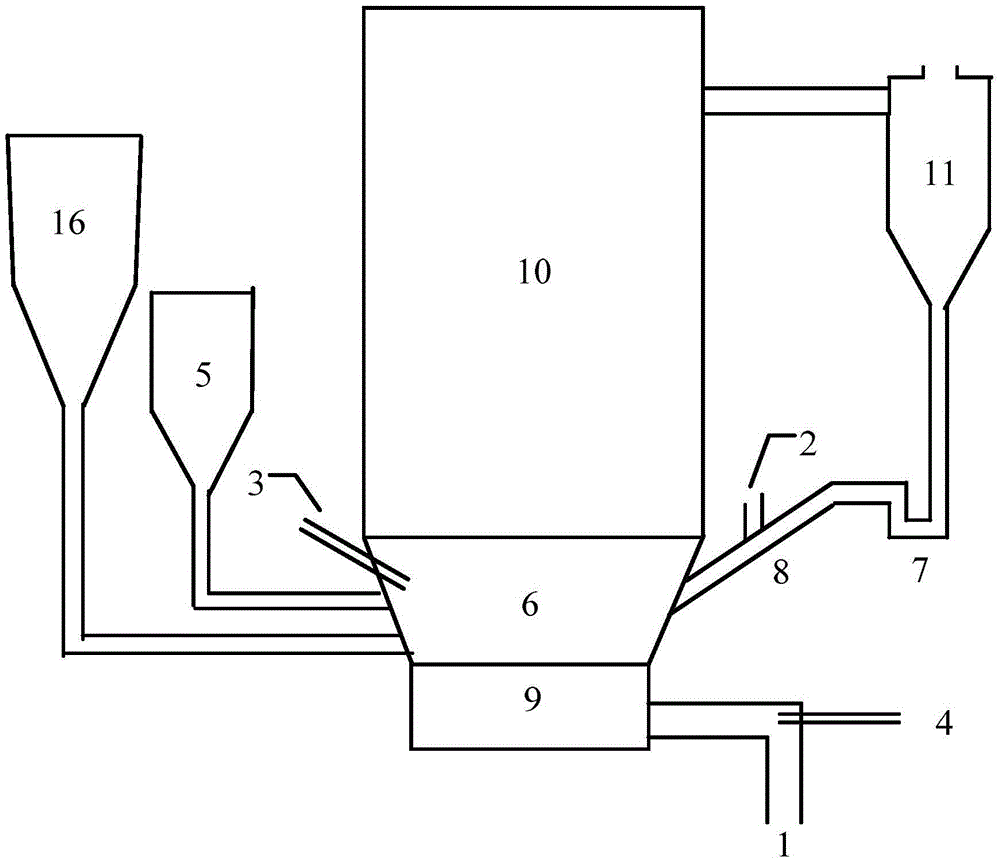

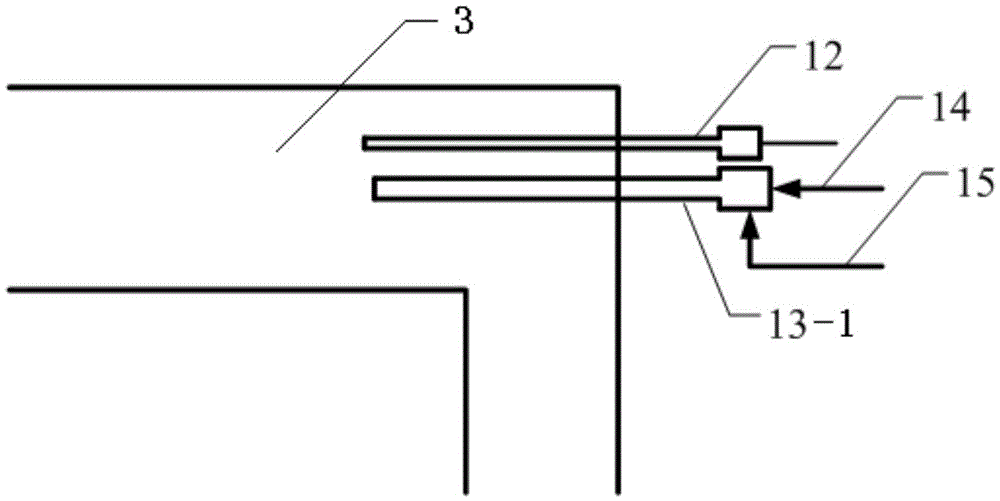

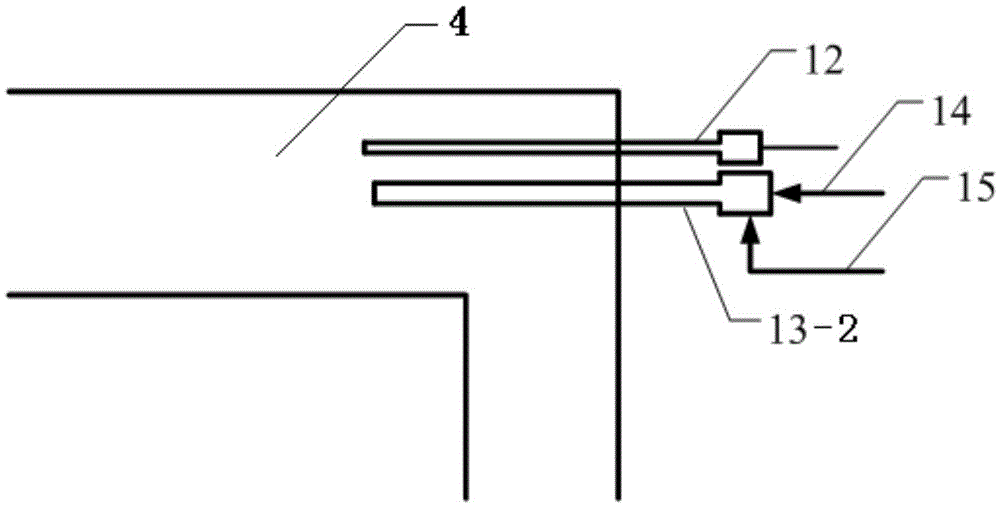

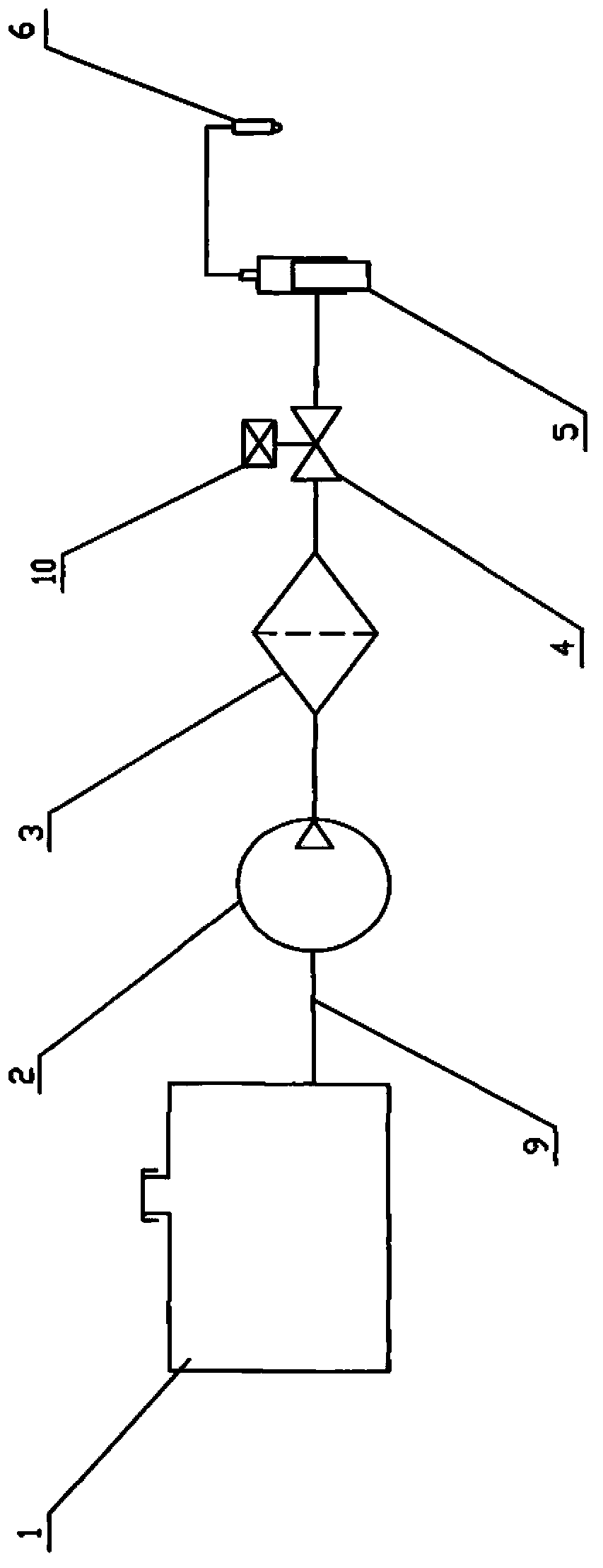

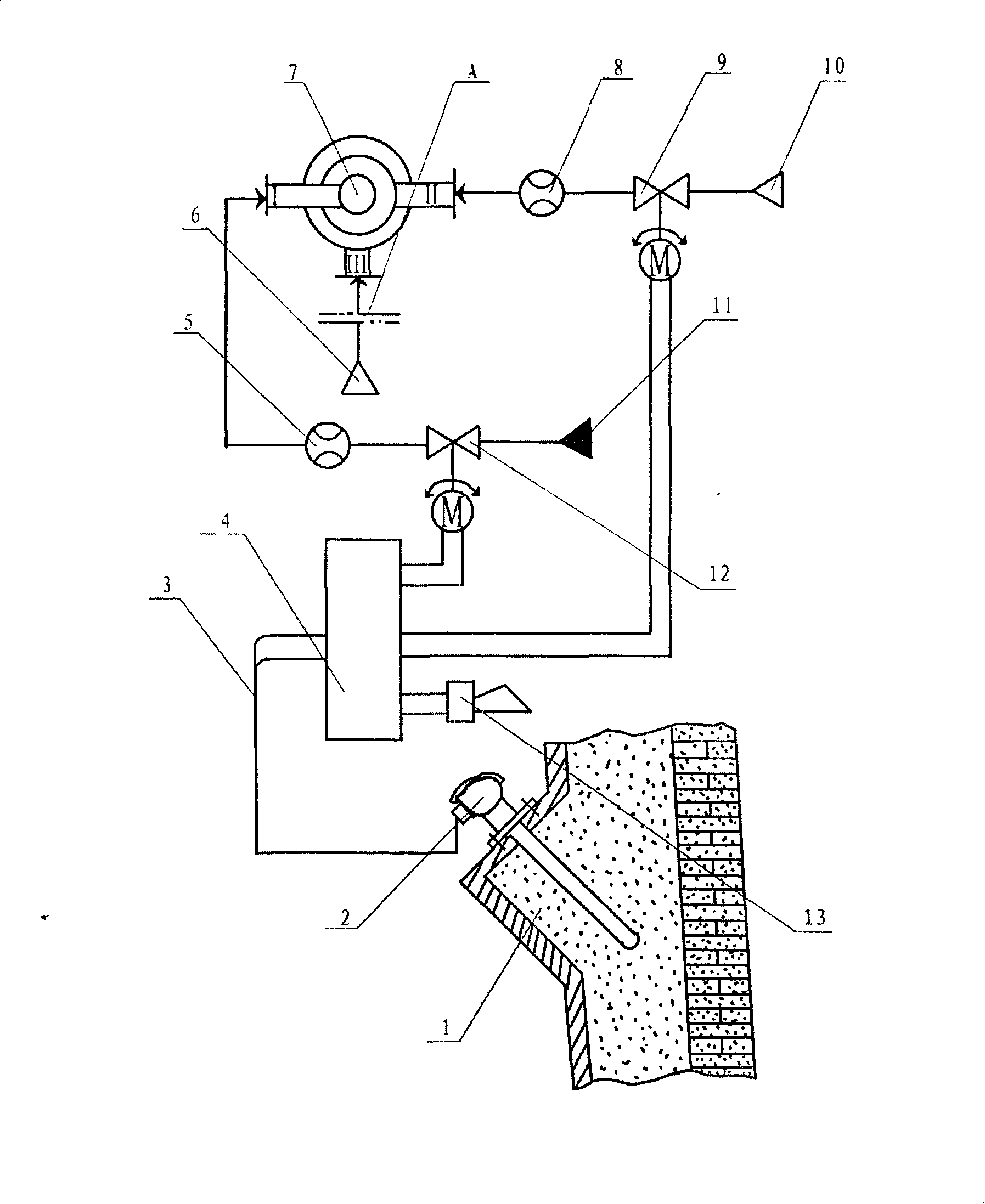

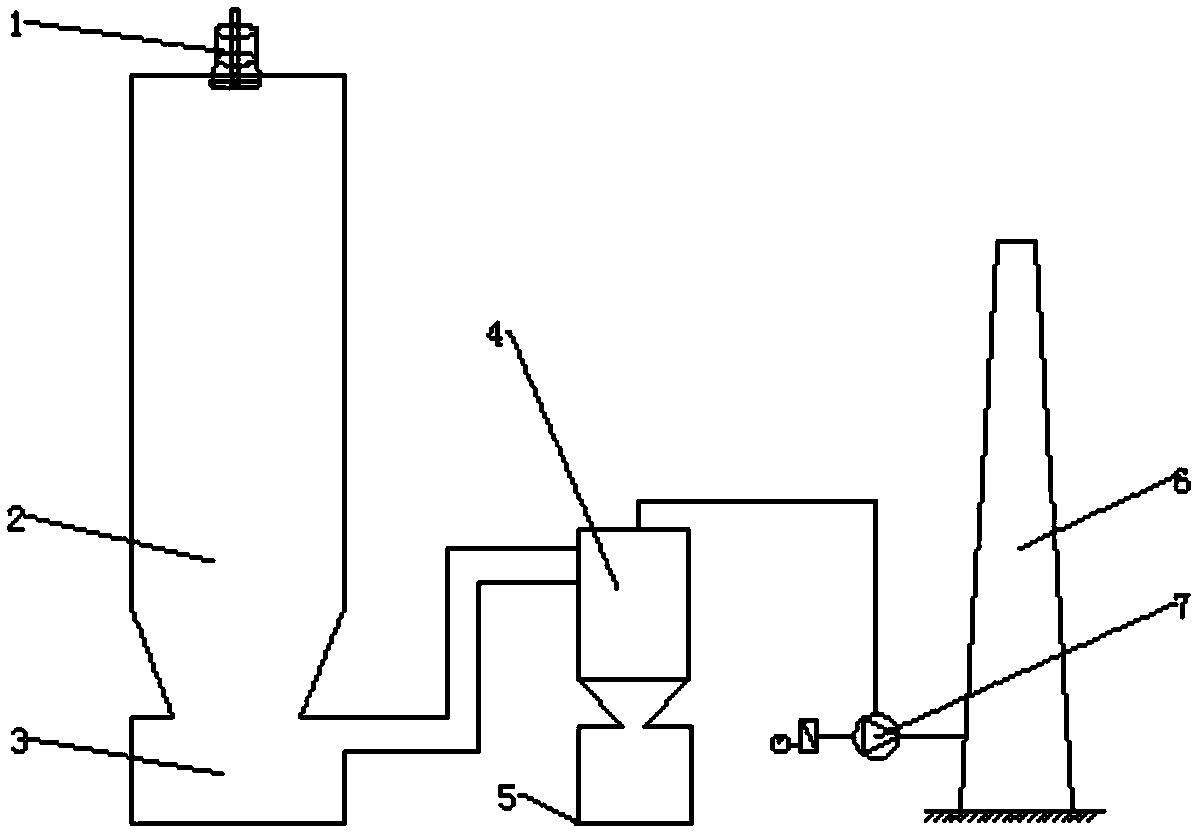

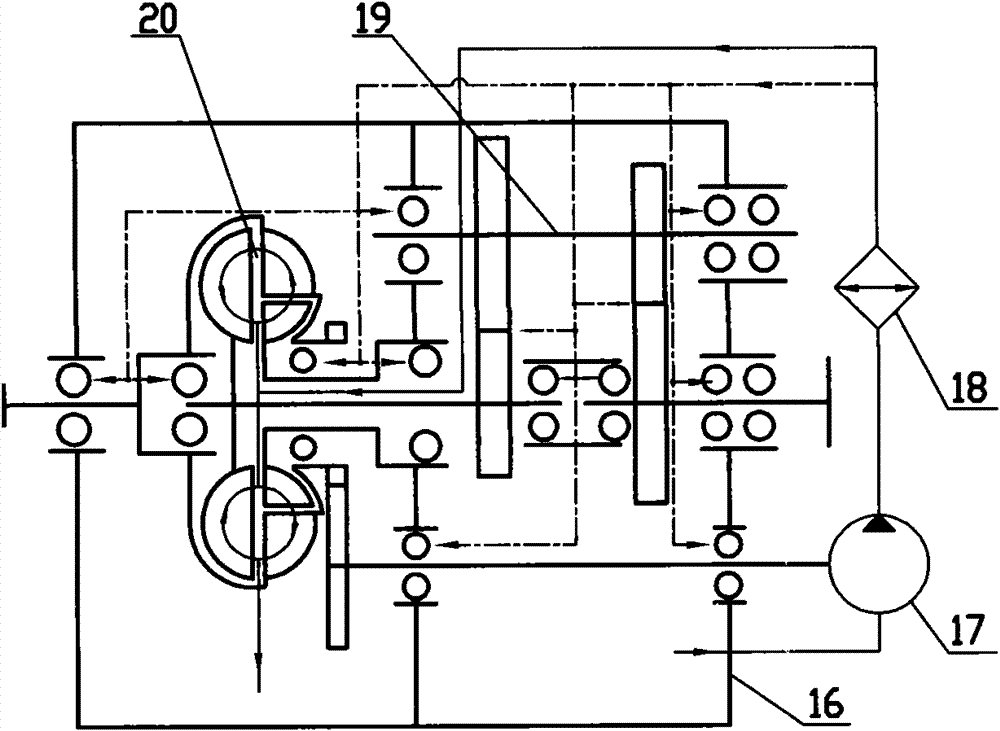

Smokeless oil-saving starting system of circulating fluidized bed boiler

InactiveCN105605564AStart fastReduce lossesFluidized bed combustionApparatus for fluidised bed combustionFuel oilCoal

A smokeless oil-saving starting system of a circulating fluidized bed boiler comprises a flow equalizing breeze system, a bed material supplementing system, a bed combustor system, an air flue combustor system, a starting fuel system, a small-size dense-phase zone and an adjustable material returning system. Micro bubbling fluidization when the boiler is started is realized through the flow equalizing breeze system, and the heat loss during starting is reduced substantially; the bed combustor system and the air flue combustor system are provided with compressed air atomization oil guns, liquid drops are small in size, high in combustion efficiency and good in heat transfer effect, coal can be fed as early as possible when the boiler is started, and fuel oil is saved; by means of the starting mode that the small-size dense-phase zone is matched with the small bed material height, starting power consumption of a primary air fan can be reduced, temperature rise time is shortened, and the material is intermittently put into the bed material supplementing system after the temperature reaches a specified value; multiple technical links are matched to finally achieve smokeless oil-saving fast starting of the boiler.

Owner:HUANENG CLEAN ENERGY RES INST

Biomass fuel steam and hot water boiler

InactiveCN101050860AAchieve reburningImprove combustion efficiencyRevolving grateRocking grateFuel typeEngineering

A steam and hot water boiler of biological material fuel type is prepared for setting secondary air inlet pipe with air inlet hole on fornication of furnace tank, transmission-connecting engine to rolling fire gate at one side of furnace body through driving handle, distributing a numbers of rolling bushing teeth on rolling bushing of rolling fire grate and distributing ventilation holes between rolling bushing teeth.

Owner:葫芦岛市华东锅炉有限公司

Coal and wood dual purpose furnace for cooking and warming

InactiveCN101655247ABurn fullySave resourcesLighting and heating apparatusBiofuelsAutomotive engineeringCoal

