Multifunctional automatic cooking system and automatic cooking method

A multi-functional and automatic technology, which is applied to cooking utensils, timing control ignition mechanisms, household appliances, etc., can solve problems that affect customer consumption experience, difficulty in achieving continuity in the cooking process, streamlined operation, and high labor costs. Skill requirements and labor intensity, the effect of improving consumer experience and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

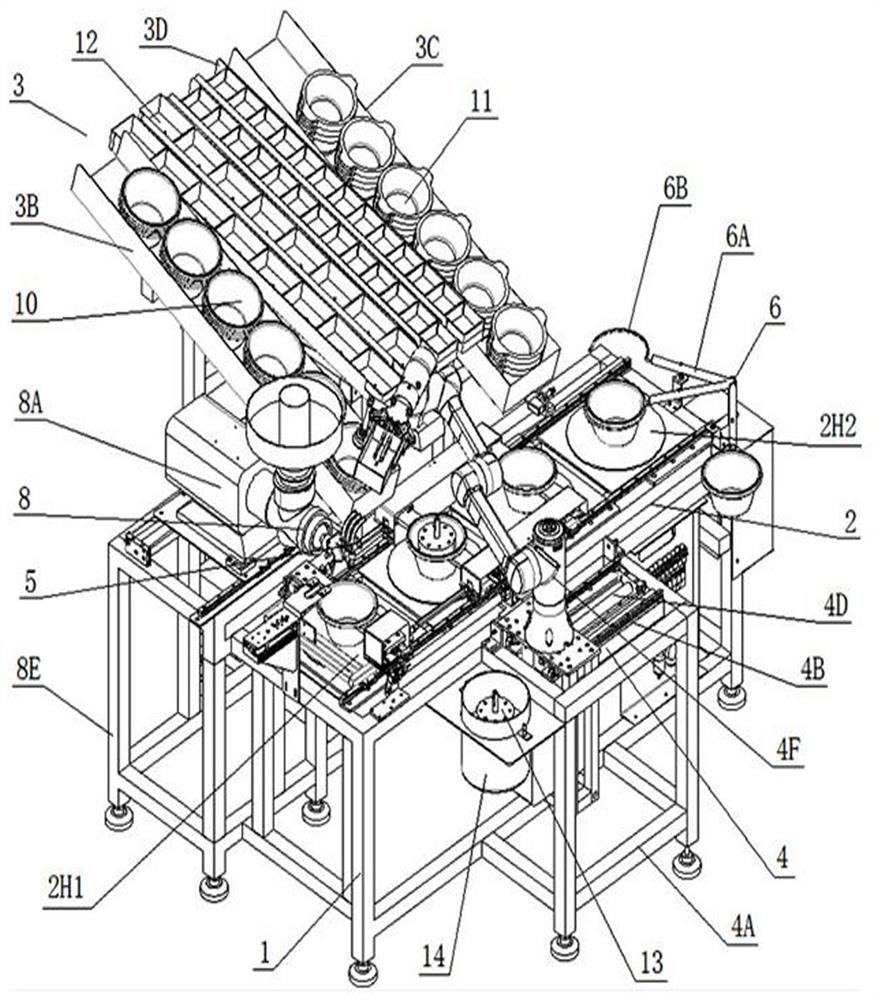

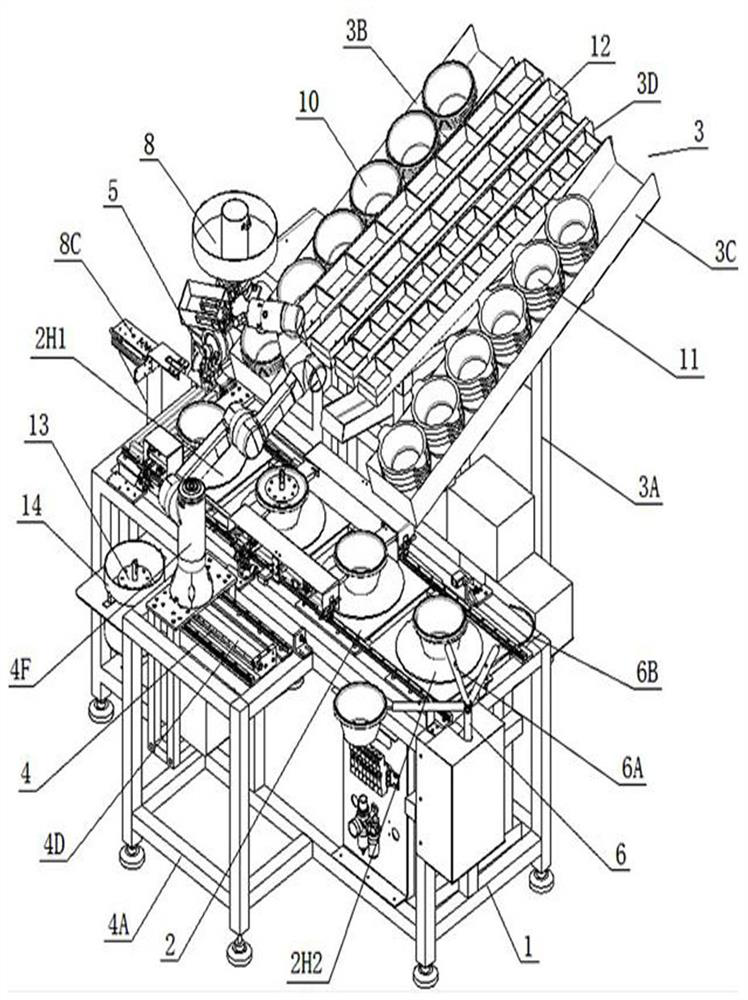

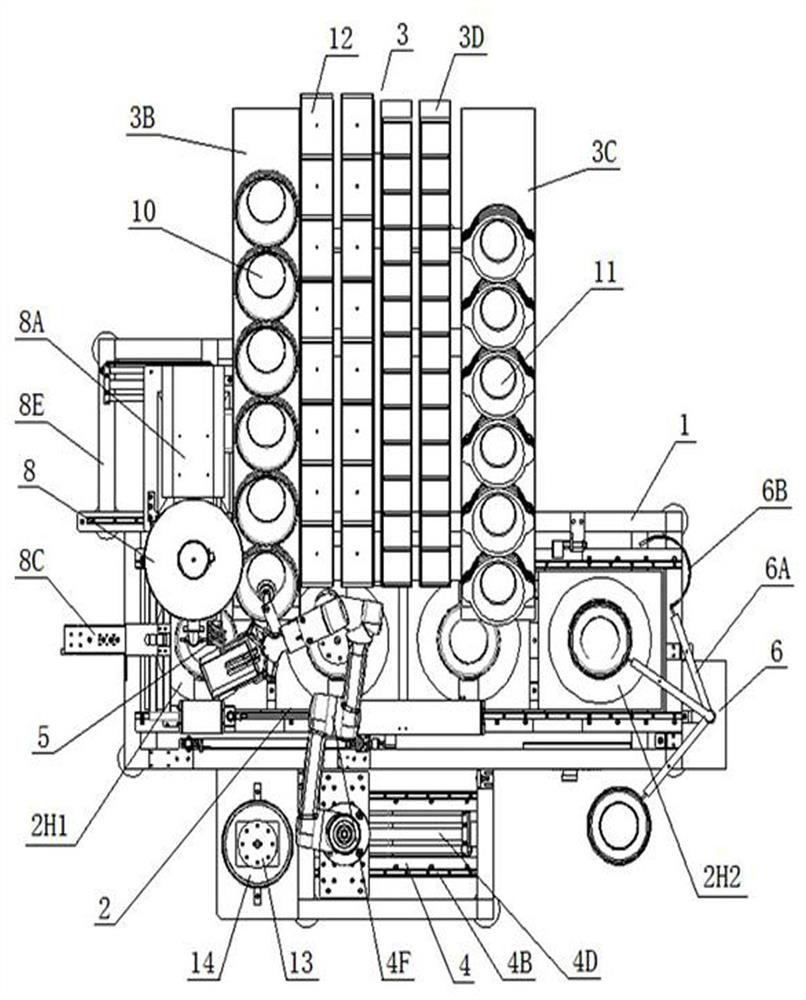

[0062] Such as Figures 1 to 8 As shown, taking the process of cooking rice noodles in a small pot by the pulsating cooking device 2 with 4 heating positions of the induction cooker 2H as an example, the execution steps are:

[0063] 1. Start the equipment, the control system of the equipment and the controllers of each sub-system perform self-inspection, the pulsating cooking device 2 returns to the ready state according to the current status of each heating position, and at the same time the mechanical parts of the robot arm system 4 and the delivery device 6 return to Preset the origin and complete the equipment operation preparation.

[0064] 2. Judging the status of the heating position:

[0065] 2.1 The first heating position reads the order information: the control system receives the customer order information pushed by the order system, and after receiving the new order, it splits the order into preset single commodity information and puts it into the commodity queue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com