Household garbage incinerator

A domestic waste incineration and waste incineration technology, which is applied in the direction of incinerators, combustion methods, combustion types, etc., can solve problems such as waste of energy, air pollution, and insufficiency, and achieve faster incineration efficiency, sufficient garbage incineration, and high combustion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

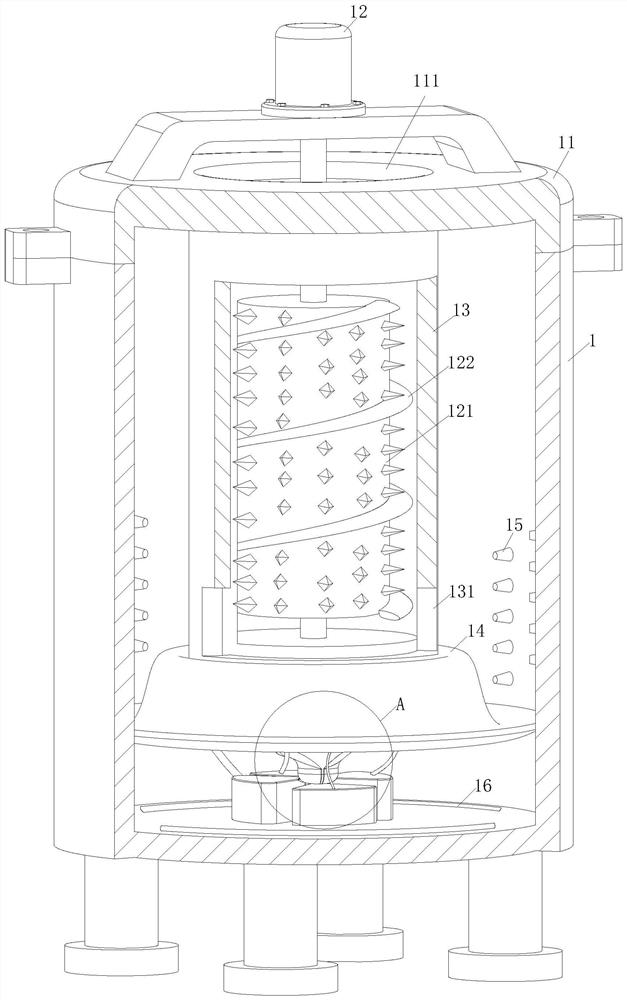

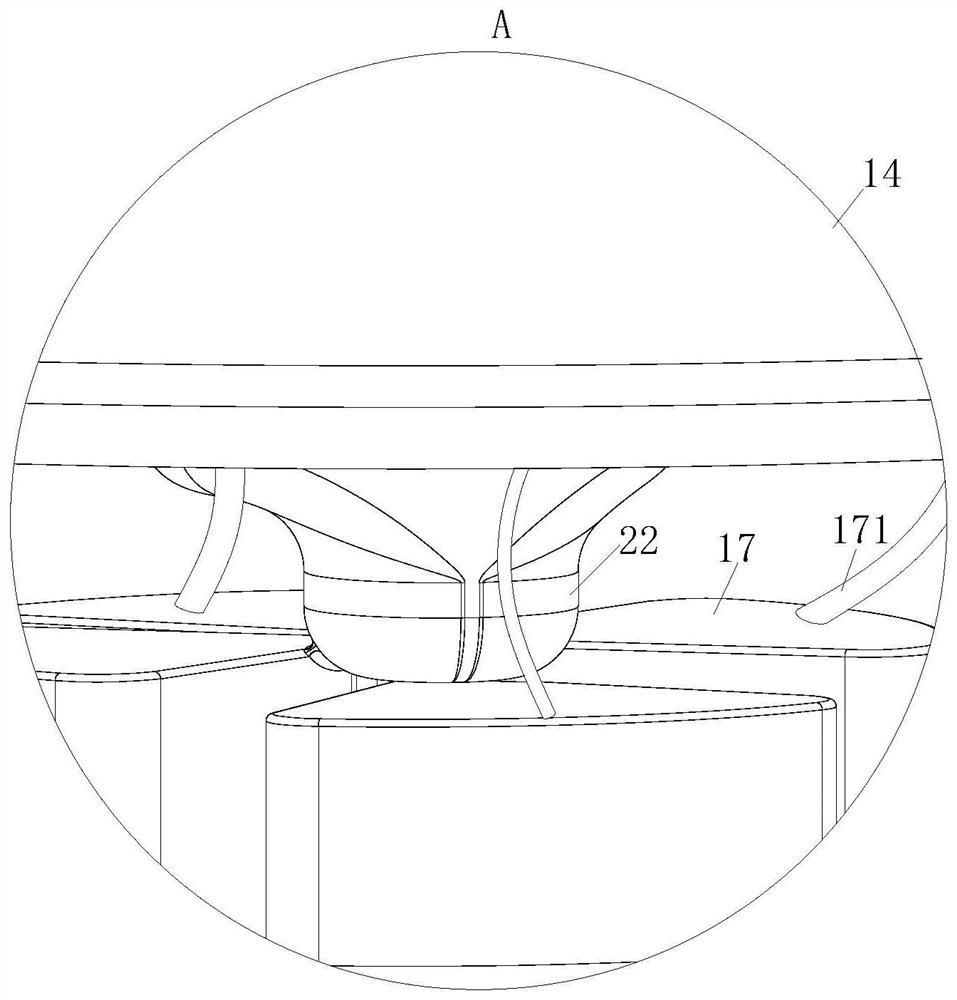

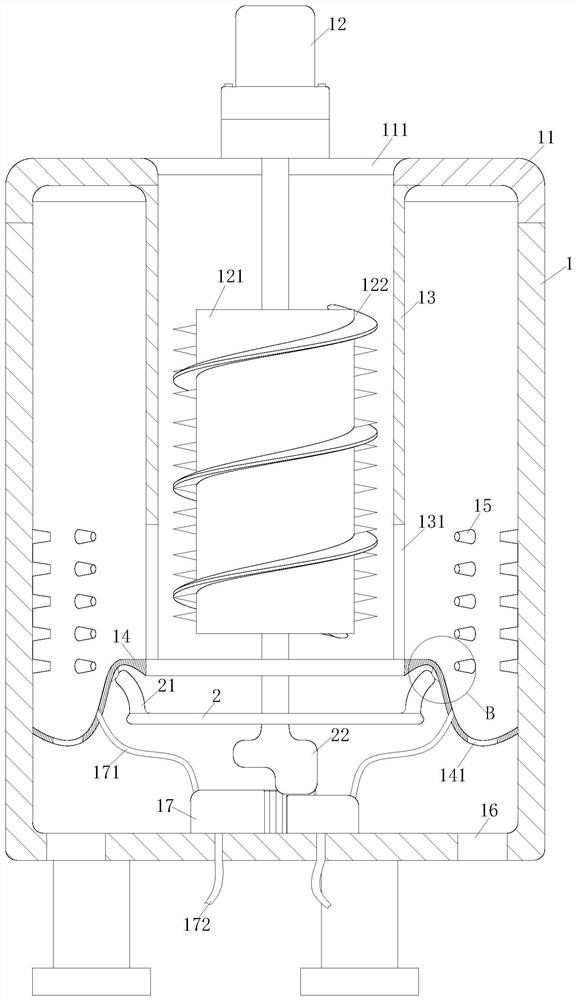

[0022] As a specific embodiment of the present invention, the outer ring of the crushing roller 121 is provided with an auger 122. When the reversing motor 12 rotates forward, the auger 122 rotates and raises the garbage in the crushing barrel 13; When the reverse motor rotates 12 times, the auger 122 rotates and lowers the rubbish in the crushing barrel 13, and at the same time blows the outside air into the crushing barrel 13 from the feeding port 111 on the end cover 11, so as to realize blowing and oxygenation during rubbish incineration; use When the garbage is passed into the crushing barrel 13 for crushing, if the input garbage has a high relative humidity and a large size of garbage, when the crushing roller 121 crushes the garbage, the moisture in the garbage cannot be effectively evaporated, and the positive and negative can be controlled. The rotating motor 12 reverses. When the forward and reverse motor 12 rotates forward, the auger 122 on the crushing roller 121 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com