The invention discloses a coal and wood dual purpose furnace for cooking and warming. The dual purpose furnace comprises a furnace body, a charging device, a fire grate, a furnace door and a cooking range, wherein the furnace body is provided with a fuel chamber and a combustion chamber, the fuel chamber is communicated with the combustion chamber, the fuel chamber is arranged above one side of the combustion chamber, the cooking range is arranged above the other side of the combustion chamber, the charging device is arranged on the furnace body and at the top of the fuel chamber, the fire grate is arranged in the combustion chamber, the lower part of the bottom of the fuel chamber is provided with a primary tuyere, and the upside of the fire grate is provided with a secondary tuyere. Thefuel chamber is arranged above one side of the combustion chamber and the cooking range is arranged above the other side of the combustion chamber so that the combustion chamber can not only heat thecooking range, but also perform dry distillation to the fuel in the fuel chamber, the volatile generated by the dry distillation of the fuel in the fuel chamber is mixed with the secondary air to burnin the combustion chamber while the fuel becomes loose after the dry distillation and carbonization so that the fuel is easy to drop into the combustion chamber to burn, the ash is discharged from the fire grate, and the combustion is extremely sufficient without black smoke.

Owner:慈鲁

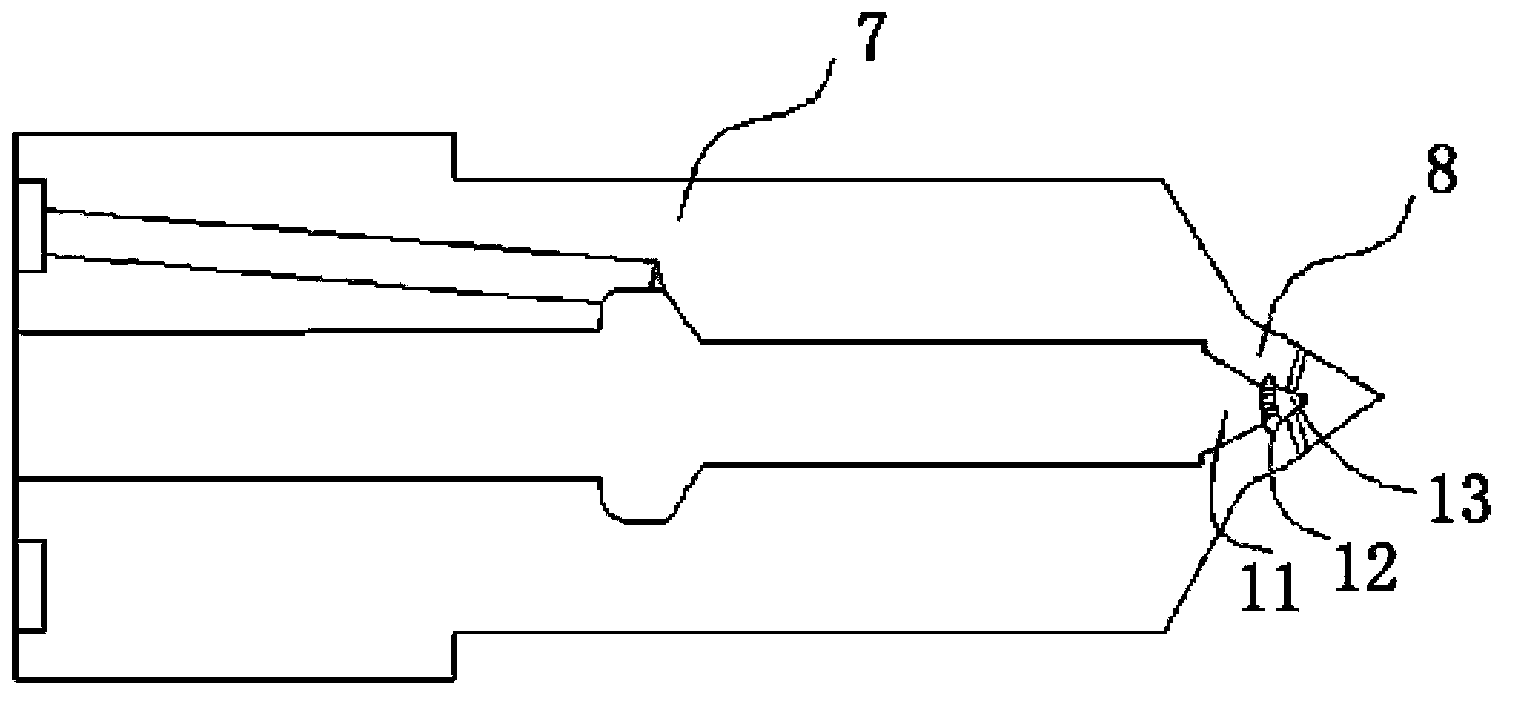

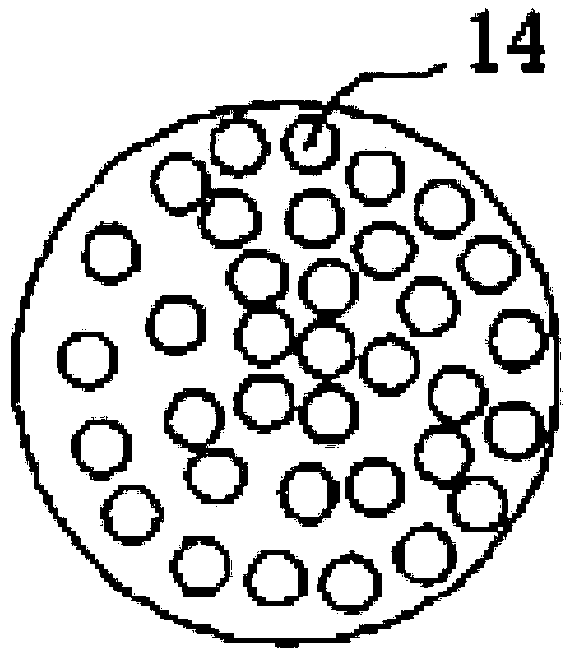

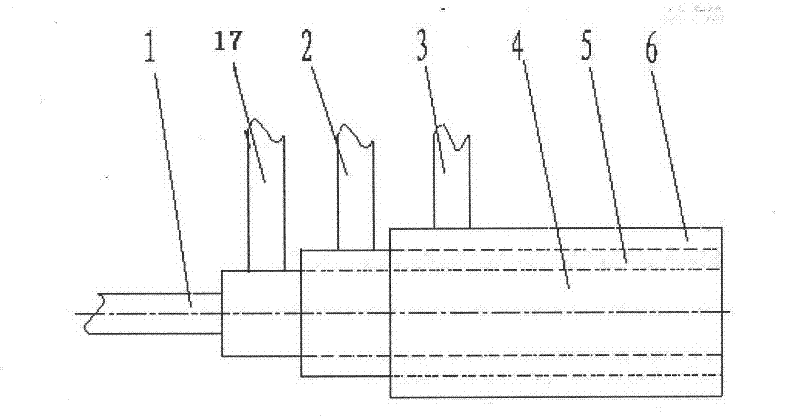

Structure improved diesel engine fuel supplying system

InactiveCN103573509AReduce volumeImprove atomization uniformityFuel injection apparatusMachines/enginesSolenoid valveFuel tank

The invention discloses a structure improved diesel engine fuel supplying system. The structure improved diesel engine fuel supplying system comprises a fuel tank, a fuel feeding pump, a filter and a fuel injection pump which are connected through pipelines; the pipeline which is arranged between the filter and the fuel injection pump is provided with a solenoid valve; the fuel injection pump is provided with a fuel injection nozzle which comprises a needle valve body and a needle valve; the needle valve body is formed by a body and an end body; the upper pressure chamber, the middle pressure chamber and the lower pressure chamber which are communicated with each other in turn are formed in the end body; the upper pressure chamber and the lower pressure chamber are of frustum-shaped structures; the middle pressure chamber is of a circular-ring-shaped structure; the needle valve is arranged in the needle valve body; the head of the needle valve is of a frustum-shaped structure which is matched with the upper pressure chamber and the lower pressure chamber; the frustum-shaped head of the needle valve is provided with the spherical segment. According to the structure improved diesel engine fuel supplying system, volumes of the pressure chambers are saved, the uniformity of atomization of the fuel is improved, and accordingly the fuel can be fully burnt, the fuel drip is avoided, the energy is saved, the overspeed rotation of an engine due to the fact that fuel supply is out of control is avoided, the engine is protected, and the environment is protected.

