Biomass fuel steam and hot water boiler

A biomass fuel and hot water boiler technology, applied in the direction of grate, incinerator, combustion type, etc., can solve the problem of not suitable for burning biomass fuel, so as to prevent black smoke, improve combustion efficiency, reduce occupancy and The effect of transmission components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

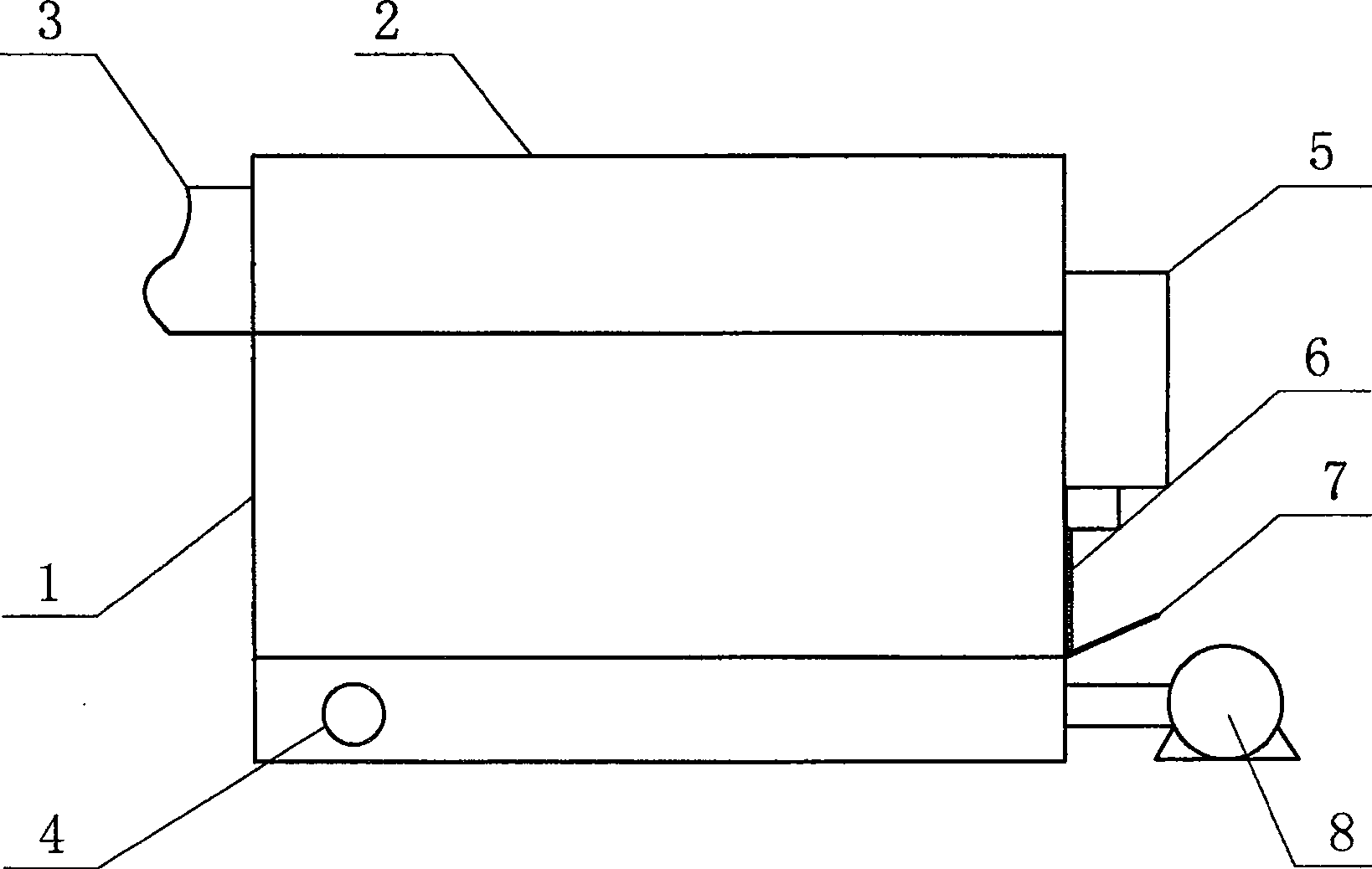

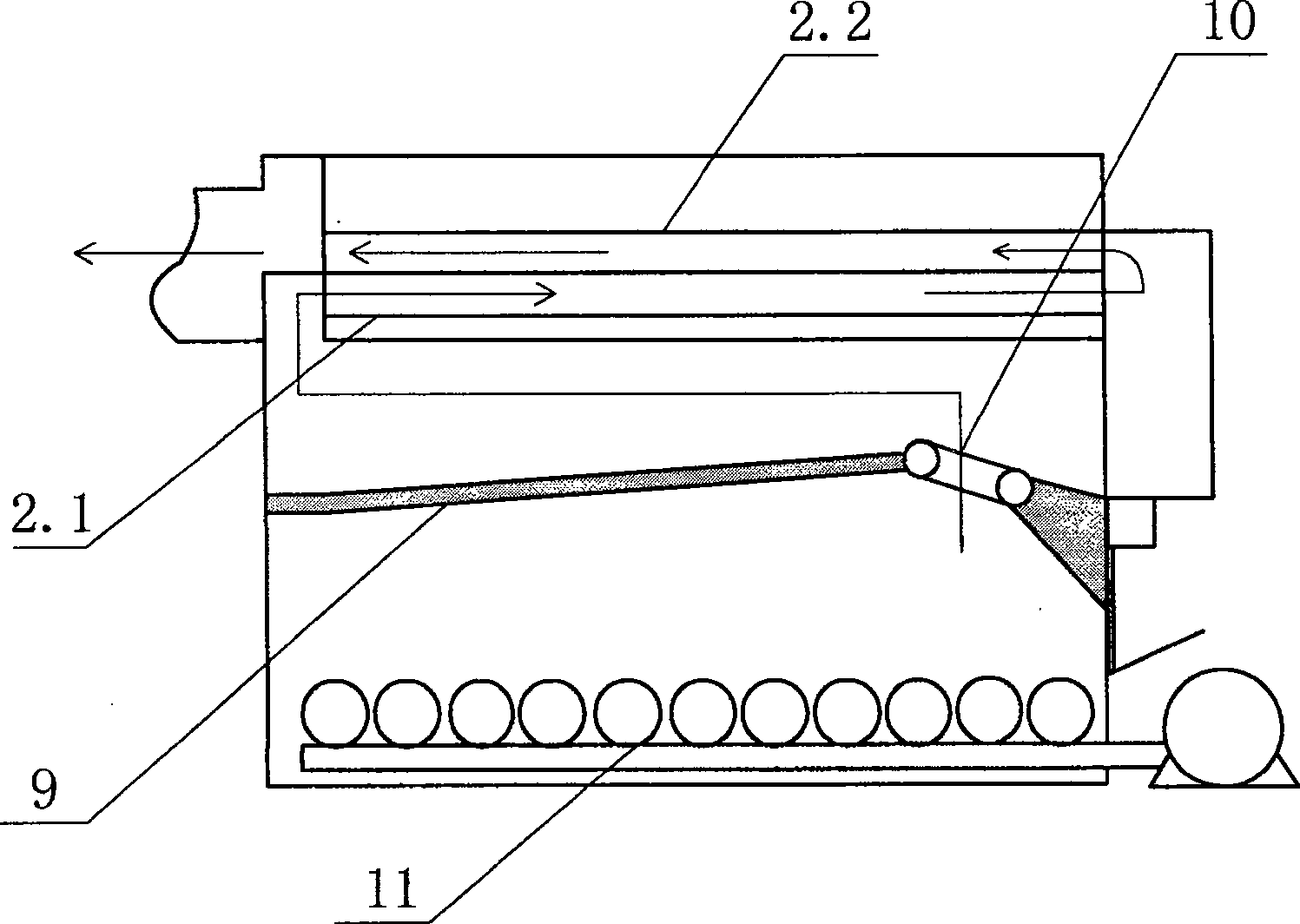

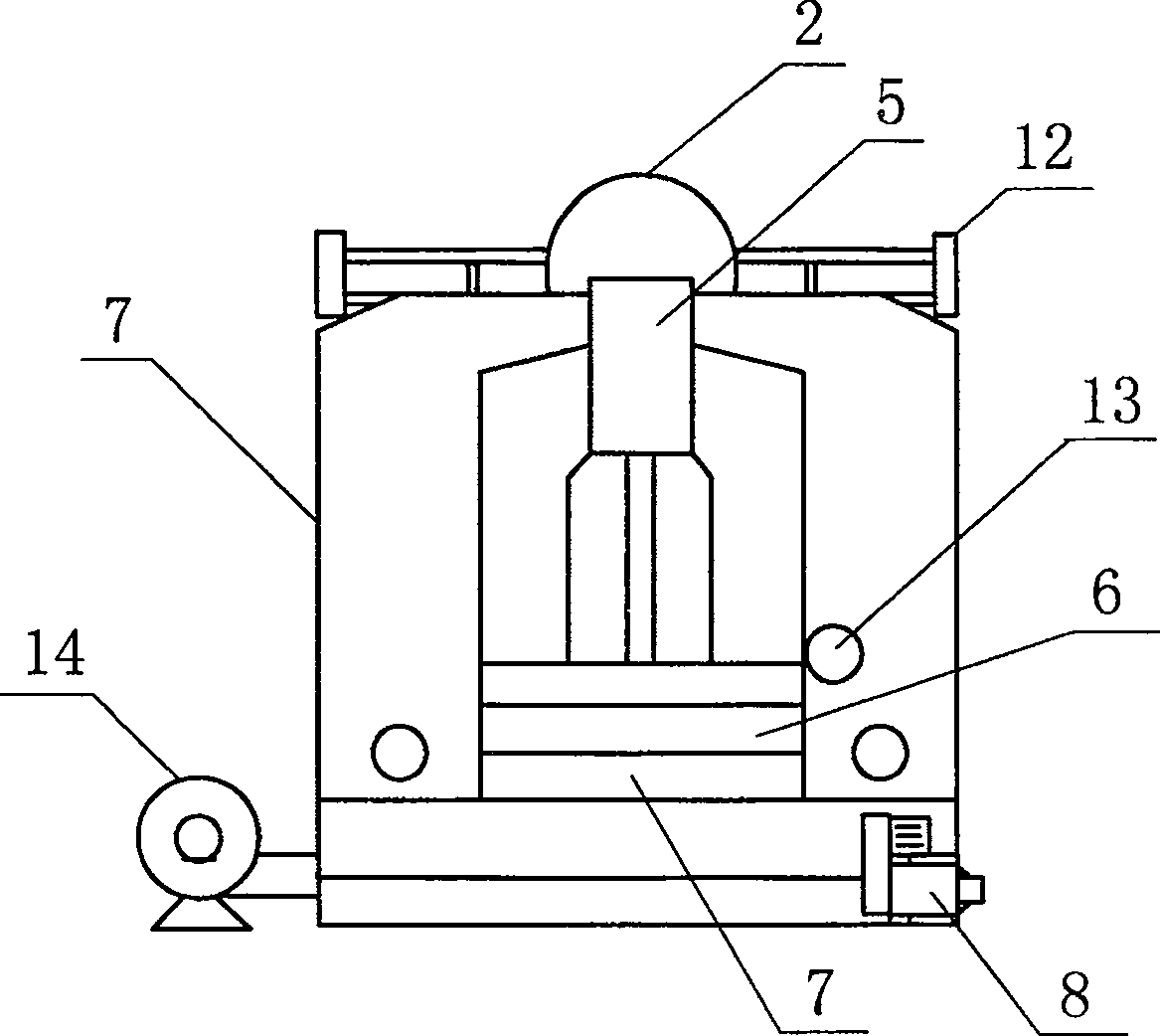

[0020] according to figure 1 , 2 As shown in and 3, an evaporator 2 is installed on the top of the body of heater 1, and an air inlet 4 is arranged on one side of the lower part, and a blower 14 is installed on the air inlet, and a return air chamber 5 is provided on the front side of the body of heater, and an air return chamber 5 is arranged on the front side of the body of heater. The lower part of the furnace is provided with a furnace mouth, the furnace door 6 is installed on the furnace door through the furnace door opening and closing turntable 13, the furnace door guide plate 7 is connected on the lower side of the furnace door, and the power machine 8 is installed on the lower part of the furnace body front side. A display instrument 12 is connected and installed on the upper side; a vault 9 is arranged in the upper middle of the furnace body furnace, and a secondary air inlet pipe 10 is installed on the vault.

[0021] according to Figure 4 As shown, the secondary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com