Smokeless oil-saving starting system of circulating fluidized bed boiler

A technology of circulating fluidized bed and start-up system, which is applied in the direction of fluidized bed combustion equipment, burning fuel in molten state, lighting and heating equipment, etc. Difficult temperature control and other problems to achieve the effect of improving operating economy, avoiding over-temperature coking or damage to refractory and wear-resistant materials, and easy control of start-up parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

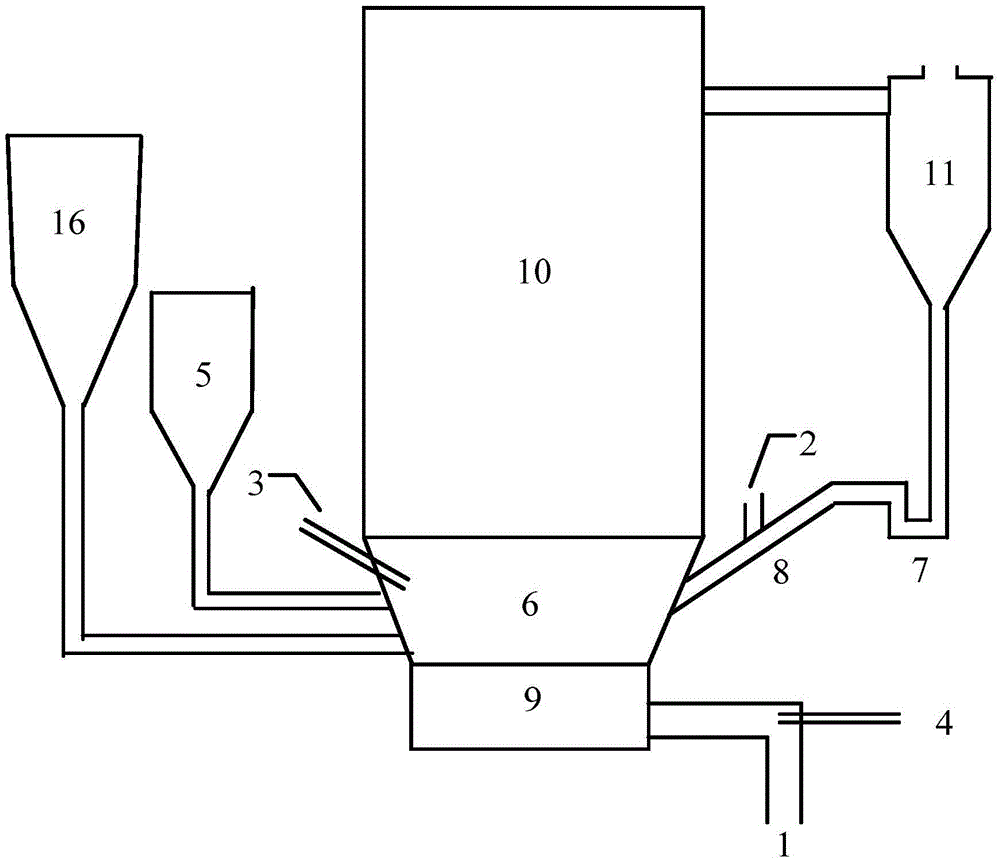

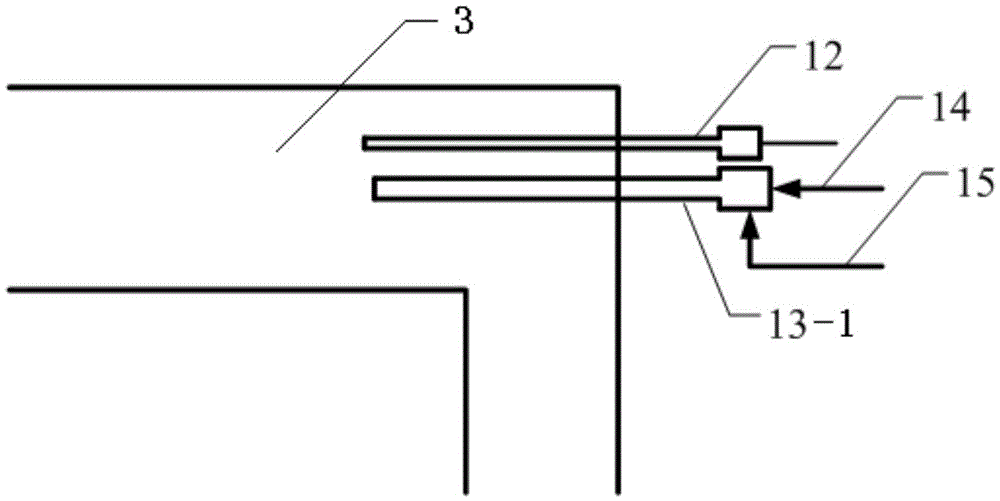

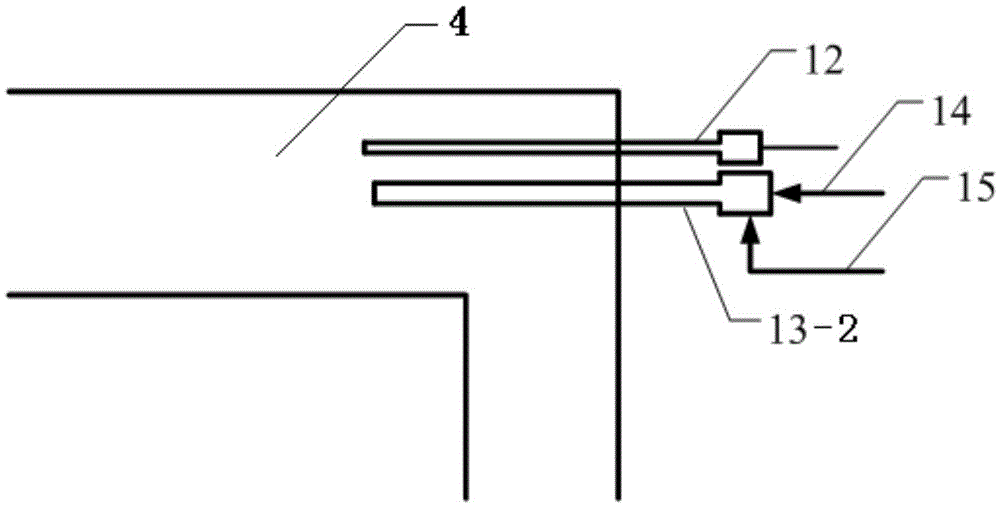

[0035] Such as figure 1 , figure 2 and image 3 As shown, taking the cold start-up of a 480t / h circulating fluidized bed boiler as an example, the coal used is anthracite with low volatile content, and the volatile content Vdaf of the coal-fired dry ash-free base of the starting fuel system is 25%. Add the bed material to a thickness of 500mm before starting, and adjust the pressure of the compressed air 14 of the combustion system to 1MPa. The bed material is maintained in a micro-bubbling fluidized state through the uniform flow breeze system 1, and then put into the air duct burner system 4, and the compressed air 14 atomizes the ignition fuel 15 into tiny oil droplets with a diameter of 30 μm and sends it into the air duct for combustion , due to the thinner bed material, the bed temperature rises rapidly, and the heating rate is controlled at 120°C / h. When the bed temperature rises to 400°C, the bed burner system 3 is put into operation. When the bed temperature rise...

specific Embodiment approach 2

[0036] Such as figure 1 , figure 2 and image 3 As shown, taking a 220t / h circulating fluidized bed boiler at warm state as an example, the coal type is anthracite, and the coal-fired dry ash-free base volatile Vdaf of the starting fuel system is 35%. Adjust the bed material to about 600mm when the boiler is pressurized. After pressing the fire, the bed temperature drops to 400°C, and then start up according to the warm state start-up procedure. Start the induced draft fan, the fluidization fan, the secondary fan and the primary fan in turn, and adjust the pressure of the compressed air 14 of the combustion system to 1MPa. The bed material is maintained in a micro-bubbling fluidized state through the uniform flow breeze system 1, and then put into the air duct burner system 4 and the bed burner system 3. When the bed temperature rises to 450°C, start the fuel system 5 and put it into operation. The system operates in the mode of micro-coal feeding, and gradually increases...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com