Automatic observing and controlling method for roasting heat accumulating type steel ladle and the device using the method

A technology of measurement and control device and measurement and control method, applied in safety devices, metal processing equipment, casting equipment, etc., can solve the problems of inability to ensure a reasonable ratio of fuel and combustion-supporting air, inaccurate temperature monitoring and flow adjustment, and high flue exhaust gas temperature , to achieve the effect of improving combustion quality, eliminating black smoke and increasing baking temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

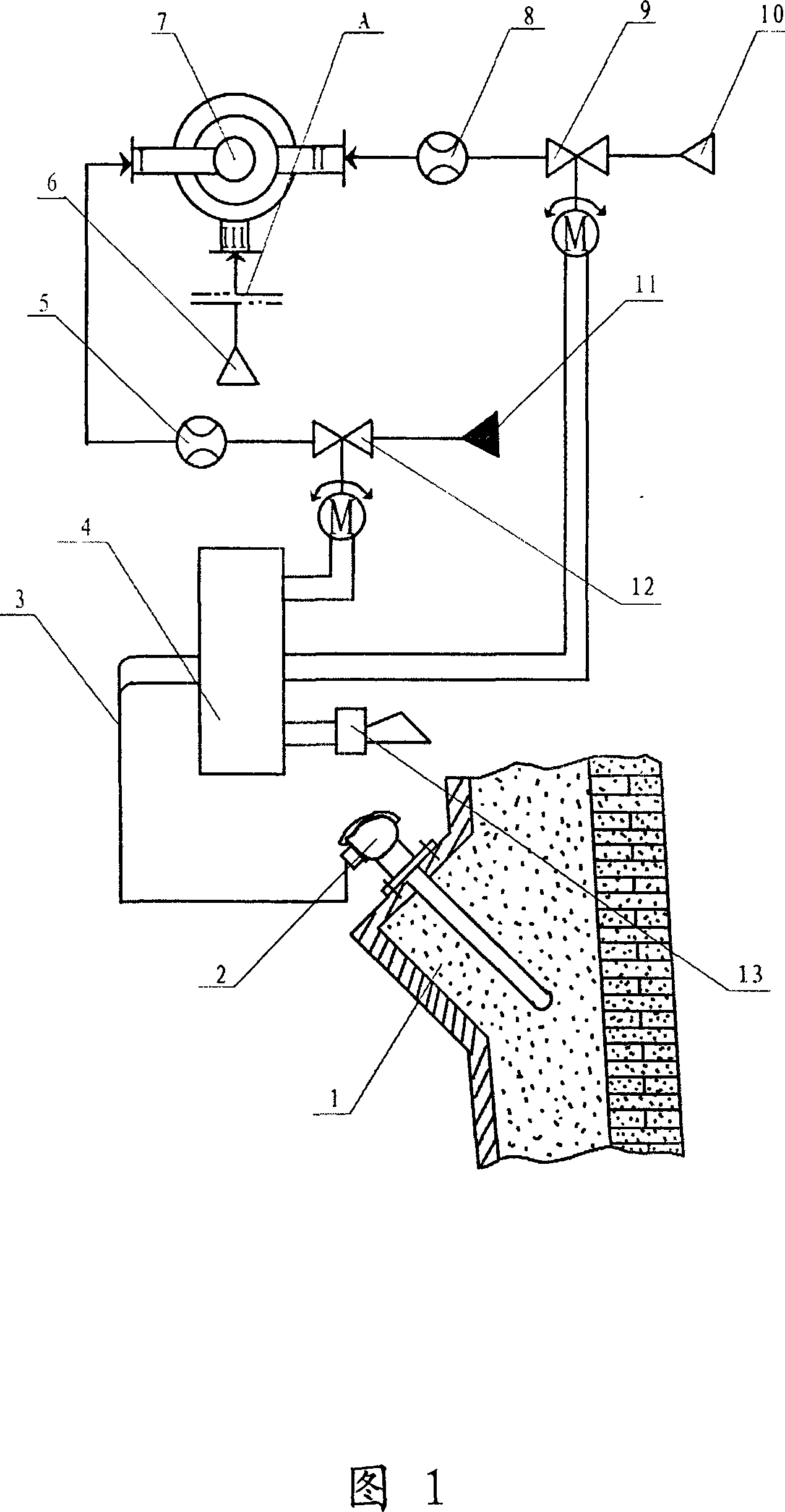

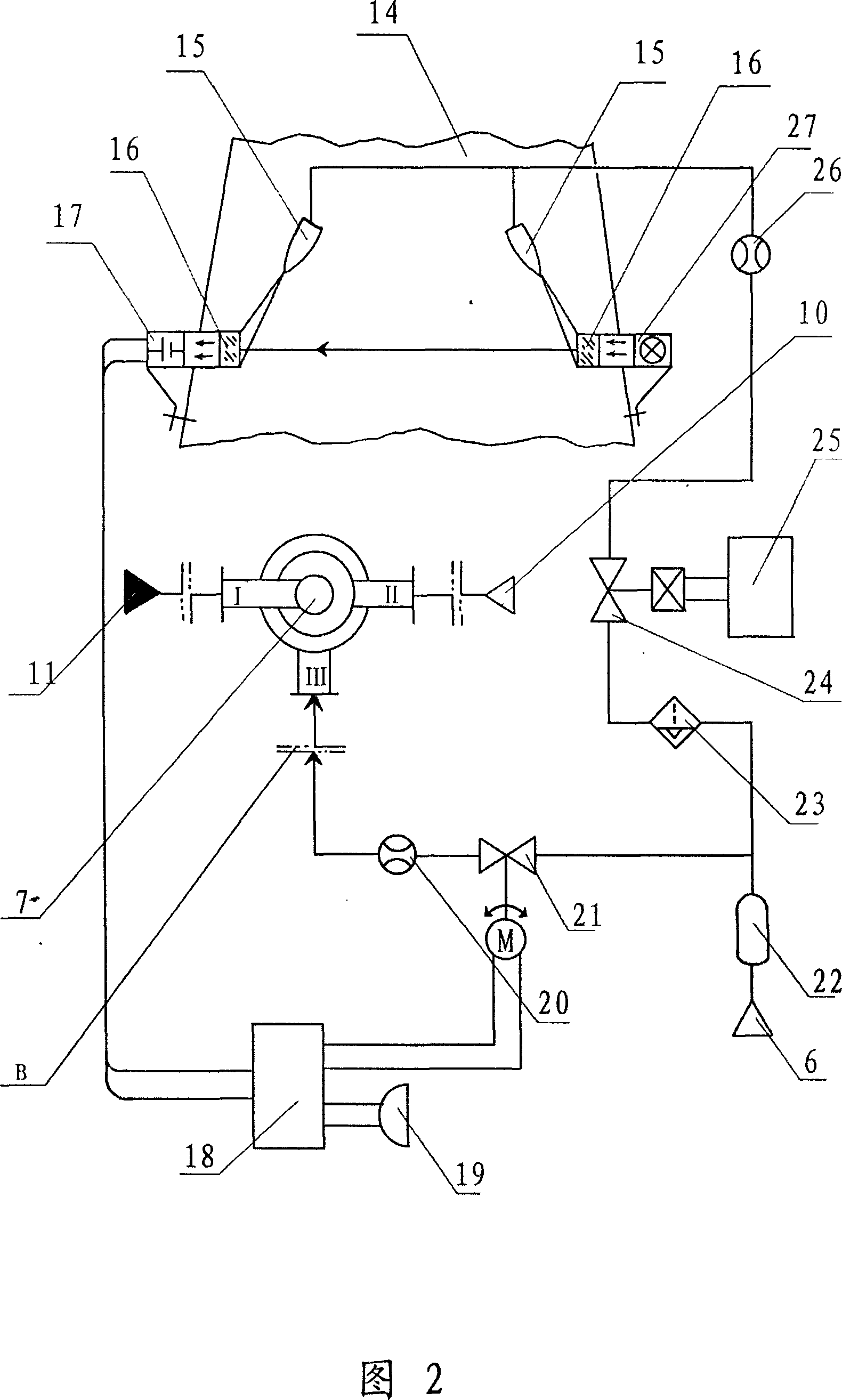

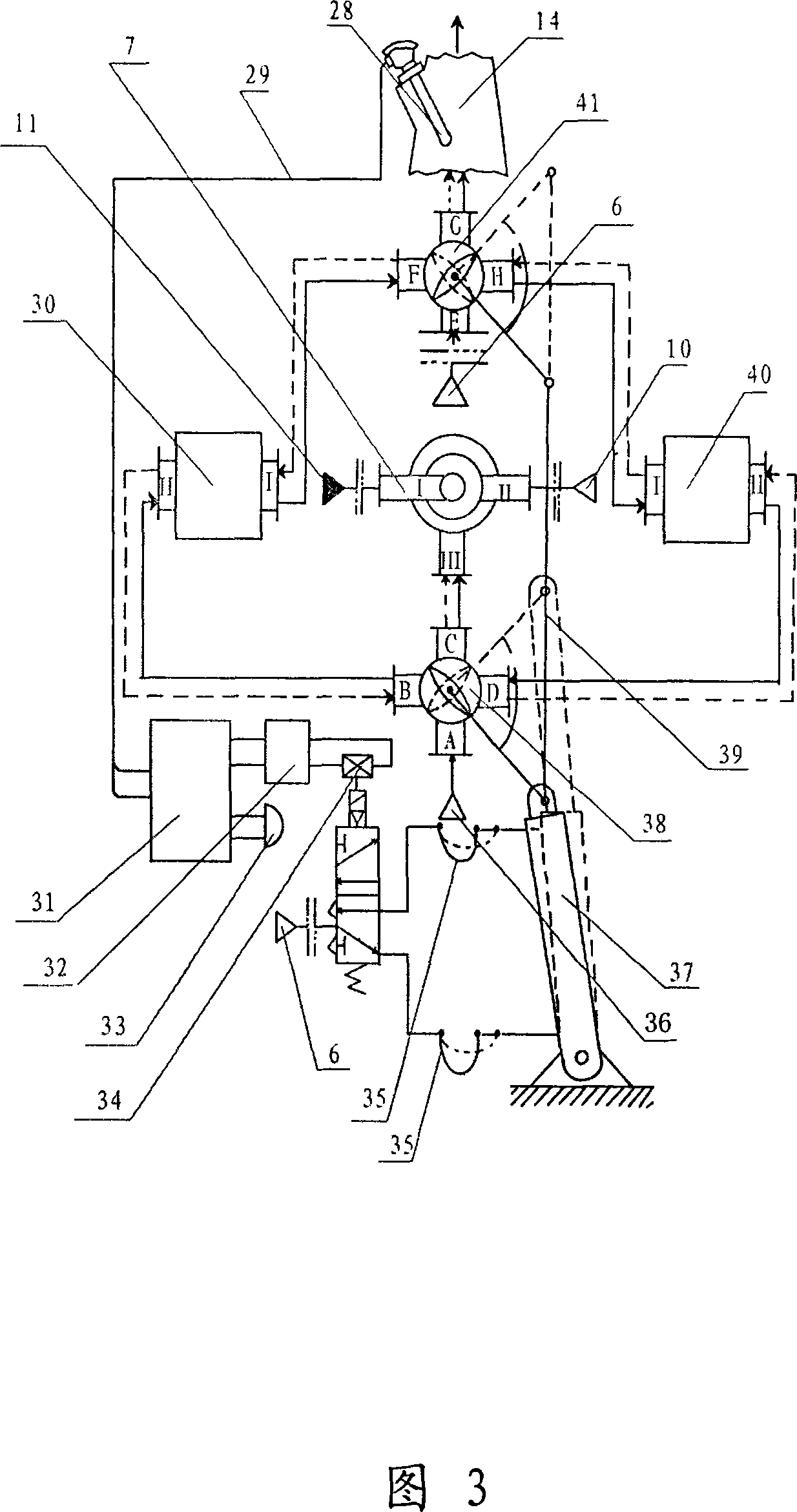

[0016] The invention is an automatic measurement and control method for a baking heat storage type ladle, which is characterized in that it includes an automatic measurement and control method for the inner lining temperature of the steel ladle, an automatic measurement and control method for the smoke concentration of flue exhaust gas and an automatic measurement and control method for the temperature of flue exhaust gas: the ladle The method of automatic measurement and control of the lining temperature is to measure the temperature of the ladle lining 1 through the temperature sensor I2 of the ladle lining temperature automatic measurement and control device, and then send the measured analog signal of the ladle lining temperature to the intelligent temperature controller I4, and through the linear The linearization processing circuit I is converted into a digital signal of the ladle lining temperature by the analog-to-digital conversion circuit I, and the digital signal of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com