Owner:JIANGSU KANGWO POWER TECH

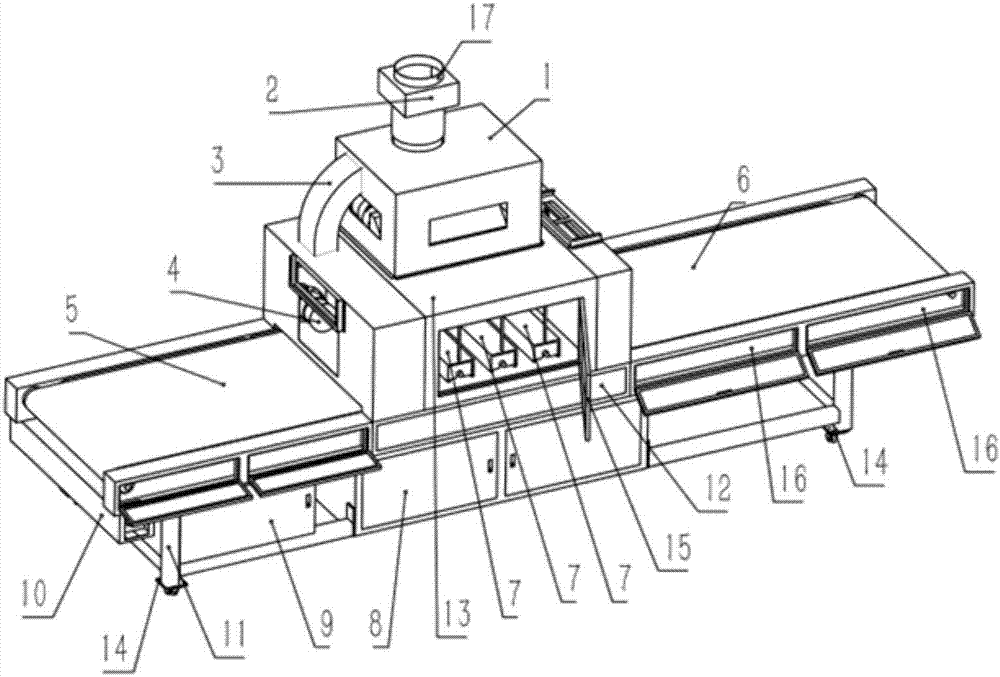

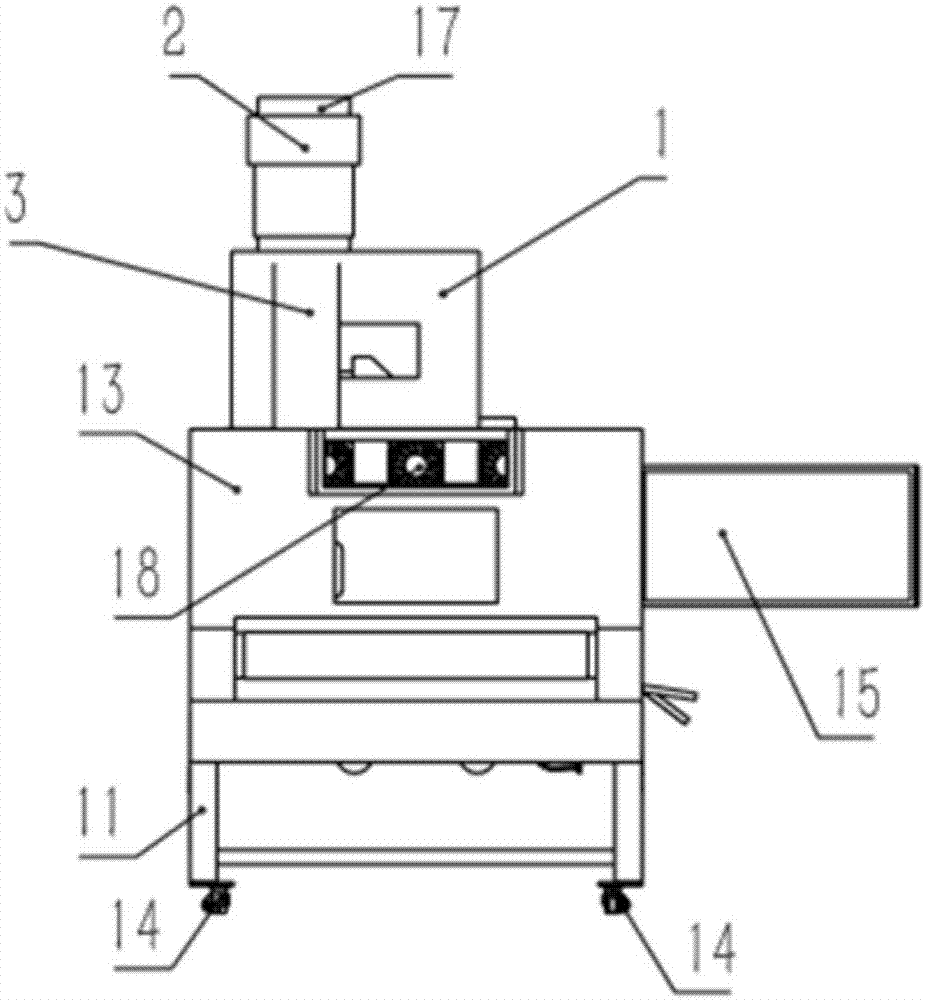

Barbecue grill

PendingCN107440549AWith refrigeration and preservation functionAvoid smokyRoasters/grillsVehicle frameEnvironmental engineering

The invention provides a barbecue grill, comprising a low-temperature plasma purifier, a range hood, an exhaust pipe of the range hood, a blower, a barbecue finished product storing area, a particle holding area, a barbecue oven, a control cabinet, a refrigerated cabinet, a water tank, a carframe, an ash receiving pan, a barbecue oven outer frame, wheels, a protective door, a tableware storing cabinet 16, an air outlet pipe and an air supplying hose. According to the barbecue grill, the barbecue grill can be used for multiple purposes, is movable, can carry sanitary water and tableware which are needed, and has the function of refrigerating and fresh keeping on food, so that the smoky and burning situations of charcoal fire and pollution to the environment are avoided while people can taste the delicacy of traditional charcoal fire barbecue.

Owner:广东清风来环保科技有限公司

Method and apparatus for controlling diesel engine

InactiveUS20030224905A1Reduce outputAvoid smokyAnalogue computers for vehiclesElectrical controlAutomatic transmissionEngineering

In a method of controlling a diesel engine that performs an injected fuel quantity reduction process for preventing black smoke based on an engine speed, and performs an injected fuel quantity reduction process for preventing shift shock during shifting of an automatic transmission, the injected fuel quantity reduction process for preventing black smoke is inhibited or the amount of reduction of the injected fuel quantity for preventing black smoke is reduced during shifting of the automatic transmission or during execution of the injected fuel quantity reduction process for preventing shift shock.

Owner:TOYOTA JIDOSHA KK

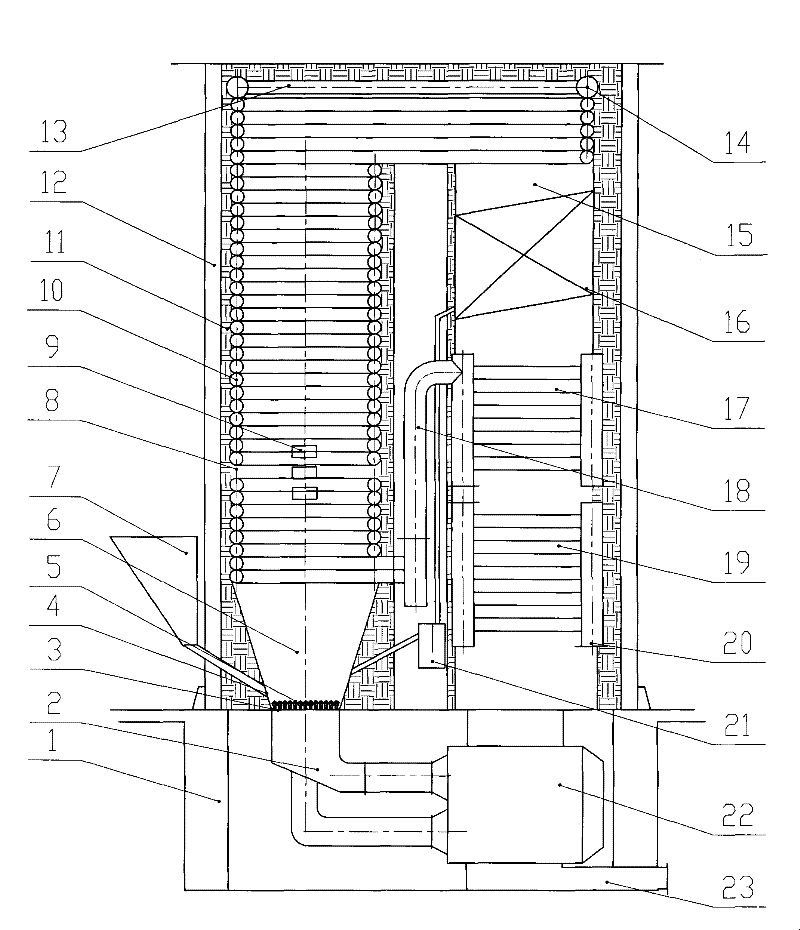

High-efficiency energy-saving emission-reduction circulating fluid bed organic heat carrier boiler

InactiveCN101545676BImprove combustion efficiencyImprove adaptabilityFluidized bed combustionStorage heatersAir preheaterHeat carrier

The invention discloses a high-efficiency energy-saving emission-reduction circulating fluid bed organic heat carrier boiler which comprises a boiler base, a coal scuttle and a heat medium circulation pump, wherein a boiler body formed by steel racks and insulation fire-resistant layers from outside to inside is arranged on the upside of the boiler base; a hearth and a flue the top parts of whichare communicated are arranged in the boiler body in parallel; a top part heating surface and a square plate radiation heating pipe bundle are arranged on the upper part of the hearth from top to bottom; a secondary wind nozzle is arranged in a clearance of coil pipes; the lower part of the hearth is provided with a grid plate, a wind cap and an equipressure wind box; the flue is sequentially provided with an outlet container, a cyclone separating device, a high-temperature convection pipe bundle, a low-temperature convection pipe bundle and an air preheater; the flue is communicated with a smoke outlet arranged on the underside through the air preheater; the cyclone separating device is communicated with the hearth by a pipeline through a back feeder; the high-temperature convection pipe bundle is communicated with the square plate radiation heating pipe bundle by a middle linkage box; the low temperature convection pipe bundle is communicated with the heat medium circulation pump; and the heating surface is communicated with a heat device by the outlet container. The invention protects the environment, saves energy and has long service life.

