Baking process for intensive baking room

A roasting process and technology for a roasting room, which is applied to the roasting technology field of an intensive roasting room, can solve the problems of difficulty in showing the strong aroma style of tobacco leaves, less oil content in tobacco leaves, and complicated operation, and achieves bright appearance, sufficient oil content, and operation. Simple and safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1, a baking process in a dense barn, using comb-type tobacco clips to install tobacco, setting 10 temperature and humidity precise control points, including the following steps:

[0023] a: After the tobacco leaves are loaded into the furnace, close the doors, windows and air inlets, ignite the fire, raise the dry bulb temperature to 36°C within 5 hours, control the wet bulb temperature to 35°C, keep the temperature stable for 5 hours until the tip of the tobacco leaves turns yellow, and the fan operates at a low speed;

[0024] b: Raise the dry bulb temperature to 38°C at a rate of 1°C in 1 hour, control the wet bulb temperature to 37°C, and keep the temperature stable for 12 hours until the tobacco leaves turn yellow by 30-40%, the leaves lose water and become slightly soft, and the fan operates at a low speed;

[0025] c: Raise the temperature of the dry bulb to 40°C at a rate of 1°C in 1 hour, control the temperature of the wet bulb at 37-36°C, and keep the t...

Embodiment 2

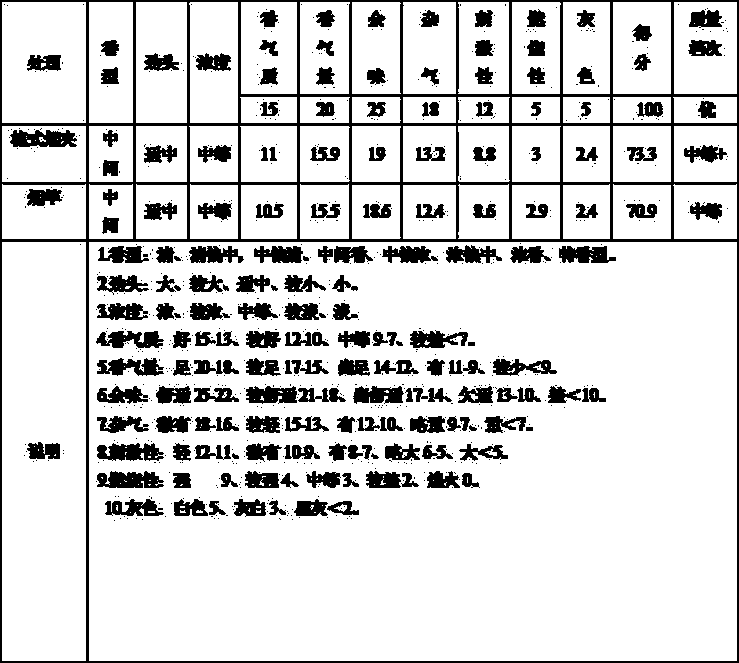

[0042] In Example 2, in order to verify the advantages of the present invention’s roasting process, conventional roasting was carried out using the existing tobacco rod loading method and the tobacco leaves were roasted using the present invention’s roasting process, and the economic properties were evaluated after roasting.

[0043] a: Zhengjiabo Tobacco Leaf Curing Factory, Jiayue Town, Zhucheng City, undertakes the tobacco leaf curing area of 1,200 mu, and has 60 curing rooms in total. From June to September 2013, experiments were carried out at this curing point, 58 of which adopted the intensive curing process of the present invention for tobacco leaf curing, and the other 2 curing rooms adopted conventional curing according to the method of loading tobacco rods.

[0044] From the point of view of the quality of tobacco leaves curing, the tobacco leaves that are packed with comb-type tobacco clips and baked according to the intensive curing process of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com