Chimney-free heat cycle heating furnace

A thermal cycle and heating furnace technology, applied in the field of heating furnace manufacturing, can solve the problems of smoke emission and environmental pollution, and achieve the effects of full combustion of smoke, high utilization of heat energy and zero emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

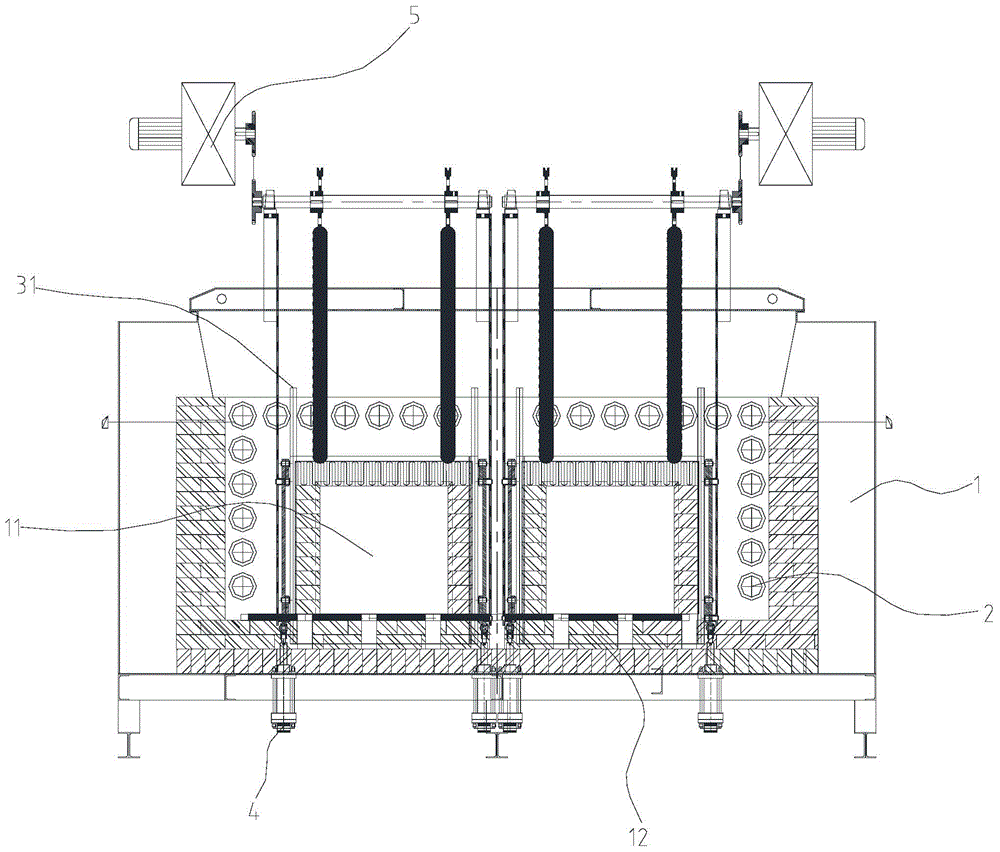

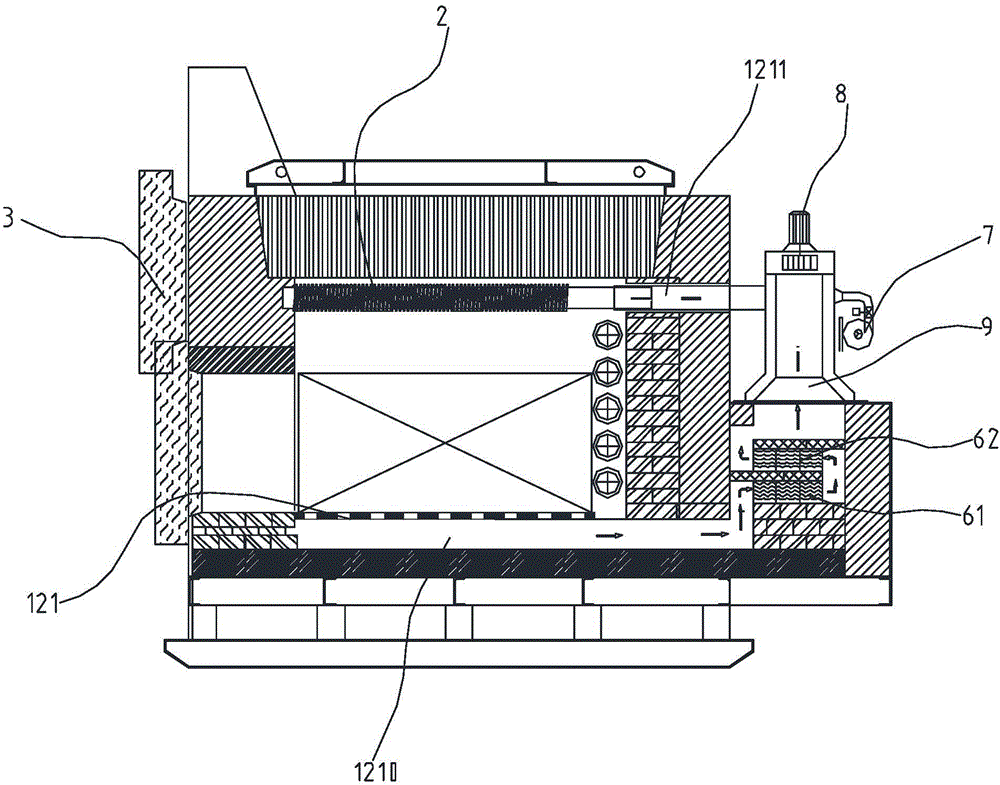

[0022] The present invention will be further elaborated below with reference to the accompanying drawings.

[0023] see figure 1 And attached figure 2 , a chimneyless heat circulation heating furnace of the present invention, which includes: a furnace body 1, at least one furnace 11 is arranged in the furnace body 1, and a circulating flue 12 is arranged on the bottom wall of the furnace 11 . A plurality of electric heaters 2, the electric heater 2 is distributed on the top wall and the surrounding side walls of the furnace, and or the bottom wall, the surface of which is coated with a selective catalytic reduction catalyst (SCR), and the SCR catalyst is Homogeneous product consisting of porous metal oxides and reactive metals. More specifically, the SCR catalyst is a honeycomb carbon removal catalyst. At least one furnace door 3, the furnace door 3 is airtightly connected with the feed port of the furnace body 1; a plurality of compression cylinders 4, the compression cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com