Owner:SHANDONG SHENGWEI BOILER

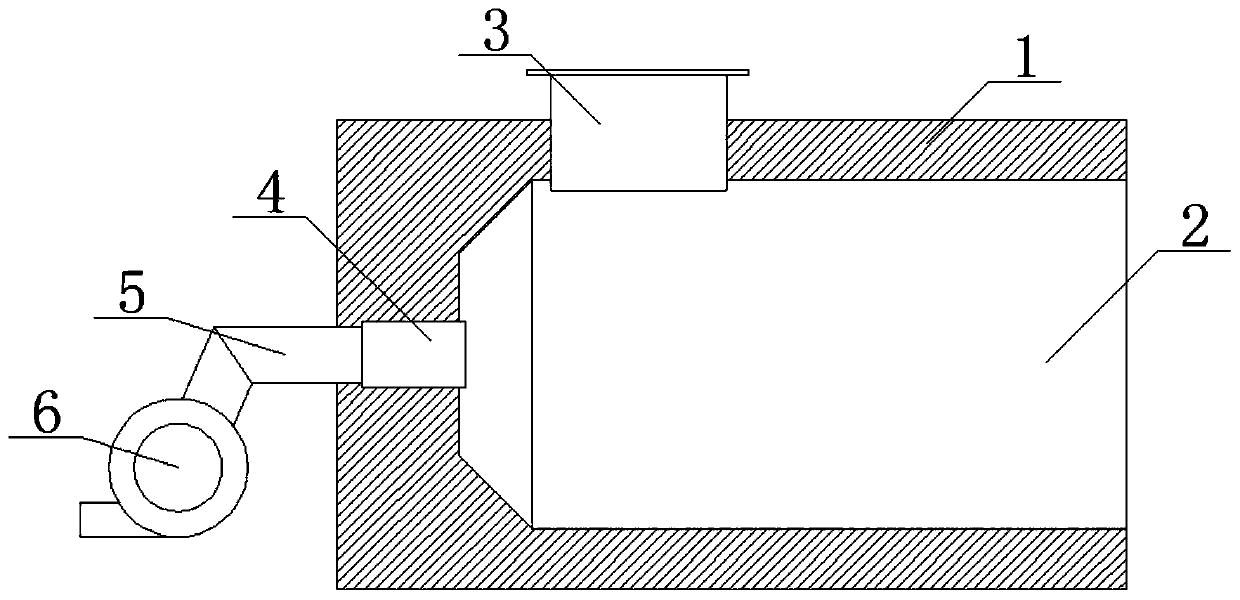

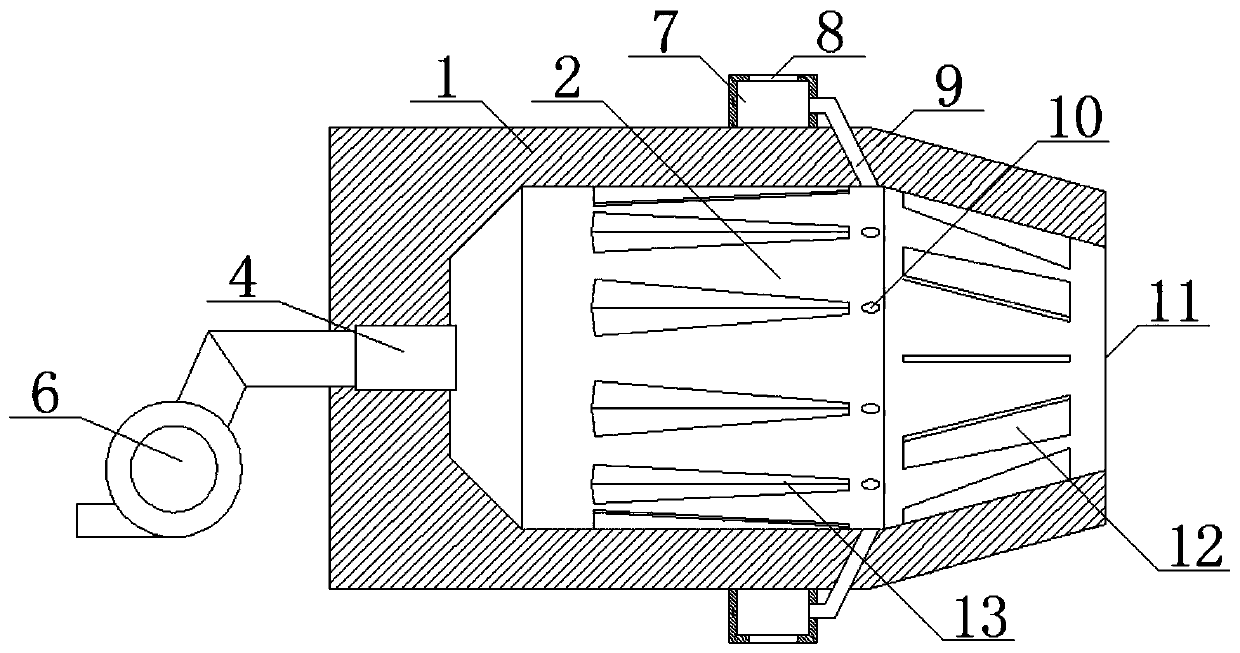

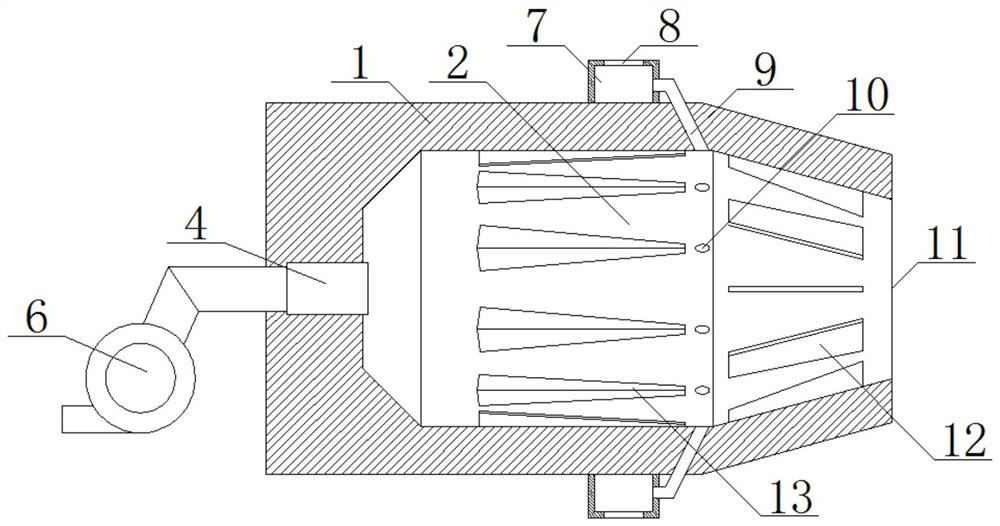

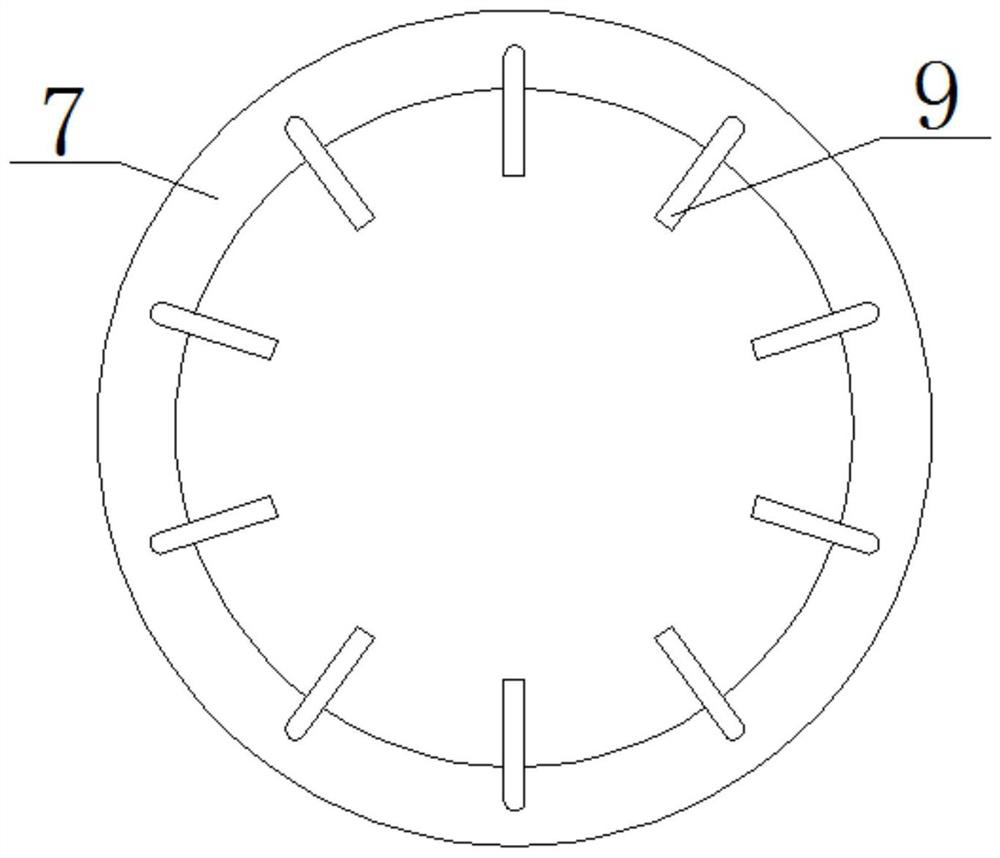

High-efficiency pulverized coal burner for boiler

InactiveCN111520710AGuaranteed service lifeFast air flowPulverulent fuel combustion burnersThermodynamicsCombustor

The invention relates to the technical field of burner equipment, and discloses a high-efficiency pulverized coal burner for a boiler. The high-efficiency pulverized coal burner for the boiler comprises a burner body and a combustion chamber, wherein a gas collection ring is welded to the middle of the burner body and is in a circular ring shape; flow-guiding gas inlets are formed in the top partand the bottom part of the gas collection ring; and gas guiding channels are welded to the right sides of the flow-guiding gas inlets. According to the high-efficiency pulverized coal burner for the boiler, through arranging a flow guiding cabin, a jet stream hole and a flow guiding plate, a first gas flow can enter the flow guiding cabin so as to be accelerated for the first time, the acceleratedgas flow flows through the area of the jet stream hole, the flow velocity of the gas flow flowing through the jet stream hole is further promoted, the gas flow flows out finally through the guiding of the flow guiding plate, and the gas flow velocity on the inner wall of the burner body is fast in the process, so that a burning flame can be driven to eject in a perfectly straight way, the occurrence of the phenomenon that the flame in an indefinite form burns out the top part of the burner body is prevented, and the service life of the burner body is guaranteed.

Owner:李庆薇

Coal and wood dual purpose furnace for cooking and warming

InactiveCN101655247BBurn fullyAvoid smokyLighting and heating apparatusBiofuelsCombustion chamberCoal

The invention discloses a coal and wood dual purpose furnace for cooking and warming. The dual purpose furnace comprises a furnace body, a charging device, a fire grate, a furnace door and a cooking range, wherein the furnace body is provided with a fuel chamber and a combustion chamber, the fuel chamber is communicated with the combustion chamber, the fuel chamber is arranged above one side of the combustion chamber, the cooking range is arranged above the other side of the combustion chamber, the charging device is arranged on the furnace body and at the top of the fuel chamber, the fire grate is arranged in the combustion chamber, the lower part of the bottom of the fuel chamber is provided with a primary tuyere, and the upside of the fire grate is provided with a secondary tuyere. Thefuel chamber is arranged above one side of the combustion chamber and the cooking range is arranged above the other side of the combustion chamber so that the combustion chamber can not only heat thecooking range, but also perform dry distillation to the fuel in the fuel chamber, the volatile generated by the dry distillation of the fuel in the fuel chamber is mixed with the secondary air to burn in the combustion chamber while the fuel becomes loose after the dry distillation and carbonization so that the fuel is easy to drop into the combustion chamber to burn, the ash is discharged from the fire grate, and the combustion is extremely sufficient without black smoke.

