Biomass fuel steam and hot water boiler

A biomass fuel and hot water boiler technology, which is applied in the direction of grates, incinerators, combustion types, etc., can solve the problems of not being suitable for burning biomass fuels, and achieve the goals of preventing black smoke, reducing pollution, and improving combustion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

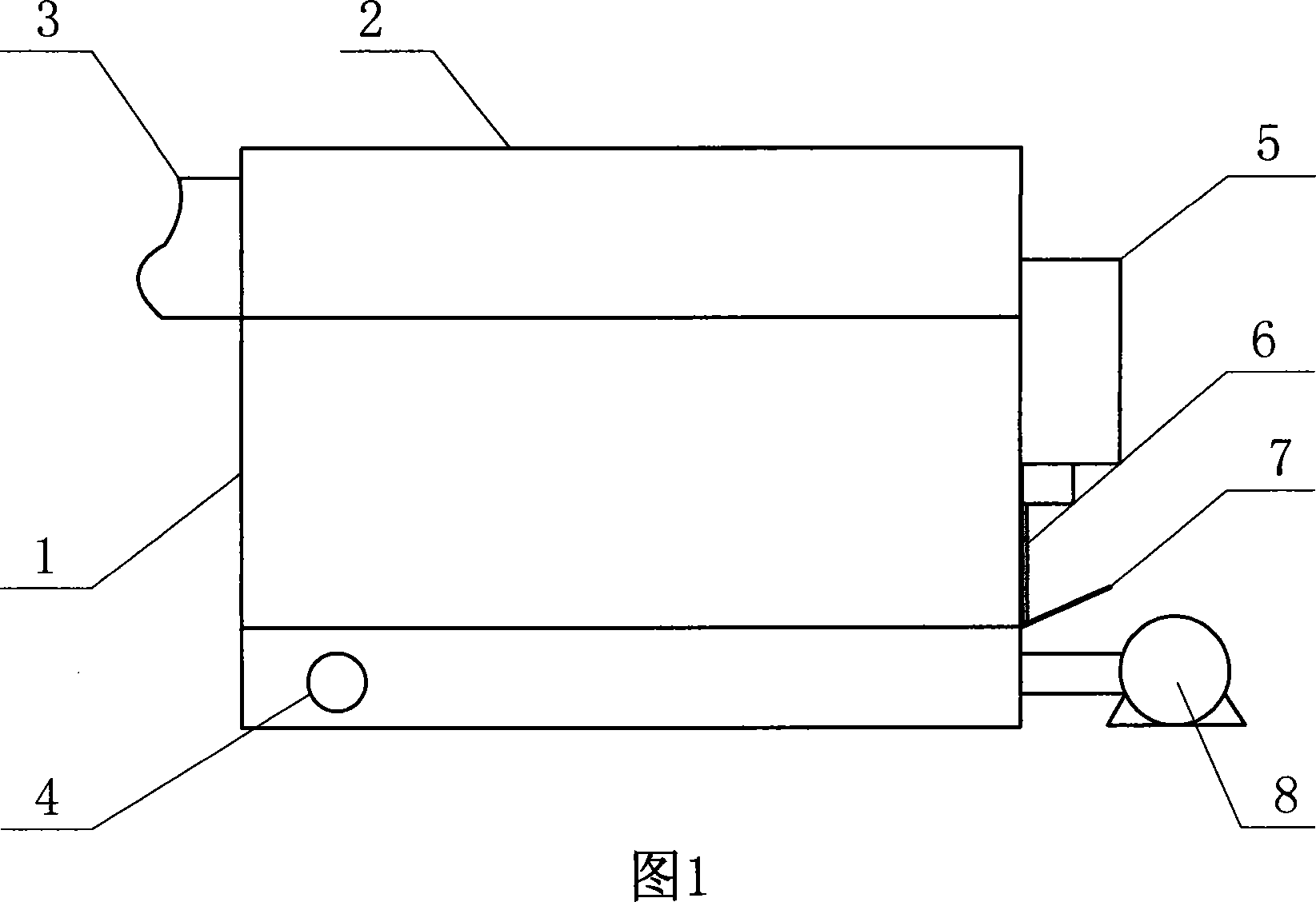

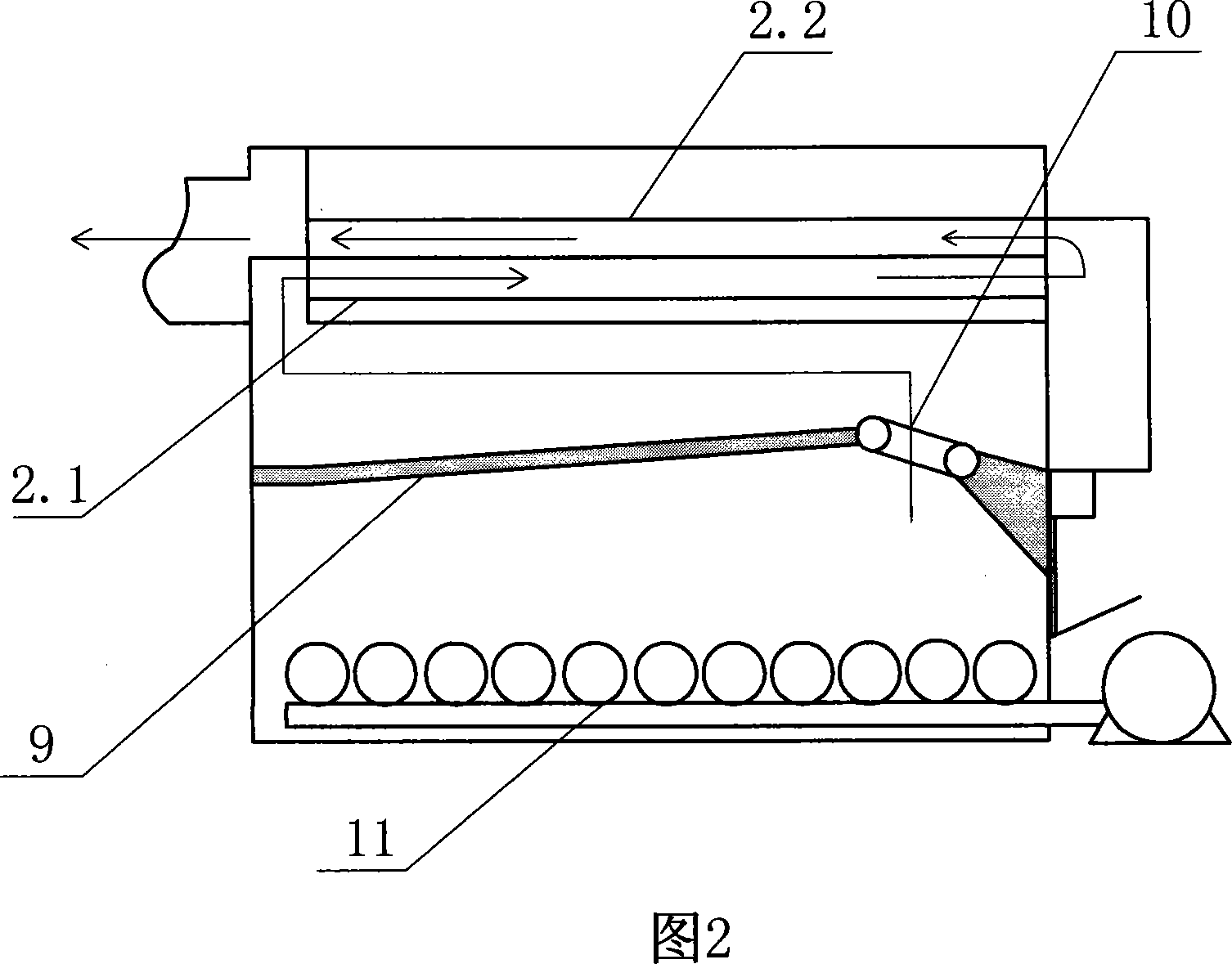

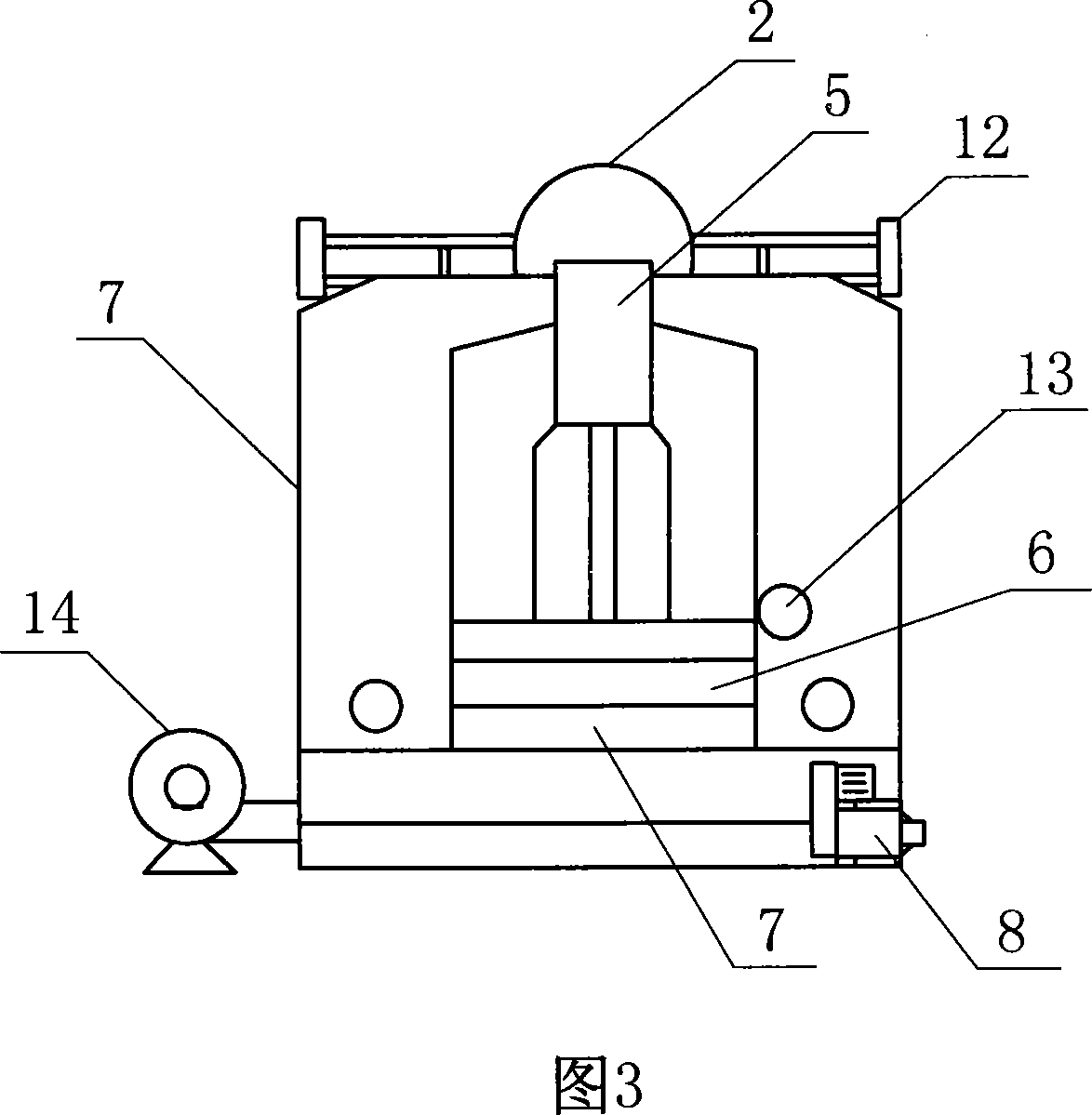

[0020] As shown in Figures 1, 2 and 3, an evaporator 2 is installed on the upper part of the furnace body 1, an air inlet 4 is arranged on one side of the lower part, a blower 14 is installed on the air inlet, and a return air cavity 5 is arranged on the front side of the furnace body. , a furnace mouth is provided at the bottom of the air return chamber, a furnace door 6 is installed on the furnace mouth through a furnace door opening and closing turntable 13, a furnace mouth guide plate 7 is connected to the lower side of the furnace door, and a power machine 8 is installed at the lower part of the front side of the furnace body A display instrument 12 is connected and installed on the upper side of the furnace body; a vault 9 is provided at the upper middle part of the furnace body furnace, and a secondary air inlet pipe 10 is installed on the vault.

[0021] As shown in Figure 4, the secondary air inlet pipe 10 is composed of four-sided closed tubular objects connected to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com