Ahead running reduction box with hydraulic torque-converting coupler

A technology of hydraulic torque converter and coupling, which is used in fluid transmission, gear lubrication/cooling, drilling equipment and methods, etc., can solve the problem of black smoke, even flameout, no torque conversion function, and deterioration of combustion conditions, etc. problems, to achieve the effect of reducing fuel consumption, reducing axial size, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

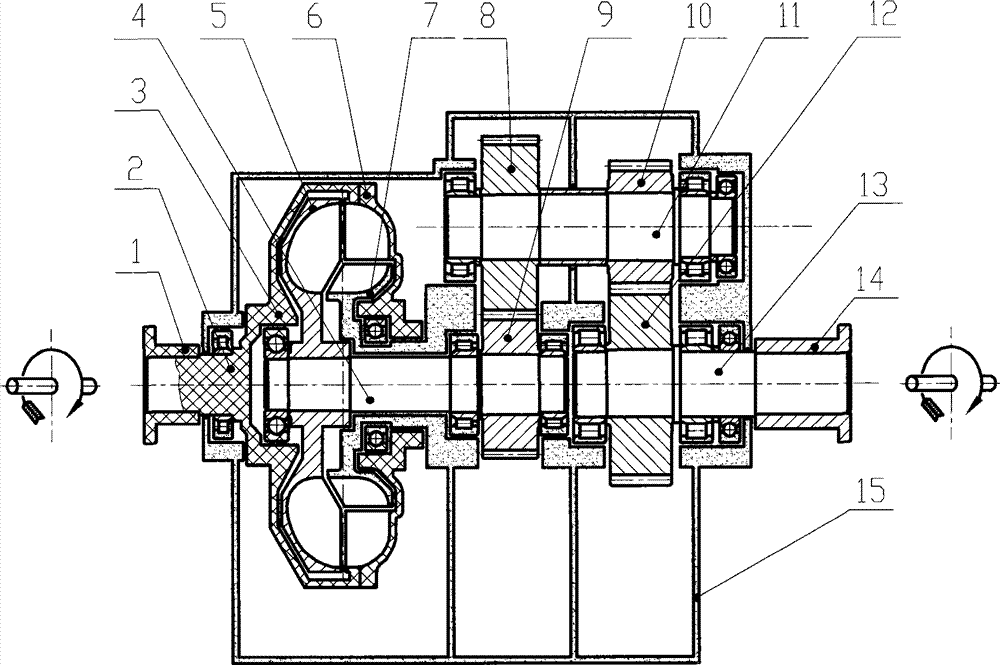

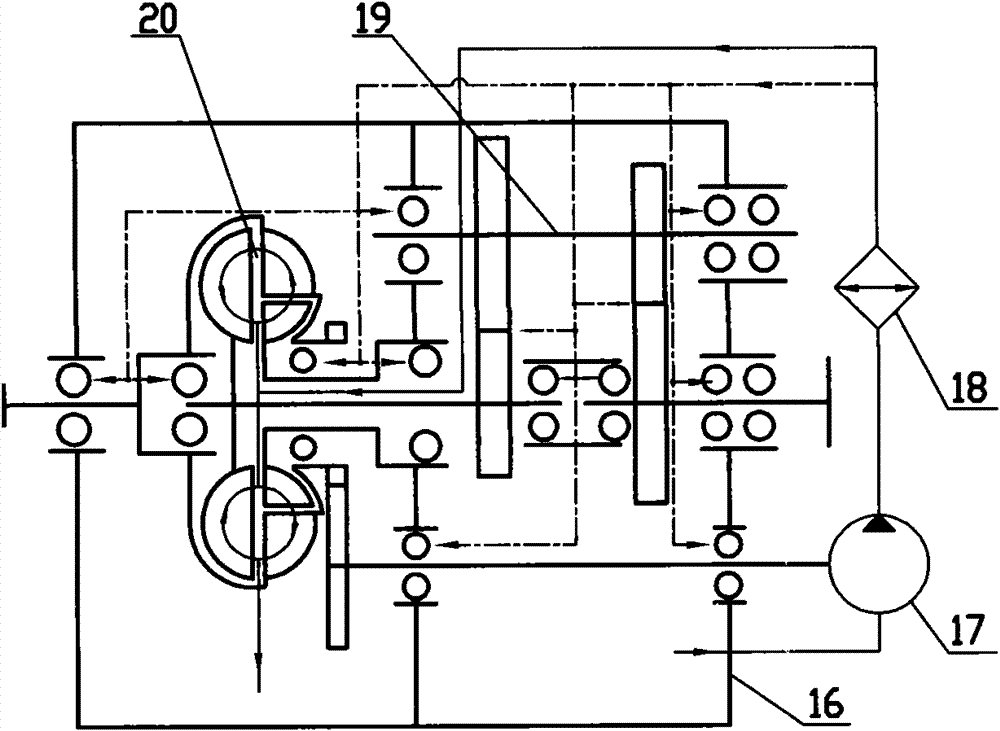

[0022] The present invention is a gear box for a hydraulic torque converter coupling, and its structural diagram is as attached figure 1 As shown, it is composed of a hydraulic torque converter coupling in the input part and a two-stage coaxial gear reducer in the output part. The input part is a three-blade hydraulic torque converter coupling composed of a short pump wheel 6 with straight blades, a turbine 5 with straight blades and a guide wheel 7 with twisted blades. It has no auxiliary chamber and its main zero The components are: input flange 1, input shaft 2, pump wheel cover 3, pump wheel 6, turbine 5, guide wheel 7 and turbine shaft 4, etc. The output part consists of the input shaft (that is, the turbine shaft of the hydraulic torque converter coupling) 4, the driving gear 9 and the driven gear 8 of the first-stage gear pair, the intermediate shaft 11, the driving gear 10 and the driven gear of the second-stage gear pair Two-stage coaxial gear reducer composed of gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com