Owner:慈鲁

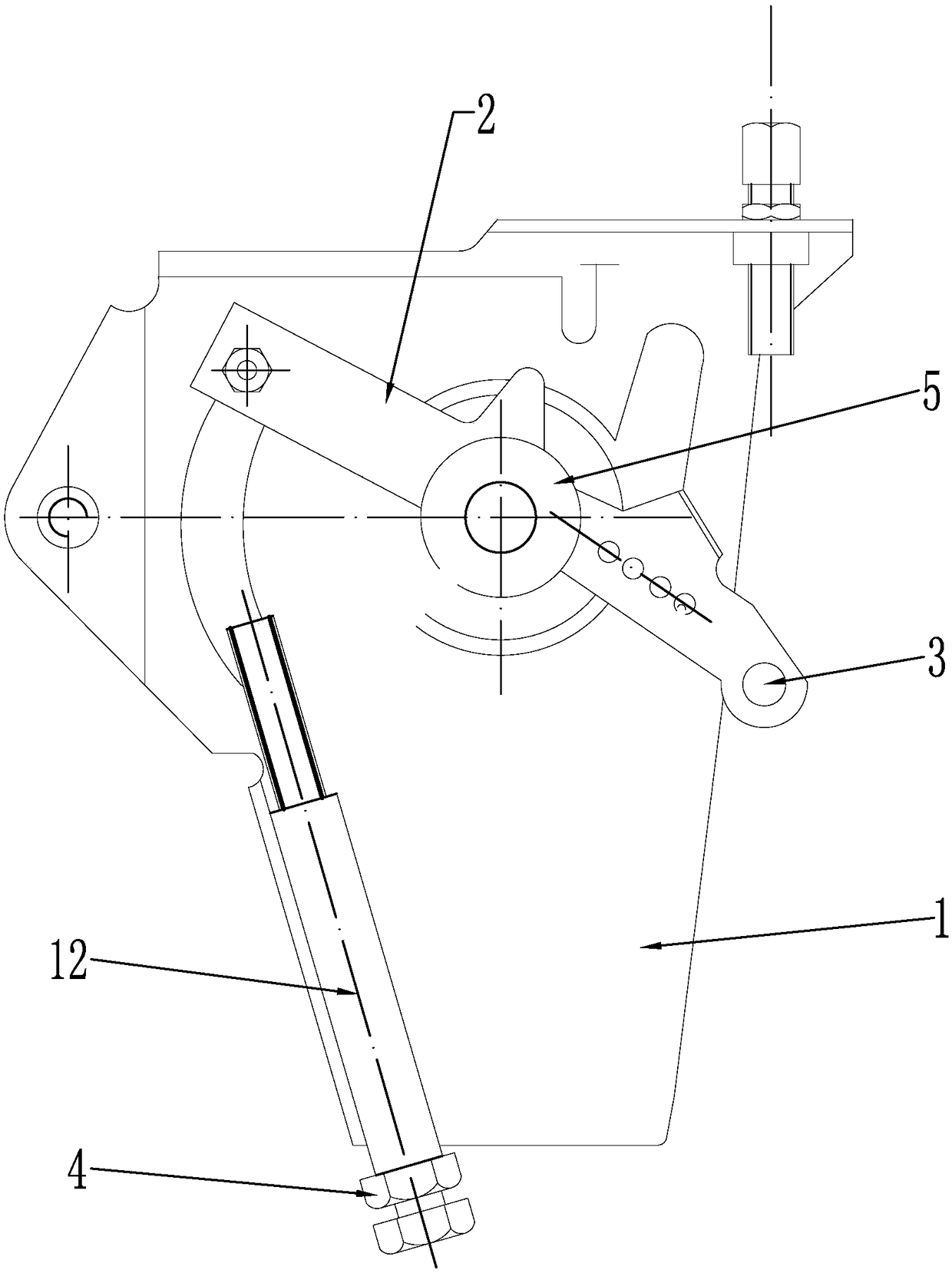

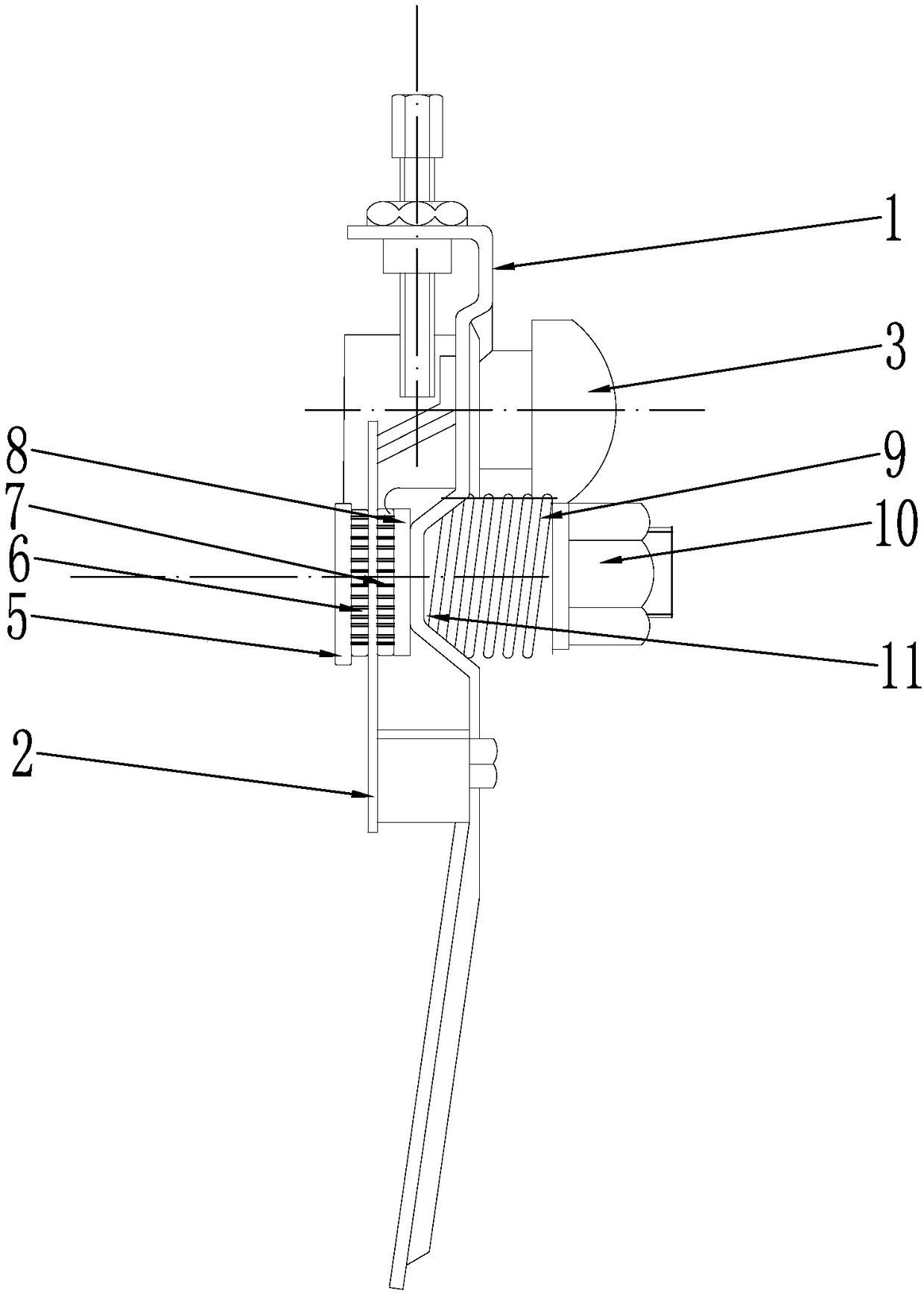

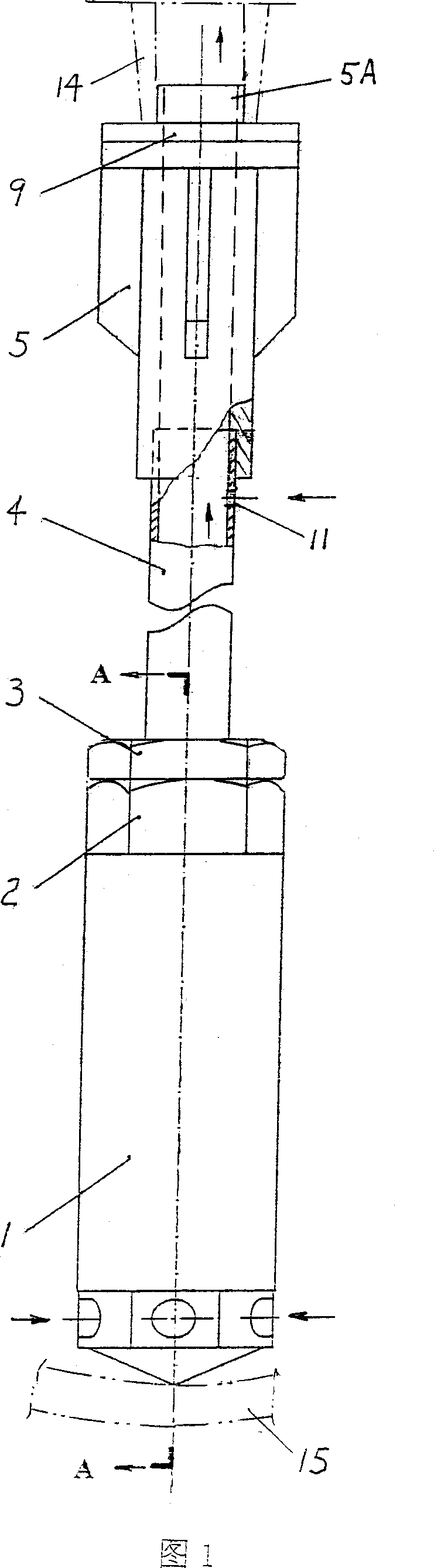

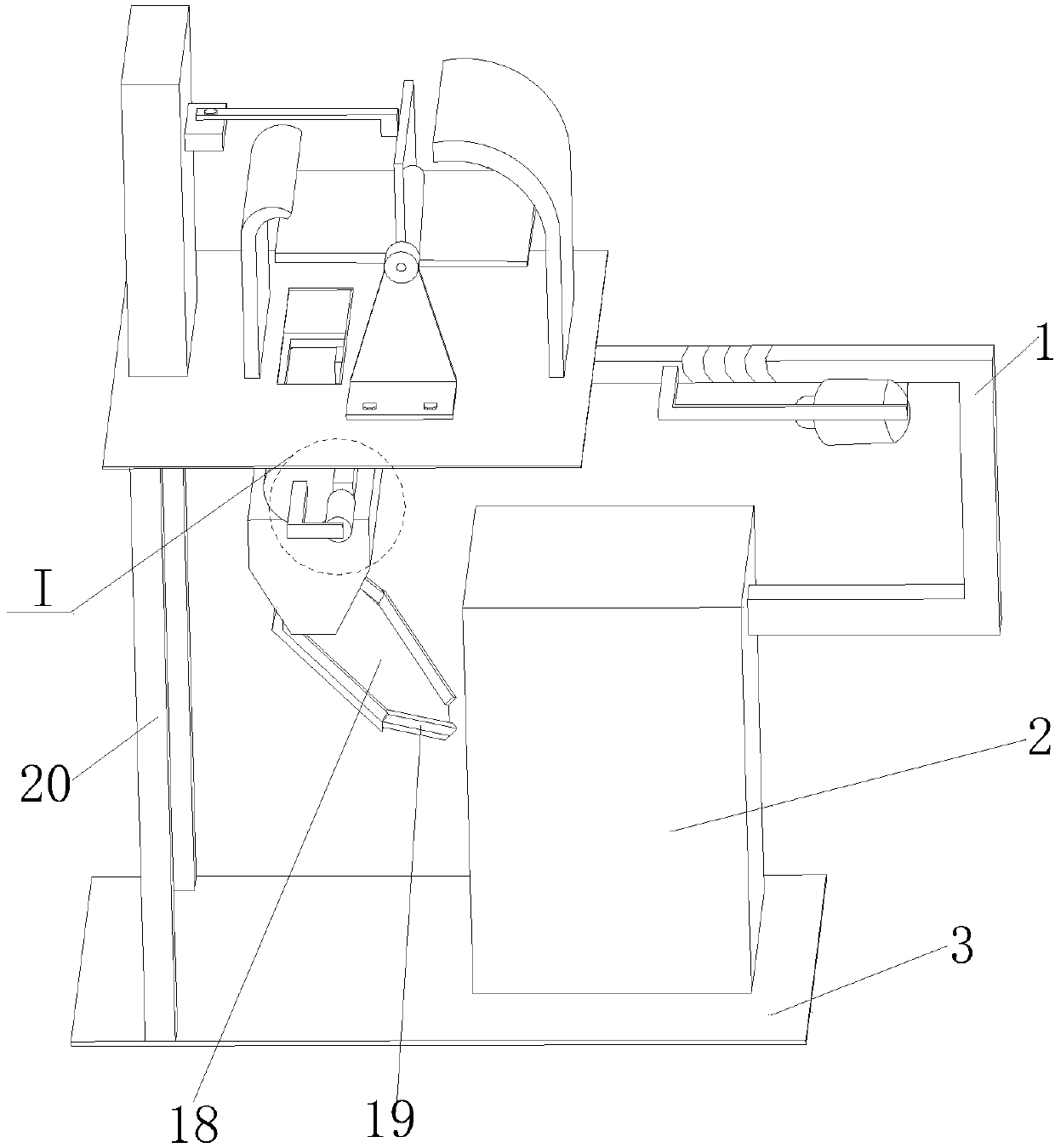

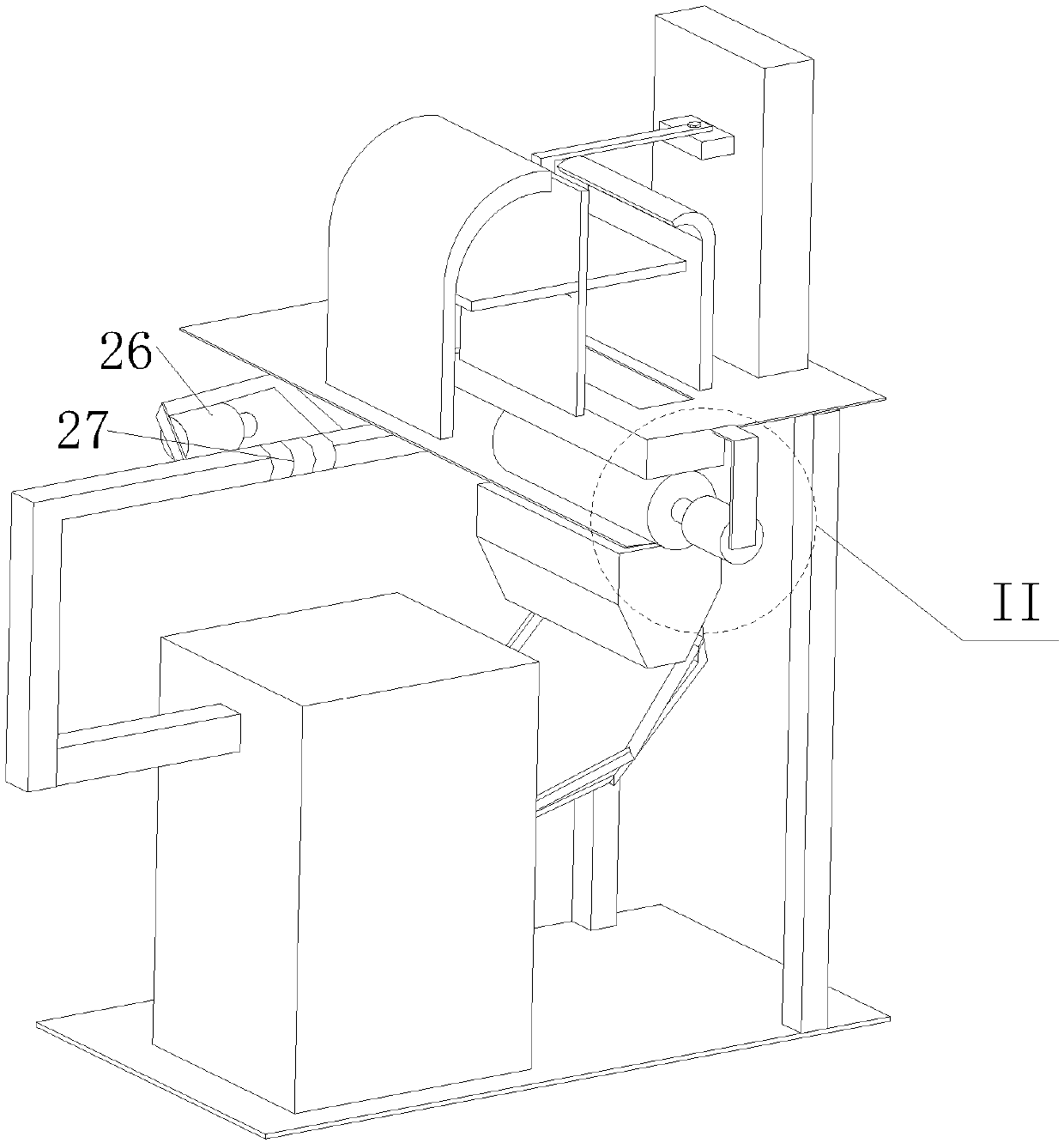

Mechanical speed regulating actuator for single-cylinder air-cooled diesel engine

PendingCN109236476AAvoid smokyAvoid undermotivationFuel-injection pumpsSpeed sensing governorsEngineeringActuator

The invention relates to a speed regulating actuator, in particular to a mechanical speed regulating actuator for single-cylinder air-cooled diesel engine, which belongs to the technical field of diesel engine. The mechanical speed regulating actuator for the single-cylinder air-cooled diesel engine comprises a speed regulating panel, a speed regulating lever and a speed limiting screw, wherein the speed regulating panel is provided with a hollow supporting screw rod; the front end of the hollow supporting screw rod passes through the speed regulating panel and is connected with the speed regulating lever through a first plane bearing; a pad is connected with one side of the speed regulating lever through a second plane bearing, the hollow supporting screw rod is sleeved with a spring, anadjusting nut is connected with the end of the hollow supporting screw rod, the front end and the rear end of the spring are respectively pressed tightly to contact the speed regulating panel and theadjusting nut; the speed limiting screw is disposed on the rotating path of the speed regulating lever, and the speed limiting screw can limit the rotating position of the speed regulating lever. Themechanical speed regulating actuator for single-cylinder air-cooled diesel engine has the advantage of simple, compact and reasonable structure, thereby effectively avoiding black smoke and insufficient power of the diesel engine caused by the dislocation of the speed regulating lever; and the shock absorber is characterized by safe and reliable sealing structure of rod end, simple operation and convenient maintenance.

