Coal and wood dual purpose furnace for cooking and warming

A technology for cooking heating and furnace body, which is applied to the field of dual-purpose cooking and heating furnaces for coal and wood, can solve the problems of polluting the environment and wasting resources, and achieves the effects of protecting the environment, saving resources and fully burning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

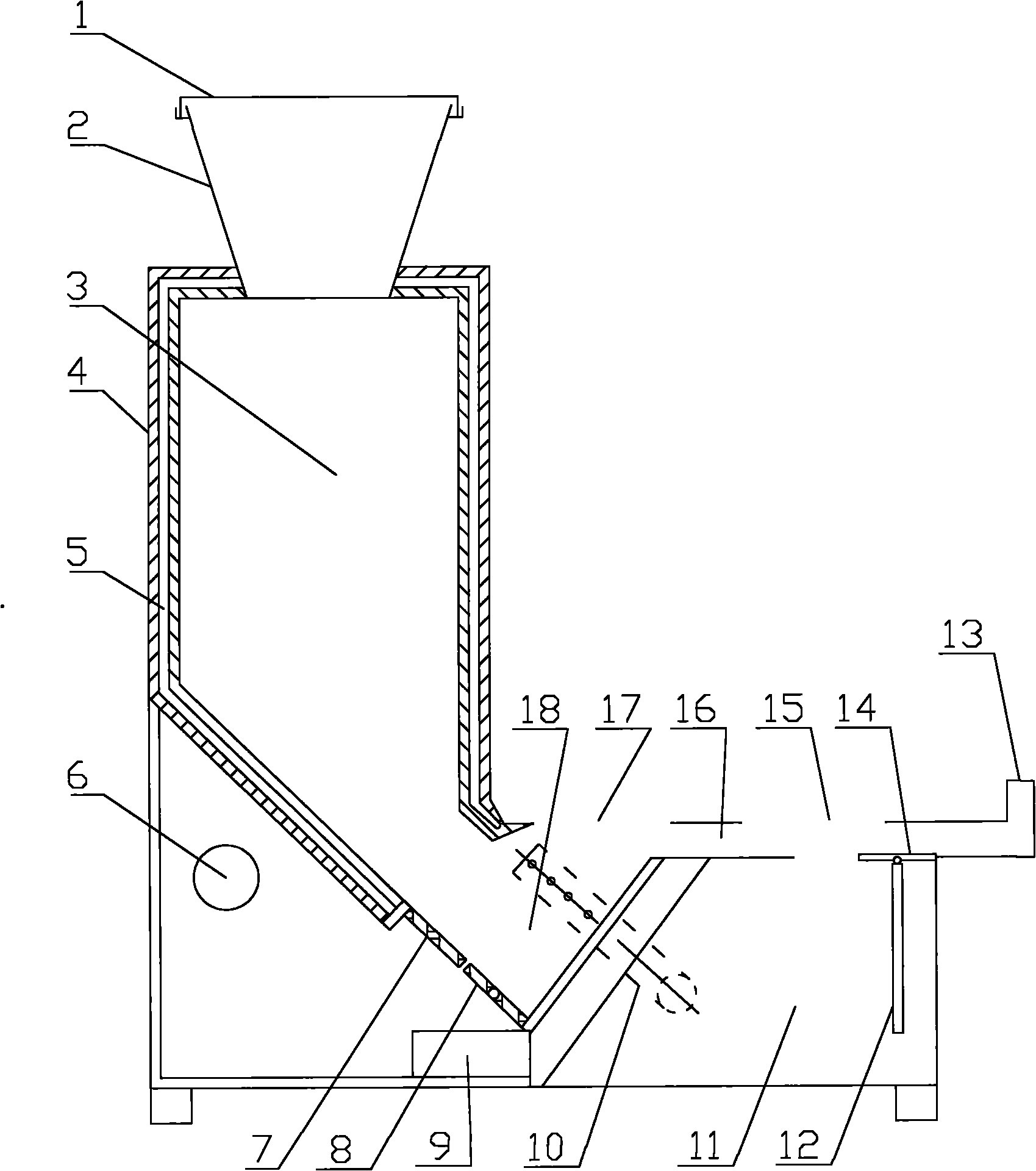

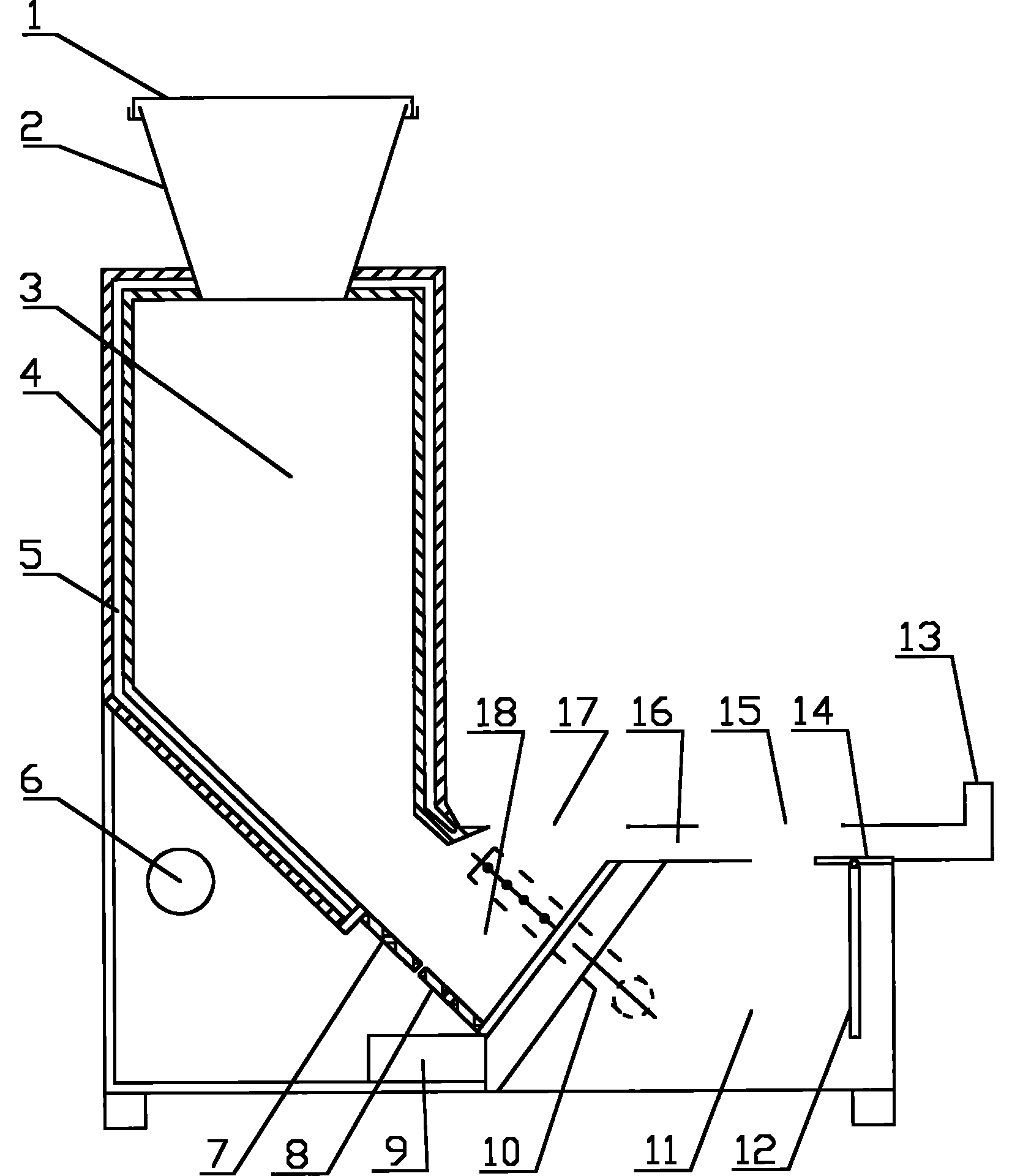

[0014] like figure 1 A specific embodiment is shown, which includes a furnace body 4, a feeding device, a fire grate, a furnace door 9, a stove mouth 15, a stove mouth 17, a primary tuyere 6, and a secondary tuyere 10. The furnace body 4 is provided with material Chamber 3 and combustion chamber 18, material chamber 3 and combustion chamber 18 are connected, material chamber 3 is positioned at the top of the left side of combustion chamber 18, stove mouth 17 is positioned at the top of the right side of material chamber, and furnace body 4 is positioned at the right side of combustion chamber 18. A heating box 11 is arranged on the side, and the bottom of the material chamber 3 is an inclined plane with the low end facing the combustion chamber 18. The inclination angle of the inclined plane is greater than 35°. The bottom of the material chamber 3 is connected, and the fire grate includes a fixed fire grate 7 and a rotating fire grate 8. The fixed fire grate 7 is fixed to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com