Combustion and smoke and dust removal method of small boiler combusting soft coal II and III

A technology for smoke and dust removal and small boilers, applied in the combustion method, combustion air/fuel supply, combustion equipment, etc., can solve the problems of high boiler operating costs, substandard smoke and dust emissions, and high anthracite coal prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

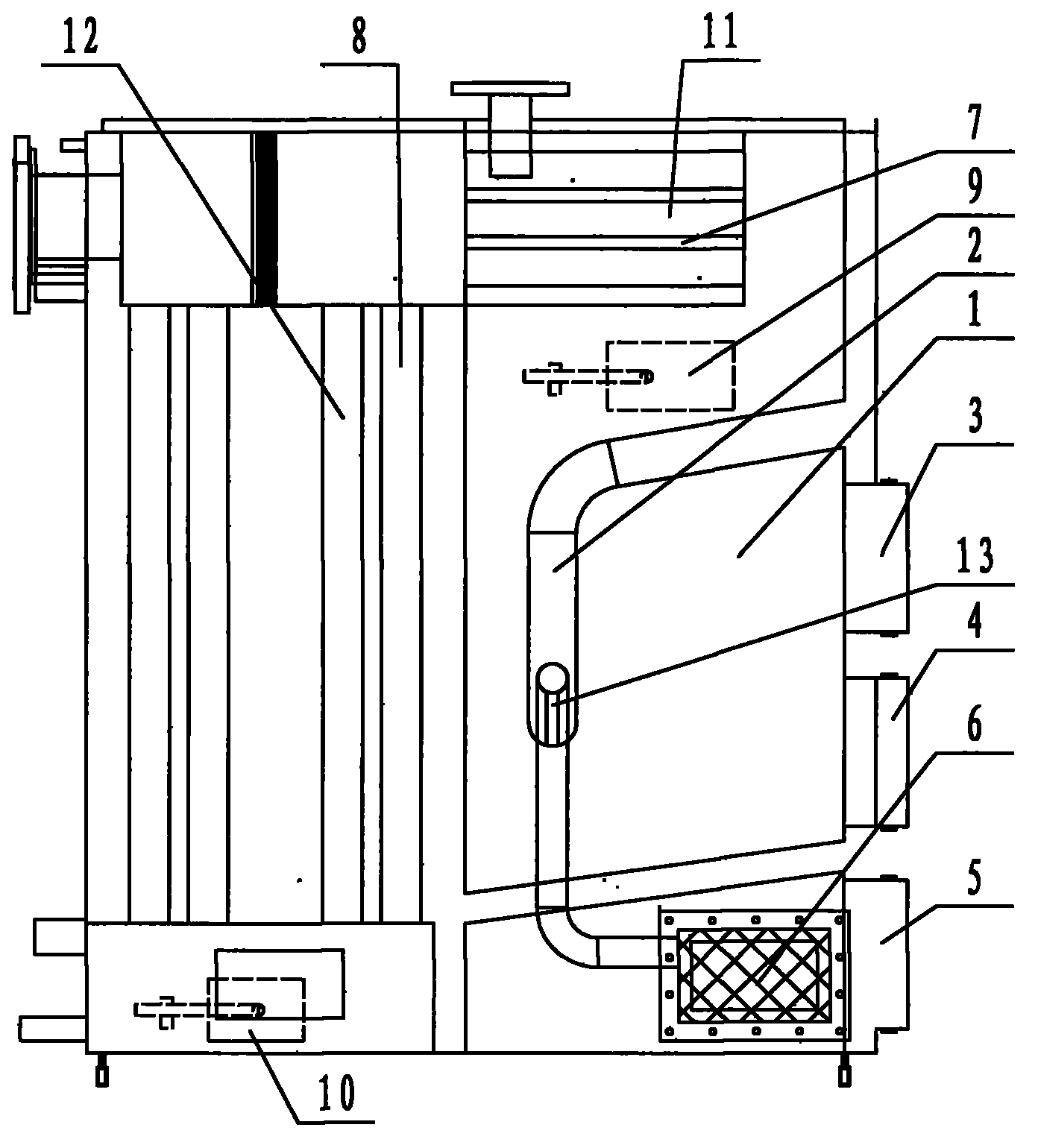

[0015] A method for eliminating smoke and dust by burning Class II and III bituminous coal in a small boiler. The boiler involved is shown in the figure, which includes a furnace 1, a furnace arch 2, a coal filling port 3, a slag loosening port 4, an ashes removal port 5, Secondary air device 6, horizontal smoke pipe 7, vertical smoke pipe 8, furnace arch ash removal port 9, and ash removal port 10; among them, the front panel of furnace 1 is provided with coal filling port 3, slag loosening port 4 and ash removal port 5 , the slag opening 4 is set under the coal filling opening 3, and the ash removal opening 5 is set under the slag opening 4; the furnace arch 2 is arranged at the rear end of the furnace 1; The second heat exchange area 12; the lower end of the right side of the furnace 1 is provided with a secondary air device 6; the first heat exchange area 11 is provided with a number of rows of horizontal smoke pipes 7, and the bottom of the horizontal smoke pipes 7 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com