Owner:WUXI KAIAO POWER MACHINERY

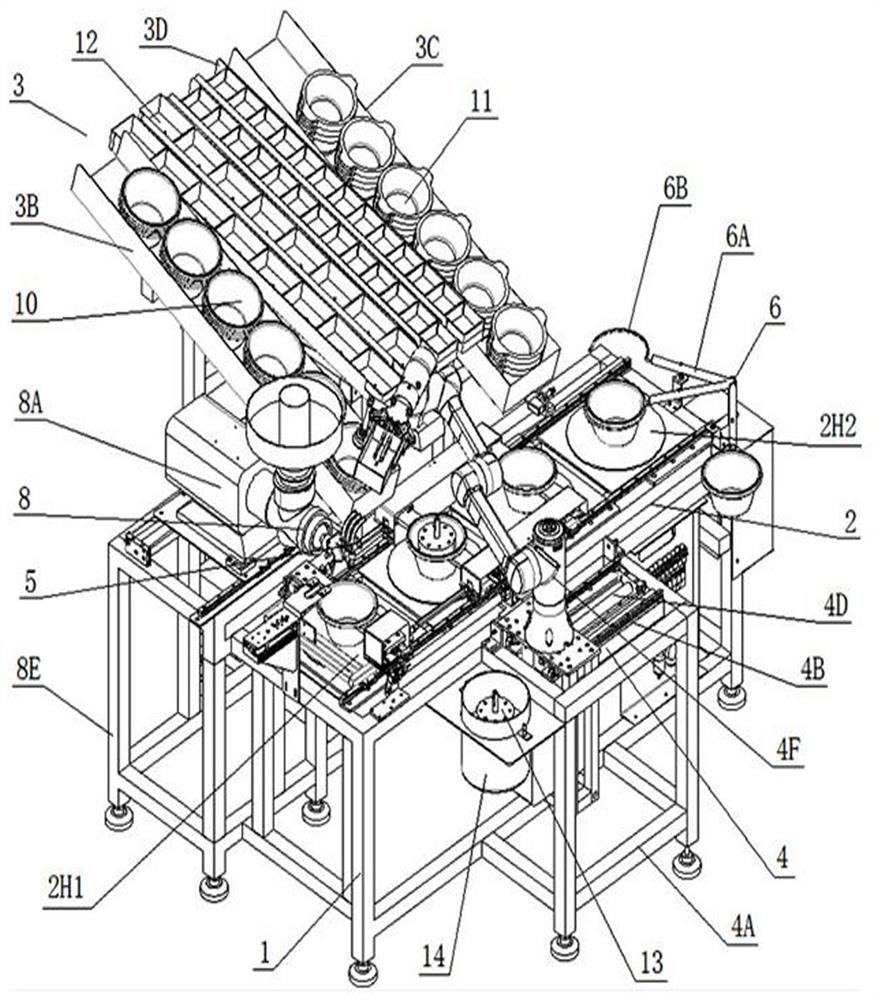

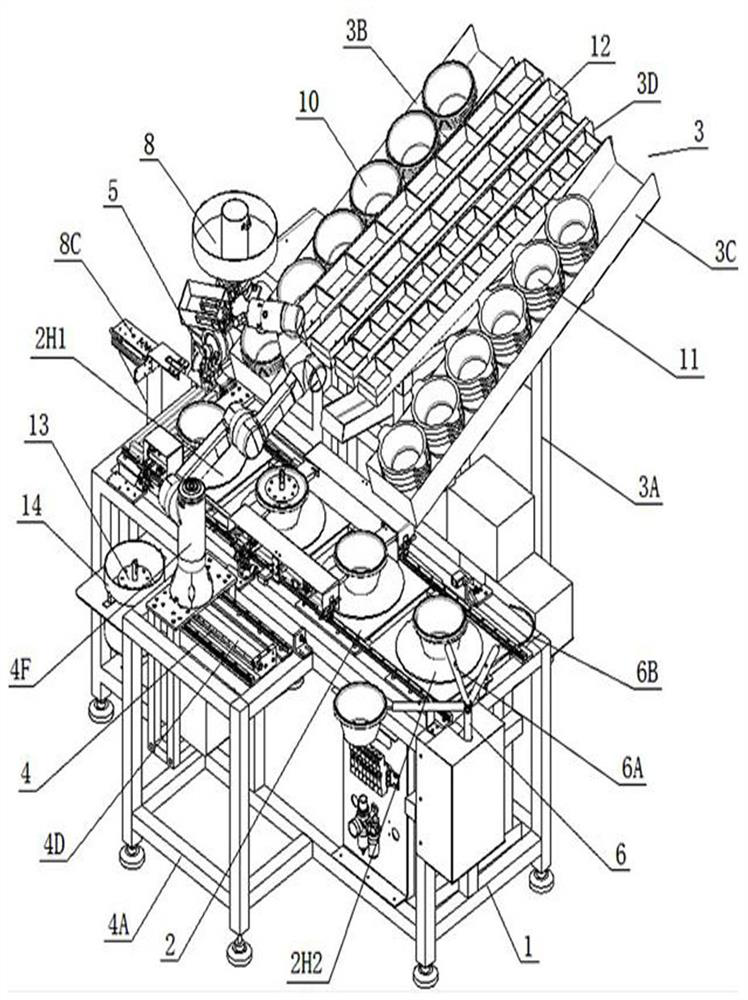

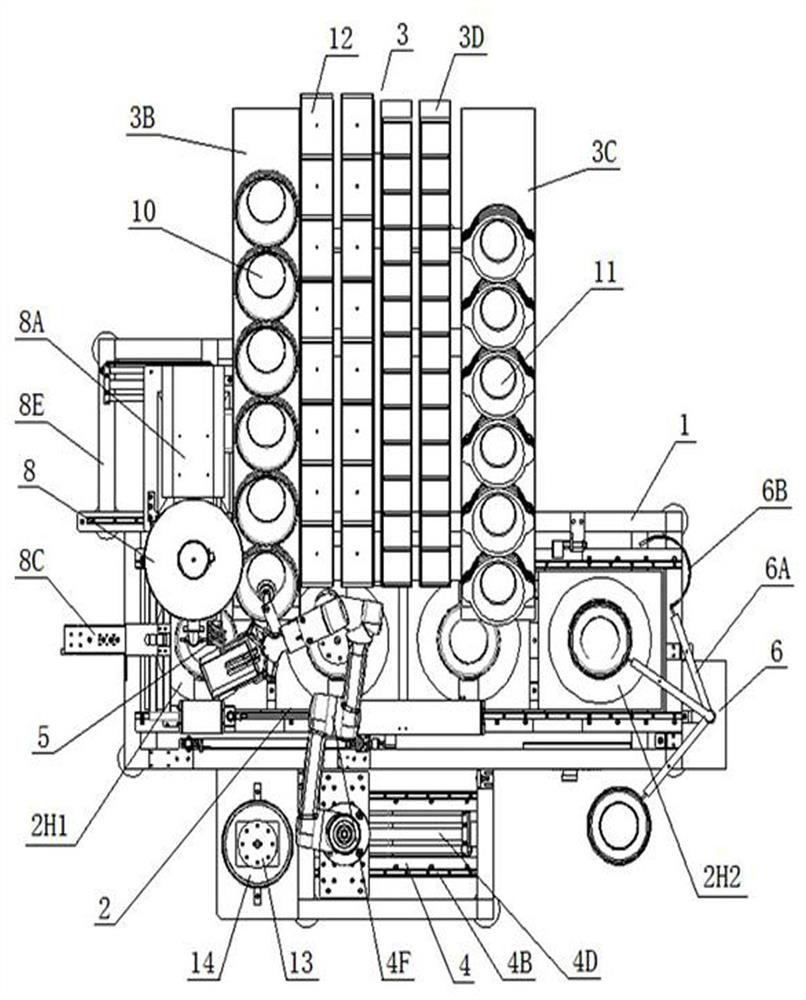

Multifunctional automatic cooking system and automatic cooking method

PendingCN112826311AImprove cooking efficiencyHigh degree of automationTime-controlled ignitorsLinear driveCooking methods

The invention discloses a multifunctional automatic cooking system and an automatic cooking method. A guide rail I and a sliding block I are arranged at the top end of a support of the cooking system, the bottom of a moving frame I is connected with the sliding block I, a linear driving unit I is connected with the support and the moving frame I, a linear driving unit IV is arranged on the lower portion of the guide rail I, a body is connected with the moving frame I, and the bottom end of a chuck is connected with the moving end of a linear driving unit III. The robotic arm system comprises a multi-axis mechanical arm arranged on the side of the pulsation cooking device and an electric claw assembly arranged at the front end of the multi-axis mechanical arm; a discharging port of a batching head of the liquid batching system points to the upper part of the preset cooking bowl at the front end; the delivery device base is arranged at the tail end of the pulsation cooking device, the rotating unit body is arranged on the base, one end of the rotating arm is connected with the rotating unit rotating shaft, and the other end of the rotating arm is connected with the taking claw; the control ends of the driving units, the multi-axis mechanical arm, the electric claw assembly and the batching head are electrically connected with the control system. The multifunctional automatic cooking system has the characteristics of high automation degree, flexibility, safety and sanitation.

Owner:杨朝中

Automatic observing and controlling method for roasting heat accumulating type steel ladle and the device using the method

The present invention discloses an automatic measurement and control method for the heating regenerative ladle comprising an automatic measurement and control method for ladle internal lining, an automatic measurement and control method for the smoke and dust density in the flue exhaust and an automatic measurement and control method for flue exhaust temperature. The present invention also discloses an automatic measurement and control method for the heating regenerative ladle comprising an automatic measurement and control method for ladle internal lining, an automatic measurement and control method for the smoke and dust density in the flue exhaust and an automatic measurement and control method for flue exhaust temperature; the present invention can ensure the sufficient burning of fuel and the heating quality of the ladle; the present invention can thoroughly remove the defect that the smoke and dust will pollute the environment and the energy-saving effect is obvious.

Owner:江苏兴利来特钢有限公司

A pulverized coal burner for boiler

InactiveCN111520710BGuaranteed service lifeFast air flowPulverulent fuel combustion burnersThermodynamicsCombustor

The invention relates to the technical field of burner equipment, and discloses a high-efficiency pulverized coal burner for a boiler. The high-efficiency pulverized coal burner for the boiler comprises a burner body and a combustion chamber, wherein a gas collection ring is welded to the middle of the burner body and is in a circular ring shape; flow-guiding gas inlets are formed in the top partand the bottom part of the gas collection ring; and gas guiding channels are welded to the right sides of the flow-guiding gas inlets. According to the high-efficiency pulverized coal burner for the boiler, through arranging a flow guiding cabin, a jet stream hole and a flow guiding plate, a first gas flow can enter the flow guiding cabin so as to be accelerated for the first time, the acceleratedgas flow flows through the area of the jet stream hole, the flow velocity of the gas flow flowing through the jet stream hole is further promoted, the gas flow flows out finally through the guiding of the flow guiding plate, and the gas flow velocity on the inner wall of the burner body is fast in the process, so that a burning flame can be driven to eject in a perfectly straight way, the occurrence of the phenomenon that the flame in an indefinite form burns out the top part of the burner body is prevented, and the service life of the burner body is guaranteed.

Owner:李庆薇

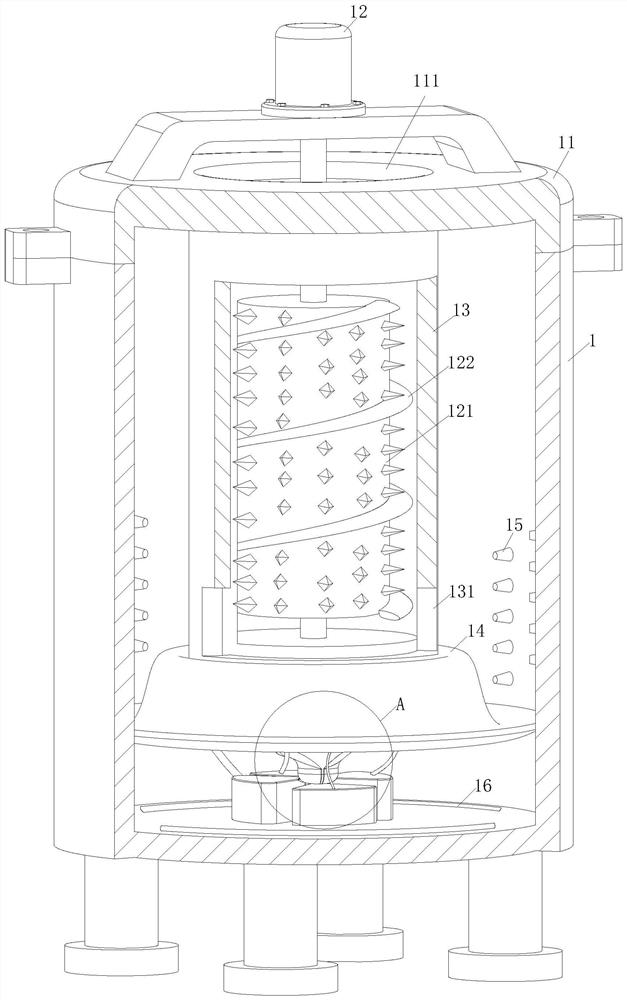

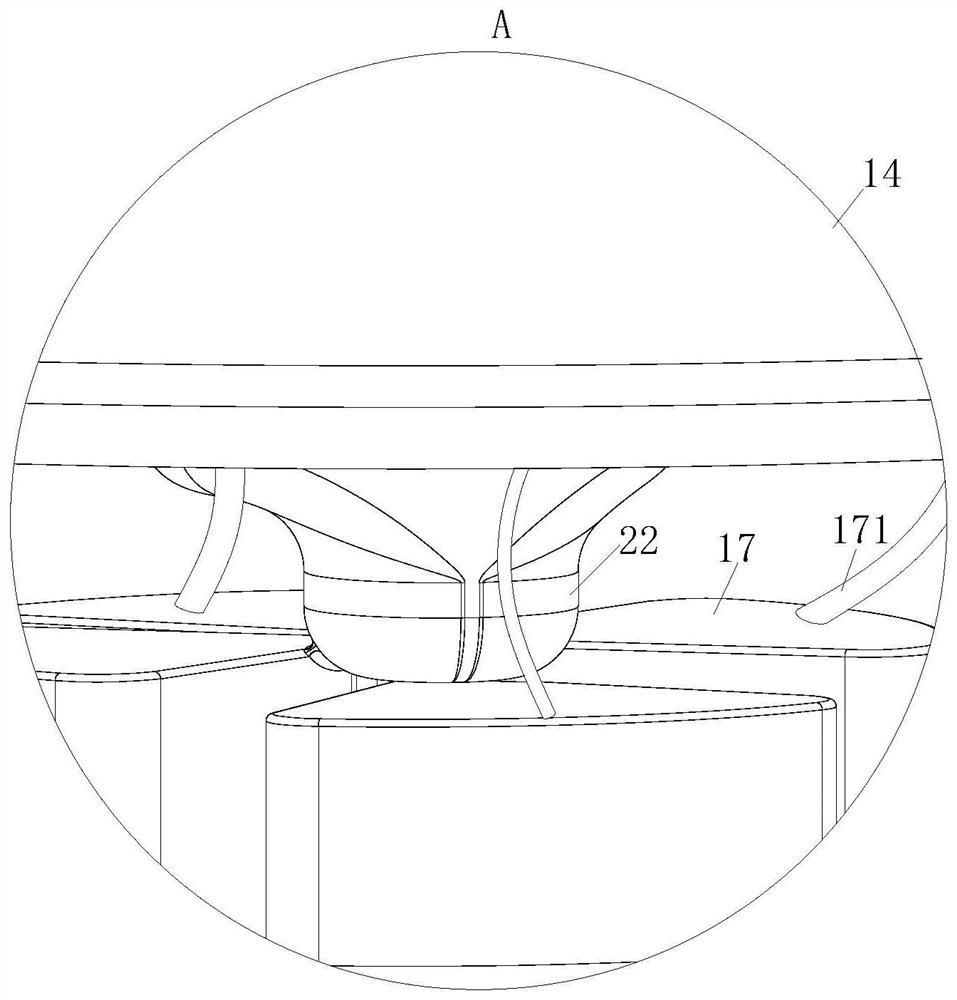

Household garbage incinerator

InactiveCN111895414AImprove incineration efficiencyBurn completelyIncinerator apparatusElectric machineryStructural engineering

The invention belongs to the technical field of garbage incineration, and particularly relates to a household garbage incinerator. The household garbage incinerator comprises a shell body; an end cover connected through a bolt is arranged at the upper end of the shell body, a forward and reverse rotation motor is arranged on the upper end face of the end cover and located above a feeding port formed in the center of the end cover, a crushing barrel is arranged on the lower end face of the end cover, a crushing roller fixedly connected with an output shaft of the forward and reverse rotation motor extends into the crushing barrel, a plurality of first through holes are formed in the side wall of the crushing barrel, a bearing plate is arranged on the lower end face of the crushing barrel; and an inner ring of the bearing plate is fixedly connected to the side wall of the lower end face of the crushing barrel, an outer ring of the bearing plate is fixedly connected to the inner side wallof the shell body, a plurality of second through holes are formed in the bearing plate, a spray head for spraying flames is arranged above a joint of the bearing plate and the shell body, the spray head communicates with an external methane supply tank, and a plurality of discharging openings are formed in the lower end face of the shell body. Through cooperation of the forward and reverse rotation motor, the crushing barrel, the crushing roller and the spray head, incineration of household garbage is achieved.

