High-efficiency energy-saving emission-reduction circulating fluid bed organic heat carrier boiler

A circulating fluidized bed, high-efficiency and energy-saving technology, applied in fluidized bed combustion equipment, fluid heaters, indirect carbon dioxide emission reduction, etc., can solve the problems of high investment in dust removal equipment, high requirements for coal-fired coal types, and low utilization rate of waste heat, etc. problem, to achieve the effect of solving the problem of single fuel type, protecting the environment and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

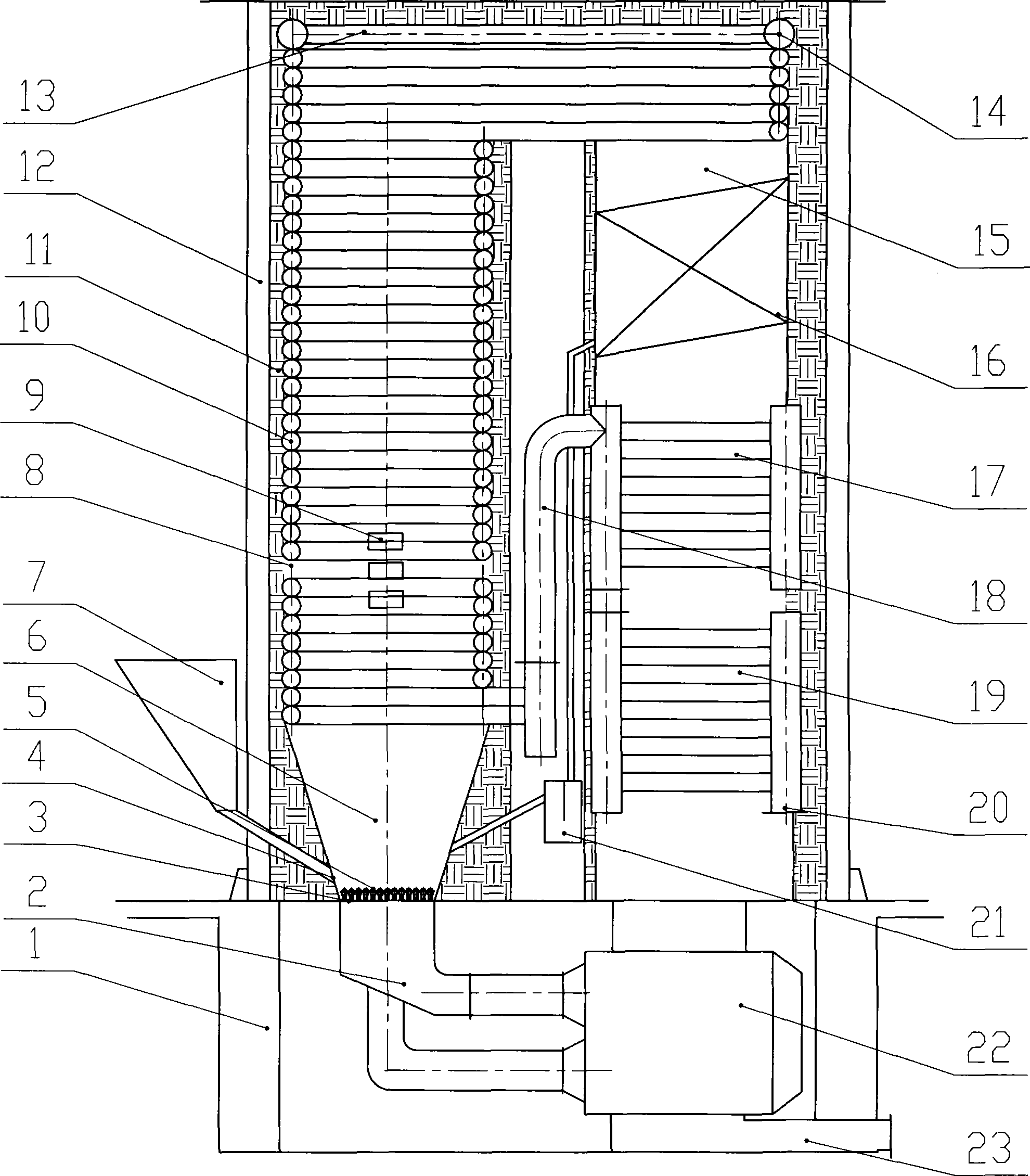

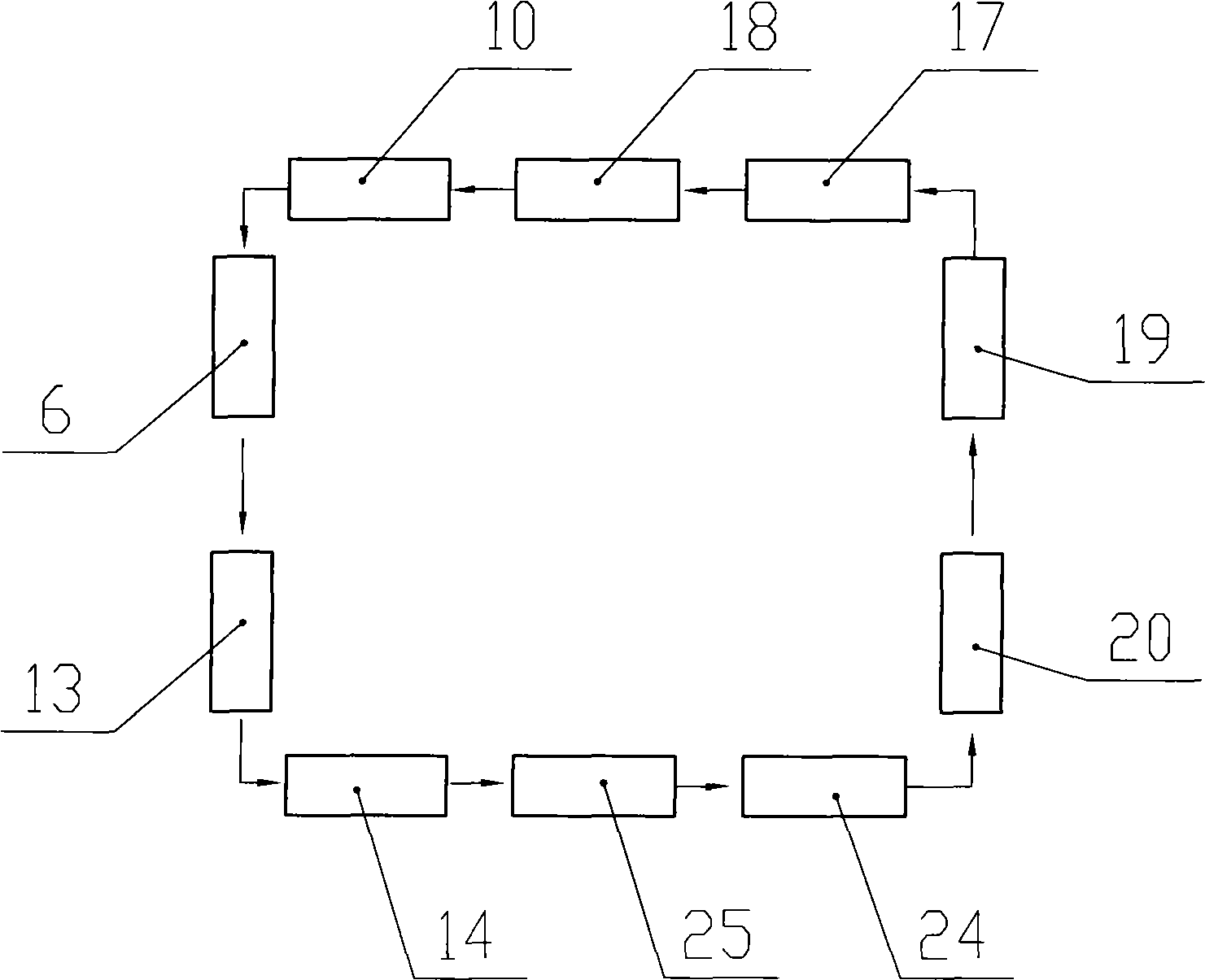

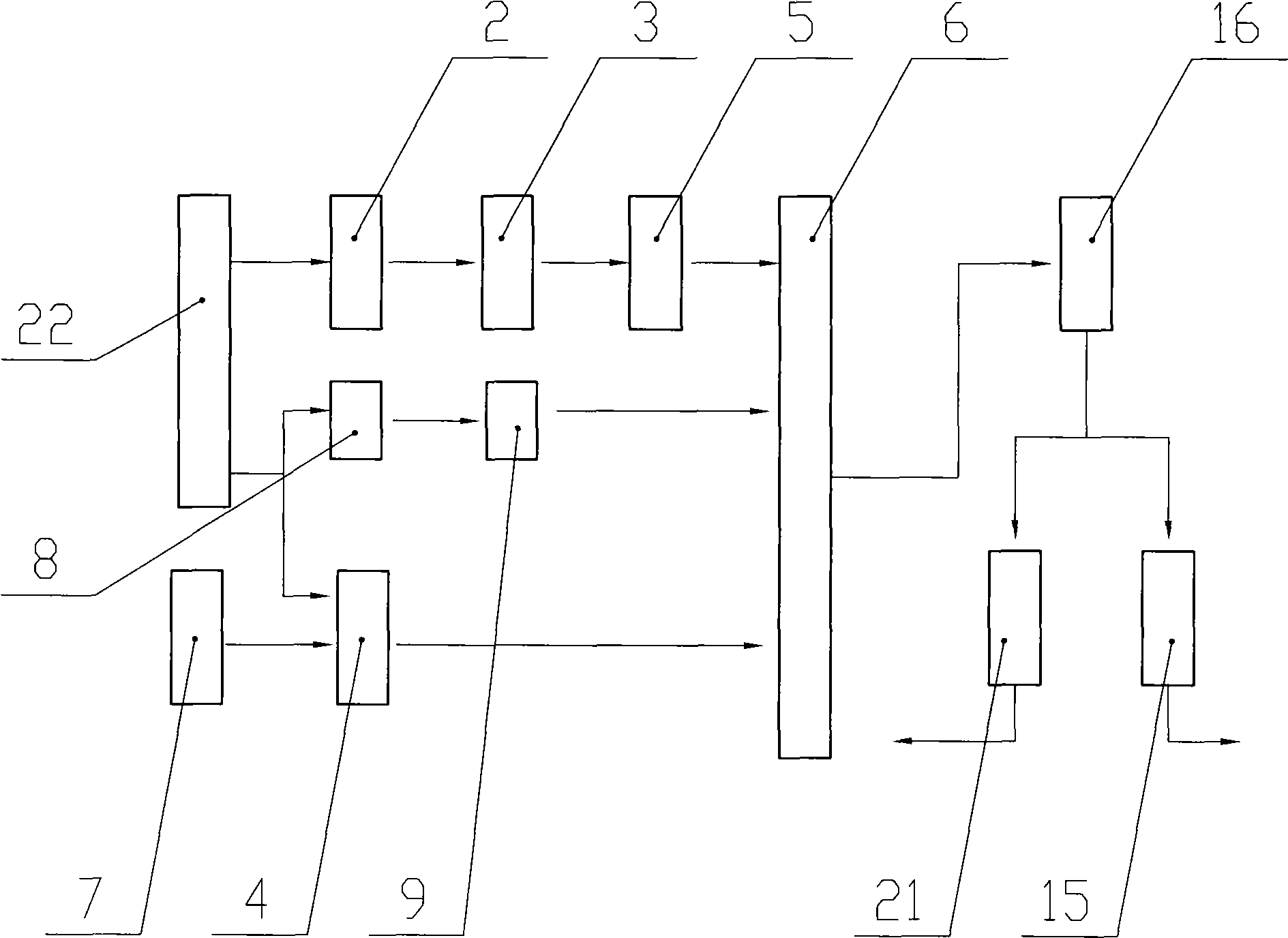

[0016] refer to figure 1 , figure 2 , image 3 and Figure 4 , the present invention includes a boiler base 1, a coal hopper 7 and a heat medium circulation pump 24. A furnace body composed of a steel frame 12 and a heat-preservation refractory layer 11 is arranged on the top of the boiler base 1 from the outside to the inside. The furnace 6 and the flue 15; the upper part of the furnace 6 is provided with a top heating surface 13, a square plate radiation heating tube bundle 10, a secondary air nozzle 9 is provided in the gap 8 of the coil tubes, and a cloth is arranged at the bottom of the furnace 6. The air plate 3 and the air distribution plate 3 are provided with a wind cap 5, the furnace 6 is connected with the coal hopper 7 through the coal supply pipe 4, and the bottom of the furnace 6 is provided with an equal pressure air box 2; the flue 15 is provided with an outlet set from top to bottom Box 14, cyclone separator 16 and interconnected high temperature convectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com