Airflow lift type flue-cure tobacco scattered leaf cuttage layered curing method

A curing method and flue-cured tobacco technology, applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of poor pertinence of tobacco leaf curing, insignificant periodic changes in dry and wet bulb temperature, and low quality of tobacco leaf curing, and achieve the goal of tobacco leaf curing. Effects of improving roasting quality, reducing yellow veins, and increasing color and oil content of tobacco leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

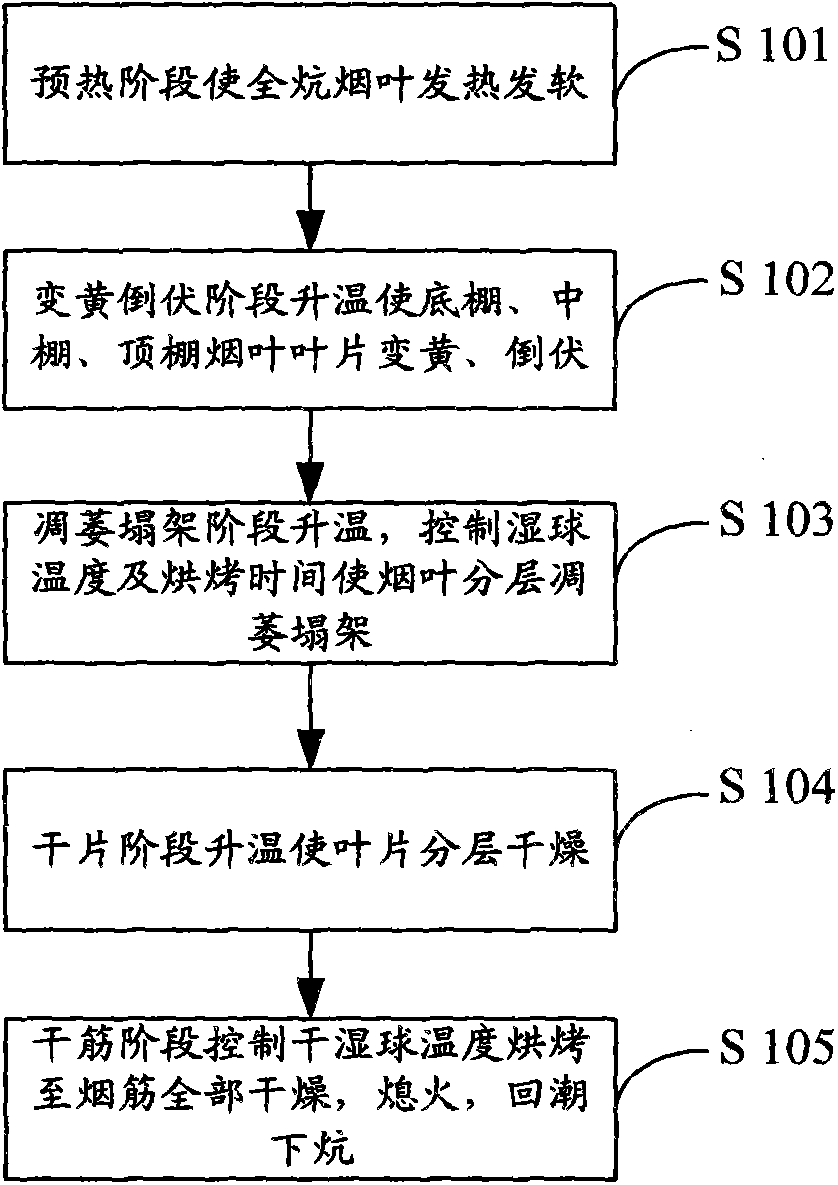

[0029] figure 1 The process of the layered roasting method for the air-up type flue-cured tobacco loose leaf inserting (skewer) provided by the present invention is shown. For ease of description, only parts related to the present invention are shown.

[0030] The air-lifting flue-cured tobacco loose-leaf insert (skewer) layered roasting method provided by the present invention overcomes the shortcomings of the existing loose-leaf roasting technology, and provides a simple and scientific accurate roasting method. In the yellowing and lodging stage, The withering shelf stage and the dry slice stage highlight the stepped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com