Owner:当涂县江心仁贵家庭农场

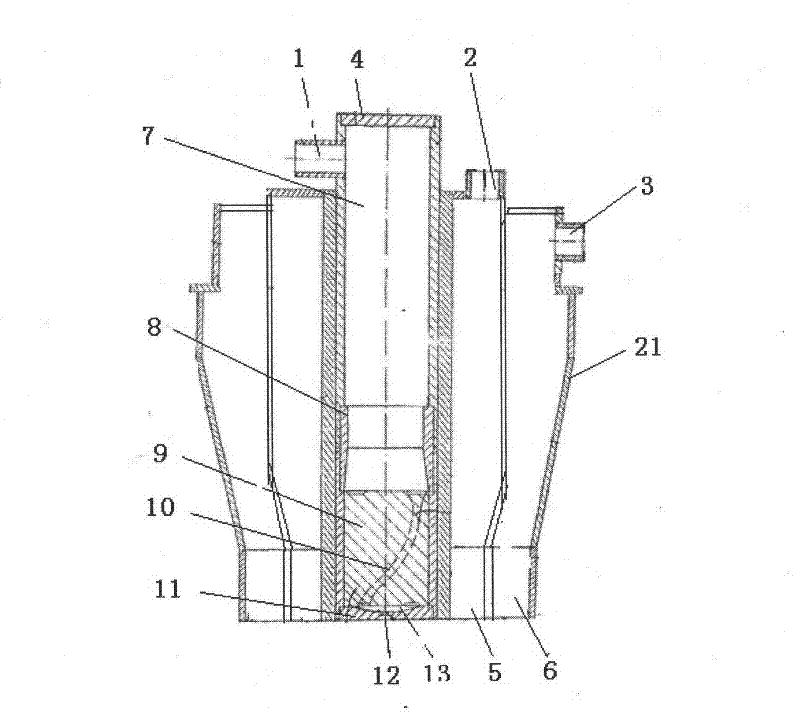

Energy-saving combustor

InactiveCN101067474AEasy to fixPrevent outflowPressure vesselsContainer discharging from pressure vesselsCombustorControl theory

An energy saving burn device includes the up joint, the down joint and the mixing pipe which the two ends are connected with the up and down joints. The character is in that: the down end of the mixing pipe extends to the inner hollow of the down joint; the inner hollow of down joint is installed with the throttle and spring; the one end of the spring is at the bottom of the down joint inner hollow, the other acts on the throttle which presses on the down end of the mixing pipe; the throttle has the channels which connect the down joint hollow and the mixing pipe. The energy saving burn device has the simple structure and burn the residue liquid without dark smoke, so it is proper for every liquid gas container.

Owner:王强

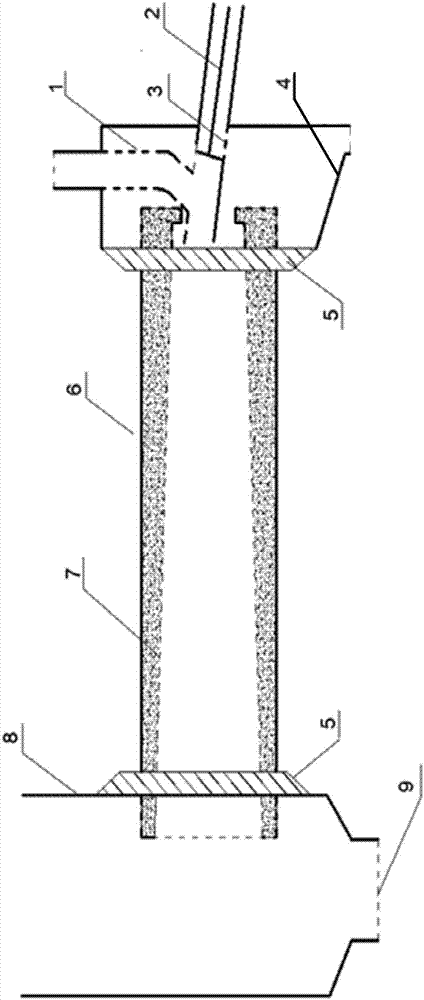

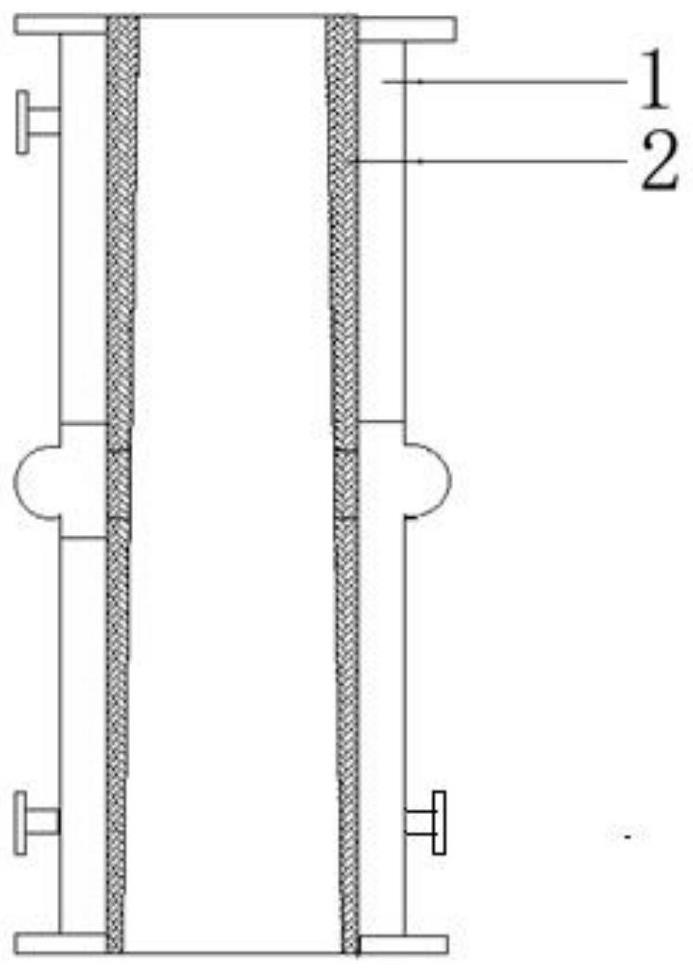

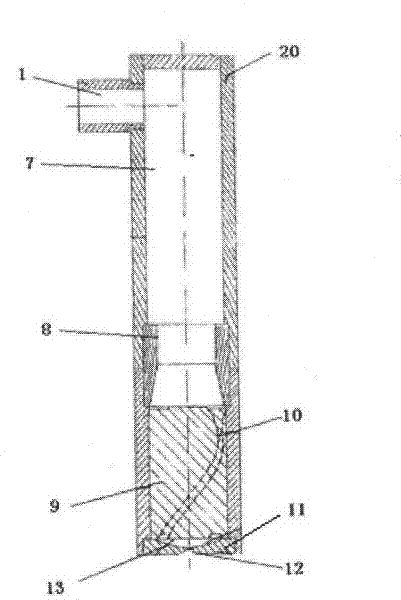

Water jacket ascension pipe heat exchanger with heat insulation and storage layer and transformation method of water jacket ascension pipe heat exchanger

PendingCN113801664AReduced wall temperature transformationReduce high temperature oxidation and high temperature creepDistillation gas withdrawalEngineeringMetallic materials

The invention discloses a water jacket ascension pipe heat exchanger with a heat insulation and storage layer and a transformation method of the water jacket ascension pipe heat exchanger. The water jacket ascension pipe heat exchanger with the heat insulation and storage layer comprises an ascension pipe heat exchanger body, and the heat insulation and storage layer is attached to the inner wall of the ascension pipe heat exchanger. The transformation method of the ascension pipe heat exchanger comprises the steps of polishing the inner wall of the ascension pipe heat exchanger, welding a fixing piece, pressing the ascension pipe heat exchanger, pouring the heat insulation and storage layer, and drying or air-drying and maintaining the heat insulation and storage layer. The problem that the inner wall of an original ascension pipe heat exchanger is coked is solved, meanwhile, the wall temperature change of the inner wall of the original ascension pipe heat exchanger is reduced, high-temperature oxidation and high-temperature creep of a pipe body metal material are reduced, and the service life of the original ascension pipe heat exchanger is prolonged by 3-5 years.

Owner:WUHAN FRONT IND EQUIP TECH

Method for flash oxygen-enriched roasting of neodymium iron boron waste

InactiveCN109504851AIncrease oxidation rateImprove sealingProcess efficiency improvementRare earthOil sludge

The invention discloses a method for flash oxygen-enriched roasting of neodymium iron boron waste. The method comprises the steps that the neodymium iron boron waste and oxygen-rich air are sprayed into a high-temperature reaction tower space together through a dispersion nozzle, so that the neodymium iron boron oil sludge waste is highly dispersed, in the process of dropping from the upper end ofa reaction tower to the lower end of the reaction tower, oil in materials fully burn, rare earth and iron are rapidly and fully oxidized by the oxygen-rich air, products float down into a collector below the reaction tower, and flue gas is subjected to dust collection and then emptied. According to the method, through flash oxygen-enriched roasting, reaction kinetic conditions are greatly optimized, the oil in the waste can fully burn, meanwhile, the iron and the rare earth in the waste are quickly and fully oxidized, the defects that the rotary kiln roasting reaction is slow, the process islong, energy consumption is high, and pollution is large are overcome, and the method has the advantages of quick reaction, short process, low energy consumption, environment friendliness and the like.

Owner:JIANGXI UNIV OF SCI & TECH

Dual-layer metering weighing device for steam-water boiler

InactiveCN107702771ASimple structureClear principleWeighing apparatus using counterbalanceCombustionFlue gas

The present invention relates to the boiler field, specially to a dual-layer metering weighing device for a steam-water boiler. The device comprises a first pedestal and a second pedestal arranged atan upper layer of the first pedestal; a boiler is arranged on the first pedestal, and a metering weighing device is arranged on the second pedestal; a drying rotation and transmission device is arranged at the lower end of the metering weighing device; and the boiler is matched with the drying rotation and transmission device, and a notch for material transmission is arranged on the second pedestal. The dual-layer metering weighing device for the steam-water boiler employs a traditional weight-type method for weighing relative to other weighing devices which employ an electronic scale for weighing and combustion so that the device provided by the invention is simple in structure, clear in principle and easy to repair; after weighing is completed, the dual-layer metering weighing device isdried to avoid incomplete combustion and black smoke caused by fuel with water; and moreover, flue gas of the boiler itself is employed to perform drying so that the drying cost is reduced, waste is reused and a pollution problem caused by direct discharge is reduced.

Owner:芜湖市通达锅炉有限公司

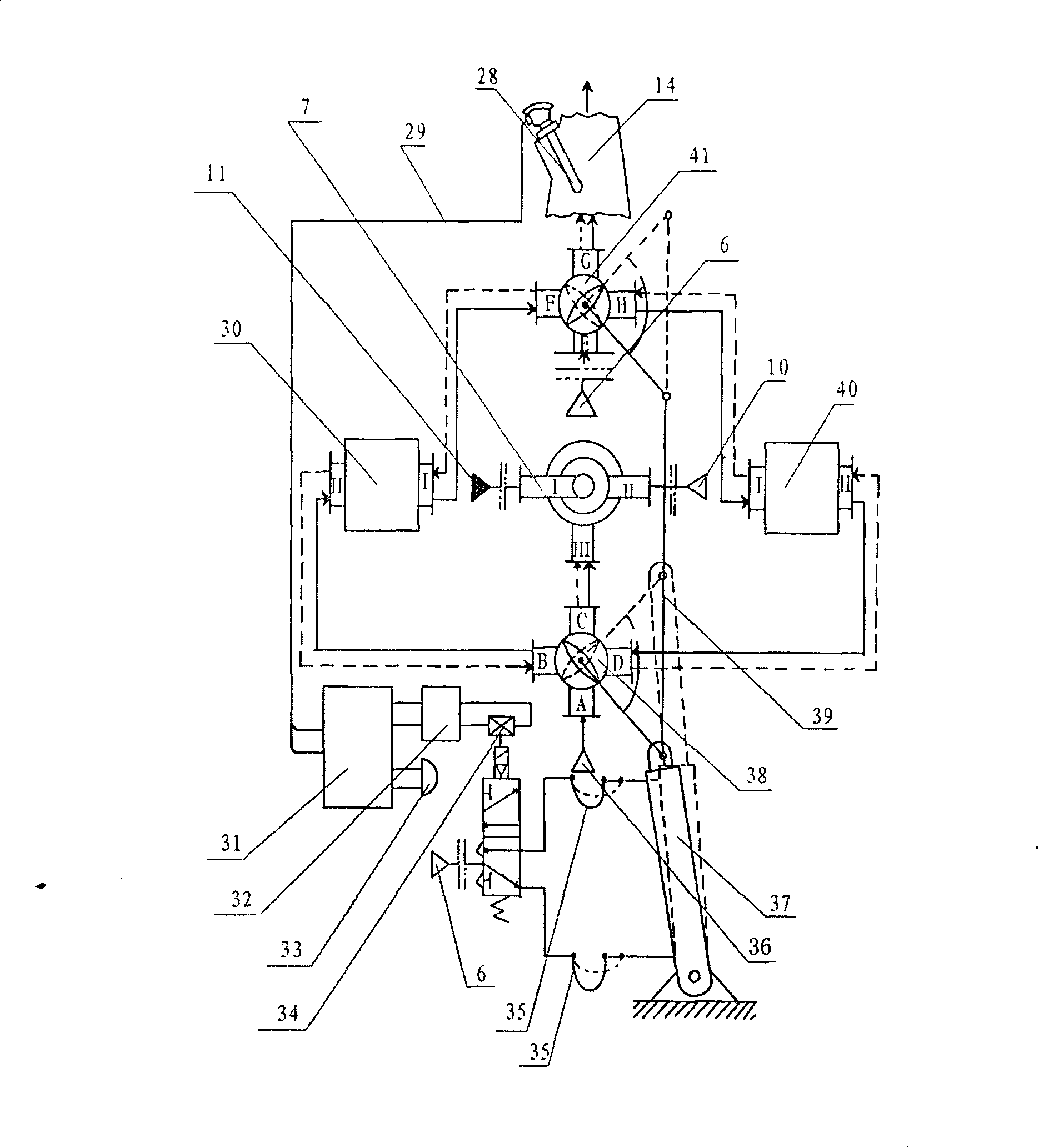

Oxygen-enriched combustion method and device

ActiveCN102506441APromote atomizationImprove thermal efficiencyIndirect carbon-dioxide mitigationNon-combustible gases/liquids supplyCombustorLiquid fuel

The invention relates to an oxygen-enriched combustion method and an oxygen-enriched combustion device. The device comprises a shell, fuel nozzles, oxygen nozzles and air nozzles, wherein the oxygen nozzles, the air nozzles and the fuel nozzles are arranged in a concentric ring shape; the fuel nozzles are positioned in the center; the air nozzles are positioned at the periphery; the oxygen nozzles are positioned between the fuel nozzles and the air nozzles; and the fuel nozzles are spiral-flow type gas fuel nozzles, liquid fuel nozzles or gas-liquid dual-purpose fuel nozzles. The oxygen-enriched combustion method comprises the following steps of: mixing fuel, air and oxygen in the combustion device and combusting, wherein oxygen consumption is 5 to 15 percent of theoretical oxygen consumption of fuel combustion, the rest is air, and the oxygen purity is 90 to 94 percent. Due to the arrangement of the oxygen nozzle, the fuel is combusted under oxygen-enriched conditions, the combustion intensity is improved, the combustion quality is improved, and the problems of coking and black smoke at an outlet of a combustor are solved. A spiral-flow type combustor has high fuel atomization performance and the fuel is fully mixed with a combustion improver, so that the fuel combustion has high thermal efficiency.

Owner:SOBC ENERGY SOURCES SCI & TECH

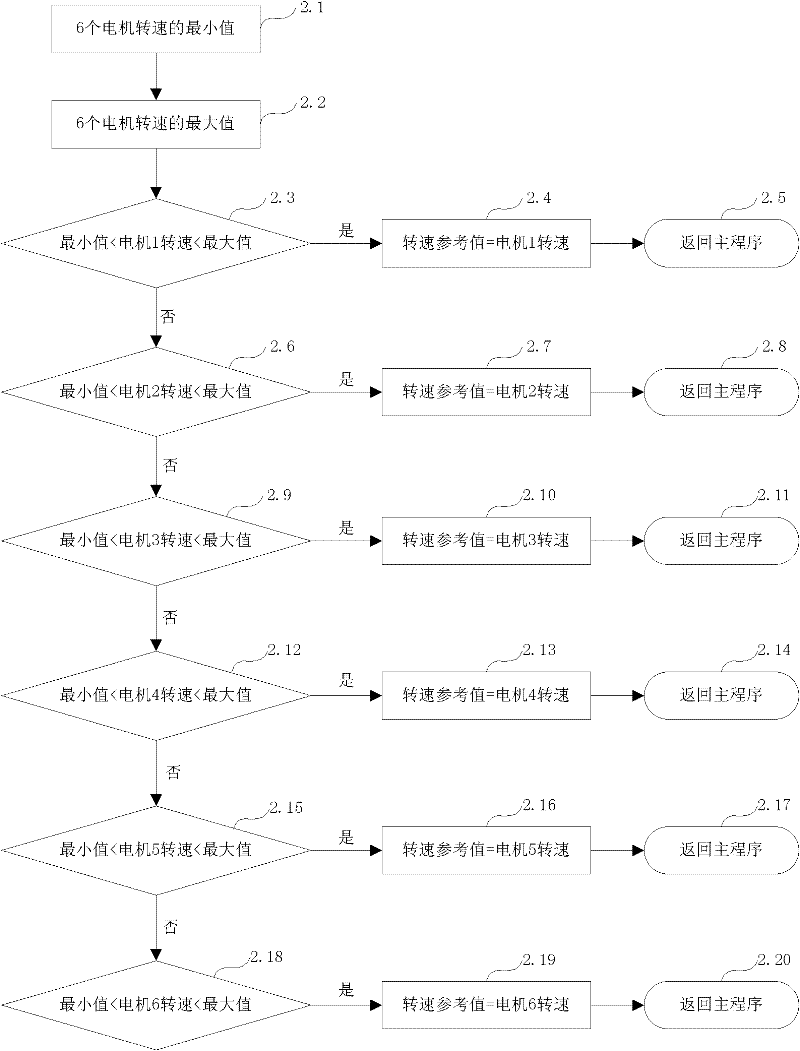

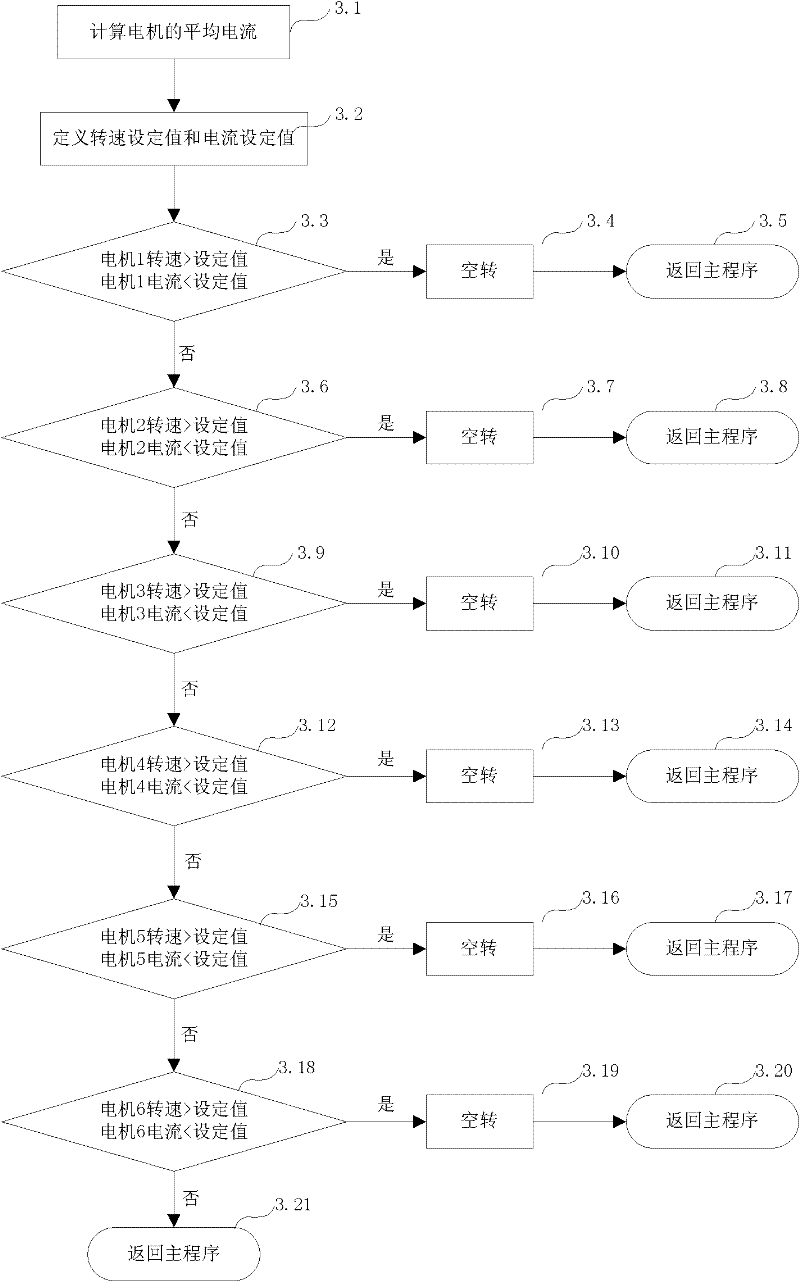

Anti-slip control method of locomotive

InactiveCN102050122BHigh Average Coefficient of AdhesionPrevent drastic changes in speedElectric devicesLocomotivesAverage currentControl theory

The invention discloses an anti-slip control method of a locomotive, comprising the following steps: processing fluctuation of a rotation speed signal, judging out a true value of rotation and an average current value of a motor, if the rotation speed of a traction motor is simultaneously more than a rotation speed set value and less than a current set value, judging that the traction motor is ina slip state, reducing output power of a main generator once in each 30ms under traction working condition or reducing exciting current of the traction motor under braking working condition, and simultaneously, sanding. When locomotive adhesion is recovered, recovering the output power of the main generator or the exciting current of the traction motor. The control method is timely and accurate in response, quick in adhesion recovery and small in change of a whole system.

Owner:CRRC DALIAN CO LTD

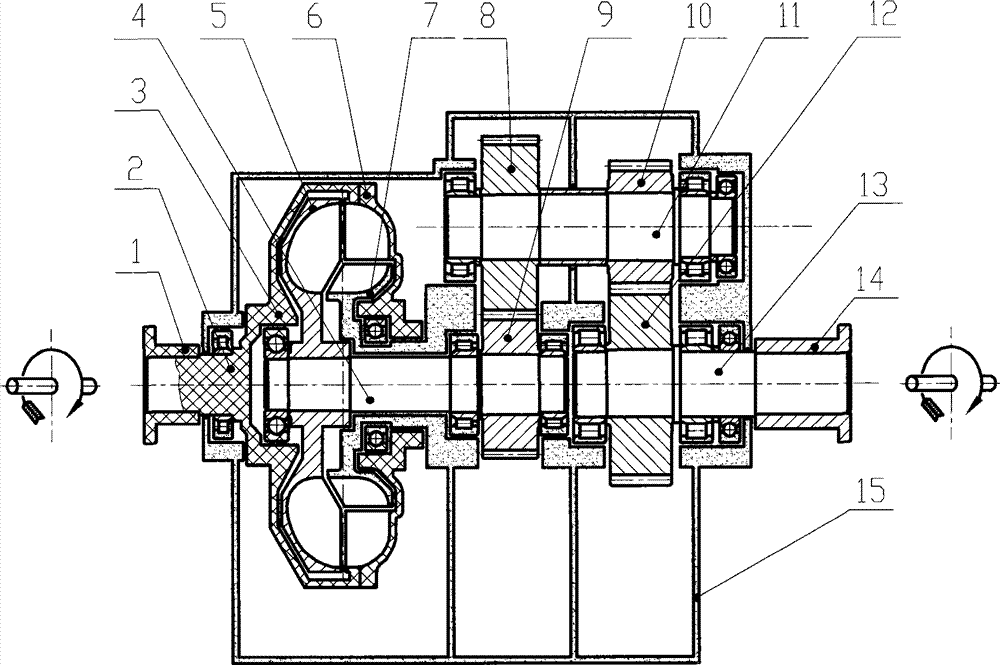

Ahead running reduction box with hydraulic torque-converting coupler

ActiveCN102052442BImprove transmission efficiencyReduce fuel consumptionConstructionsGear lubrication/coolingCombustionReduction drive

The invention discloses an ahead running reduction box with a hydraulic torque-converting coupler. The ahead running reduction box with the hydraulic torque-converting coupler is a transmission device arranged between a diesel engine and a compound chain box in a mechanical transmission oil drilling rig, and comprises the hydraulic torque-converting coupler used as an input part and a two-stage coaxial gear reducer used as an output part, wherein the input part is the hydraulic torque-converting coupler without an auxiliary cavity, and is installed in the same box body together with the two-stage coaxial gear reducer used as the output part; a turbine shaft and the input shaft of the two-stage coaxial gear reducer have the same radical axis; and the power oil in a working cavity and the lubricating oil in the two-stage coaxial gear reducer are the same oil product, and share an oil circulation system with an oil pump and a cooler. The transmission device has the advantages that the transmission efficiency is high, and the fuel oil consumption can be greatly reduced; a torque converting function is achieved, thus the well-drilling efficacy is greatly improved; and the permeability number is smaller, thus the combustion conditions of the diesel engine can be improved, and the service life is improved.

Owner:DALIAN HENGTONG HYDRAULIC MACHINERY CO LTD

Air conditioning control panel system of electrombile and control method thereof

ActiveCN102501814BControl start and stopAvoid smokyAir-treating devicesVehicle heating/cooling devicesFuel oilAir conditioning

The invention relates to an air conditioning control panel system of an electrombile and a control method thereof. The air conditioning control panel system of the electrombile comprises an air conditioning control panel, a positive temperature coefficient (PTC) heating element and a fuel oil heater, wherein the PTC heating element and the fuel oil heater are installed on a finished electrombile and used for heating the finished electrombile. The air conditioning control panel is in control connection with the PTC heating element and the fuel oil heater and used for judging whether the PTC heating element or the fuel oil heater is assembled on the finished electrombile and for sending out corresponding start-up information to start up the PTC heating element or the fuel oil heater.

Owner:CHERY AUTOMOBILE CO LTD

Biomass fuel steam and hot water boiler

InactiveCN100538179CAchieve reburningImprove combustion efficiencyRevolving grateRocking grateFuel typeEngineering

A steam and hot water boiler of biological material fuel type is prepared for setting secondary air inlet pipe with air inlet hole on fornication of furnace tank, transmission-connecting engine to rolling fire gate at one side of furnace body through driving handle, distributing a numbers of rolling bushing teeth on rolling bushing of rolling fire grate and distributing ventilation holes between rolling bushing teeth.

Owner:葫芦岛市华东锅炉有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com